Longitudinal magnetizing device for crankshaft magnetizing machine

A technology of longitudinal magnetization and magnetization machines, applied in the direction of material magnetic variables, etc., can solve problems such as questionable effect, easy deformation, easy arc welding at the opening and closing of the coil, etc., and achieve the effect of safe and reliable failure rate and sufficient magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the examples.

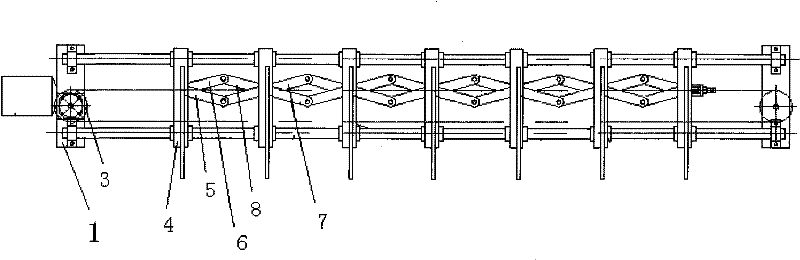

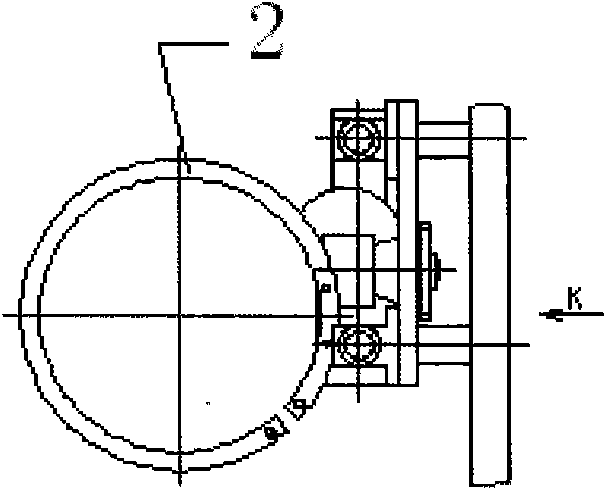

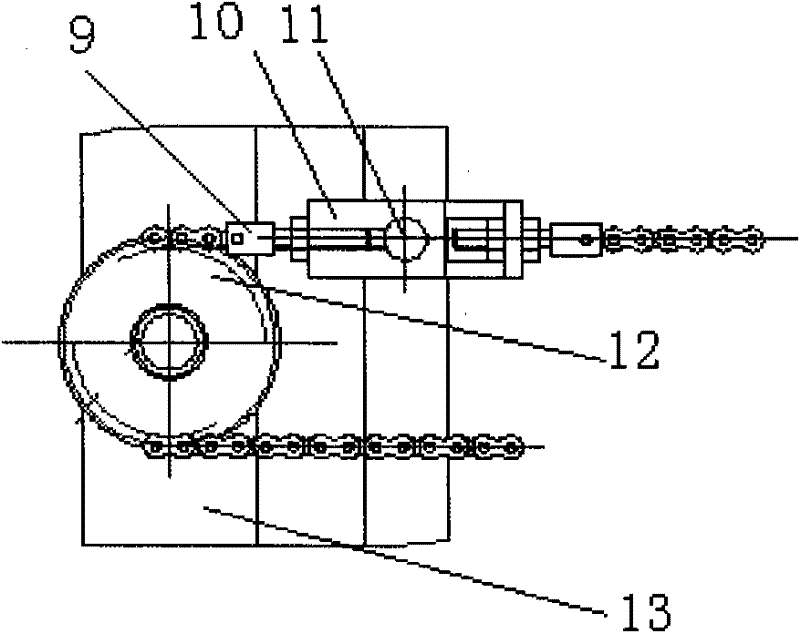

[0019] Such as Figure 1 to Figure 3 As shown, a longitudinal magnetizing device for a crankshaft magnetizing machine provided by the present invention includes a motor plate 1 and a sprocket plate 13, two linear shafts are arranged up and down between the motor plate 1 and the sprocket plate 13, and the deceleration The motor and the driven sprocket 12 are respectively fixed on the motor plate 1 and the sprocket plate 13. The drive sprocket 3 is arranged on the output shaft of the reduction motor, and linear bearings are respectively installed on the upper and lower sides of the seven coil fixing frames 4, and the sleeves On the two linear axes (the linear axes are the linear guide rails), there are 14 linear bearing sleeves that move left and right on the upper and lower two linear axes. The coil fixing frames 4 are connected in pairs by telescopic mechanisms. Coil 2 is verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com