Method for improving reconstituted cut tobacco blending accuracy

A technology of blending accuracy and shredded leaves, which is applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems of large investment and equipment transformation, high energy consumption of industrial warehouses, high energy consumption of workshops, etc., and achieve low operation and maintenance costs , energy consumption and operation and maintenance costs are low, and the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

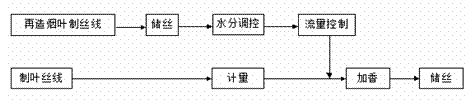

[0018] The method for improving the blending accuracy of reconstituted shreds is carried out in the following steps:

[0019] 1. After the shredded leaves are processed through drying, winnowing and other processes, the blending amount of reconstituted shredded leaves is calculated according to the flow signal of the shredded shredded electronic scale and the formula blending ratio (this is the existing technology), and the blending is controlled. Match the reconstituted shredded leaf flow with added shredded leaf;

[0020] 2. The processed reconstituted silk products are stored in the storage cabinet for standby. When the production and blending of the reconstituted silk products are carried out, the finished reconstituted silk products go through the moisture control process from the storage cabinet (increased on the production line between the storage cabinet and flow control). Expanded shredded shredded moisture control equipment, which is the prior art) is used to humidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com