De-oiling furnace for waste oil catalyst

A catalyst and petroleum technology, which is applied in the field of waste petroleum catalyst deoiling furnace, can solve the problems of incomplete removal of impurities such as sulfur and carbon, inability to achieve catalyst deoiling, desulfurization, decarbonization, and inability to meet the requirements of staged combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

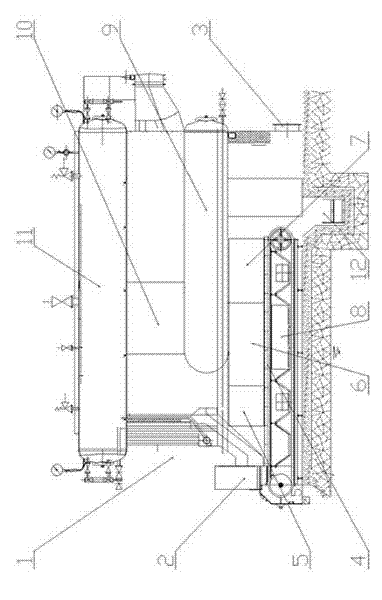

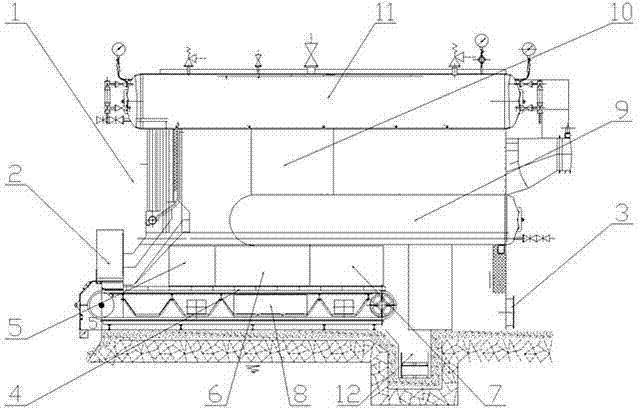

[0009] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. like figure 1 Shown: a waste petroleum catalyst deoiling furnace, including a furnace body 1 as a base, on the furnace body 1, a feed port 2 and a discharge port 3 are respectively arranged, and a feeding port is also provided inside the furnace body 1 Fire grate 4, in the furnace body 1 between the feed port 2 and the discharge port 3, a preheating chamber 5, a combustion chamber 6 and a cooling chamber 7 are arranged in sequence, and a furnace wall of the combustion chamber 6 is provided with a Chamber 8 is connected to the air door, and in order to prevent the high temperature during combustion from damaging the furnace body 1, it also sets a refractory brick layer in the core area of high temperature; The furnace body 1 above is provided with a hot water drum 9, which can use the waste heat of the waste petroleum catalyst in the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com