Coal gangue circulating fluidized bed calcinator device

A technology of circulating fluidized bed and coal gangue, which is applied in fluidized bed furnaces, furnaces, furnace components, etc., can solve the problems of large floor area, poor quality, and high operation and combustion costs, so as to improve the utilization effect and improve the vanadium grade , Simplify the roasting process and the effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

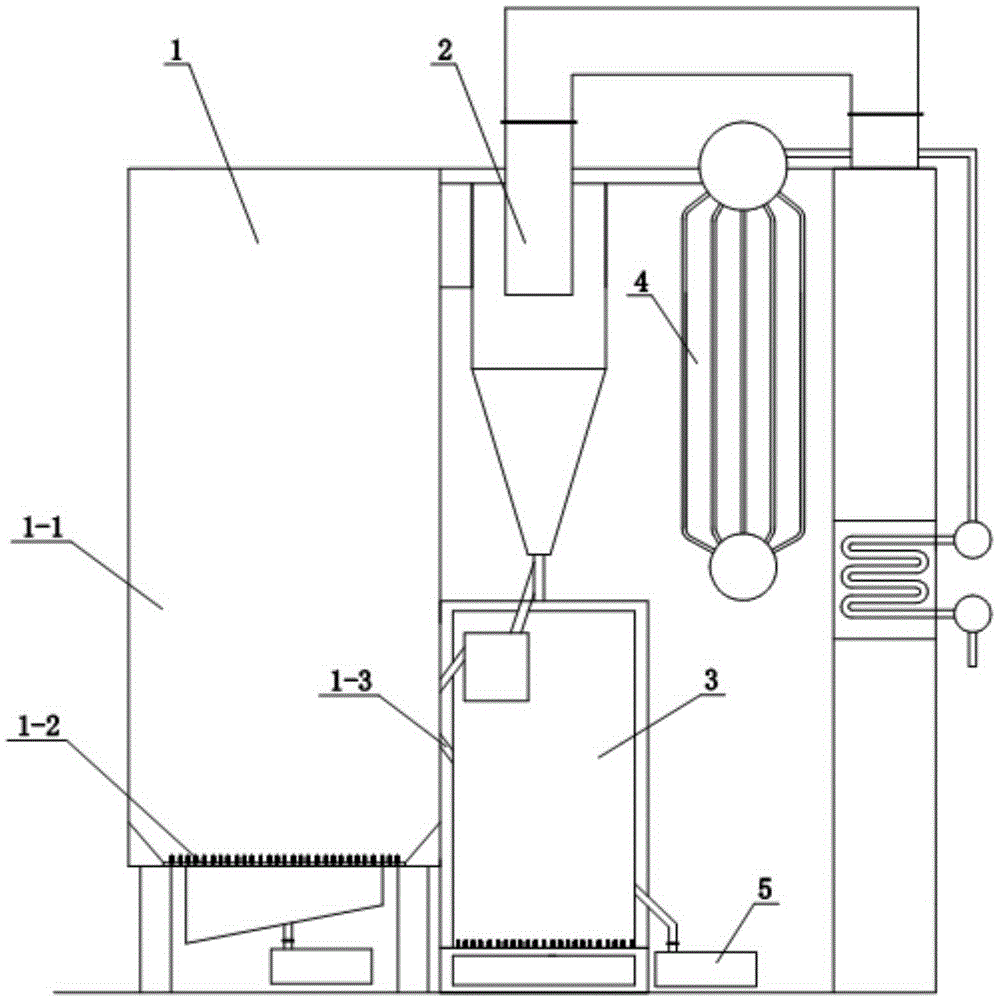

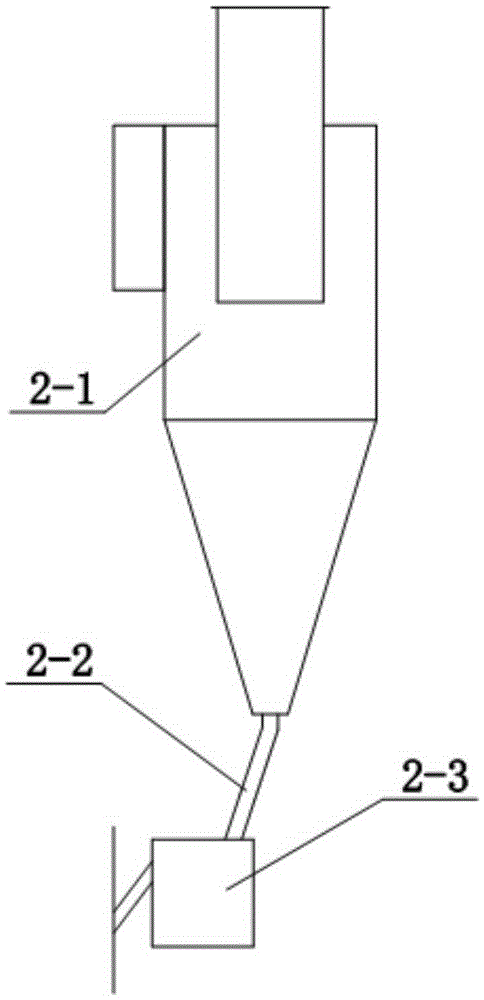

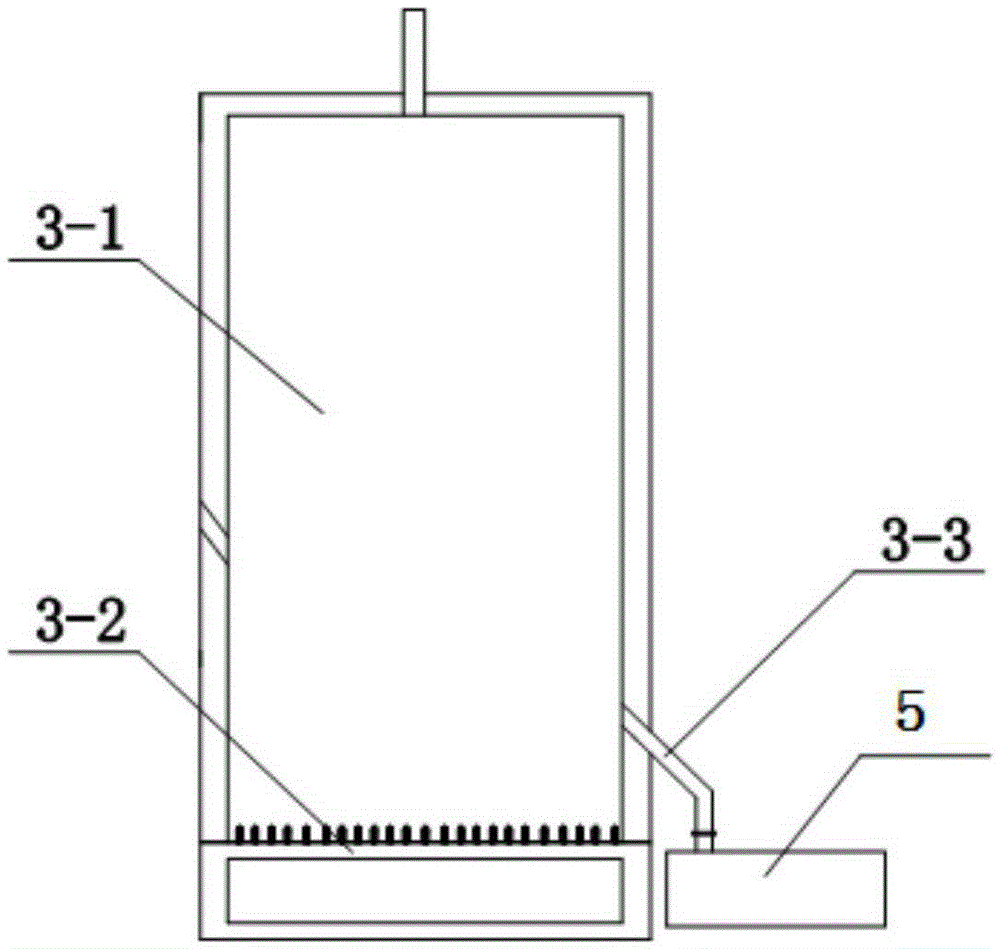

[0031] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the vanadium-containing low calorific value coal gangue circulating fluidized bed roaster device includes a combustion chamber 1, a fly ash circulation system 2, a secondary roasting and heat preservation area 3, an evaporation heating surface 4, and an ash cooler 5.

[0032] The furnace does not arrange a water-cooled wall heating surface in the main body (1-1) of the fluidized bed combustion chamber. Vanadium coal gangue and matching lime are put into the furnace and then ignited with charcoal. The heat released by the combustion of vanadium coal gangue is used to increase the temperature of the furnace body, flue gas and ash, and continuously heat the subsequent coal gangue into the furnace. The temperature of the furnace can be raised to 950-1000°C, so that the coal gangue with high ash content, high moisture content and low calorific value can be fully burned to complete the purpose of decarbonization...

Embodiment 2

[0037] like figure 1 , image 3 , Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the hood of the air distribution plate (3-2) is a small hole type, the hood is longer, there are many holes on it, the aperture is small, the pressure of the fan is high, and this area The material in the section is not fluidized, so that the ash and slag accumulated here can supplement oxygen, and complete the secondary roasting, decarburization and heat preservation.

[0038] To meet the requirements of the vanadium extraction process, the roasted materials are discharged from the discharge pipe (3-3) to the ash cooler (5) to recover the physical heat in the ash, and adjust the speed of the ash cooler to control the secondary roasting and heat preservation The thickness of the material layer in the area, the storage capacity of the material and the holding time, and the ash and slag are sent to the vanadium extraction system by the conveyor after cooling do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com