Inner flow feeding type silk screen grating cleaner

A technology of wire mesh and decontamination machine, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems that cannot meet the requirements of membrane treatment process and ultra-fine filtration, and achieve compact structure, The effect of less investment in equipment transformation and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

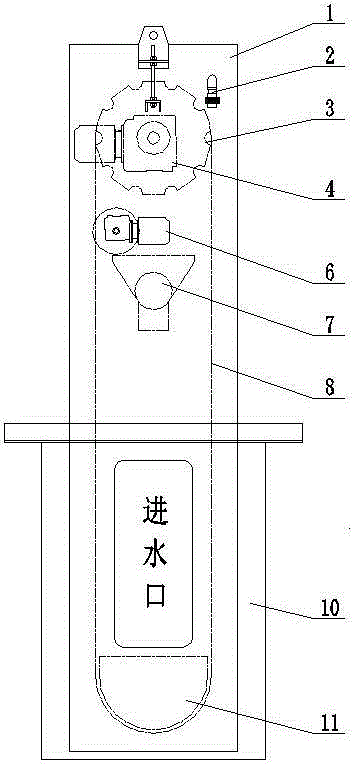

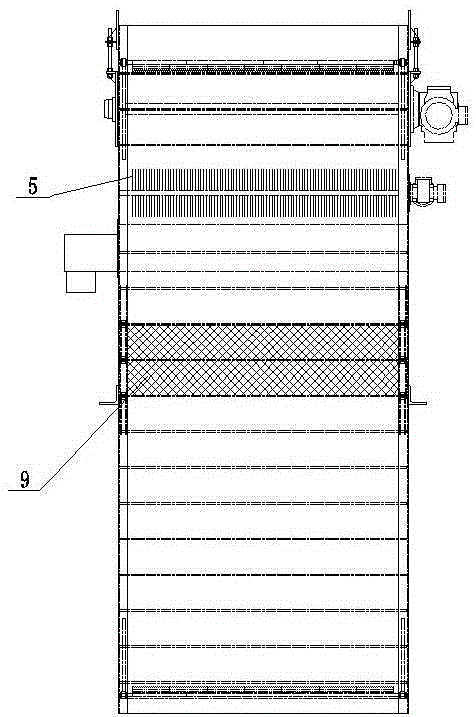

[0037] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

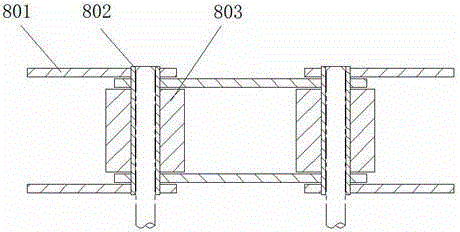

[0038] The internal inflow wire mesh grille decontamination machine of this embodiment adopts a new type of ultra-fine filter screen key components, and is equipped with a driving device, a frame, a transmission chain group, a cleaning brush, a washing system, a slag collecting tank, a guide The structure design of flow baffle, guide wheel and electronic control system forms a new type of inner flow wire mesh grille decontamination machine. For details, please refer to the schematic diagram of the overall structure of the equipment. figure 1 and figure 2 shown.

[0039] Part 1: Rack

[0040] The carrier of the complete set of equipment provides high-strength support for the equipment, and all other components are installed on the rack. The frame is an integral cuboid rigid structure assembled and welded by stainless steel plate and sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com