Method of producing super low carbon steel using vacuum degassing

An ultra-low carbon steel, vacuum degassing technology, applied in the field of vacuum refining, can solve the problem of reduced decarburization capacity, and achieve the effect of improving decarburization performance, reducing rolling, and saving investment in equipment renovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

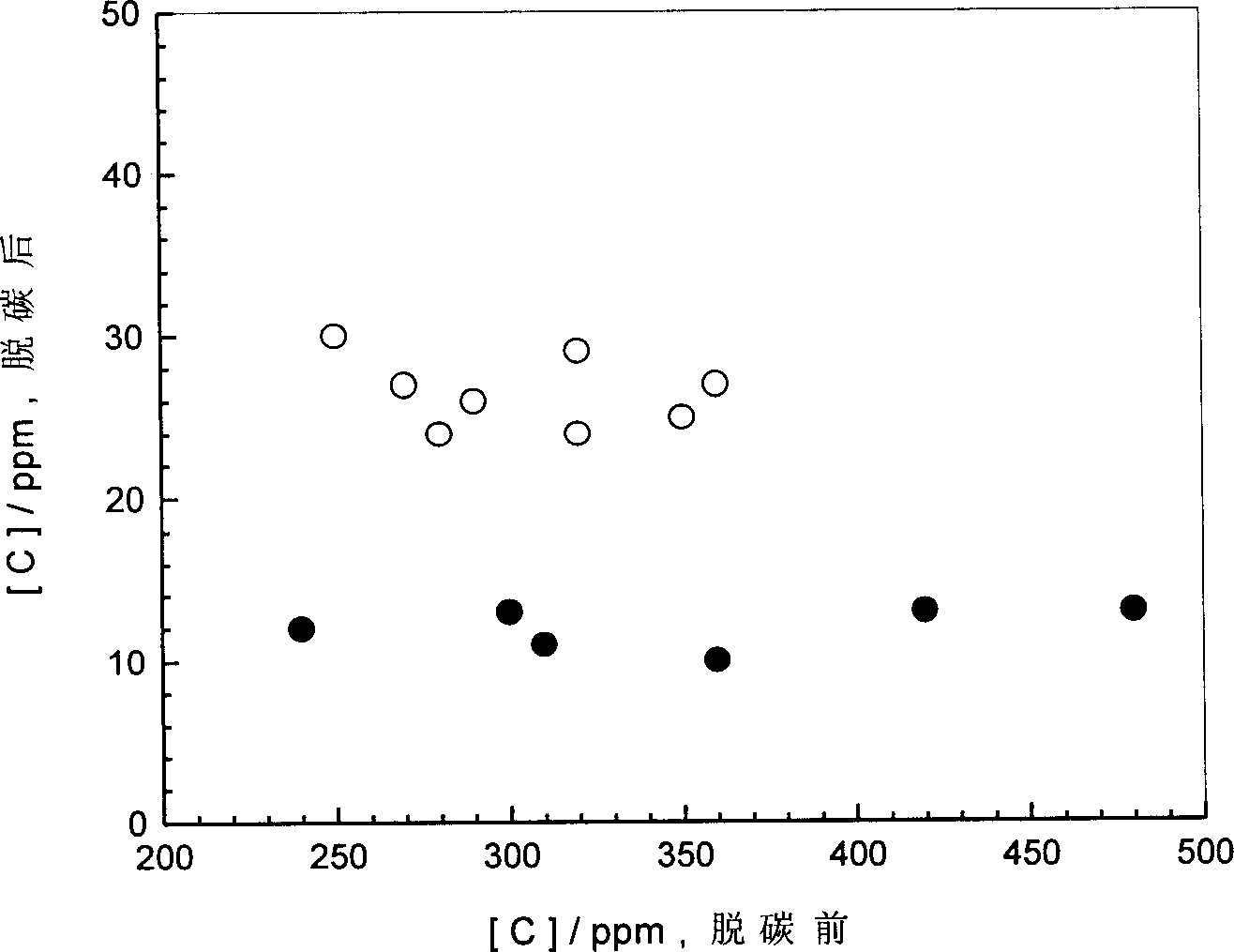

[0019] The decarburization operation using the method of the present invention is shown in Table 1, and the decarburization operation of the comparative example is shown in Table 2. The actual capacity of the ladle molten steel in the treatment process is 78t.

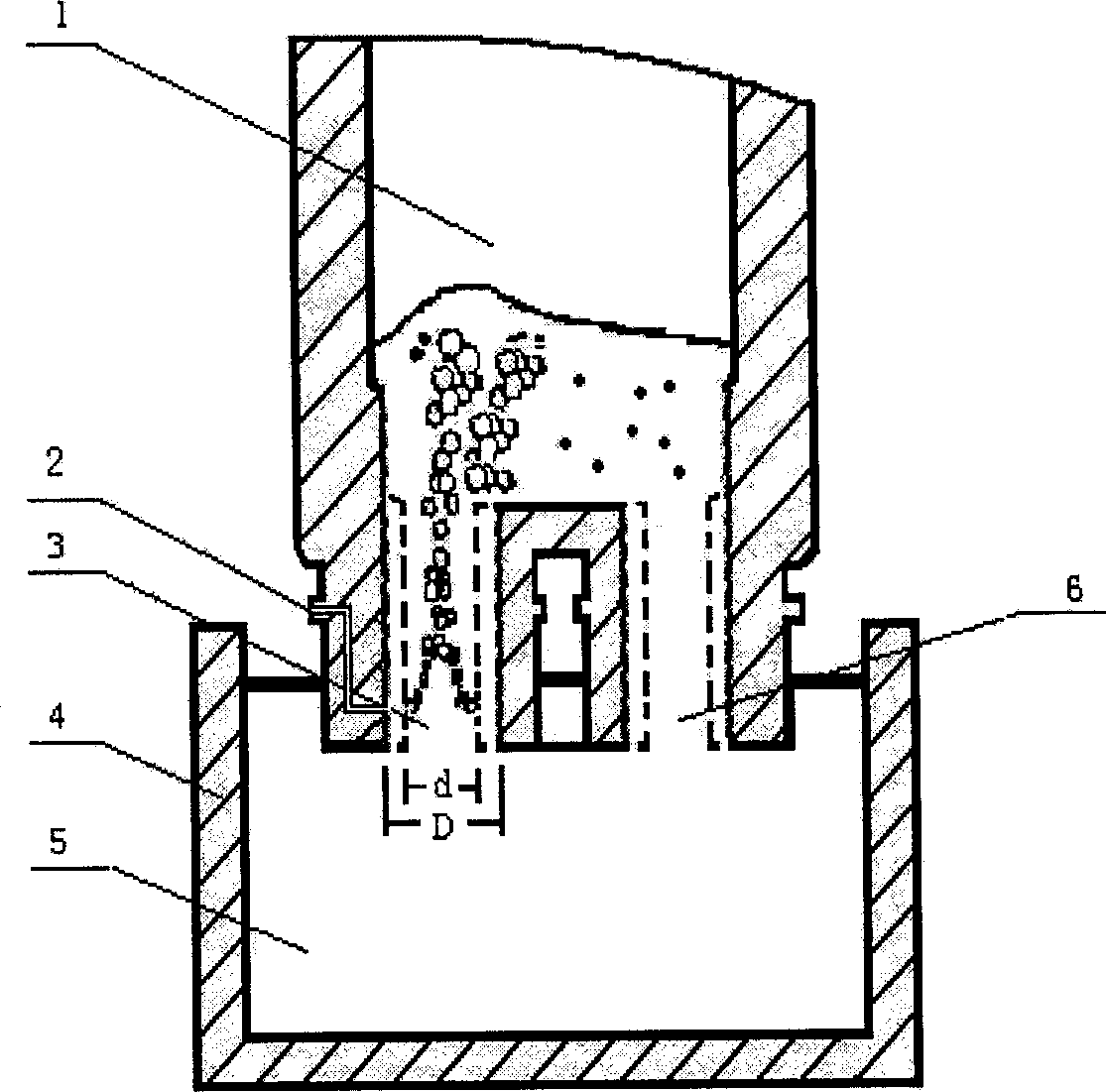

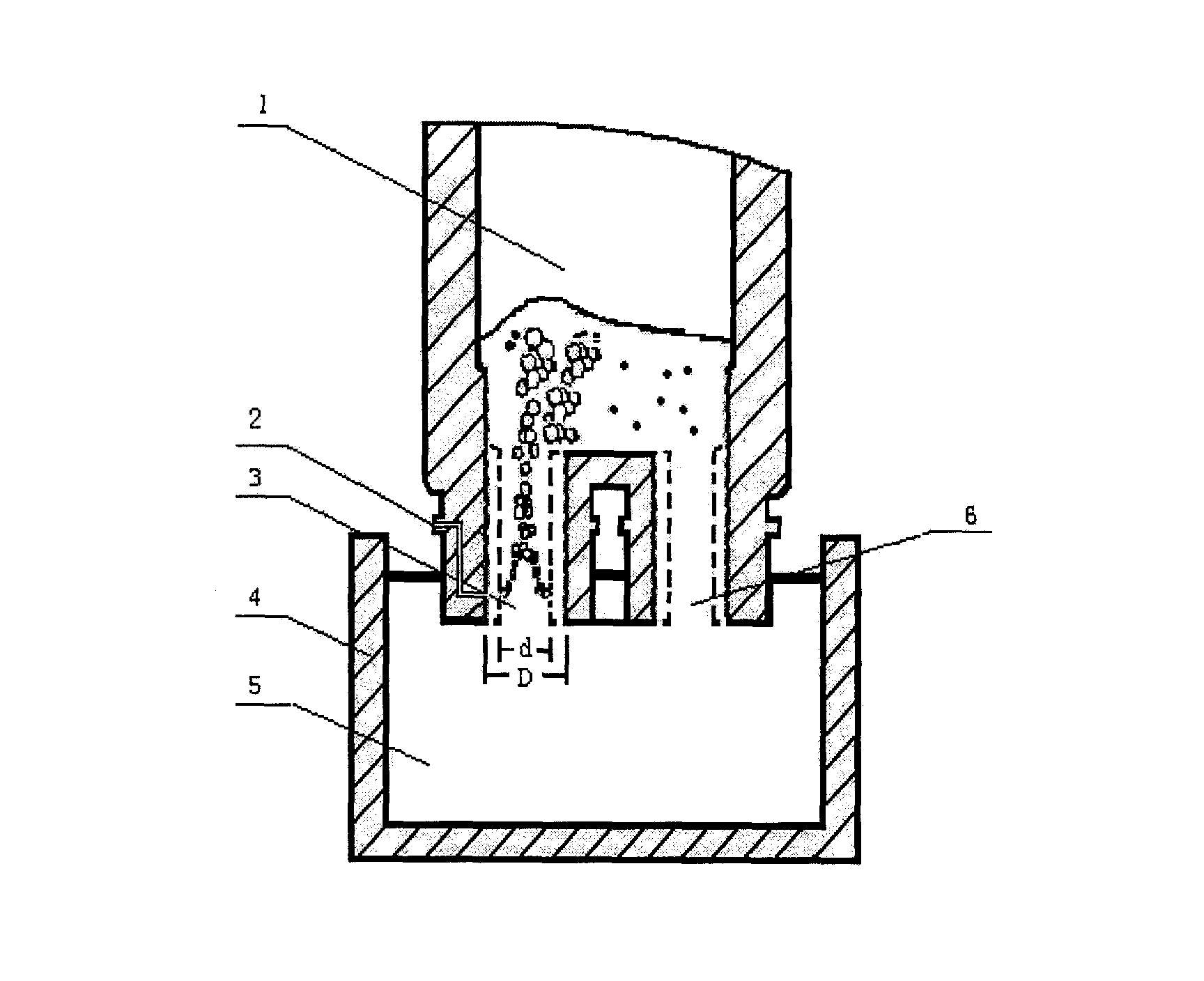

[0020] During the decarburization process, connect the insertion tube of the vacuum chamber ①, the ascending pipe ③ and the descending pipe ⑥, and simultaneously immerse in the molten steel ⑤ of the ladle ④ to draw a vacuum, and continuously inject argon gas from the conduit ② to drive the circulation of the molten steel for decarburization.

[0021] Furnace service period

Increase argon flow Nl / min·t

Vacuum

decarburization time

First 20 furnaces

≤9min >9min

10min

15min

5.2 6.4

≤0.2kPa

After 20 furnaces

10min

8min

15min

5.2 7~7.2 7.7~9

≤0.2kPa

[0022] Furnace service ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com