Quick cooling decarburization method of high-carbon chromium iron

A high-carbon ferrochromium and rapid cooling technology, applied in the field of high-carbon ferrochromium to reduce carbon content, can solve the problems of complex process, serious environmental pollution and high product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

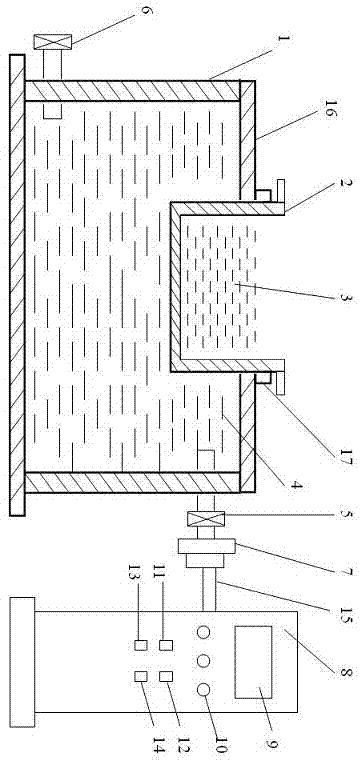

[0043] The present invention will be further described below in conjunction with accompanying drawing:

[0044] figure 1 As shown, it is the state diagram of high-carbon ferrochrome melt casting, rapid cooling and decarburization, and the position and connection relationship of each part must be correct, and the ratio should be adjusted according to the quantity, and the operation should be carried out in sequence.

[0045] The melt casting and rapid cooling decarburization of high-carbon ferrochrome are carried out in the cooling water tank and completed under the rapid cooling of the external water circulation;

[0046] The cooling water tank 1 is a rectangular parallelepiped. The upper part of the cooling water tank 1 is a tank cover 16, and the inside is cooling water 4. The casting mold 2 is placed on the tank cover 16 of the cooling water tank 1 and fixed by a fixed frame 17. The casting mold is placed in the cooling water tank 1. In the water 4, the cooling water 4 sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com