Moulding and flanging mould for machining automobile parts

A technology for auto parts and flanging molds, applied in forming tools, manufacturing tools, casting and molding equipment, etc., can solve problems such as sheet forming size exceeding the error range, affecting the production efficiency of auto parts, and deformation of forming flanging molds. , to achieve the effect of superior performance, good decarburization effect and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

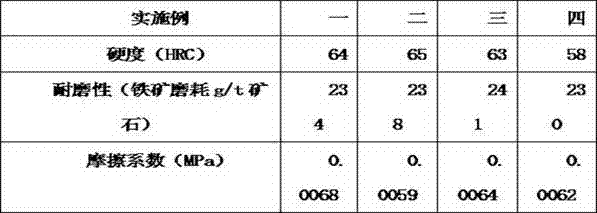

Examples

Embodiment 1

[0021] A forming flanging mold for processing auto parts proposed by the present invention is cast from steel, and the steel includes the following raw materials in weight percentage: C 1.20, Si 0.40, Mn 0.45, Cr 1.45, Mo 0.45, W 1.5, Ni 0.25, Cu0.30, Ga 1.1, carbide 2.3, rare earth metal 2.25, S ≤ 0.03, P ≤ 0.03, balance Fe.

[0022] Its preparation method comprises the following steps:

[0023] S1: Preparation of steel mixed melt. After melting the steel raw materials, inspect the melt and adjust the composition content, and then continue to feed inert gas for 15 minutes, and the flow rate of the inert gas is 1700Nm 3 / min, and add refining agent under the protection of inert gas, and react for 20min to obtain pure mixed molten steel;

[0024] S2: Preparation of semi-finished products, casting the pure steel mixed melt into the basic shape of the mold, and cleaning the castings to obtain the semi-finished mold;

[0025] S3: post-processing, apply carburizing agent on the m...

Embodiment 2

[0028] A forming flanging mold for processing auto parts proposed by the present invention is cast from steel, and the steel includes the following raw materials in weight percentage: C 1.25, Si 0.35, Mn 0.45, Cr 1.55, Mo 0.40, W 1.5, Ni 0.20, Cu0.35, Ga 1.2, carbide 2.2, rare earth metal 2.20, S ≤ 0.03, P ≤ 0.03, balance Fe.

[0029] Its preparation method comprises the following steps:

[0030] S1: Preparation of steel mixed melt. After melting the steel raw materials, inspect the melt and adjust the composition content, and then continue to feed inert gas for 20 minutes, and the flow rate of the inert gas is 1650Nm 3 / min, and add refining agent under the protection of inert gas, and react for 20min to obtain pure mixed molten steel;

[0031] S2: Preparation of semi-finished products, casting the pure steel mixed melt into the basic shape of the mold, and cleaning the castings to obtain the semi-finished mold;

[0032] S3: post-processing, apply carburizing agent on the m...

Embodiment 3

[0035] A forming flanging mold for processing auto parts proposed by the present invention is cast from steel, and the steel includes the following raw materials in weight percentage: C 1.25, Si 0.45, Mn 0.45, Cr 1.45, Mo 0.45, W 1.4, Ni 0.20, Cu0.30, Ga 1.0, carbide 2.4, rare earth metal 2.20, S ≤ 0.03, P ≤ 0.03, balance Fe.

[0036] Its preparation method comprises the following steps:

[0037] S1: Preparation of steel mixed melt. After melting the steel raw materials, inspect the melt and adjust the composition content, and then continue to feed inert gas for 20 minutes. The flow rate of the inert gas is 1500Nm 3 / min, and add refining agent under the protection of inert gas, and react for 15min to obtain pure mixed molten steel;

[0038] S2: Preparation of semi-finished products, casting the pure steel mixed melt into the basic shape of the mold, and cleaning the castings to obtain the semi-finished mold;

[0039] S3: post-processing, apply carburizing agent on the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com