Patents

Literature

37results about How to "Good decarburization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

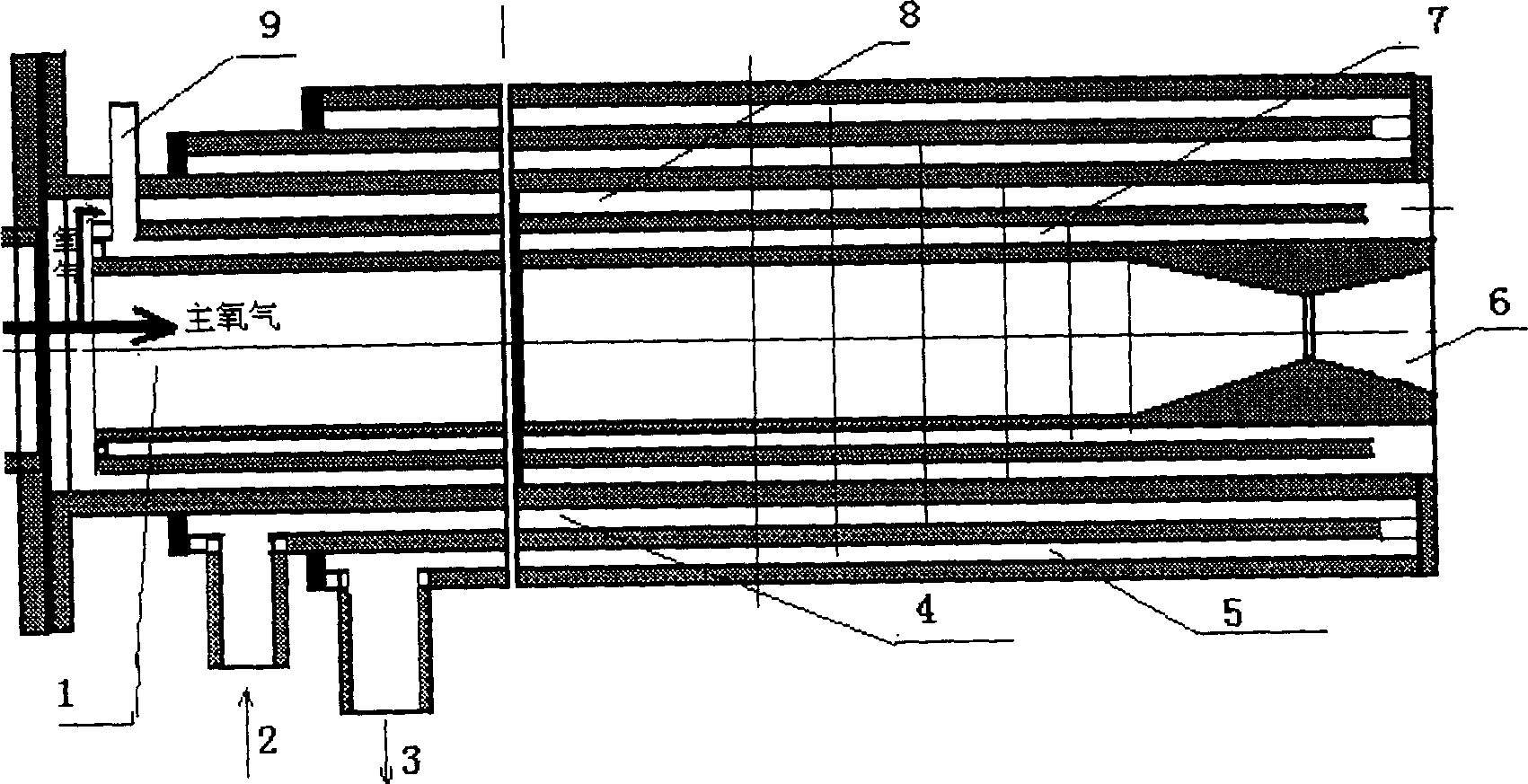

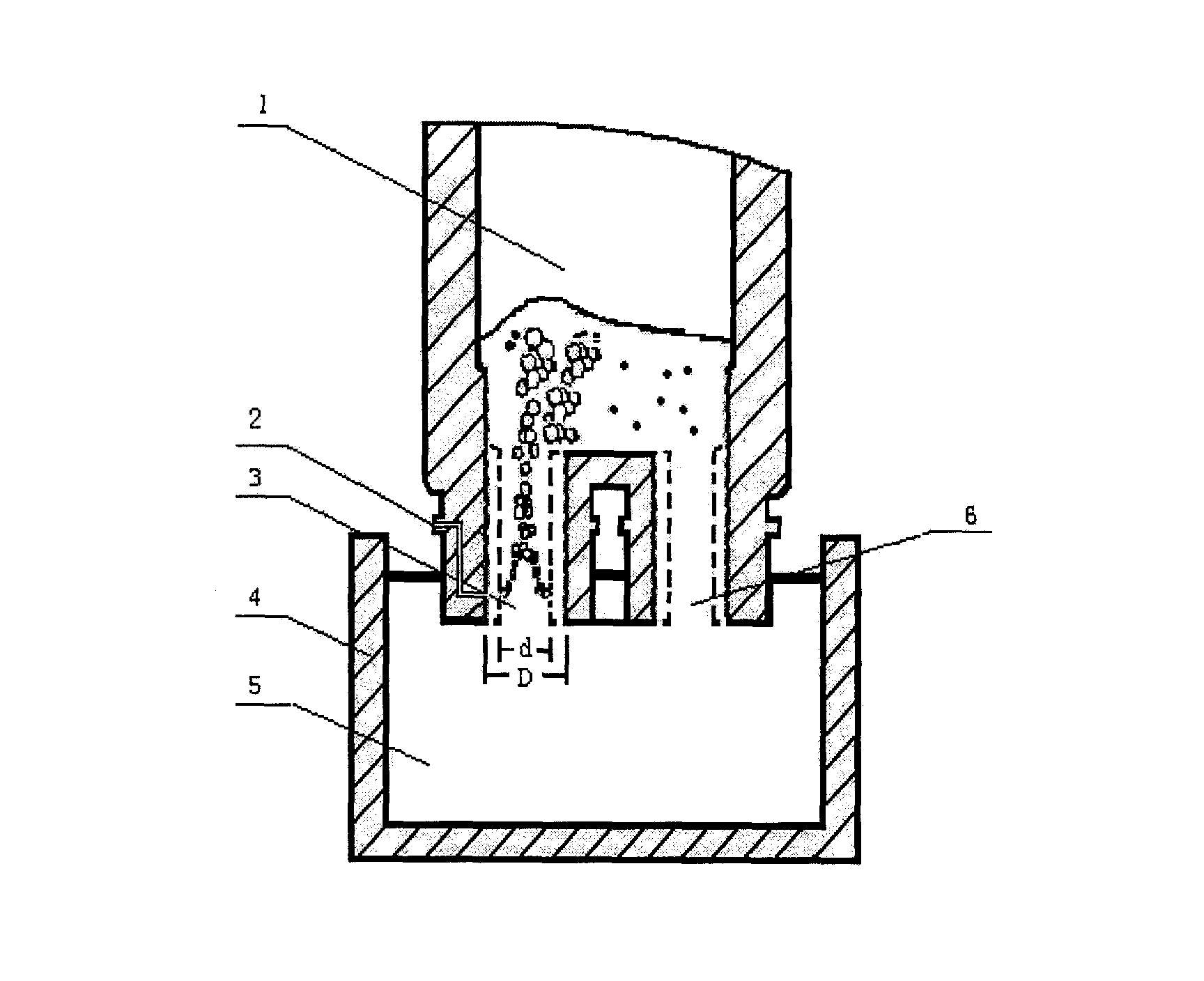

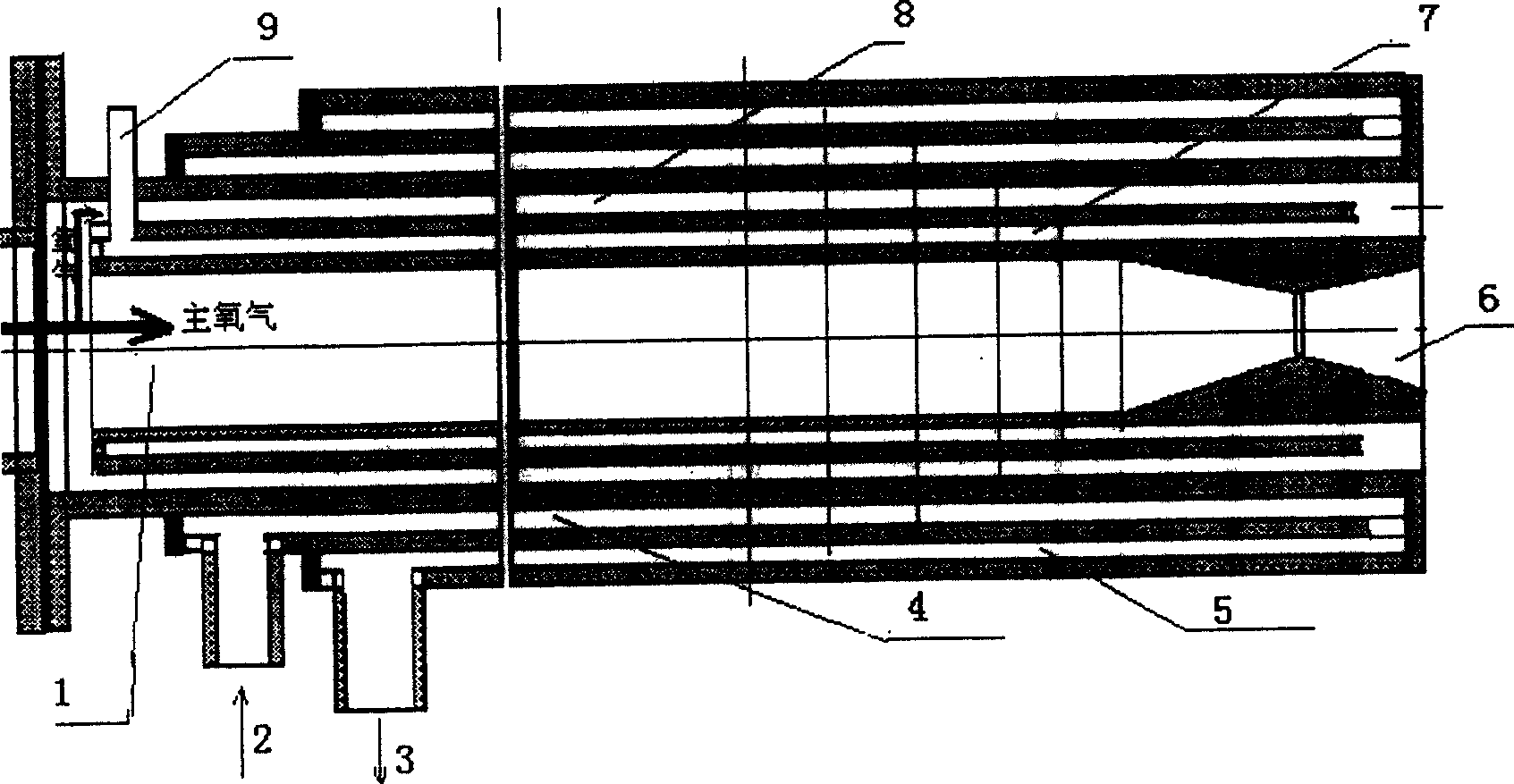

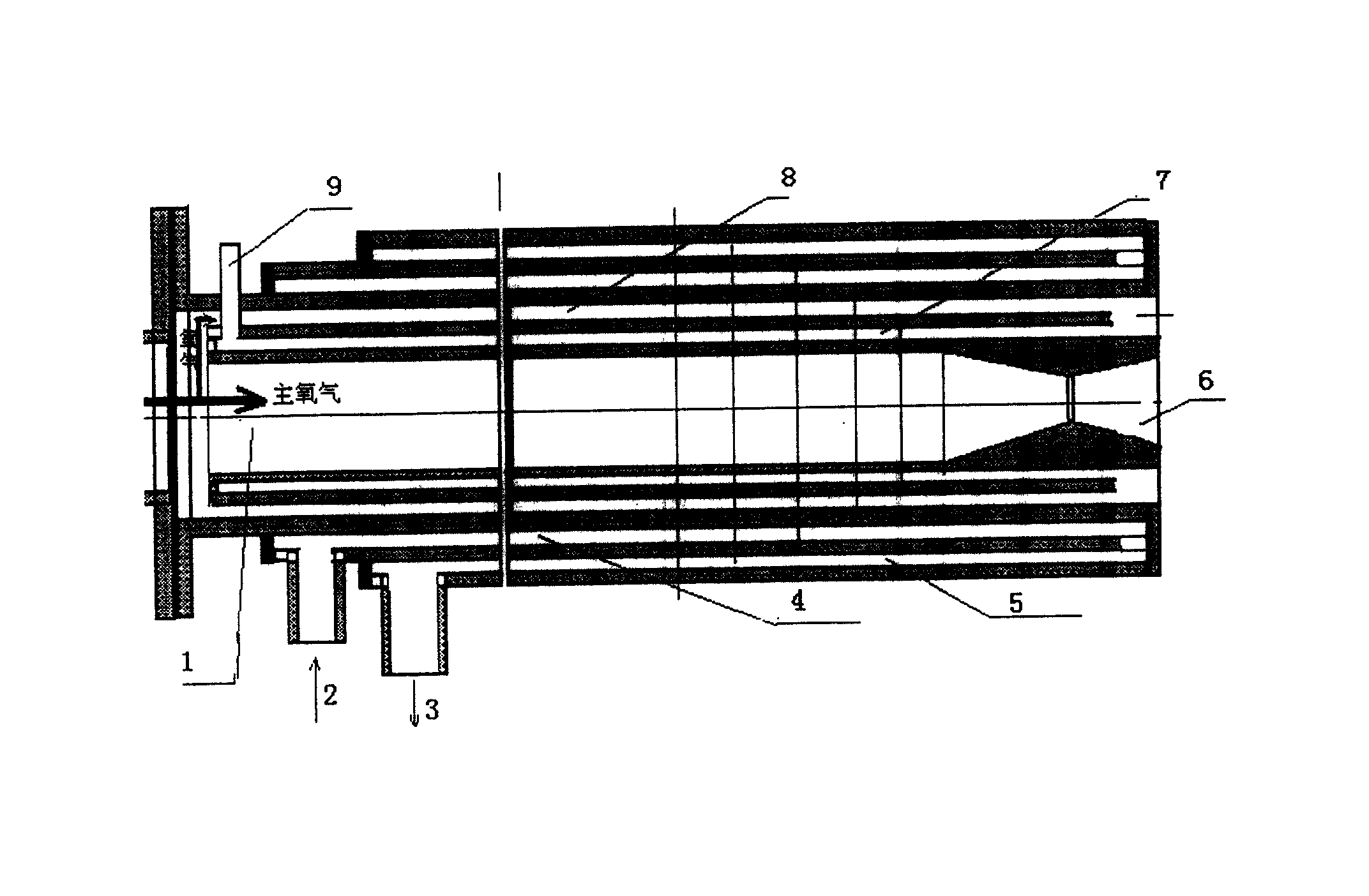

Oxygen blowing apparatus for smelting steel, technology and application

InactiveCN1379115AImprove utilization efficiencyReduce concentrationCharge manipulationLiquid spraying apparatusMelting tankSlag

A concentrated oxygen jet gun for smelting steel in electric furnace features that its primary oxygen jet channel has its outer layer surrounded by a protecting system composed of fuel spray pipe, and the said protecting system composed of fuel injecting tube, secondary oxygen inlet and fuel inlet nozzle. The concentrated oxygen jet gun is arranged on the furnace wall and blows oxygen at the position 400-1000 mm above the slag line. The gas generated by burning gas or liquid fuel and secondary oxygen is used as protecting gas to keep the original impact force and the speed of primary oxygen at the distance of 800-2000 mm far from the gun. Its advantages are high decarbonizing speed, high utilization rate of oxygen, and the function of helping smelting and secondary combustion of CO.

Owner:UNIV OF SCI & TECH BEIJING

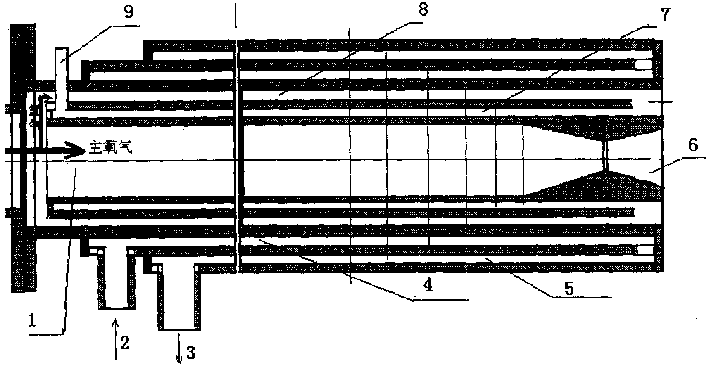

Method of producing super low carbon steel using vacuum degassing

InactiveCN1410559AAvoid damageSolve the problem that the decarburization ability increases with the erosion of the inner diameter of the insertion tubeMetallurgyVacuum level

A process for preparing ultralow-carbon steel by vacuum degassing features that the argon flow and the vacuum level are dependent on the service age of the furnace, that is, for the initial 20 batches, the argon flow is matched with inner diameter of insertion-in tube, and for the following batch whose decarbonizing time is longer than 5 min, the argon flow is increased by more than 20%. Before decarbonizing the molten steel, the vacuum chamber is depressurized in advance. Within 0-10 min after beginning decarbonization, the depressurizing speed is increased.

Owner:武钢集团有限公司

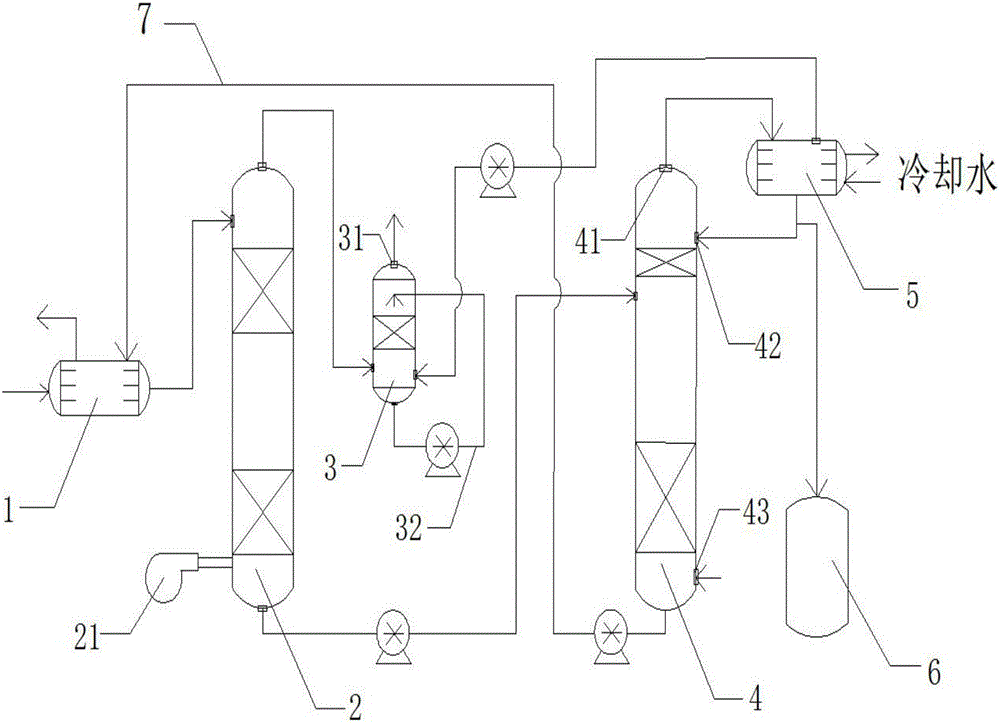

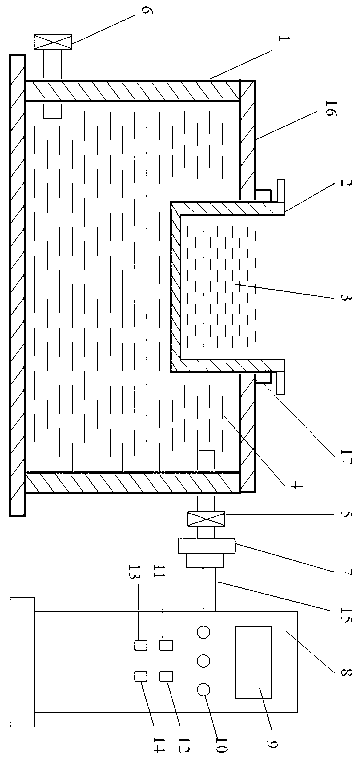

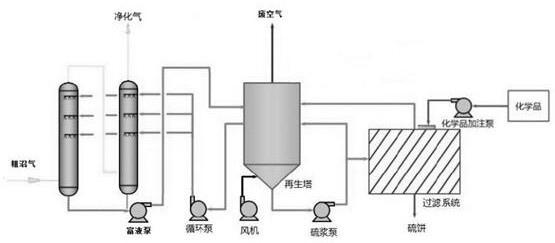

Biogas slurry decarbonization and deamination combined system

ActiveCN106315726AReduce pressure requirementsLower distillation temperatureWater contaminantsDispersed particle separationWater vaporWater storage tank

The invention provides a biogas slurry decarbonization and deamination combined system. The system comprises a preheater (1), a decarbonization tower (2), a deamination tower (4), a condenser (5), an ammonia water storage tank (6) and a pipeline (7), wherein the preheater (1) preheats a biogas slurry raw material and feeds the biogas slurry raw material into the decarbonization tower (2), and the decarbonized biogas slurry raw material enters the deamination tower (4), is brought out by water vapor in the deamination tower (4), then is cooled by the condenser (5) and enters the ammonia water storage tank (6). By virtue of equipment designed on the device, ammonia nitrogen in biogas slurry can be effectively removed, and energy saving and environment protecting effects are achieved; meanwhile, the whole device is also easy to control and can be further popularized and applied.

Owner:江苏金茂源生物化工有限责任公司

Method for producing nickel-based steel from high-phosphorus molten iron

ActiveCN111411300AOptimizing the Converter ProcessMeet the needs of industrial productionManufacturing convertersProcess efficiency improvementTemperingSlag

The invention discloses a method for producing nickel-based steel from high-phosphorus molten iron, and relates to the technical field of steel smelting. By adopting converter smelting, the P contentof used molten iron is 0.130% to 0.150%, by adopting a method of slag retention at the early stage and double slag at the later stage, the final smelting temperature is 1580-1620 DEG C, in the middleand later periods of smelting, the bottom stirring flow is 350-400 NL / min, the final slag alkalinity is 4.0, the final slag control amount is 10-12 tons, the converter decarburization rate is larger than or equal to 99%, and the dephosphorization rate is larger than or equal to 96%; and through LF refining, RH vacuum treatment, arc continuous casting machine pouring, by adopting TMCP rolling and ACC water cooling to 300 + / -20 DEG C, air cooling is performed to room temperature, a steel plate is heated to 550 + / -10 DEG C, tempering is performed for 3*h min, and air cooling is performed to roomtemperature. The converter process is optimized, a product is conveyed to a heating furnace to be heated after vacuum treatment and casting of an arc-shaped continuous casting machine, TMCP rolling and ACC water cooling are adopted, and after tempering treatment, performance detection is qualified.

Owner:NANJING IRON & STEEL CO LTD

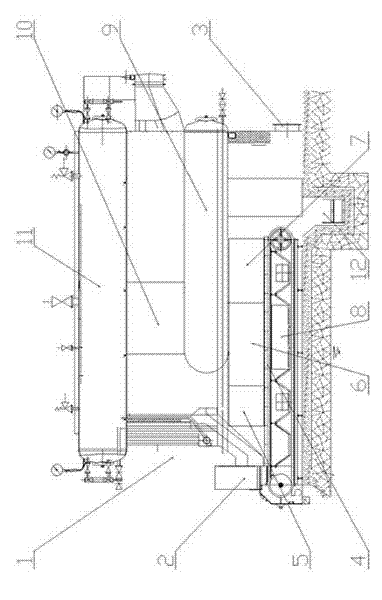

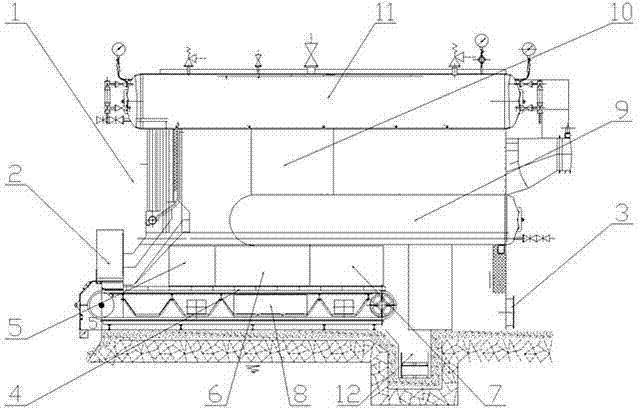

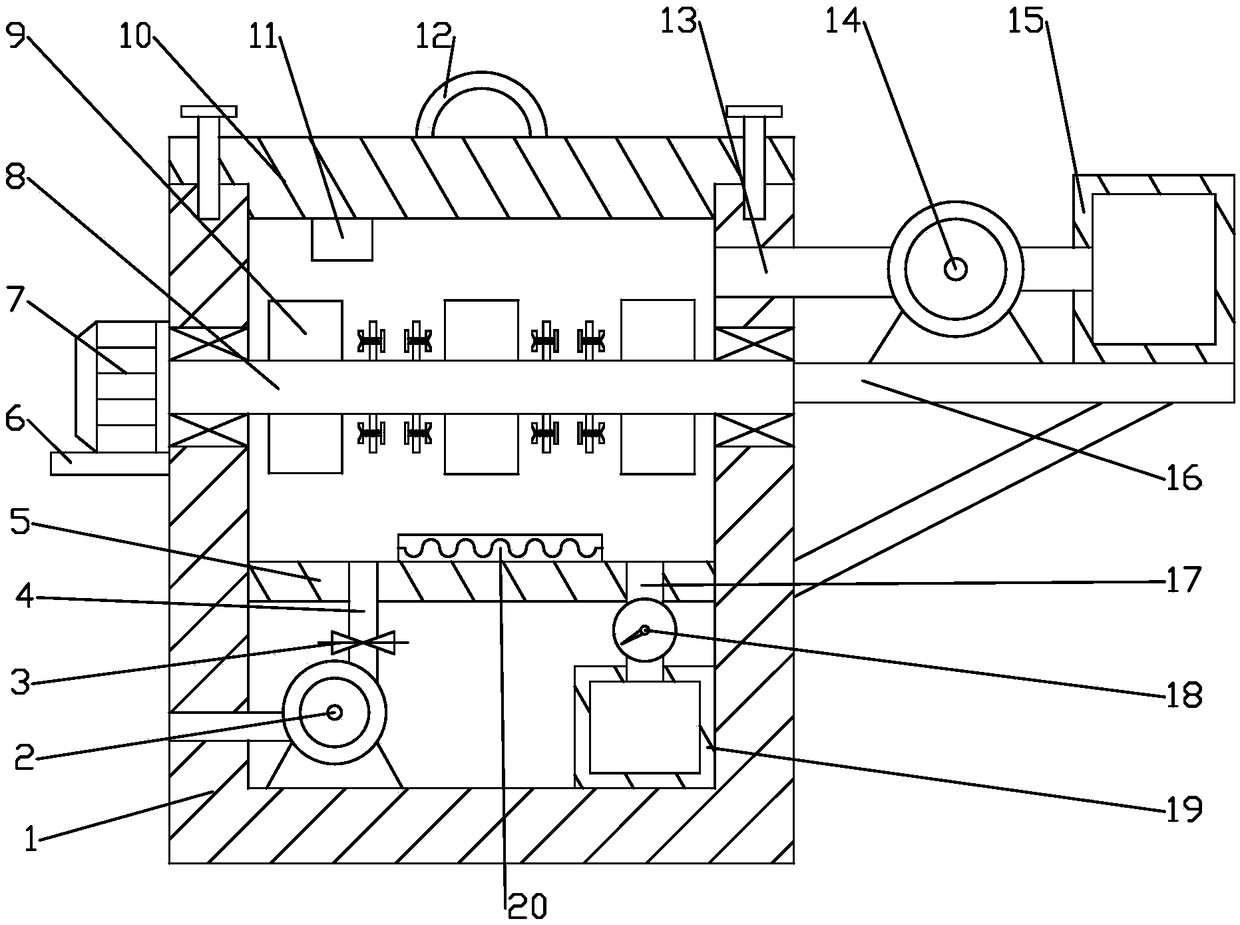

De-oiling furnace for waste oil catalyst

The invention discloses a de-oiling furnace for waste oil catalyst, comprising a furnace body; the furnace body is provided with a material inlet and a material outlet; a furnace grate for sending material is disposed in the furnace body; wherein the material inlet and the material outlet are both provided with a cooling device; and a pre-heating chamber, a burning chamber and a cooling chamber are orderly arranged between the material inlet and the material outlet; a firebrick layer is set in the burning chamber; and the furnace wall of the burning chamber is provided with a ventilation door connected with a ventilation room; and the end part of the furnace grate is further provided with a slag remover; a water heating pot cylinder is disposed in the furnace above the burning chamber; the water heating pot cylinder is provided with a drainage pipeline. The invention is featured in simple structure and smart design; the oil, sulfur and carbon compound are removed from the waste oil catalyst by the way of burning; and the heat produced by waste heat is used for heating the media, so as to supply industrial production or other occasions which need high-temperature media.

Owner:DALIAN DONGTAI RESOURCE RENEWABLE

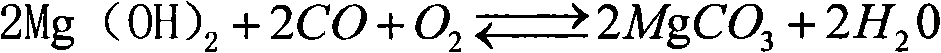

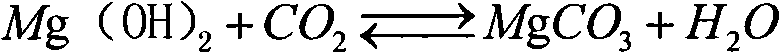

Coal-saving decarburization combustion improver

InactiveCN101870899AHigh thermal efficiencyGood decarburization effectSolid fuelsActivated carbonStrontium carbonate

The invention discloses a coal-saving decarburization combustion improver. The improver is prepared by evenly mixing the following components by weight percent: 20-30% of activated calcium oxide, 9-12% of magnesium hydroxide, 12-20% of sodium carbonate, 8-10% of activated carbon, 12-15% of FeSi powder, 8-12% of manganese dioxide, 3-5% of strontium carbonate and 5-7% of barium hydroxide. By adding the combustion improver of the invention in fire coal, the dosage of coal can be reduced by 2-15%, the thermal efficiency can be increased by 0.5-5%, and the decarburization effect is good.

Owner:广州中科高成环保科技有限公司

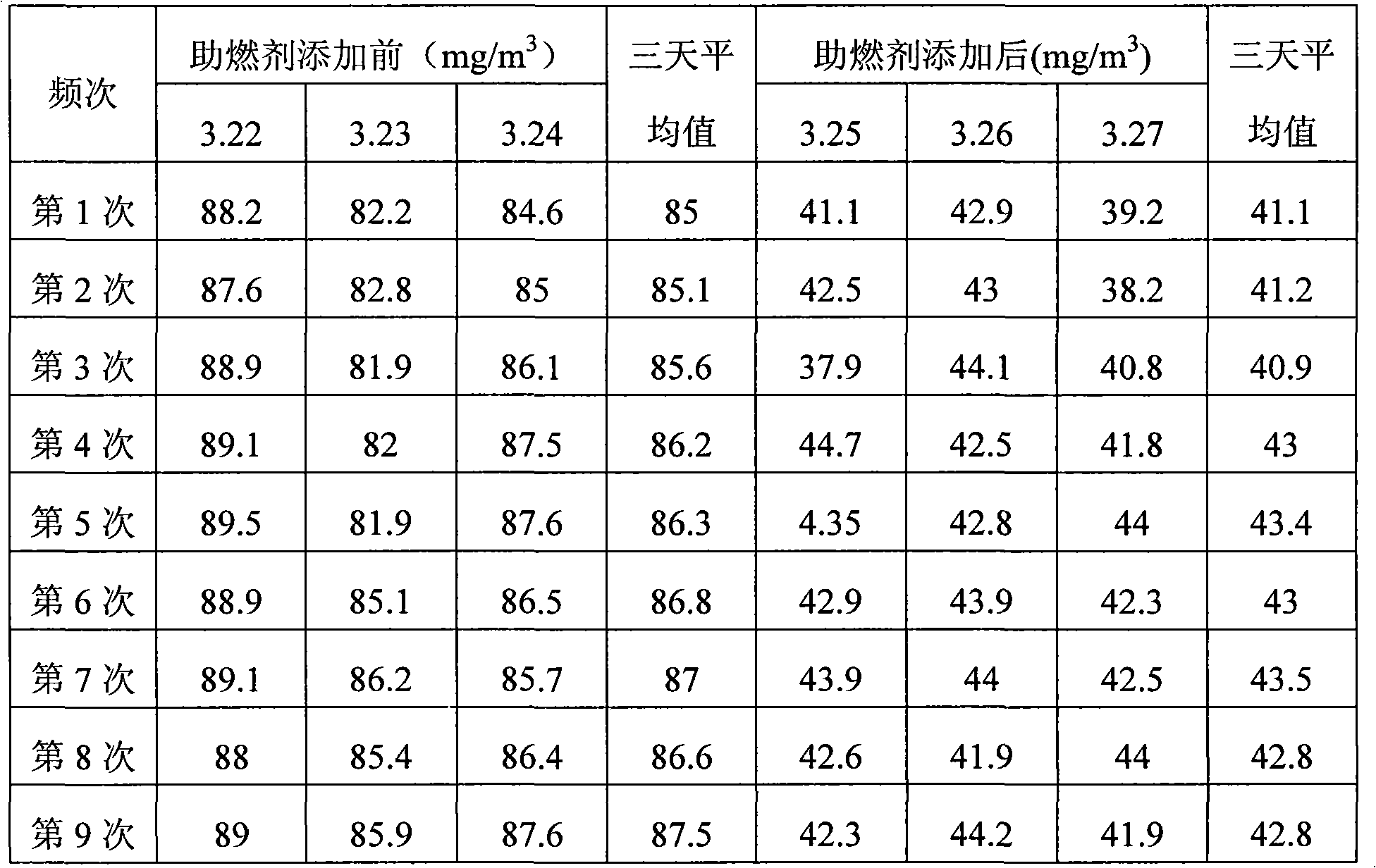

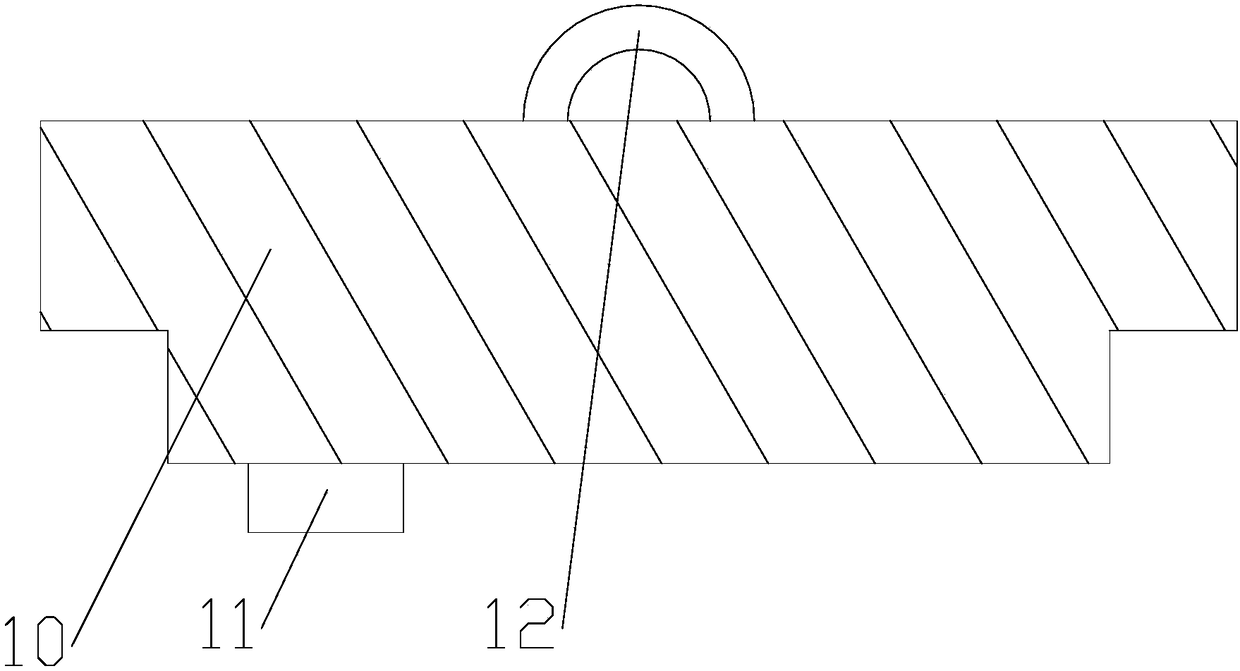

Moulding and flanging mould for machining automobile parts

InactiveCN107447169AThe proportion of components is reasonableReduce coefficient of frictionShaping toolsFoundry mouldsHeat resistanceCarbide

The invention discloses a moulding and flanging mould for machining automobile parts. The moulding and flanging mould for machining the automobile parts is formed by casting steel, and the steel comprises, by weight, 1.10-1.25% of C, 0.35-0.45% of Si, 0.40-0.50% of Mn, 1.35-1.65% of Cr, 0.35-0.55% of Mo, 1.2-1.6% of W, 0.15-0.25% of Ni, 0.25-0.35% of Cu, 0.8-1.2% of Ga, 1.8-2.6% of carbide, 2.15-2.35% of rare earth metals, less than or equal to 0.03% of S, less than or equal to 0.03% of P, and the balance being Fe. All components of the steel used in the moulding and flanging mould is reasonable in ratio, excellent in performance, little in friction coefficient of prepared mould, excellent in anti-fatigue performance, heat resistance performance and anti-pressing performance, long in service life, low in using cost and good in decarburization effect in the preparing process of molten steel.

Owner:CHUZHOU KAIXUAN MOLD MFG

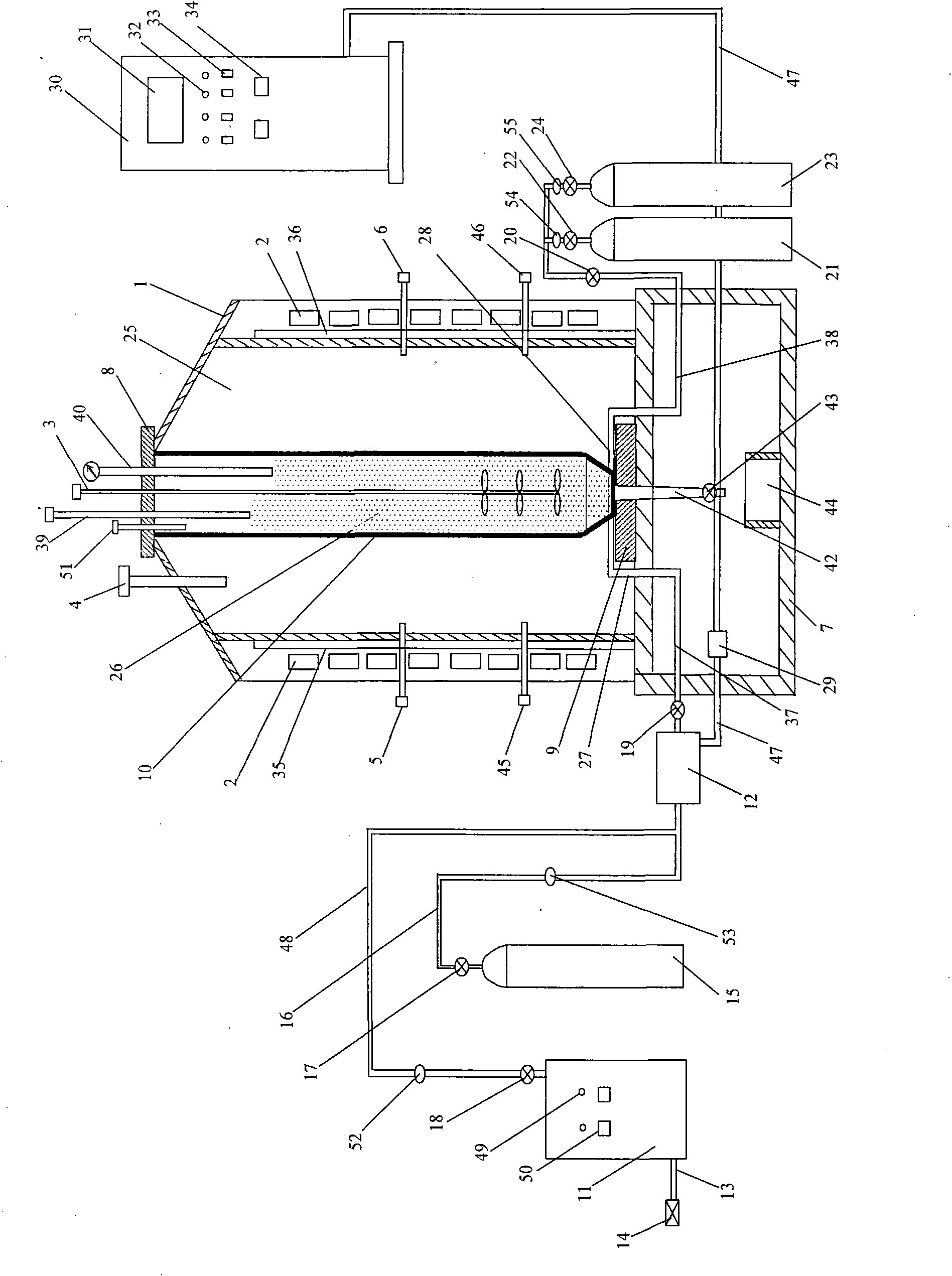

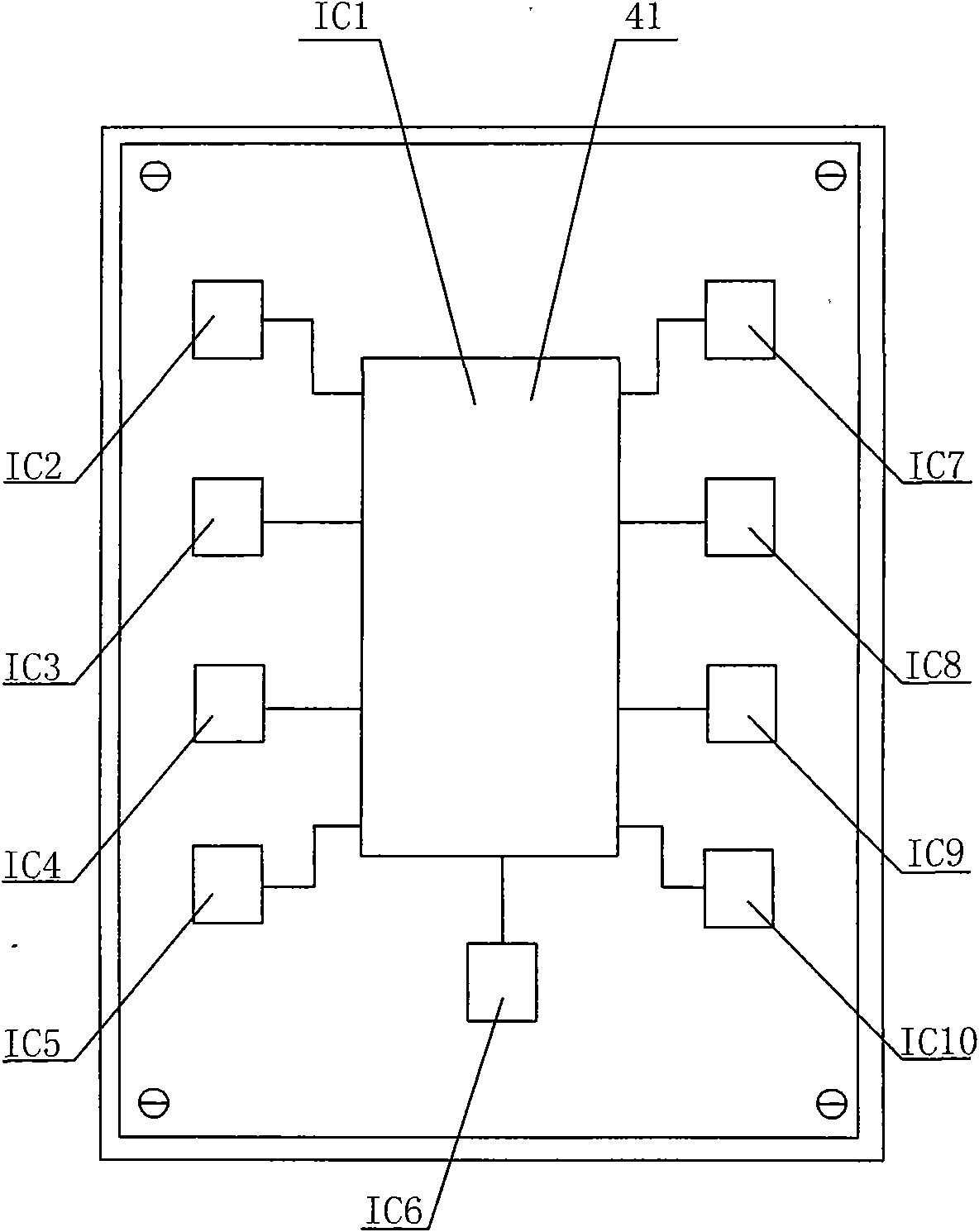

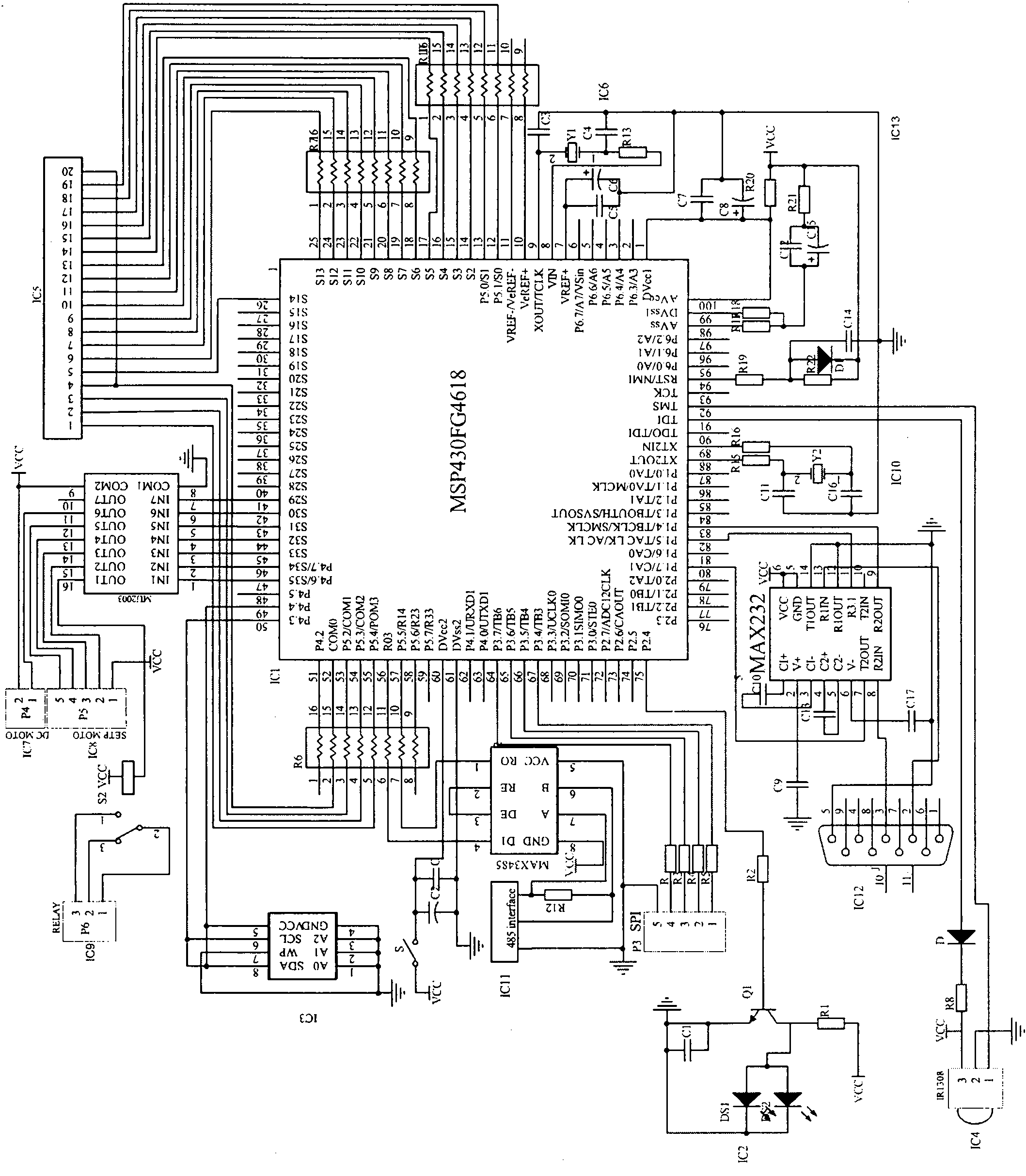

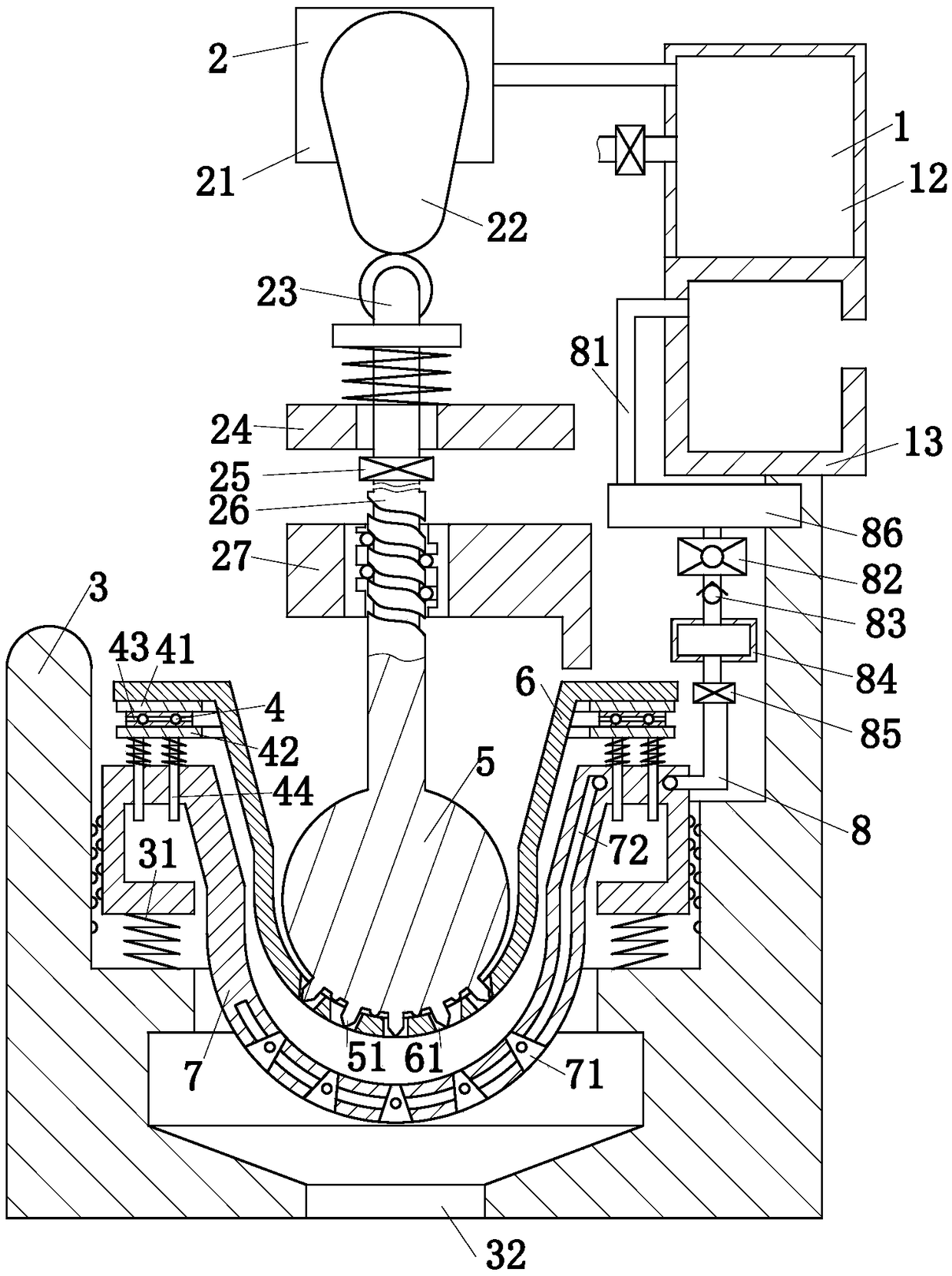

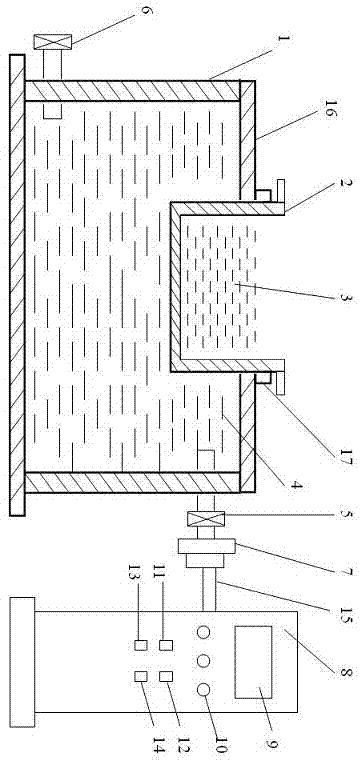

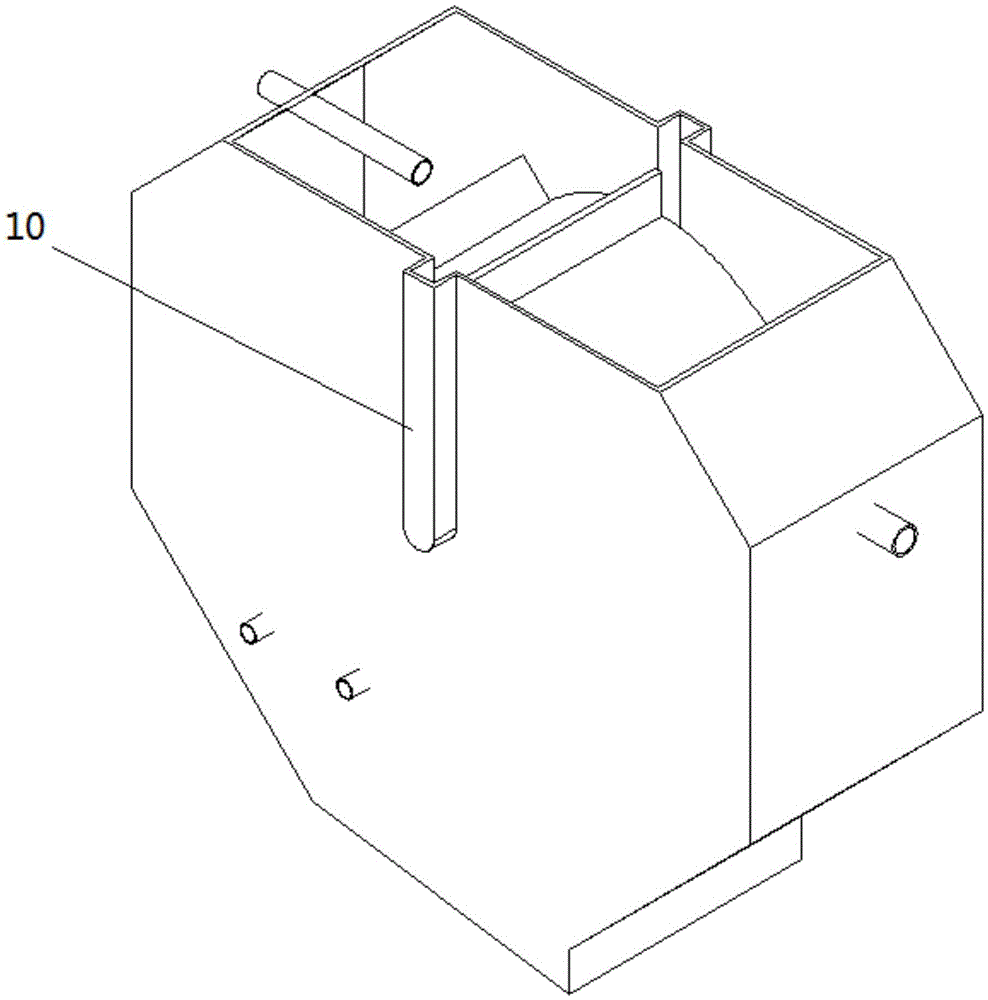

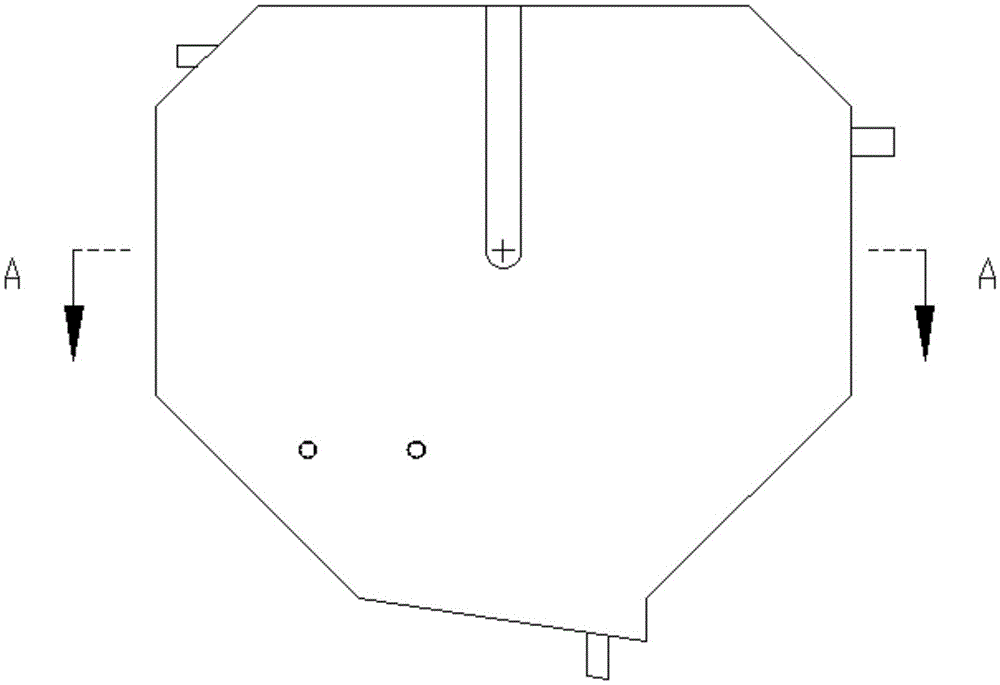

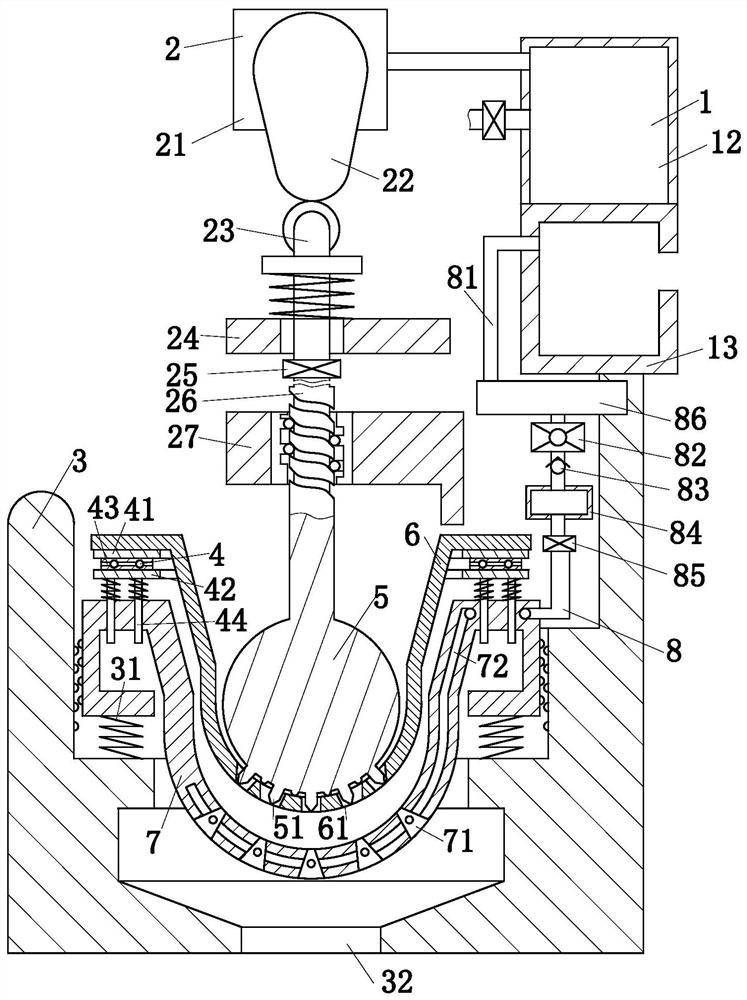

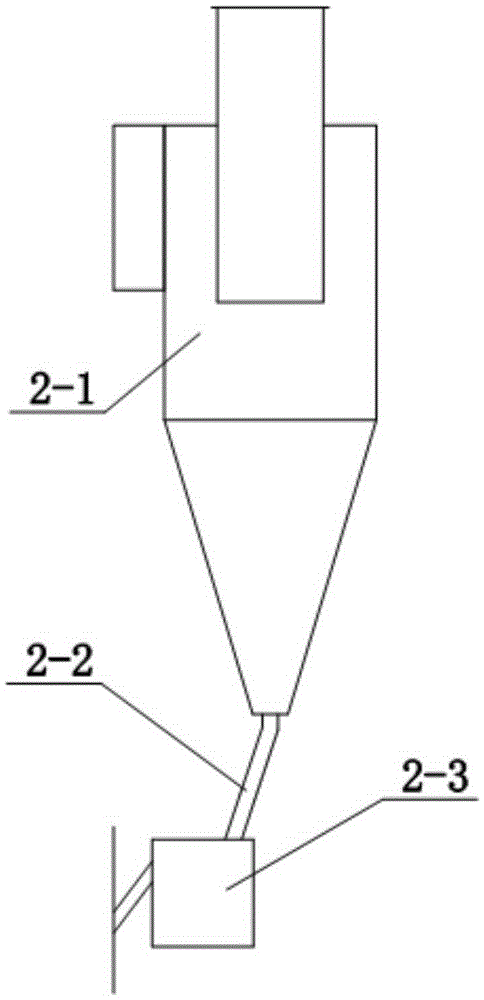

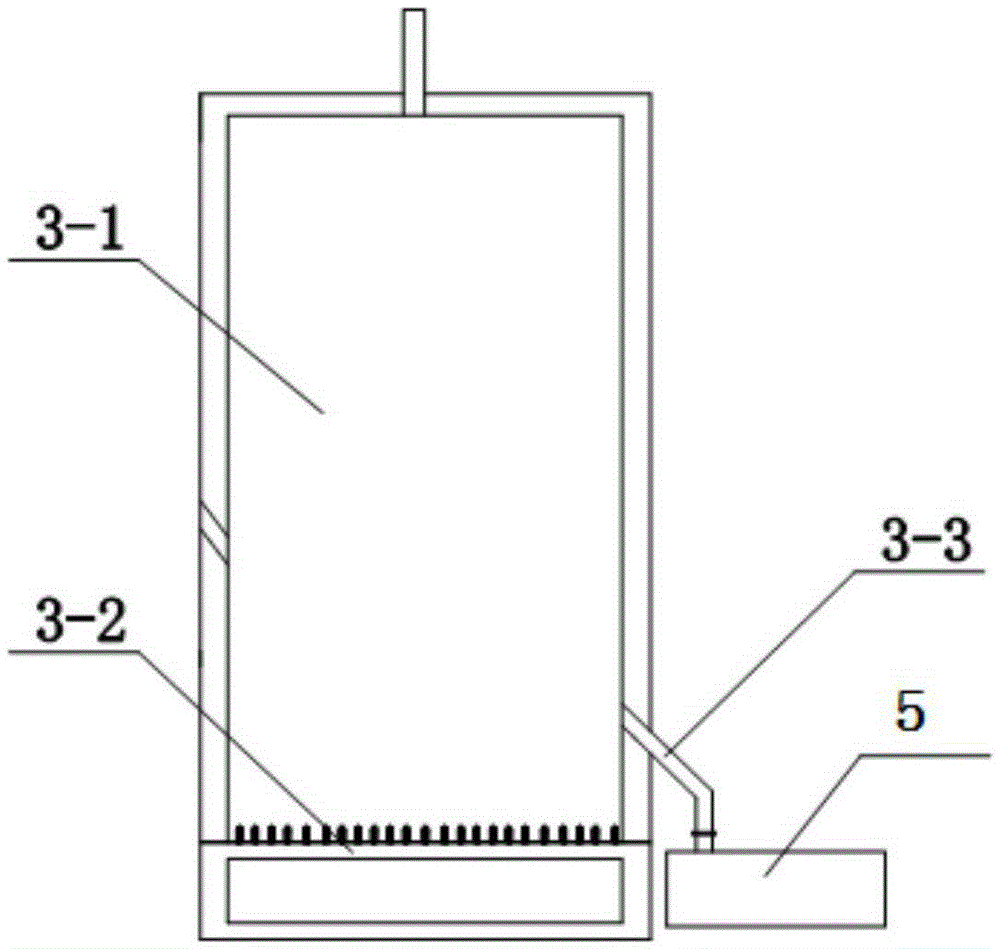

Microwave-heated spouted fluidized decarbonization device

The invention relates to a microwave-heated spouted fluidized decarbonization device. The device is provided with a circular fluidized bed body and a straight spouted fluidized pipe; a stirrer, a temperature sensor, a barometer and an outlet valve are arranged on the spouted fluidized pipe; the upper left part of the fluidized bed body is provided with a dust collector, and the peripheral side part is provided with an observation window and a microwave heater; the spouted fluidized pipe is made of a ceramic refractory material; the bottom left of the spouted fluidized pipe is communicated with blown fluidizing gas CO2+H2O, and the bottom right is communicated with N2+Ar inertia protective gas; fluidized powder in the spouted fluidized pipe is subjected to fluidized separation; and the fluidized bed is controlled by a complete program of an electric cabinet circuit microcomputer processor. The microwave-heated spouted fluidized decarbonization device has the advantages of advanced and reasonable design, compact structure, complete functions, safe, reliable and stable microwaving heating, convenient installation and use, good effect and high efficiency of decarbonization, desulfuration and dephosphorization, and the decarbonization rate of 70 to 90 percent, improves the efficiency by 90 percent compared with the prior art, and is an ideal spouted fluidized decarbonization device.

Owner:TAIYUAN UNIV OF TECH

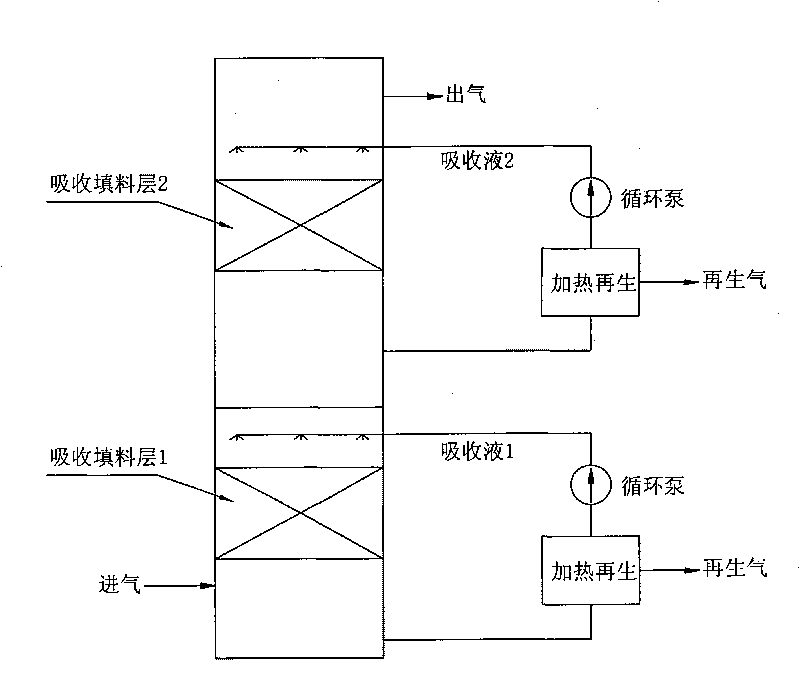

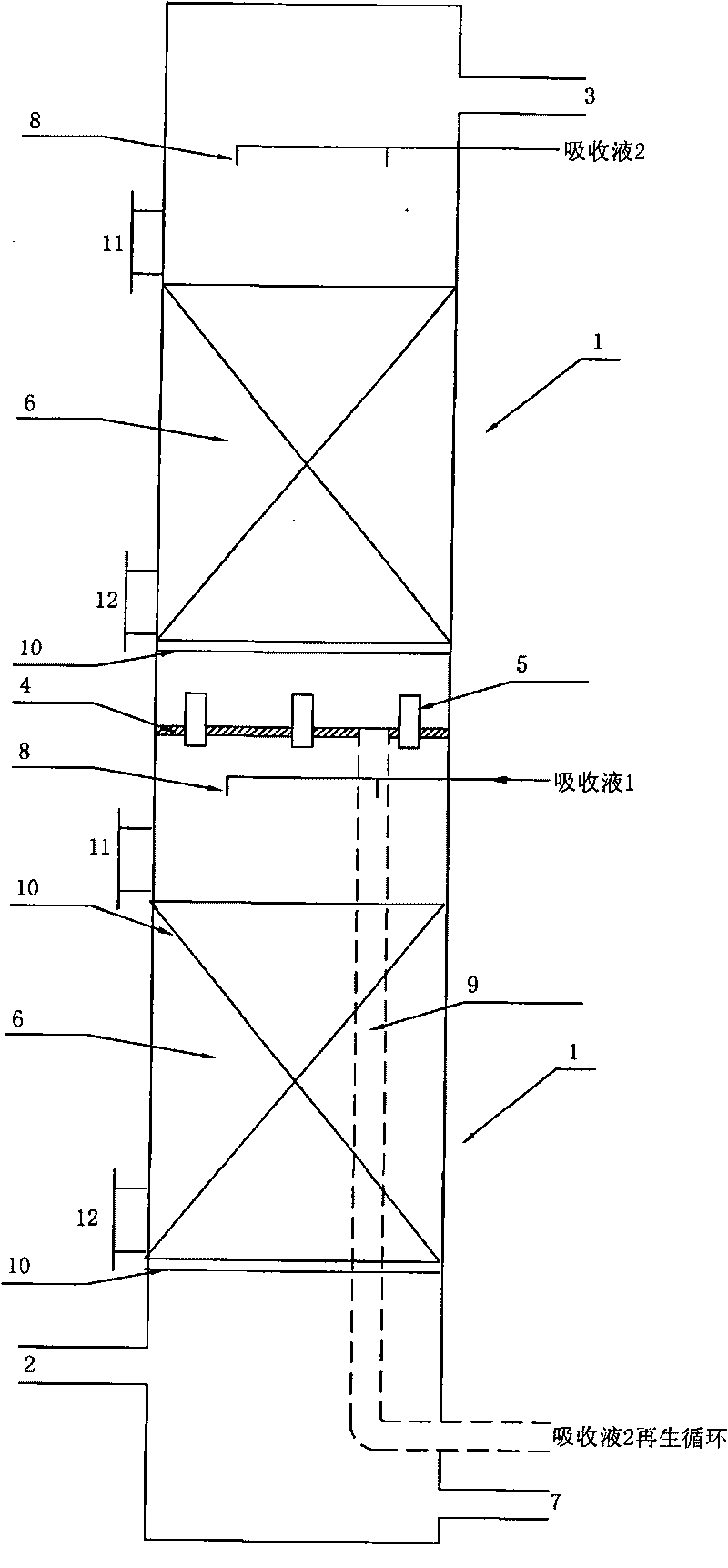

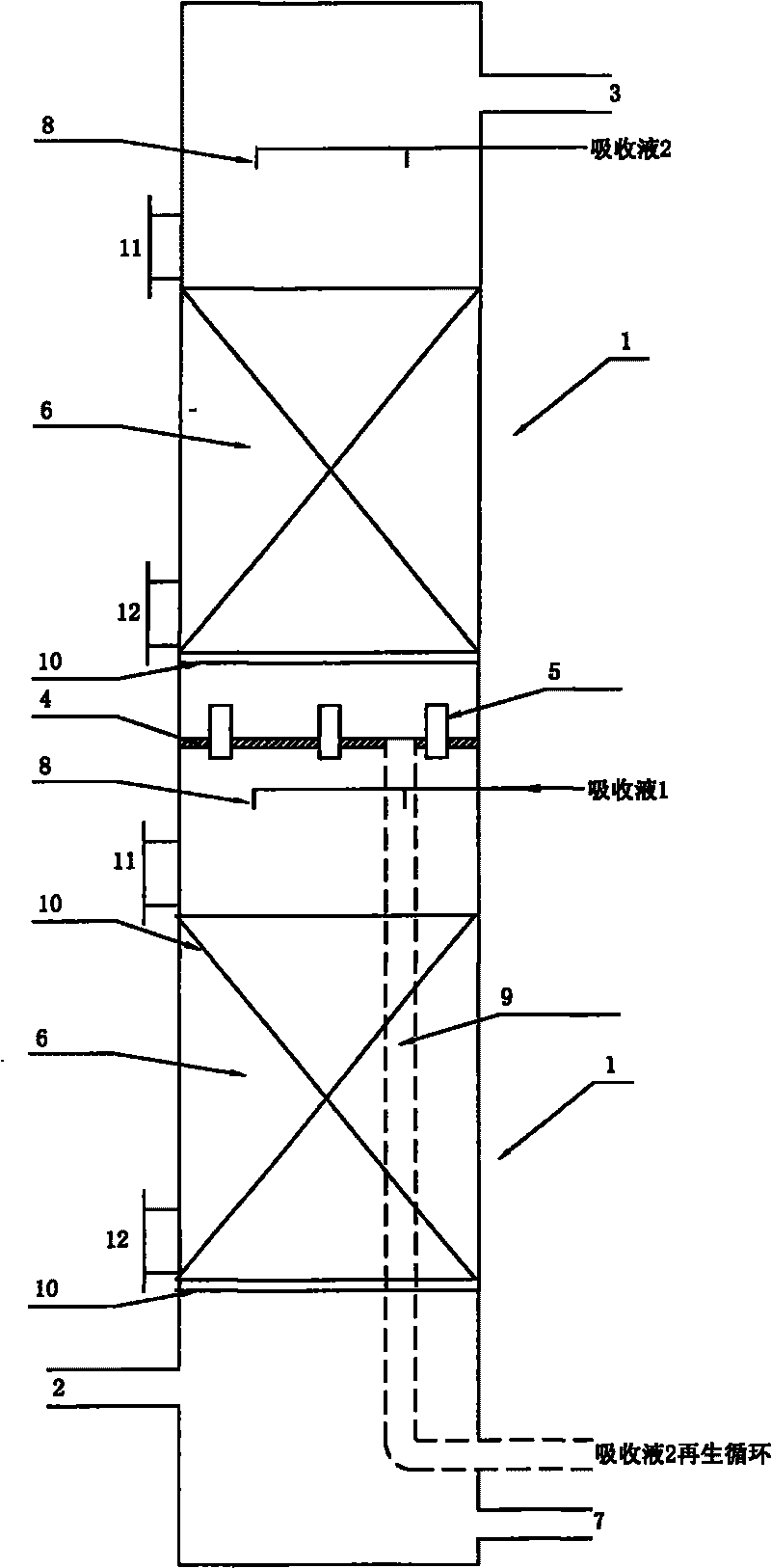

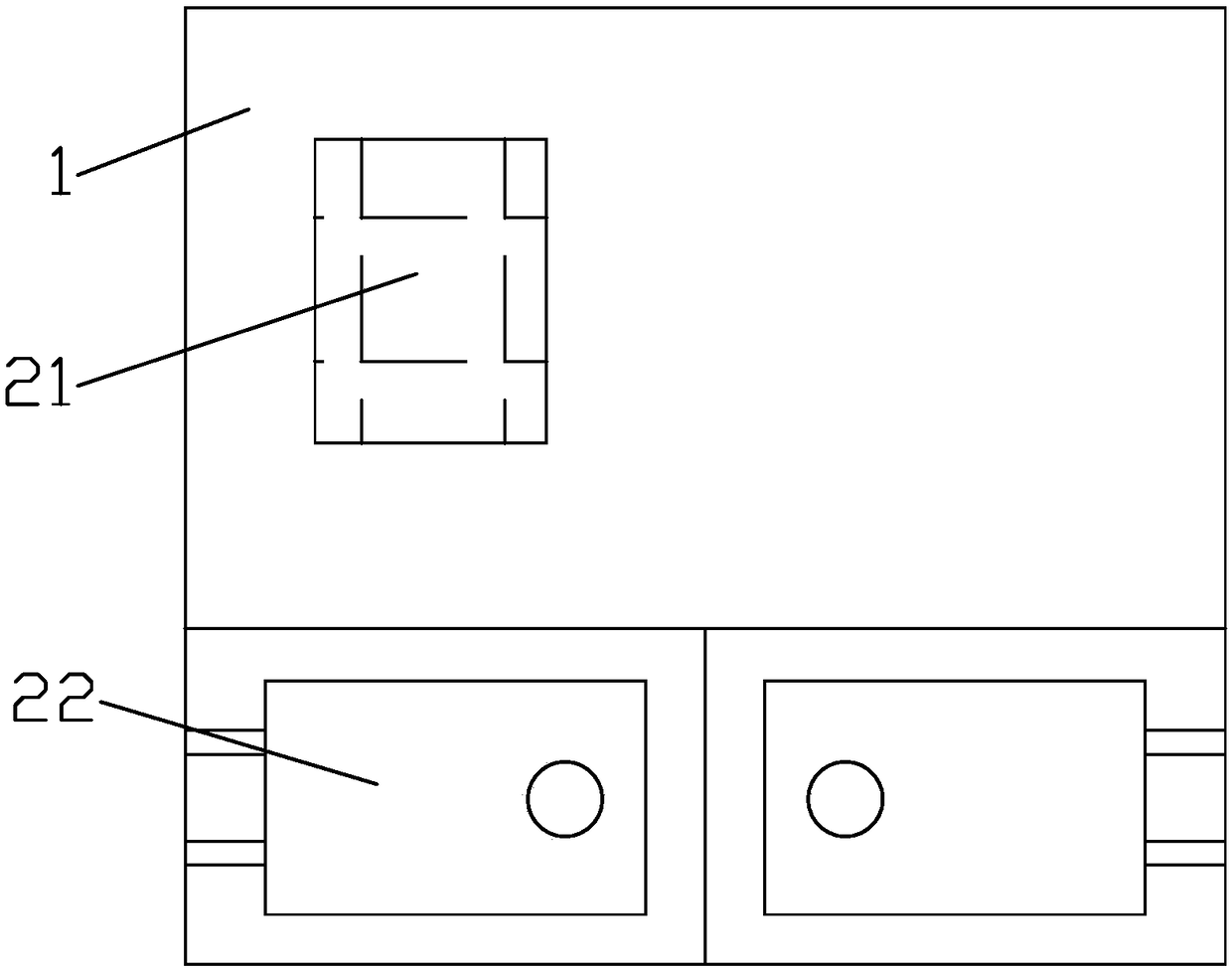

Bio-gas two-stage normal-pressure decarbonization device

InactiveCN101703870ASimple structureEasy to manufactureDispersed particle separationEngineeringTower

The invention relates to a bio-gas two-stage normal-pressure decarbonization device which is characterized by at least comprising filler towers (1) formed by overlapping through two stages, wherein the bottom of the filler tower (1) positioned at a bottom layer is provided with a bio-gas inlet (2) and a bottom layer absorption liquid regenerative cycle outlet (7), the filler tower (1) positioned at a top layer is provided with a bio-gas outlet (3), the upper part of a filler layer (6) of each filler tower (1) is provided with an absorption liquid spraying pipe (8), a baffle plate is arranged between the adjacent filler towers (1), an air elevation pipe (5) which is communicated with the adjacent filler towers (1) is arranged on the baffle plate (4) in a penetrating way, a liquid drop hole is arranged on the baffle plate (4) and is connected with a liquid drop pipe (9) which introduces absorption liquid settled on the baffle plate out of the filler towers, and the liquid drop pipe (9) extends out of the filler towers (1) from the bottoms of the adjacent filler towers (1) or the bottom of the filler tower (1) at the bottom layer. The invention features simple structure, convenient manufacture and low cost.

Owner:NANJING UNIV

Oxygen blowing apparatus for smelting steel, technology and application

InactiveCN1225314CImprove utilization efficiencyReduce concentrationCharge manipulationLiquid spraying apparatusSteelmakingShielding gas

A concentrated oxygen jet gun for smelting steel in electric furnace features that its primary oxygen jet channel has its outer layer surrounded by a protecting system composed of fuel spray pipe, and the said protecting system composed of fuel injecting tube, secondary oxygen inlet and fuel inlet nozzle. The concentrated oxygen jet gun is arranged on the furnace wall and blows oxygen at the position 400-1000 mm above the slag line. The gas generated by burning gas or liquid fuel and secondary oxygen is used as protecting gas to keep the original impact force and the speed of primary oxygen at the distance of 800-2000 mm far from the gun. Its advantages are high decarbonizing speed, high utilization rate of oxygen, and the function of helping smelting and secondary combustion of CO.

Owner:UNIV OF SCI & TECH BEIJING

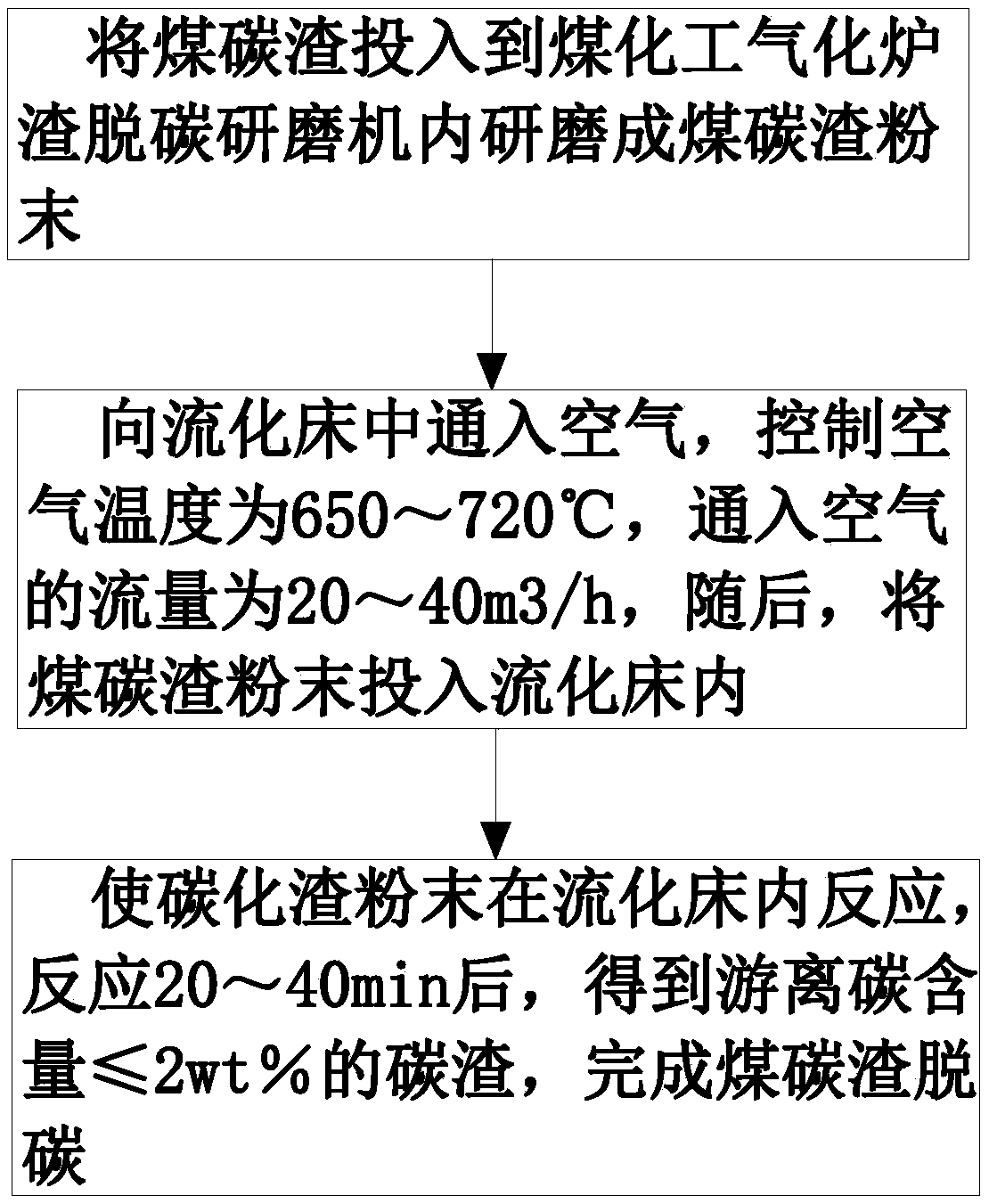

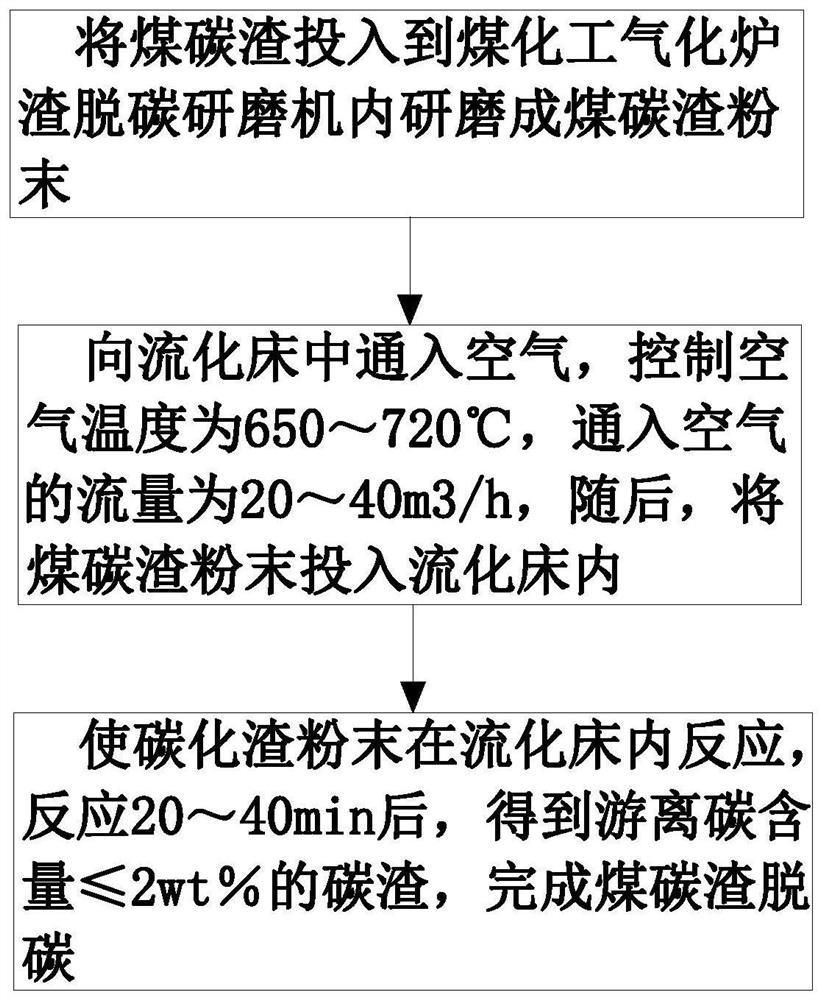

Coal carbon slag decarburization method

ActiveCN109022046AImprove decarbonization effectGood decarburization effectGasification processes detailsGrain treatmentsSlagDecarburization

The invention belongs to the technical field of gasifier coal gas slag, and concretely relates to a coal carbon slag decarburization method. The method comprises the following steps: adding coal carbon slag into a coal chemical industry gasifier slag decarburization grinder, and grinding the coal carbon slag to form coal carbon slag powder; introducing air into a fluidized bed, controlling the temperature of the air to be 650-720 DEG C and the flow of the introduced air to be 20-40 m<3> / h, and then adding the coal carbon slag powder into the fluidized bed; and reacting the coal carbon slag powder in the fluidized bed for 20-40 min to obtain carbon slag having a free carbon content of 2 wt% or below in order to complete the decarburization of the coal carbon slag. The coal chemical industrygasifier slag decarburization grinder improves the coal carbon slag decarburization method, and makes the coal carbon slag fully ground and crushed before being decarburized, and the crushed coal carbon slag powder is heated, so the improvement of the decarburization effect of the coal carbon slag is benefited; and the temperature and the flow of the air in the gasifier are controlled to make thecoal carbon slag fully reacted in the gasifier, so the decarburization effect of the coal carbon slag is improved.

Owner:六安联众工业自动化技术有限公司

Quick cooling decarburization method of high-carbon chromium iron

The invention relates to a quick cooling decarburization method of high-carbon chromium iron, which is used for overcoming the defect that the carbon content of the high-carbon chromium iron is high. The quick cooling decarburization method comprises the following steps of: quickly cooling for separating out graphite to prepare cast ingot in a smelting-casting process of the high-carbon chromium iron; and carrying out crushing, ball-milling and milling, and separating the separated-out graphite particles by adopting a microwave heating method to prepare chromium iron powder with low carbon content. The quick cooling decarburization method is advanced in process, full and accurate in data; the graphite is firstly separated out by a quick cooling method, and the graphite particles are removed through crushing and a microwave heating method, so that the decarburization effect is good, and the carbon content of the high-carbon chromium iron is not more than 3%, and therefore, the quick cooling decarburization method is a very ideal decarburization method of the high-carbon chromium iron.

Owner:TAIYUAN UNIV OF TECH

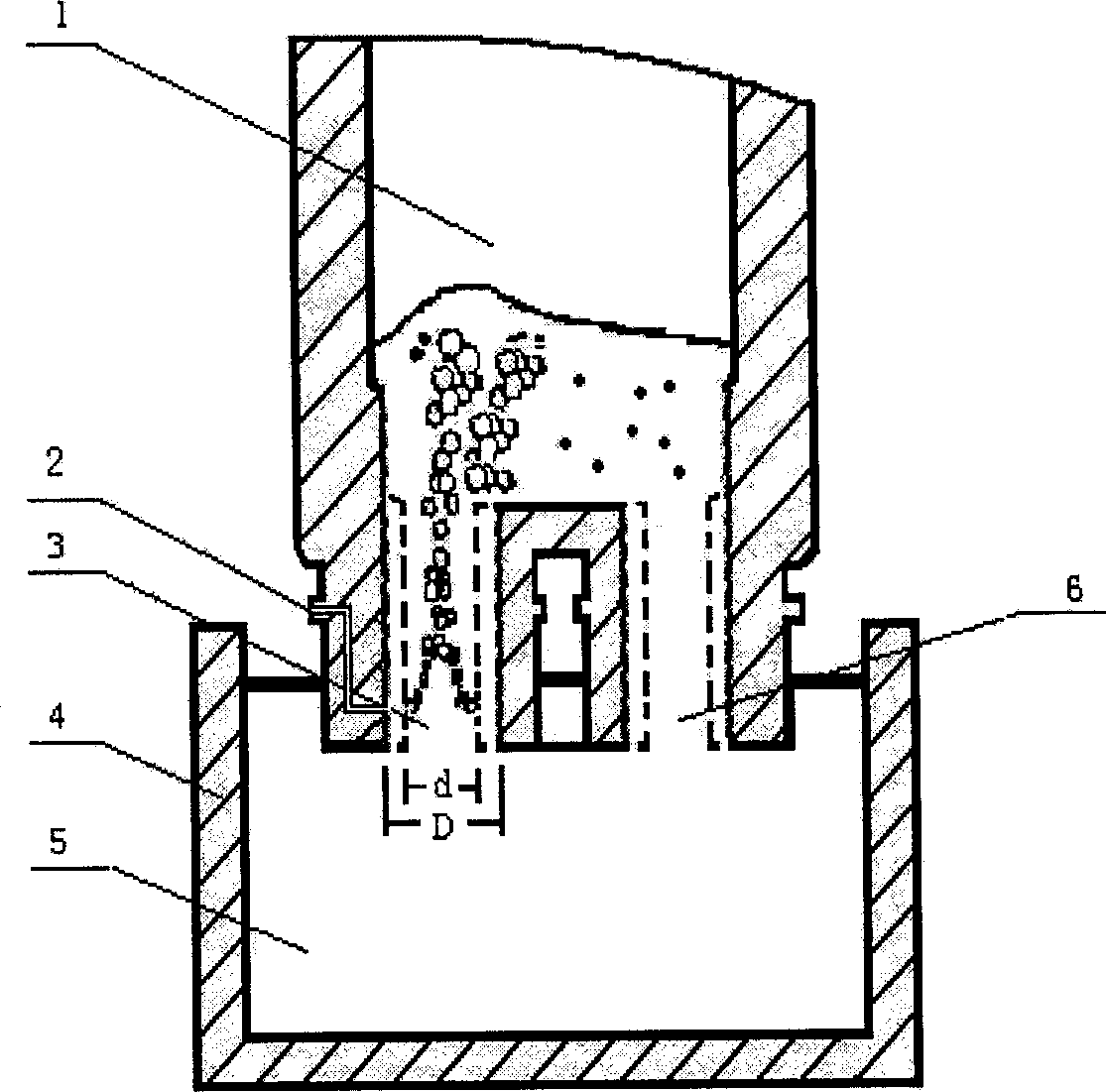

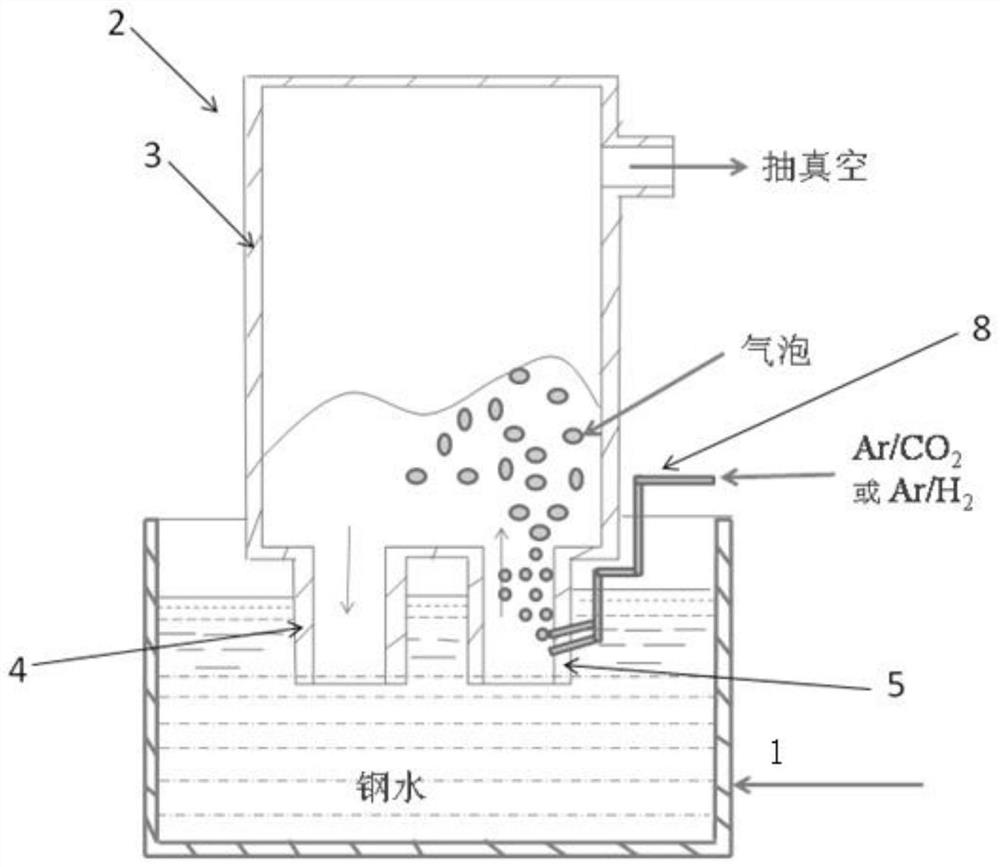

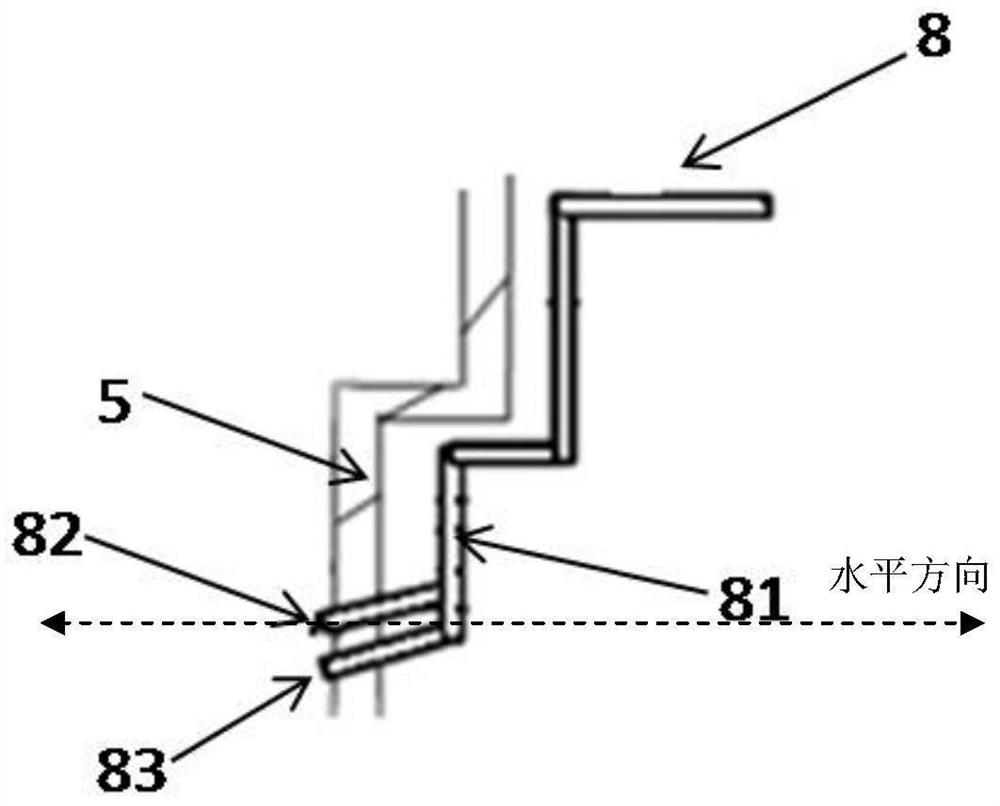

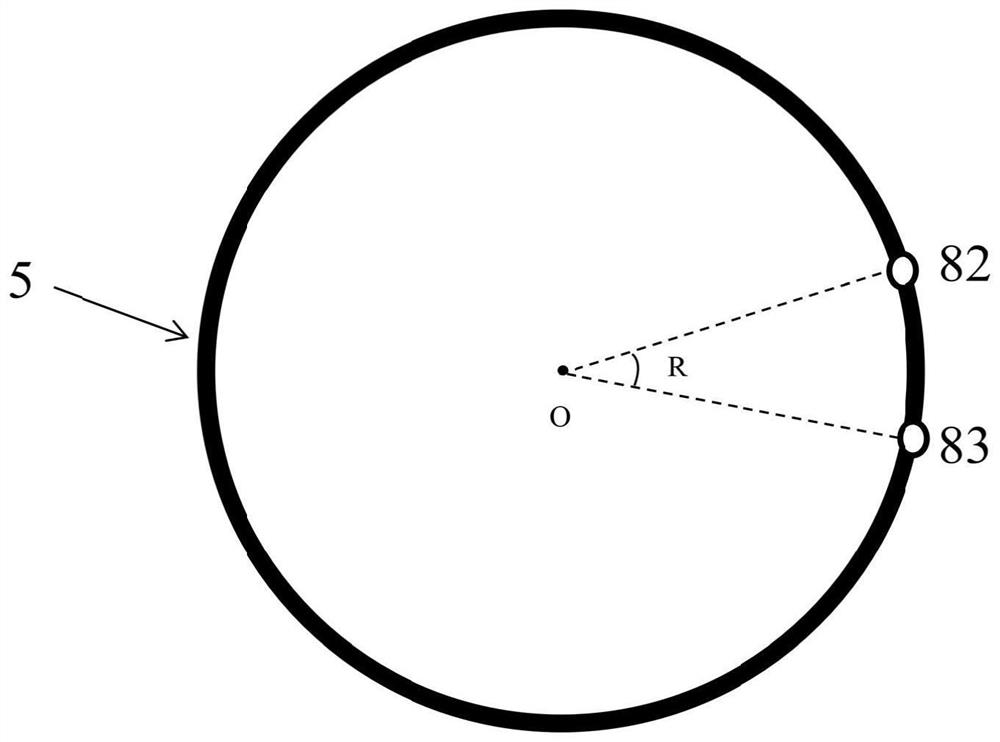

A method for rh deep decarburization of molten steel

The invention discloses a method for RH deep decarburization of molten steel, comprising the following steps: a1) setting and supplying CO on the RH vacuum treatment equipment 2 ‑Argon blowing tube of Ar mixed gas; a2) Insert the RH vacuum treatment equipment into the ladle containing molten steel, turn on the vacuum pump to make the vacuum of the RH vacuum treatment equipment less than the first pressure, and start blowing CO 2 ‑Ar mixed gas makes the molten steel circulate; a3) When the vacuum pump makes the vacuum of the RH vacuum treatment equipment to be less than the second pressure, start to stop supplying CO 2 -Ar mixed gas and the argon blowing pipe starts to supply the first gas to circulate the molten steel; a4) When the vacuum pump makes the vacuum of the RH vacuum treatment equipment less than the third pressure, continue to supply the first gas for 4-6min. The RH deep decarburization method of molten steel of the present invention can realize the end point carbon content of 13-17ppm or 12-14ppm when the gas is injected into the anaerobic lance, and the smelting time is shortened by 2-3min.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Compound organic absorbent used for flue-gas CO2-removal technology and preparation method thereof

InactiveCN103357249BImprove operating conditionsImprove removal efficiencyDispersed particle separationBy absorptionCompound organicCo2 removal

The invention relates to a compound organic absorbent used for a flue-gas CO2-removal technology and a preparation method thereof. The compound organic absorbent is a mixture of an imidazole glycinate ionic liquid and piperazine. The compound organic absorbent comprises a 1-butyl-3-methyl imidazole glycinate ionic liquid, the piperazine and water. The mass concentration of the compound organic absorbent is 10-40%, wherein the mass ratio of the 1-butyl-3-methyl imidazole glycinate ionic liquid to the piperazine is 0.1-1:1. The compound organic absorbent has advantages of easily available raw materials, simple operation conditions, small use amount, high removal efficiency, and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A method for producing nickel-based steel from high-phosphorus molten iron

ActiveCN111411300BHigh phosphorus contentReduce phosphorus contentManufacturing convertersProcess efficiency improvementSlagHeating furnace

The invention discloses a method for producing nickel-based steel from high-phosphorus molten iron, which relates to the technical field of iron and steel smelting. It uses a converter for smelting, and the P content of the molten iron used is 0.130% to 0.150%. The end point temperature is 1580-1620°C, the bottom stirring flow rate in the middle and later stages of smelting is 350-400NL / min, the final slag basicity is 4.0, and the final slag control amount is 10-12 tons. The decarburization rate of the converter is ≥99%, and the dephosphorization rate is ≥96%. ; After LF refining, RH vacuum treatment, arc casting machine casting, TMCP rolling, ACC water cooling to 300±20°C and air cooling to room temperature, steel plate heating to 550±10°C, tempering for 3×h minutes, air cooling to room temperature. The converter process is optimized, the product is vacuum treated, cast by the arc continuous casting machine, and then sent to the heating furnace for heating, TMCP rolling and ACC water cooling are adopted, and the performance test is qualified after tempering treatment.

Owner:NANJING IRON & STEEL CO LTD

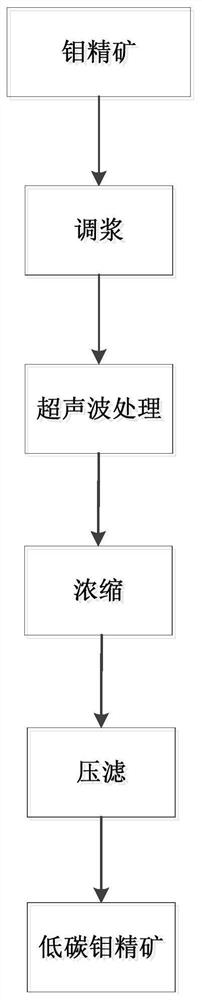

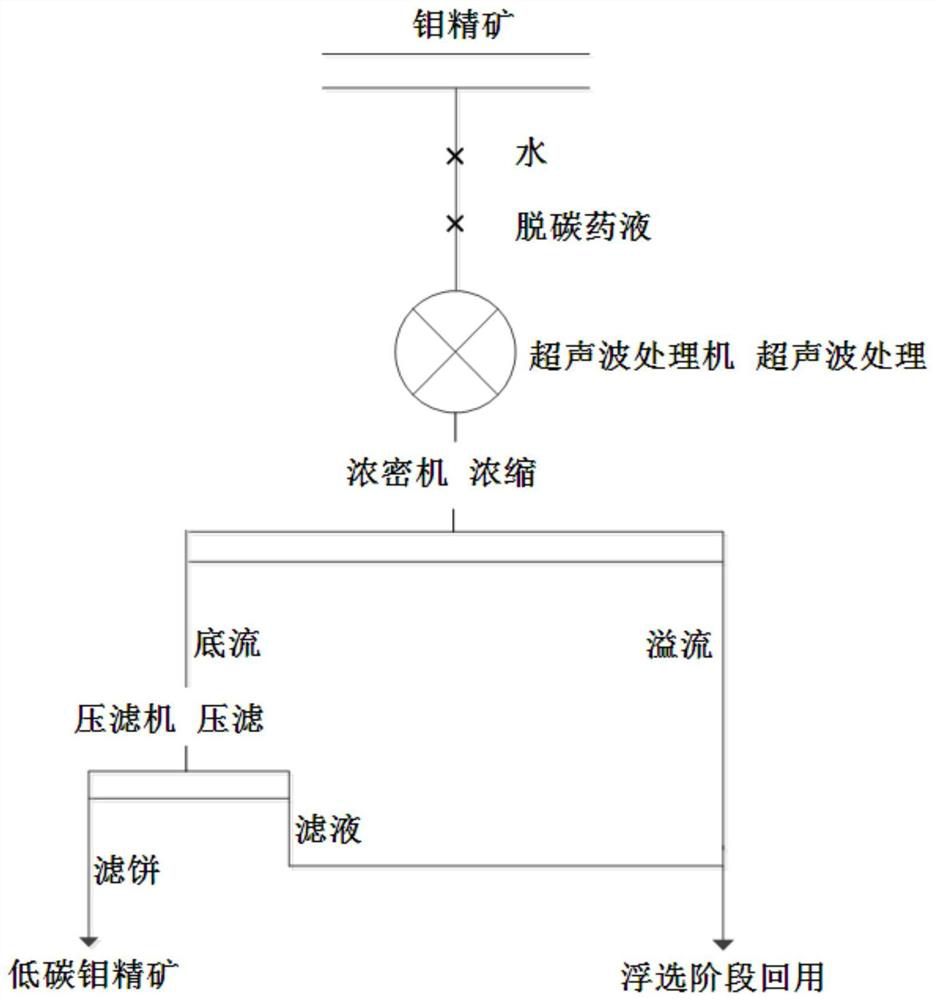

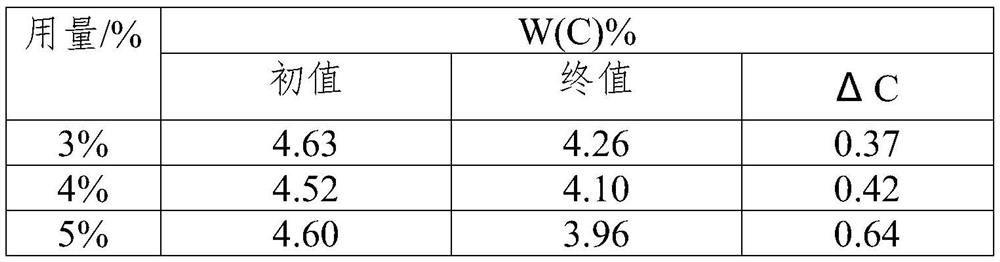

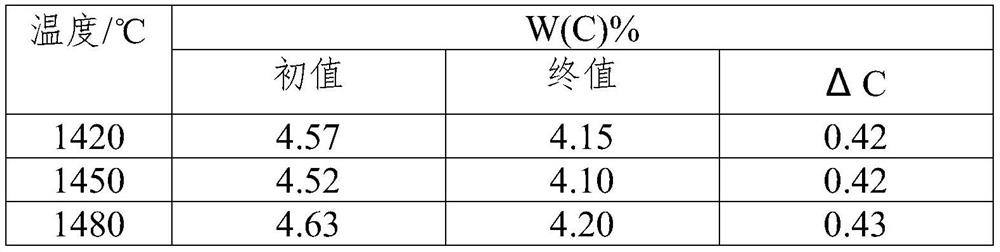

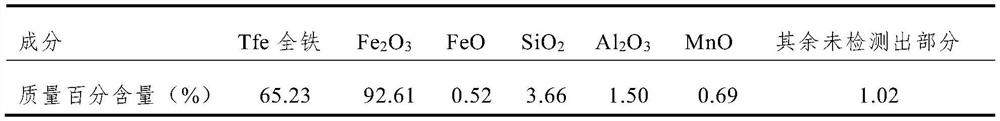

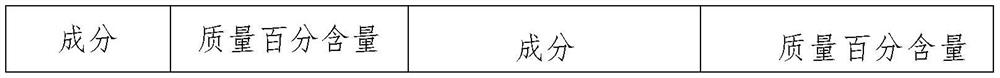

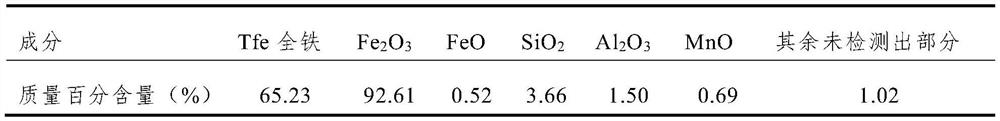

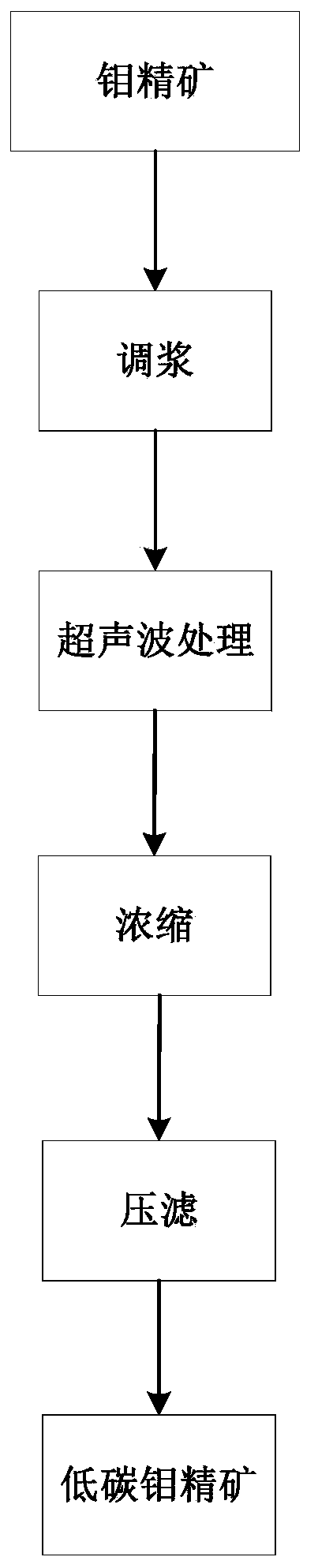

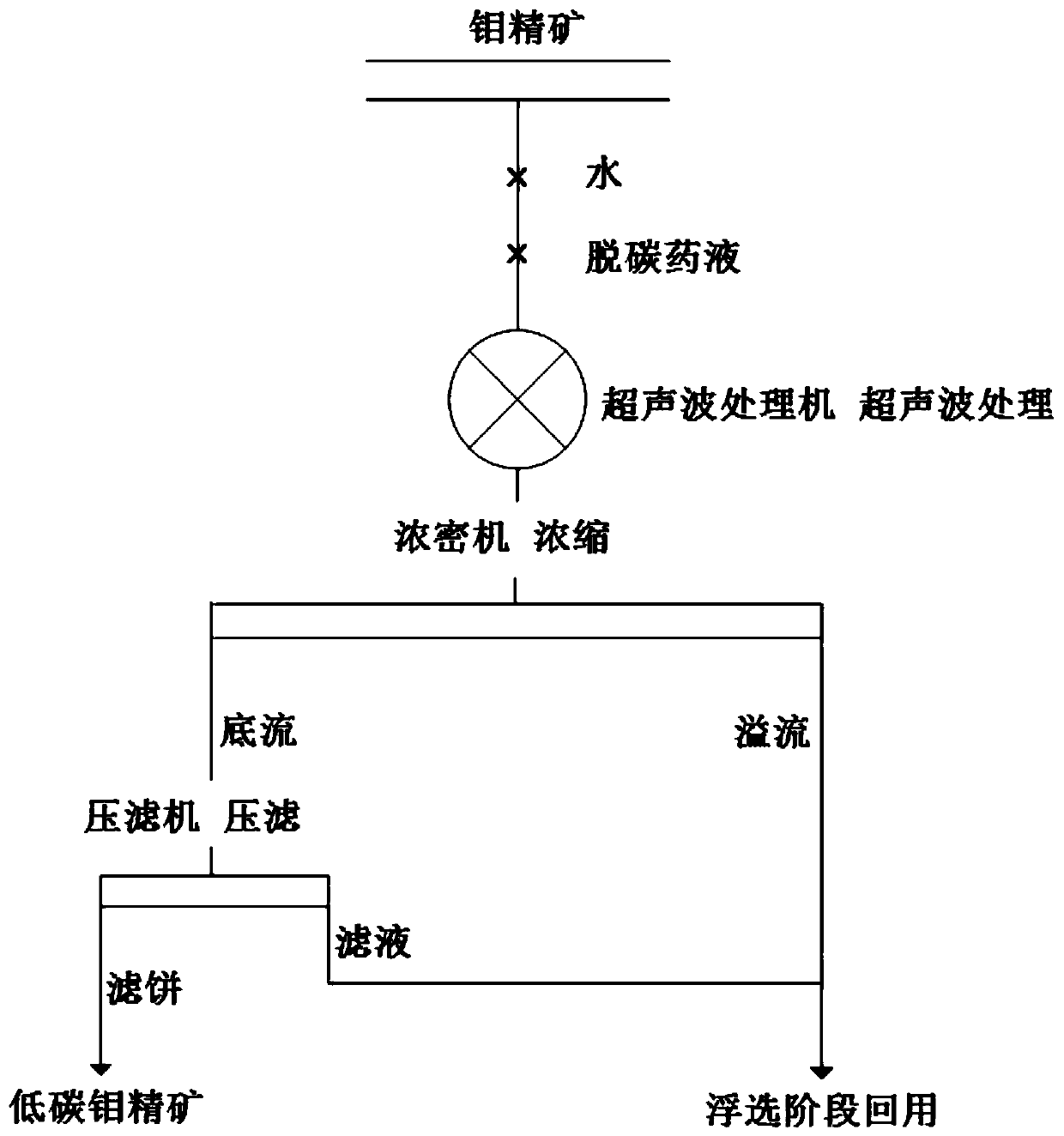

A molybdenum concentrate decarburizer and a process for reducing the carbon content of molybdenum concentrate

ActiveCN110184457BGood decarburization effectReduce carbon contentProcess efficiency improvementPhosphateSodium dodecylbenzenesulfonate

Owner:CHINA MOLYBDENUM

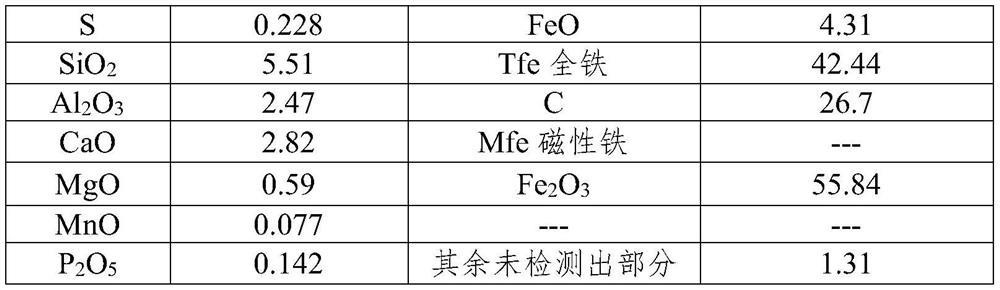

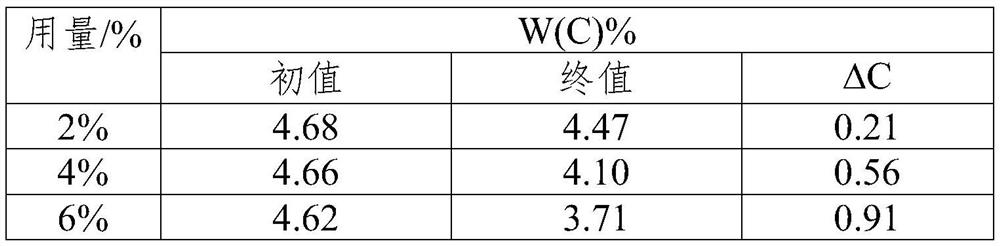

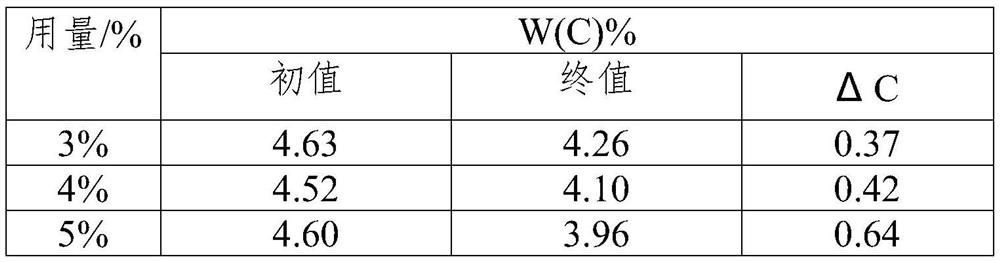

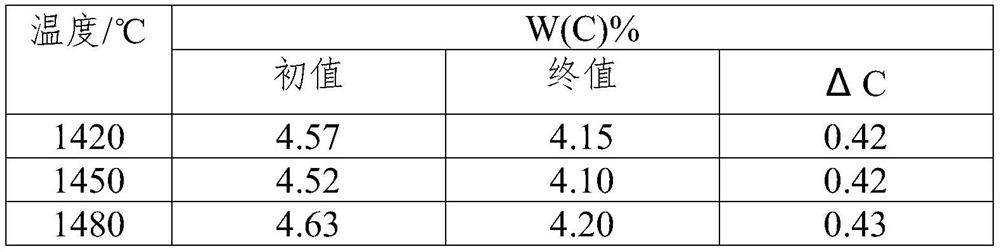

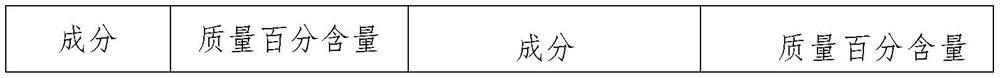

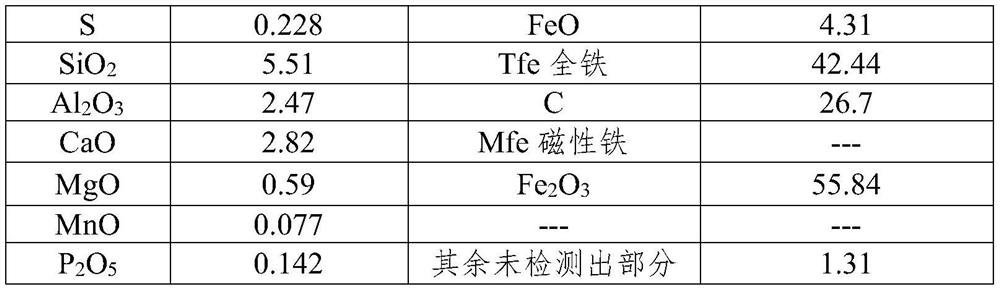

Processing method for decarbonization of blast furnace molten iron based on converter LT dust-removing ash

ActiveCN111826499AThe decarburization effect is obviousImprove use valueResource recoveryDust control

The invention relates to a processing method for the decarbonization of blast furnace molten iron based on converter LT dust-removing ash. The method includes the steps that the converter LT dust-removing ash, as a decarbonizer, is mixed with the molten iron from a blast furnace to oxidize the molten iron to achieve the decarbonization of the molten iron, so as to reduce carbonaceous dust producedby the drop of the temperature of the molten iron. The processing method for the decarbonization of the blast furnace molten iron based on the converter LT dust-removing ash lowers the content of carbon in the molten iron by adding the converter LT dust-removing ash as the decarbonizer to the molten iron from the blast furnace, so as to fundamentally solve the graphite dust pollution problem caused in the molten iron backward-pouring process in a steel plant. The decarbonizer is the converter LT dust-removing ash from a steel mill. The converter LT dust-removing ash has obvious effect on decarbonizing the blast furnace molten iron, and reduces the content of carbon separated out of the molten iron, so as to alleviate the problem of the graphite dust pollution in the steel mill. Therefore,waste resources are fully used, iron from the converter LT dust-removing ash is recovered, and the utilization value of the converter LT dust-removing ash is improved.

Owner:NORTHEASTERN UNIV

Quick cooling decarburization method of high-carbon chromium iron

The invention relates to a quick cooling decarburization method of high-carbon chromium iron, which is used for overcoming the defect that the carbon content of the high-carbon chromium iron is high. The quick cooling decarburization method comprises the following steps of: quickly cooling for separating out graphite to prepare cast ingot in a smelting-casting process of the high-carbon chromium iron; and carrying out crushing, ball-milling and milling, and separating the separated-out graphite particles by adopting a microwave heating method to prepare chromium iron powder with low carbon content. The quick cooling decarburization method is advanced in process, full and accurate in data; the graphite is firstly separated out by a quick cooling method, and the graphite particles are removed through crushing and a microwave heating method, so that the decarburization effect is good, and the carbon content of the high-carbon chromium iron is not more than 3%, and therefore, the quick cooling decarburization method is a very ideal decarburization method of the high-carbon chromium iron.

Owner:TAIYUAN UNIV OF TECH

A rotary moving bed biological filter device

ActiveCN104261552BUniform and stable cycle motionEvenly distributedTreatment using aerobic processesWater contaminantsFiltrationBiological filter

The invention relates to a rotary moving bed biological filtration device. The rotary moving bed biological filtration device is characterized by comprising a moving bed box body, wherein a roller is horizontally arranged inside the moving bed box body, the roller is supported by a baffle and can rotate around the central rotating shaft of the roller; the outer wall of the roller is made of a porous plate, a biological filter material is arranged in the roller, and outer diameter of the biological filter material is larger than pore diameter of the porous plate; multiple plug flow plates are uniformly arranged on the outer wall of the roller along radial direction; the left side and the right side of the upper part of the moving bed box body are respectively horizontally provided with a water inlet pipe and a water outlet pipe, and the water inlet pipe corresponds to plug flow plates on the top of the roller in positions; at least one air inlet pipe is horizontally arranged at a position, corresponding to the longitudinal direction of the water inlet pipe, at the lower part of the moving bed box body, and a row of aeration holes with openings upwards are formed in the upper part of the air inlet pipe; aeration thrust of the air inlet pipe and water inlet thrust of the water inlet pipe act on the plug flow plates at the same time to drive the roller to rotate; and a sewage draining outlet is formed in the bottom of the moving bed box body. The rotary moving bed biological filtration device is simple to make, low in investment, low in energy consumption and high in ammonia nitrogen treatment capacity.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

A kind of coal carbon slag decarburization method

ActiveCN109022046BImprove decarbonization effectGood decarburization effectGasification processes detailsGrain treatmentsSlagFluidized bed

The invention belongs to the technical field of gasifier coal gas slag, and concretely relates to a coal carbon slag decarburization method. The method comprises the following steps: adding coal carbon slag into a coal chemical industry gasifier slag decarburization grinder, and grinding the coal carbon slag to form coal carbon slag powder; introducing air into a fluidized bed, controlling the temperature of the air to be 650-720 DEG C and the flow of the introduced air to be 20-40 m<3> / h, and then adding the coal carbon slag powder into the fluidized bed; and reacting the coal carbon slag powder in the fluidized bed for 20-40 min to obtain carbon slag having a free carbon content of 2 wt% or below in order to complete the decarburization of the coal carbon slag. The coal chemical industrygasifier slag decarburization grinder improves the coal carbon slag decarburization method, and makes the coal carbon slag fully ground and crushed before being decarburized, and the crushed coal carbon slag powder is heated, so the improvement of the decarburization effect of the coal carbon slag is benefited; and the temperature and the flow of the air in the gasifier are controlled to make thecoal carbon slag fully reacted in the gasifier, so the decarburization effect of the coal carbon slag is improved.

Owner:六安联众工业自动化技术有限公司

Blast-furnace hot metal decarburization method utilizing blast-furnace dust

The invention relates to a blast-furnace hot metal decarburization method utilizing blast-furnace dust. The method comprises the steps of S1, adopting the blast-furnace dust as a raw material, and preparing a blast-furnace hot metal decarburizer according to one of the following methods: (1) aerobic roasting, and (2) mixing the blast-furnace dust subjected to aerobic roasting and at least one of iron concentrate powder and steel-rolling ferric oxide sheets according to a certain proportion; and S2, mixing the blast-furnace hot metal decarburizer in the form of powder or blocks with blast-furnace hot metal at the reverse installation process, and oxidizing carbon in the hot metal to achieve a decarburization effect, so that the carbonic powder dust produced by hot metal temperature reduction is reduced. By utilizing the method provided by the invention, the problem of serious graphite dust pollution in the reverse installation process of the blast-furnace hot metal in an iron and steelplant is solved from the root. According to the blast-furnace hot metal decarburization method utilizing the blast-furnace dust provided by the invention, the decarburizer adopts the blast-furnace dust as a basic material, so that on one hand, the decarburization processing of blast-furnace taping is effectively realized, the problem of graphite dust pollution produced in the reverse installationprocess of the hot metal is reduced, meanwhile, iron elements in the blast-furnace dust are effectively recycled, and the use value of the blast-furnace dust is improved.

Owner:NORTHEASTERN UNIV

A decarburization treatment method for blast furnace molten iron based on converter LT dedusting

The invention relates to a blast furnace molten iron decarburization treatment method based on converter LT dedusting ash. The method is as follows: the converter LT dedusting ash is used as a decarburizing agent and mixed with molten iron from the blast furnace, and the carbon in the molten iron is oxidized to achieve the purpose of decarburization , to reduce the carbon-containing dust generated by the temperature drop of molten iron. The invention reduces the content of carbon in molten iron by adding converter LT dedusting ash into blast furnace tapping as a decarburizing agent, and fundamentally solves the problem of graphite dust pollution in the inversion of molten iron in iron and steel plants. The decarburizing agent is converter LT dedusting ash in steelmaking plants, which has a significant decarburization effect on molten iron in blast furnaces, can reduce the amount of carbon precipitation in molten iron, alleviate the problem of graphite dust pollution in steelmaking plants, make full use of waste resources, and recycle converter LT dedusting ash iron, which improves the utilization value of converter LT dedusting ash.

Owner:NORTHEASTERN UNIV LIAONING

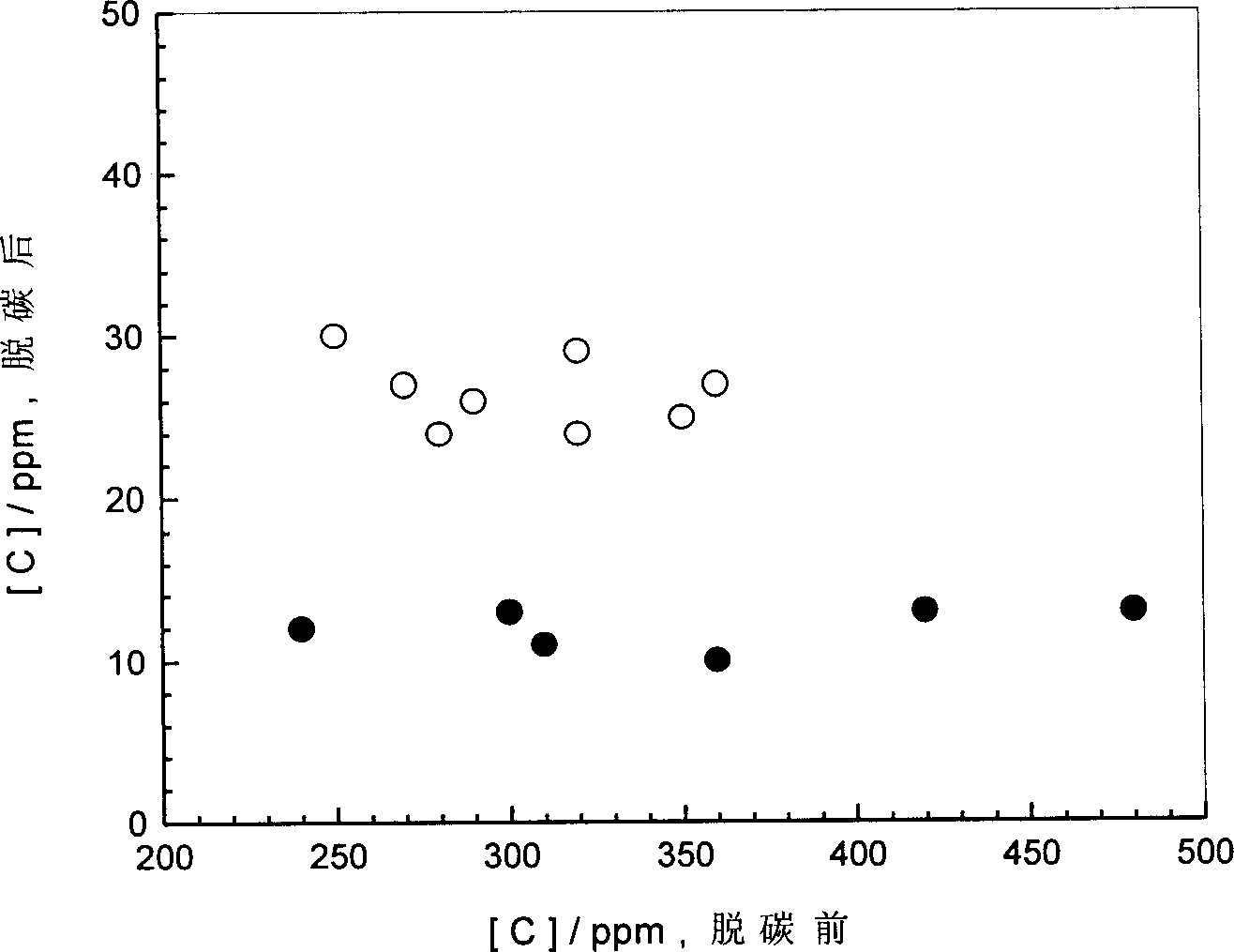

Manufacturing method of grain-oriented electrical steel sheet

PendingUS20220081749A1StablyCarbon reductionInorganic material magnetismFurnace typesElectrical steelDecarburization

This manufacturing method of a grain-oriented electrical steel sheet is a manufacturing method of a grain-oriented electrical steel sheet having no forsterite film, in which in a decarburization annealing process, a cold-rolled steel sheet is (i-1) heated at an average heating rate (HR1) of 40 to 500° C. / sec in a temperature range of 550° C. or higher and lower than 720° C., (i-2) heated at an average heating rate (HR2), which is 5 to 50° C. / sec, in a temperature range of 720° C. to T1° C. (770° C.≤T1 (° C.)≤900° C.), and (ii) retained at the temperature of T1° C. for 50 to 1000 seconds to make an amount of C 25 ppm or less in an atmosphere of an oxygen partial pressure (P1) which is 0.0010 to 0.20.

Owner:NIPPON STEEL CORP

Molybdenum concentrate decarburization agent and process for reducing carbon content of molybdenum concentrate

ActiveCN110184457AGood decarburization effectReduce carbon contentProcess efficiency improvementPhosphateEnergy consumption

The invention provides a molybdenum concentrate decarburization agent and a process for reducing carbon content of molybdenum concentrate. The molybdenum concentrate decarburization agent is preparedfrom the following components in parts by weight: 20-25 parts of sodium dodecyl benzene sulfonate, 2-5 parts of phosphate, 1-2 parts of diethanolamine, and 1-2 parts of a dispersant. The molybdenum concentrate decarbonizing agent can be used for reducing the carbon content of the molybdenum concentrate; in the process for reducing the carbon content of the molybdenum concentrate, the molybdenum concentrate decarbonizing agent is prepared into feed liquid, through the methods of ultrasonic treatment, concentration and filter pressing, the decarbonizing rate of the molybdenum concentrate can reach 75% or more, and the molybdenum concentrate with the carbon content less than 0.7% can be continuously and steadily produced; dust raising and environmental pollution are avoided, and environmentalprotection is facilitated; and production energy consumption is low, and resources are saved.

Owner:CHINA MOLYBDENUM

A kind of decarburization smelting method of iron-nickel alloy recycled material

ActiveCN108929934BReduce cleanupReduce pollutionProcess efficiency improvementOrganic solventSmelting process

The invention relates to a decarburization and smelting method for an iron-nickel alloy reclaimed material, which belongs to the technical field of iron-nickel alloy refining. An organic solvent is used for sampling the oil percentage of the iron-nickel alloy reclaimed material, and the oxidized scale which is crushed, screened, baked and tested for oxygen content is used as a decarburizing agent,the pre-treated iron oxidized scale is subjected to oxygen content determination by a chemical analysis method, a non-vacuum induction furnace is used for melting, the oxidized scale is added after the furnace charge is completely melted, and the decarburization smelting is completed after the disappearance of an oxidized scale slag layer and continued for 5 to 8 minutes. The method has advantages that the smelting process is reasonable in design and easy to operate, the environment pollution is extremely small, and the loss of metal elements is extremely low. The decarburization agent has large output and low price, has remarkable decarburization effect, can be adapted to large-scale industrial production, and can realize recycling of the iron-nickel alloy reclaimed material economically, efficiently and environmentally.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Smelting process for producing ultralow-carbon phosphor nickel series steel by high-phosphor molten iron

InactiveCN111455260AOptimizing the Converter ProcessMeet the needs of mass industrial productionManufacturing convertersProcess efficiency improvementSmelting processMaterials science

The invention discloses a smelting process for producing ultralow-carbon phosphor nickel series steel by high-phosphor molten iron, and relates to the technical field of steel smelting. The smelting process adopts converter smelting, and phosphor content of the used molten iron is 0.130%-0.150%; a way of leaving slag at an early stage and using a dual-slag process at a later stage is adopted, a smelting terminal temperature is 1580-1620 DEG C, bottom stirring flow at the middle and later period of smelting is 350-400 NL / min, final basicity of slag is 4.0, final slag control amount is 10-12 tons, a converter decarburization rate greater than or equal to 99% is realized, and a dephosphorization rate greater than or equal to 96% is achieved. The converter process is optimized, and the nickelseries steel smelting process meets batch industrial production needs.

Owner:NANJING IRON & STEEL CO LTD

Surface machining device for neurological operation scalpel

InactiveCN108411084APrevent falling off and deformingAvoid oxidation reactionsFurnace typesHeat treatment furnacesExhaust valveEngineering

The invention provides a surface machining device for a neurological operation scalpel. The surface machining device comprises a box. A top cover is fixedly mounted on the upper side of the box through bolts. A handle is fixedly connected to the outer surface wall of the upper side of the top cover. A temperature gauge is arranged on the outer surface wall of the lower side of the top cover. Stirring blades are arranged below the temperature gauge. A partition plate is arranged below the stirring blades. An exhaust pipe is mounted on the inner wall of the partition plate in an inlaid mode. A first valve is arranged on the exhaust valve. A vacuum pump is arranged below the first valve. A hydrogen storage tank is arranged on the right side of the vacuum pump. A gas guide pipe is mounted on the inner wall of the upper side of the hydrogen storage tank in an inlaid mode. A second valve is arranged on the gas guide pipe. A heating plate is arranged above the left side of the air guide pipe.The surface machining device is simple in structure, reasonable in design, good in decarburization effect and high in practicability.

Owner:WENZHOU HAILAN IND DESIGN

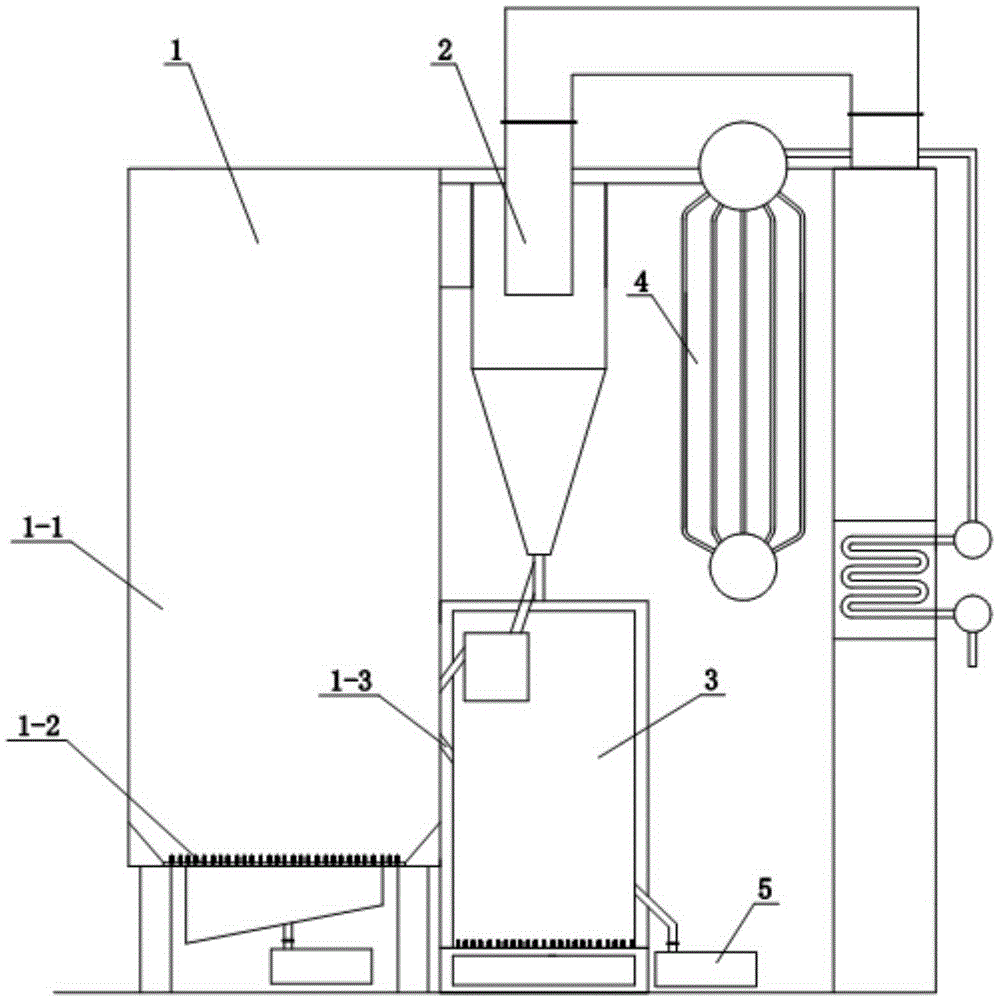

Coal gangue circulating fluidized bed calcinator device

InactiveCN105403043AGood vanadium gradeVanadium Grade ImprovementFluidised-bed furnacesWaste heat treatmentCombustion chamberProcess engineering

The invention discloses a coal gangue circulating fluidized bed calcinator device. The coal gangue circulating fluidized bed calcinator device comprises a fluidized bed combustion chamber (1), a fly ash circulating system (2), a secondary roasting and heat preservation area (3), a heating surface (4) and an ash cooler (5), wherein the fluidized bed combustion chamber (1) and the secondary roasting and heat preservation area (3) are communicated through an overflow port (1-3); the fly ash circulating system (2) and the heating surface (4) are connected with a smoke exhaust pipe of the fluidized bed combustion chamber (1); the ash cooler (5) and the secondary roasting and heat preservation area (3) are connected, and the ash cooler (5) is used for collecting ash. The coal gangue circulating fluidized bed calcinator device can directly use bulk coal gangue which are not balled and 0-6 mm in low-calorific-value particle diameter, and heat obtained by combustion of the coal gangue can maintain operation of the whole coal gangue circulating fluidized bed calcinator device. In addition, the ash obtained after the coal gangue containing vanadium is processed has good vanadium grade and can be directly used for vanadium extraction.

Owner:伍蔚恒 +1

A method for decarburizing blast furnace hot metal using blast furnace ashes

The present invention relates to a blast furnace hot metal decarburization method using blast furnace ash. The method includes: S1: using blast furnace ash as a raw material, making a blast furnace hot metal decarburizer according to one of the following methods: Method 1: aerobic roasting; Method 2: Mix aerobic roasted blast furnace ash with at least one of iron concentrate powder and rolled iron scale in a certain proportion; S2: Mix the blast furnace molten iron decarburizer in the form of powder or block The blast furnace molten iron in the loading link is mixed to oxidize the carbon in the molten iron to achieve decarburization and reduce the carbon-containing dust generated by the temperature drop of the molten iron. The method of the invention solves the problem of serious graphite dust pollution in the blast furnace hot metal inversion link of the iron and steel plant from the root. The decarburizing agent of the present invention uses blast furnace ash as the base material. On the one hand, it not only effectively realizes the decarburization treatment of blast furnace iron, reduces the graphite dust pollution problem caused by the inversion of molten iron, but also realizes the effective removal of iron elements in blast furnace ash. Recycling, improving the utilization value of blast furnace ash.

Owner:NORTHEASTERN UNIV LIAONING

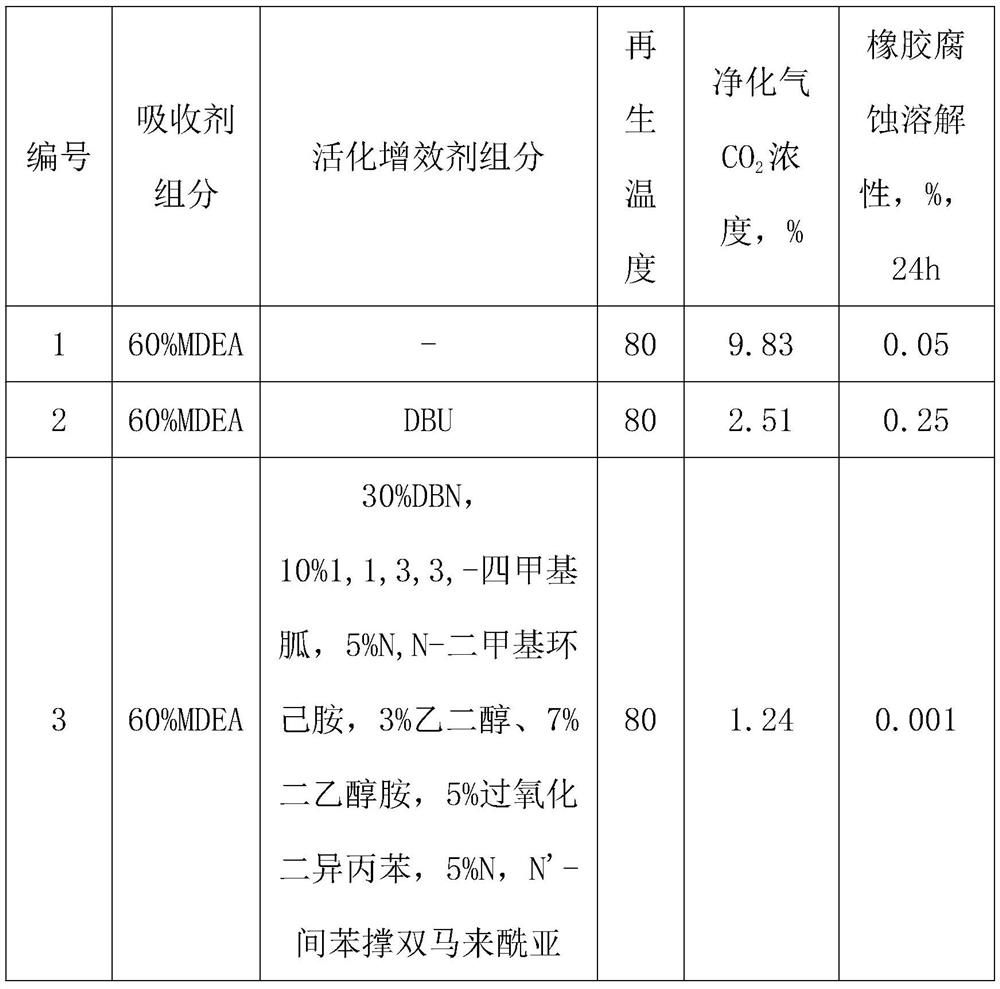

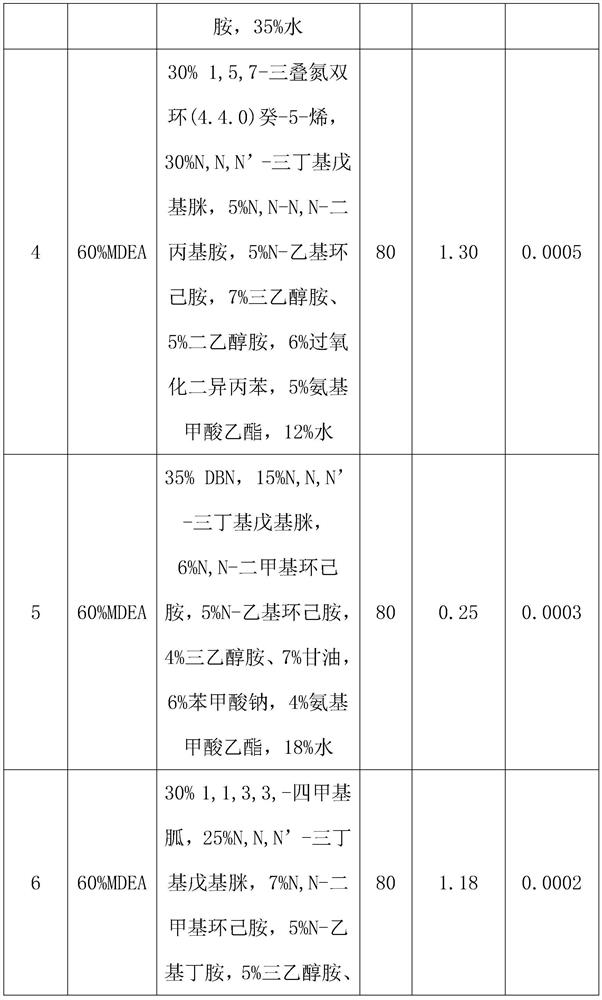

Activation synergist for natural gas decarburization based on MDEA method

PendingCN114015486AGood decarburization effectCorrosion swelling is smallGaseous fuelsDecarburizationCorrosive substance

An activation synergist for natural gas decarburization based on an MDEA method is an activation synergist for natural gas decarburization based on the MDEA method, the activation synergist comprises an amidine compound, an alcohol compound, an alcohol amine compound and a rubber swelling corrosion inhibitor, the provided activation synergist can effectively improve the removal of carbon dioxide, during the process application process, good circular utilization of the activation synergist is realized, the regeneration of the activation synergist can be realized at a low temperature, and the activation synergist has the characteristics of low energy consumption, high CO2 removal efficiency, and low equipment corrosion, and has a good popularization and application prospect.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com