Patents

Literature

204results about How to "Reasonable space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

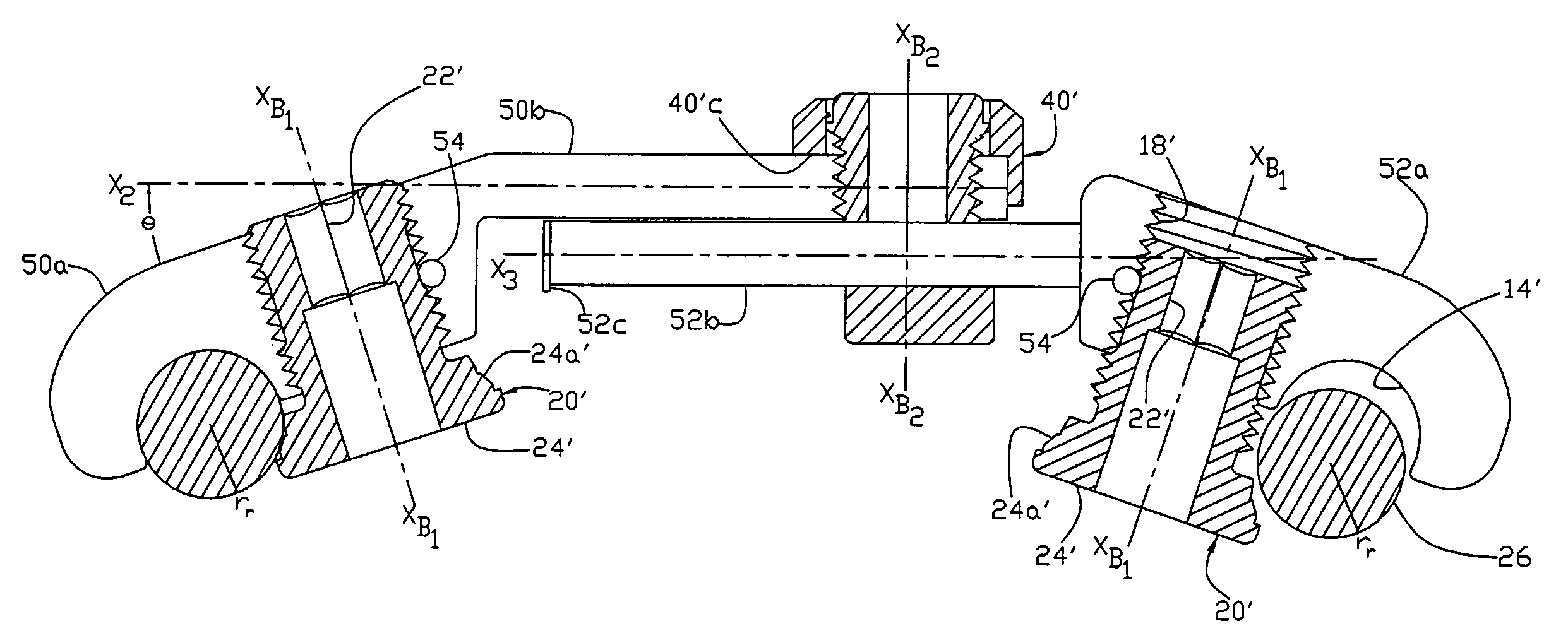

Transverse connector system

ActiveUS7771474B2Easy to installReasonable spaceInternal osteosythesisJoint implantsSpatial OrientationsSet screw

A transverse connector system for interconnecting two spinal rods includes a connector arranged to span the distance between the rods with a rod receiving recess and a pin receiving bore on each end. A one-piece pin member such as a set screw is disposed within each bore with an enlarged head protruding from the bottom of the connector so that when the set screw is retracted into the bore the head engages a side of the respective rod to clamp the rod within the recess. The connector may comprise two elongated members with a recess and pin receiving bore at one end of each member, a middle coupler which allows three degrees of freedom between the members to accommodate any anticipated spatial orientation between the members and a set screw for securing the other ends of the members together.

Owner:SEASPINE

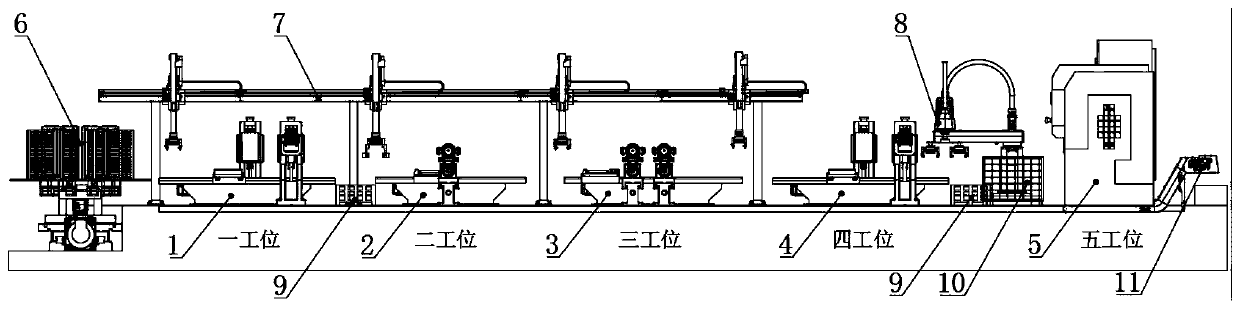

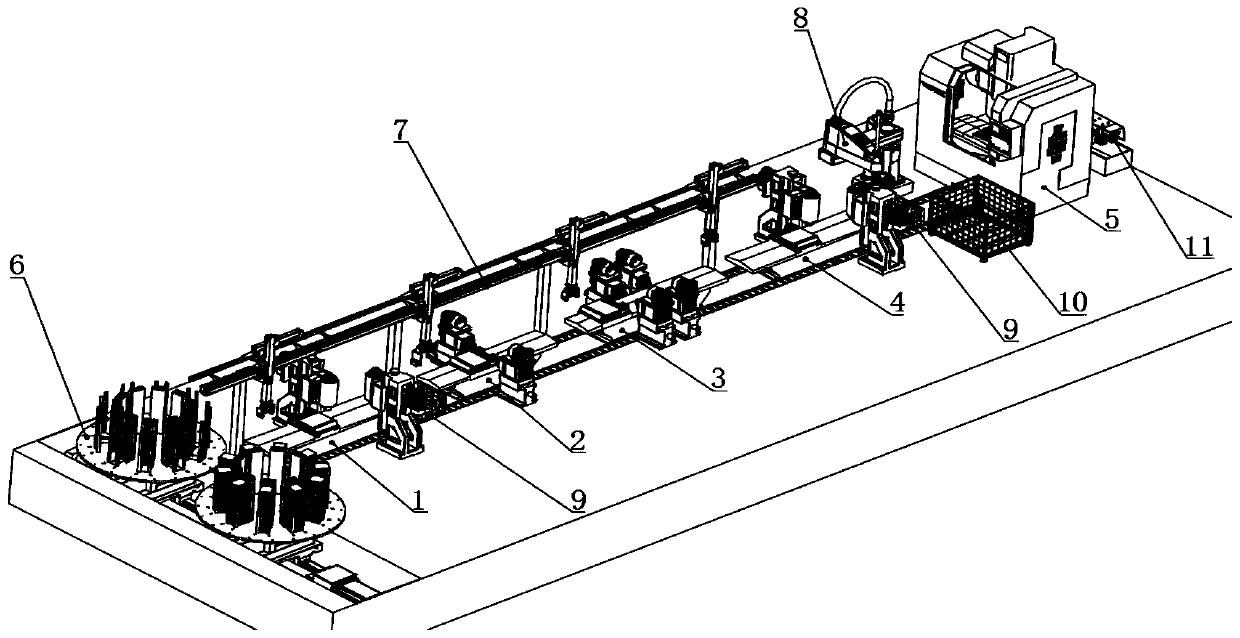

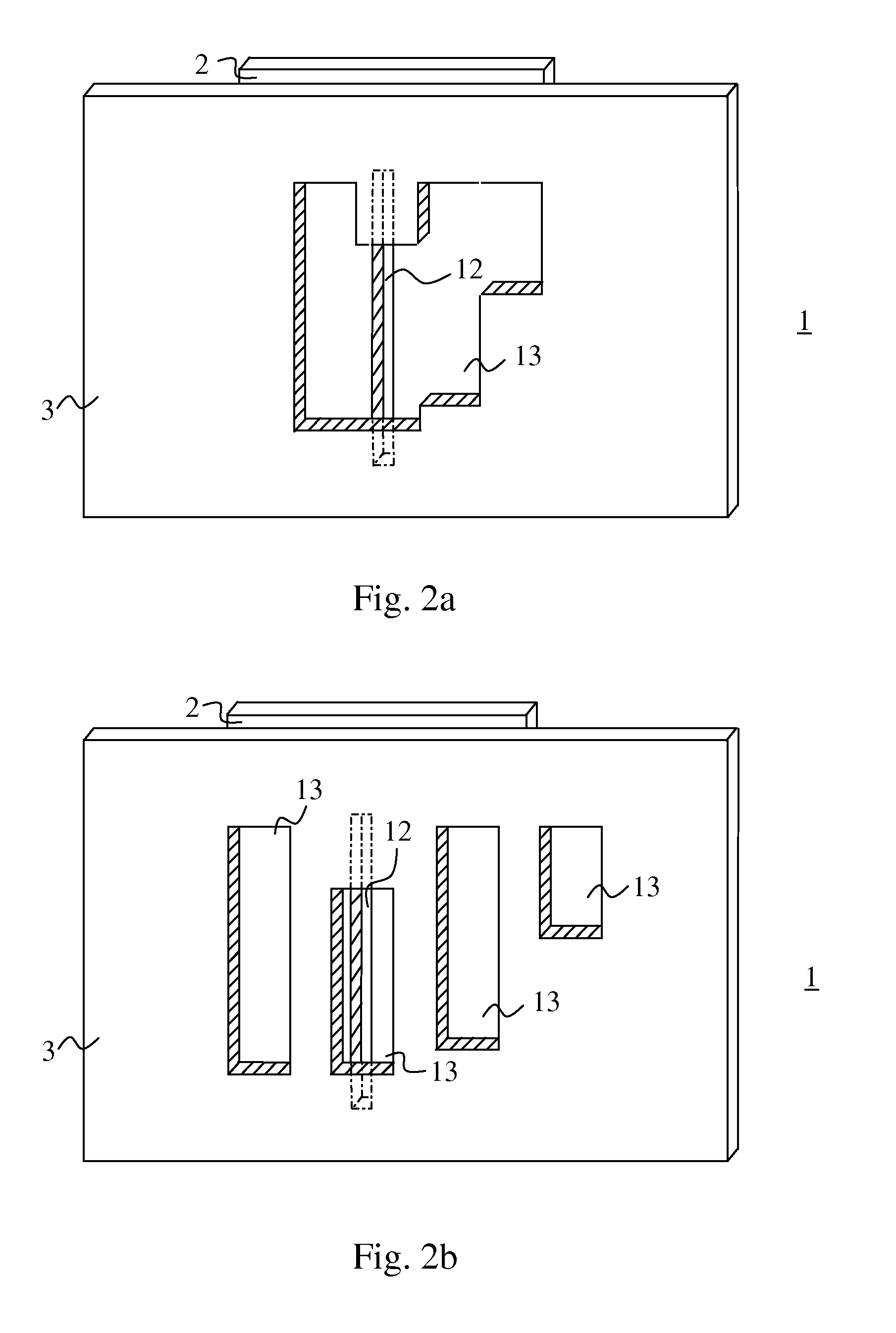

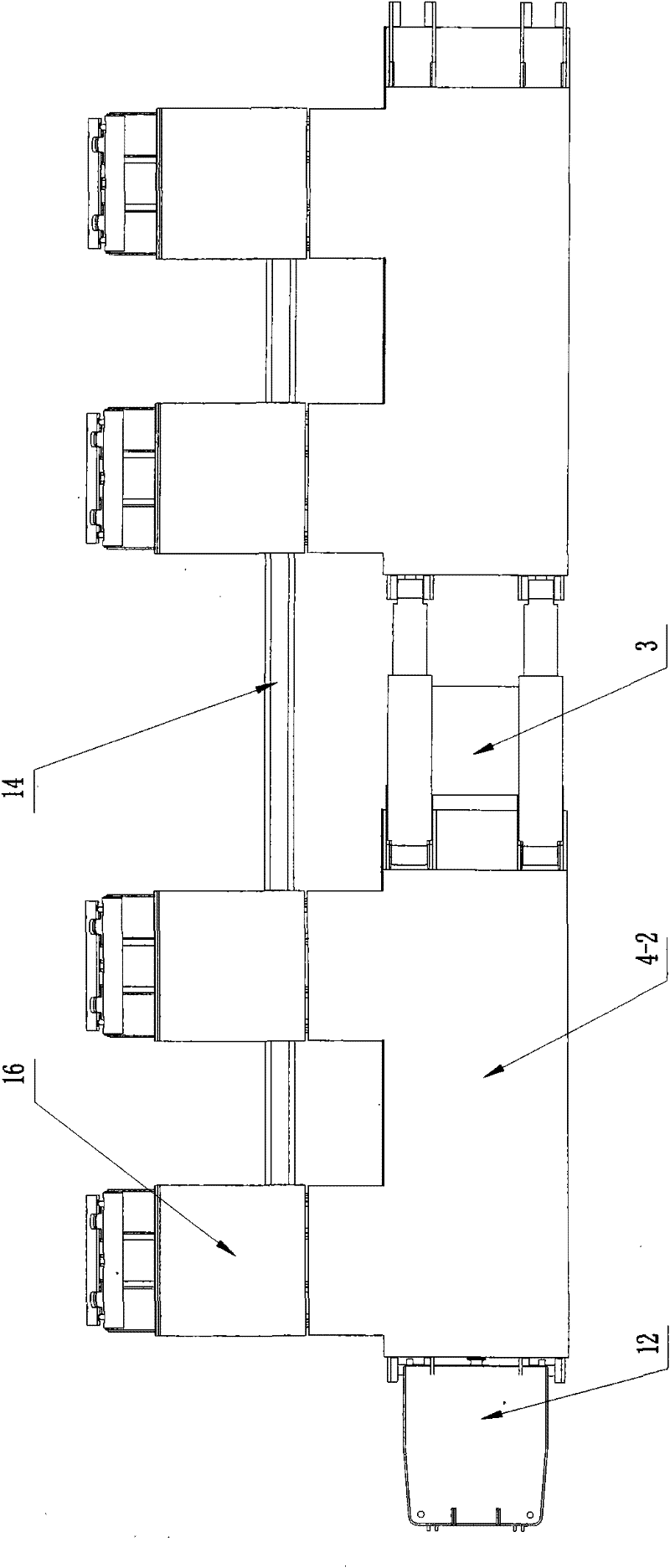

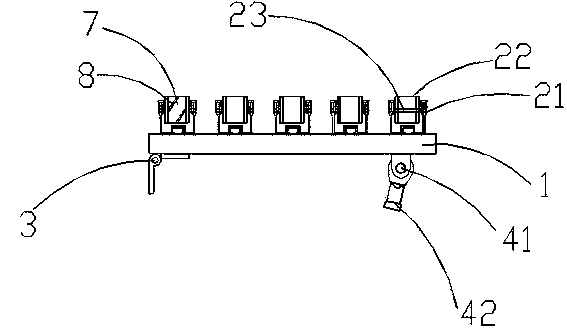

Intelligent plate part machining production line provided with universal equipment and special equipment

ActiveCN110773779AGuaranteed production efficiencyImprove production efficiencyOther manufacturing equipments/toolsMilling equipment detailsProduction lineRobot hand

The invention provides an intelligent plate part machining production line provided with universal equipment and special equipment. Four special machining tools and a universal machining tool are sequentially and linearly arranged from an automatic feeding device, wherein the four special machining tools are located on a first station, a second station, a third station and a fourth station, and the universal machine tool is located on a fifth station; a truss conveying transport device is arranged behind the first station, the second station, the third station and the fourth station in parallel, and four mechanical arms are arranged on the truss transport device to transfer materials on the corresponding stations; a four-axis manipulator is arranged between the fourth station and the fifthstation and is used for transferring the materials between the fourth station and the fifth station and discharging finished products; industrial cameras are arranged on the second-station mechanicalarm and the four-axis manipulator and are used for recognizing defective products; waste boxes are arranged between the first station and the second station as well as between the fourth station andthe fifth station and are used for storing the defective products; a discharging box is arranged on the front side of the fifth station and is used for storing the finished products; and a scrape conveying mechanism is arranged below the whole production line and is used for collecting and transferring scrapes. According to the intelligent plate part machining production line, the universal equipment and the special equipment are combined, and flexible clamps and sliding rail cylinders are used, so that the production line is flexible, the machining times of the stations are balanced, and theproduction efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH +1

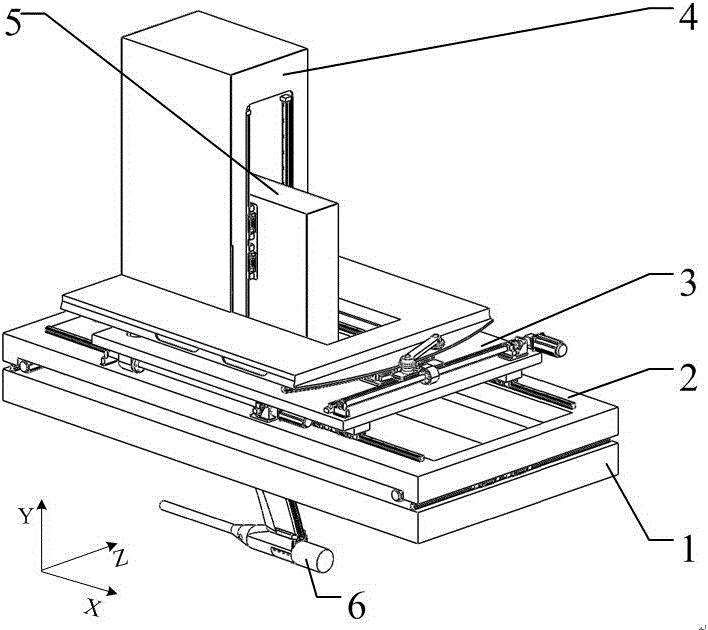

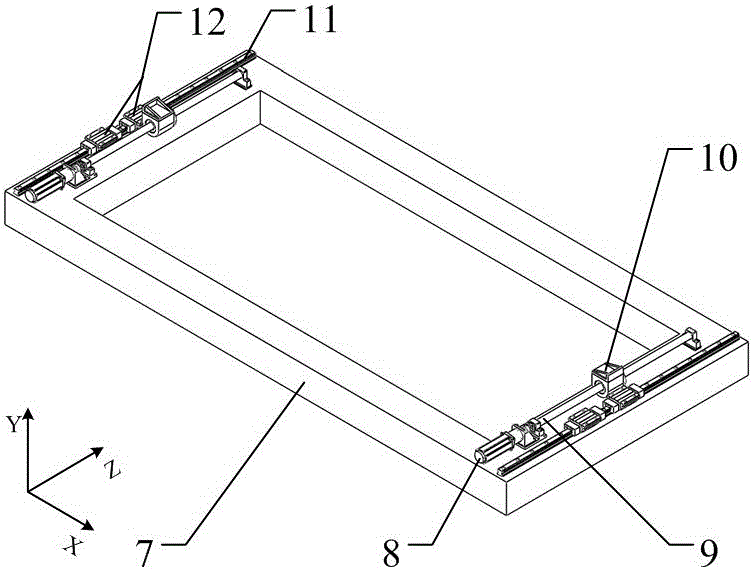

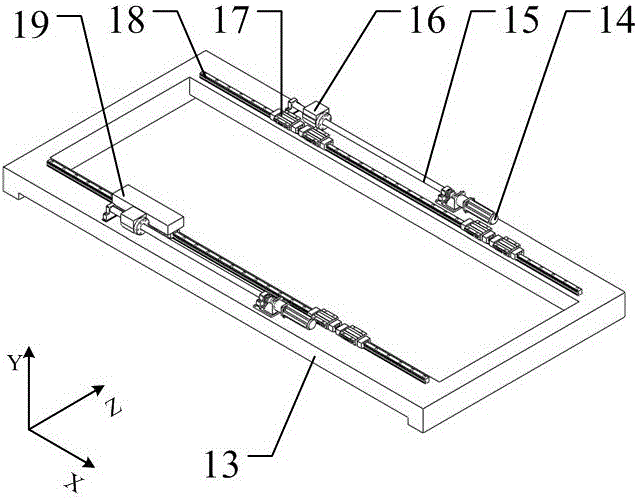

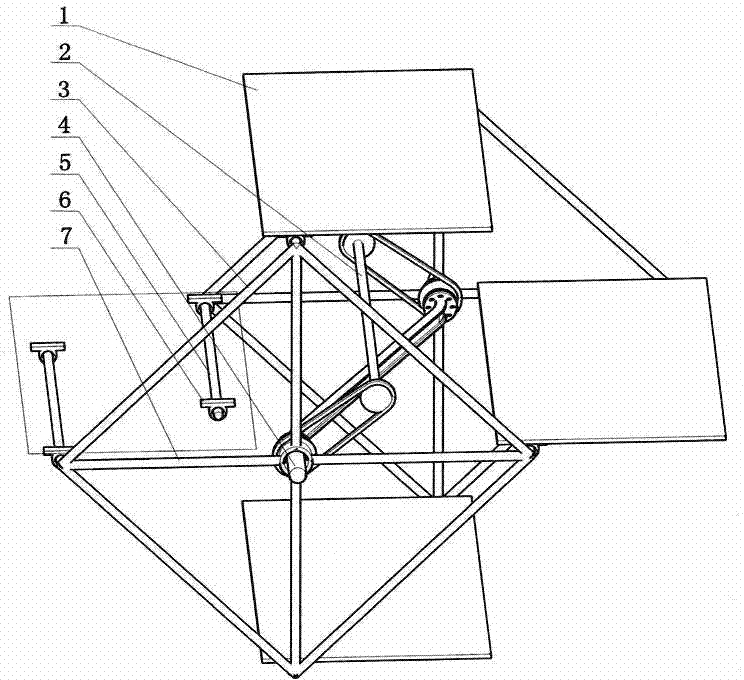

Space six-degrees-of-freedom mechanism used for hypersonic wind tunnel multi-body separation test

ActiveCN106124157ASmall degree of blockageGuaranteed independence movementAerodynamic testingThree degrees of freedomDrive motor

The invention provides a space six-degrees-of-freedom mechanism used for a hypersonic wind tunnel multi-body separation test. The mechanism comprises Z, X and Y three degrees of freedom straight-line motion mechanisms and [beta], [alpha] and [gamma] three degrees of freedom angular displacement motion mechanisms. The six-degrees-of-freedom are realized layer by layer and are connected step by step, and in terms of structure, embedment integration is achieved by a box stacking mode. A Z-direction mechanism, an X-direction mechanism and a [beta] mechanism are sequentially overlapped from bottom to top, and a Y-direction mechanism and a [alpha] mechanism are in embedded connection from outside to inside. A [gamma] mechanism is fixedly connected with the [alpha] mechanism through a bent blade, and is individually arranged in a wind tunnel flow field. Each of the Z-direction mechanism, the X-direction mechanism and the Y-direction mechanism adopts two driving assemblies in symmetric arrangement, so that the power and the size of a driving motor are effectively reduced, and the overall stability of the mechanism is improved. The [beta] mechanism and the [alpha] mechanism adopt line-to-arc mechanisms for implementation, so that overlapping of traditional three degrees of freedom rotation pairs is prevented, and the mechanism cantilever length is shortened. The structure is compact, the rigidity is good, andsix-degrees-of-freedom movement of high speed, high precision and high bearing capacity is achieved.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

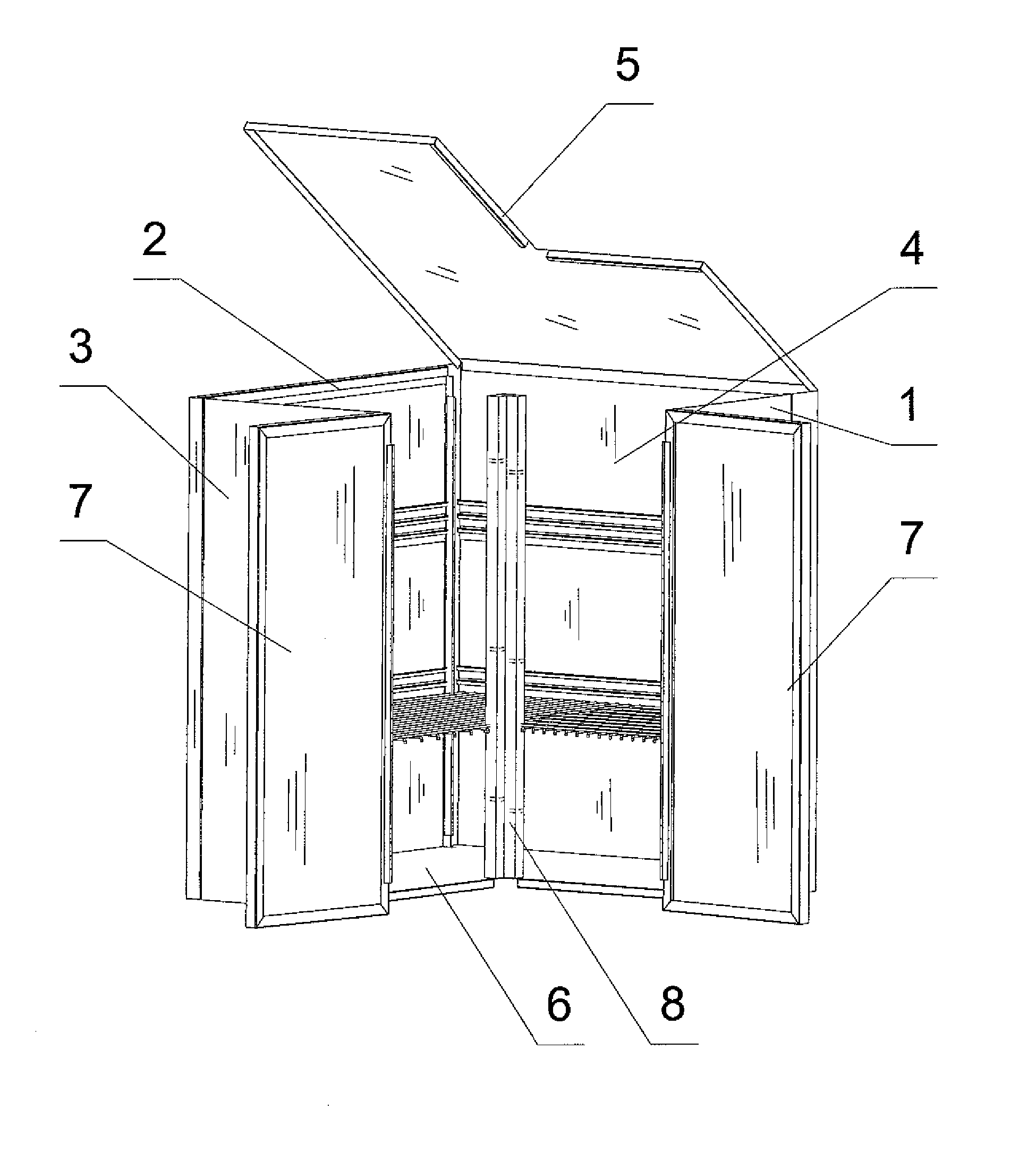

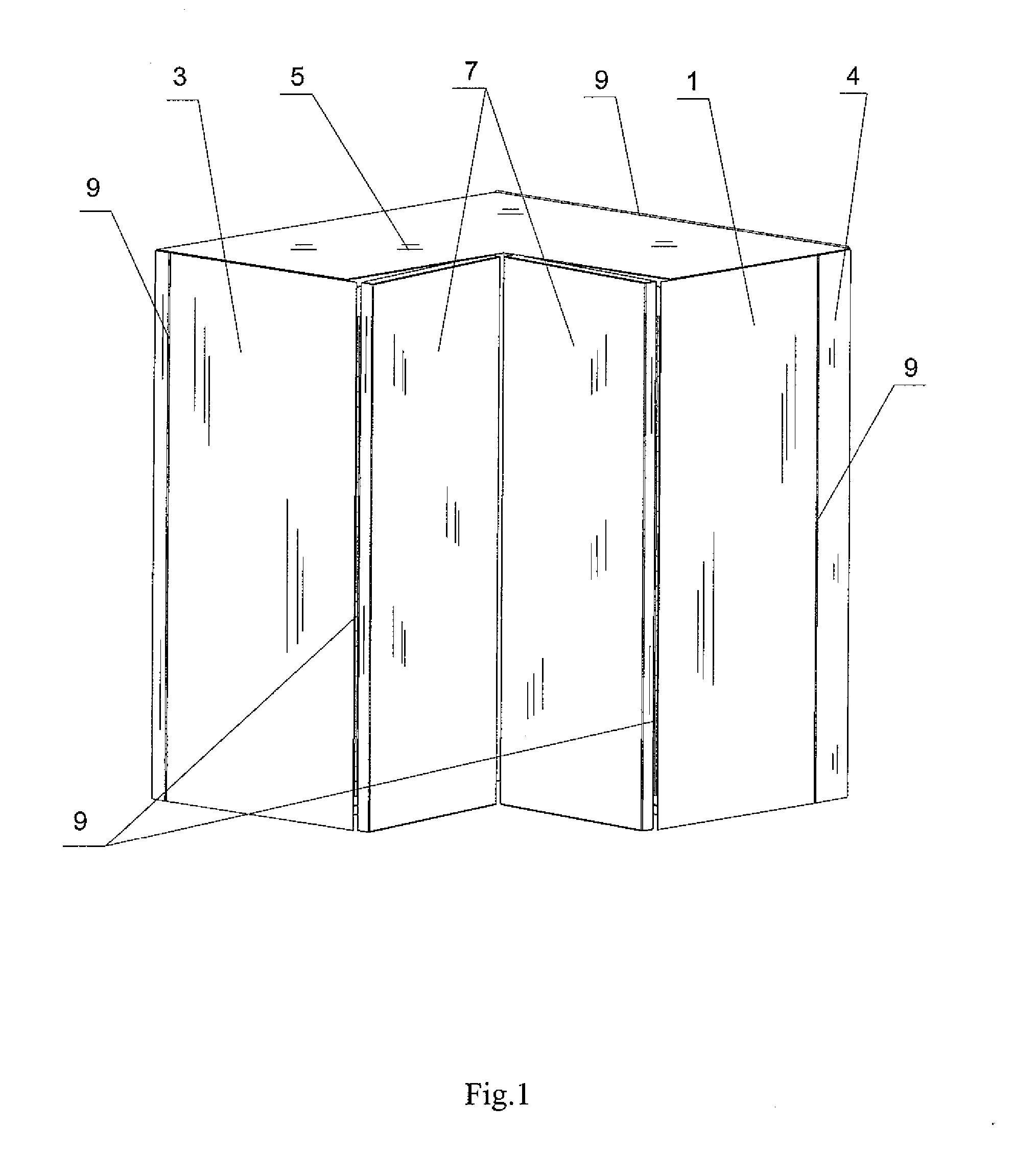

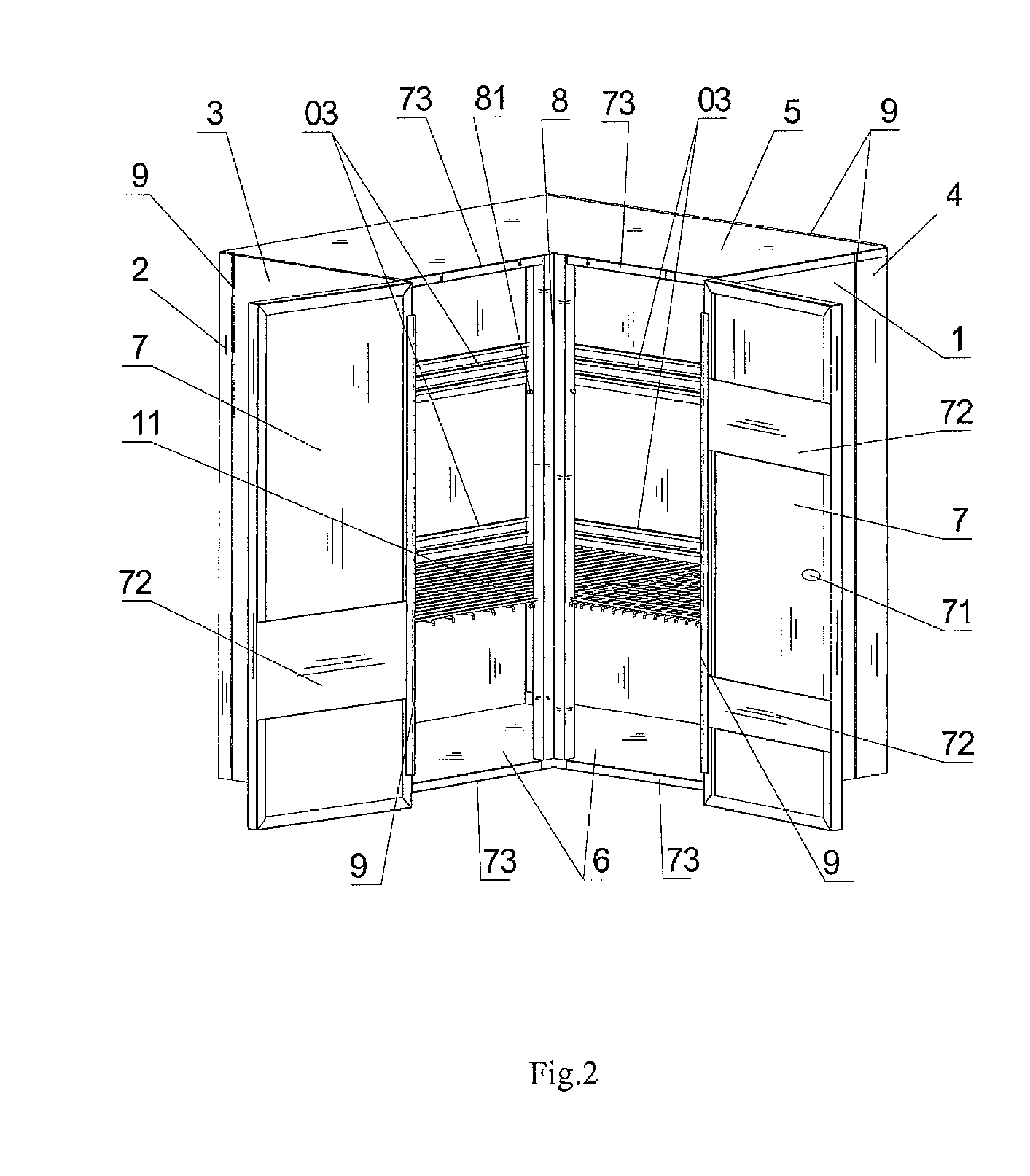

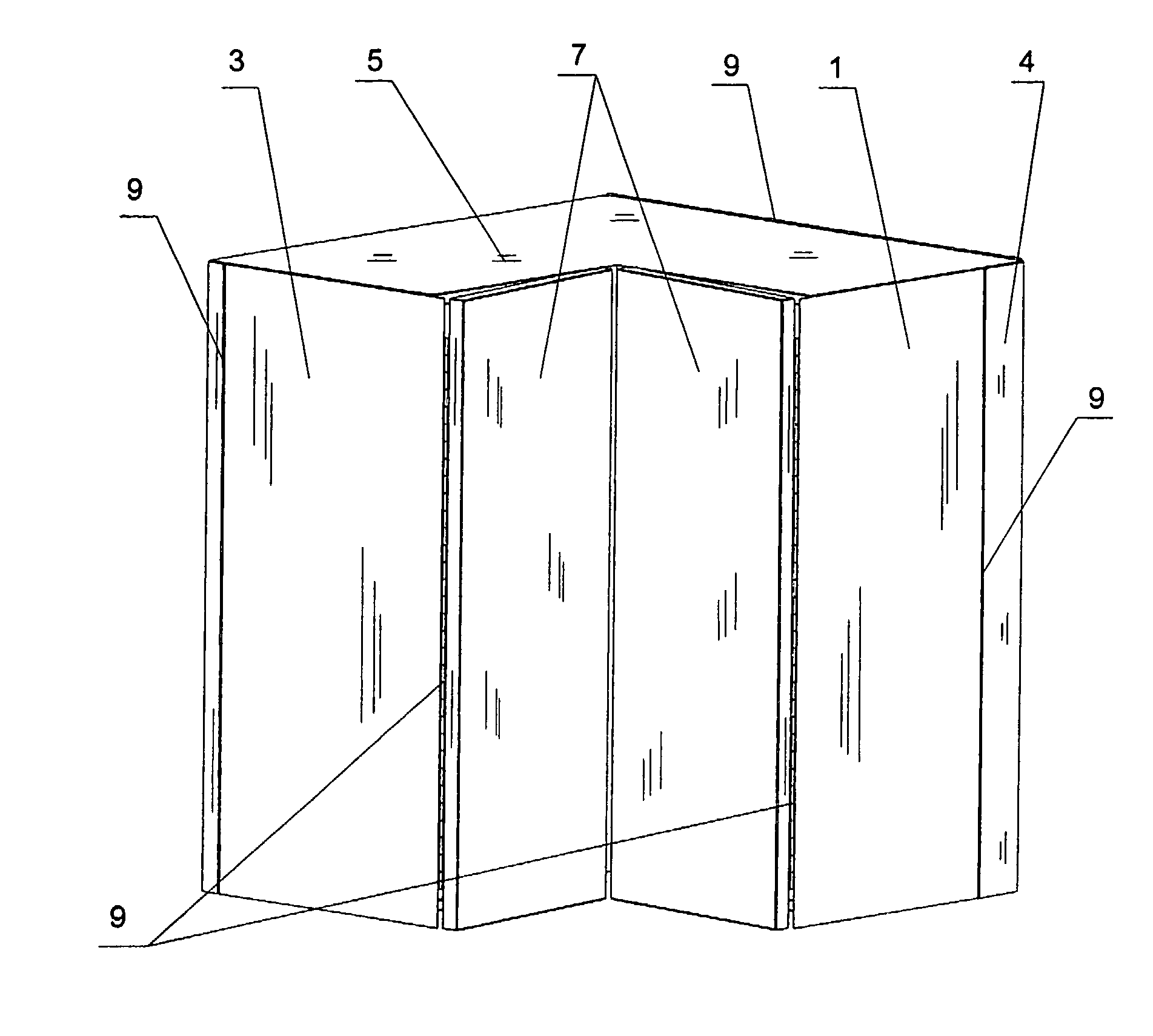

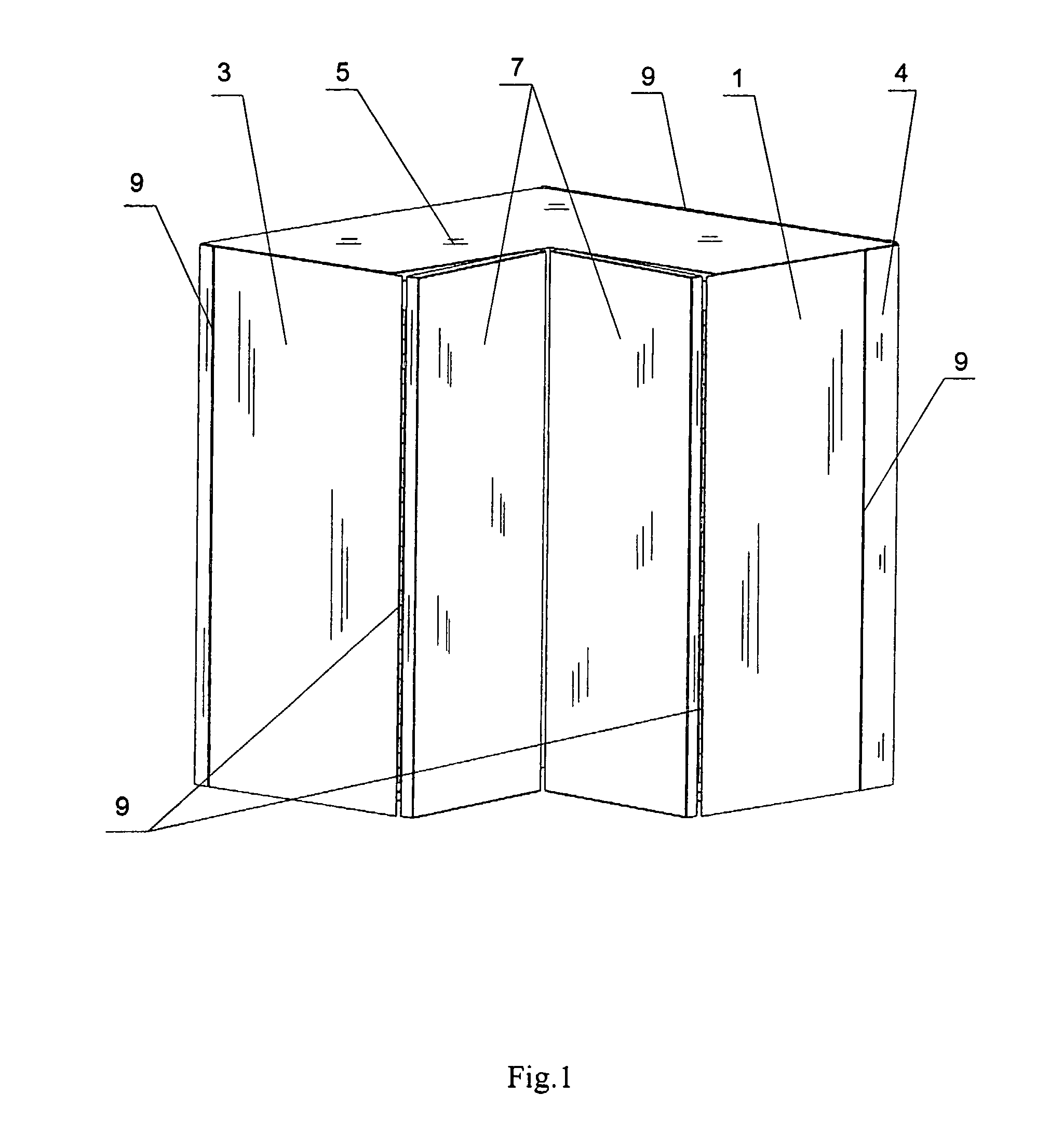

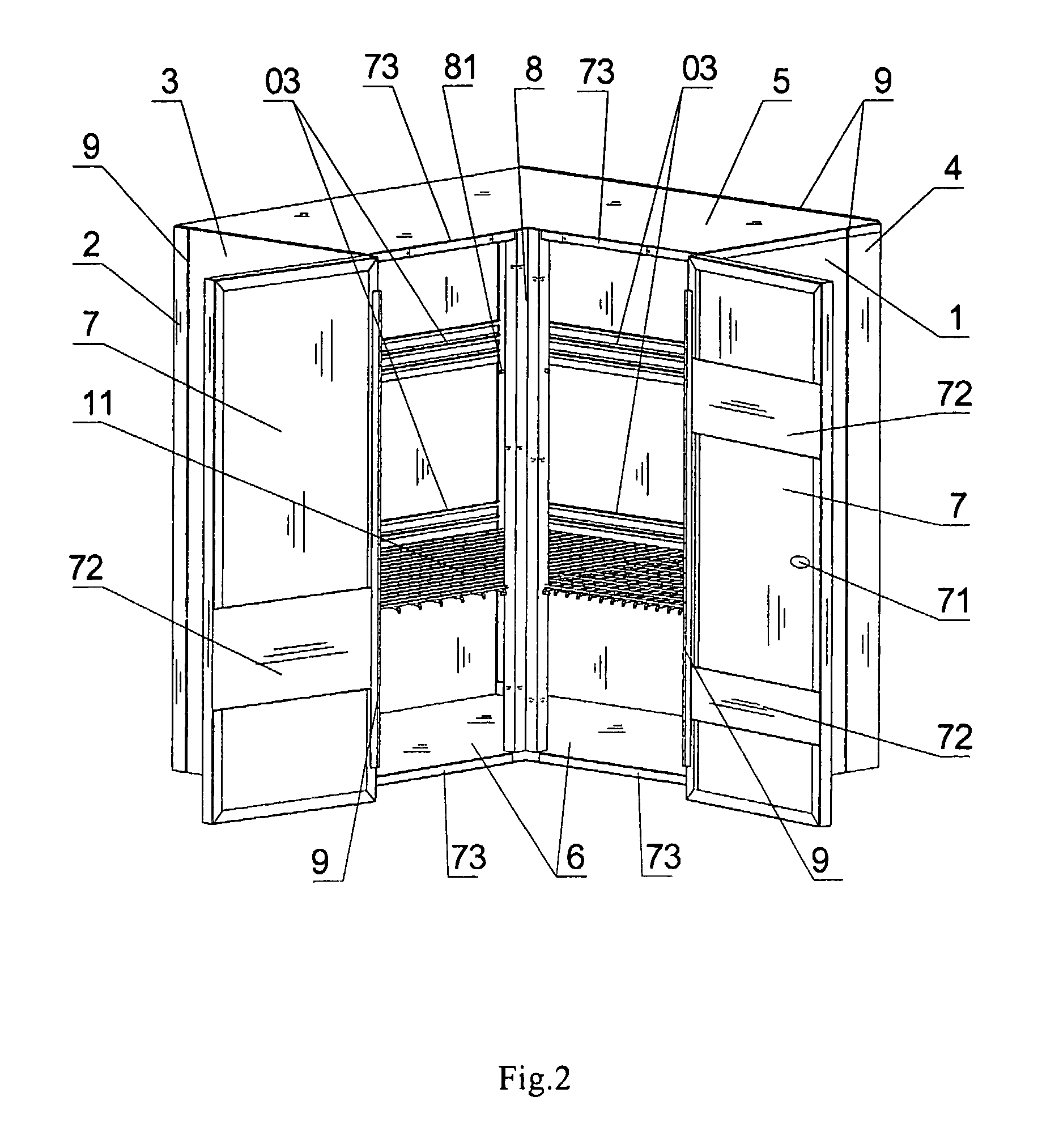

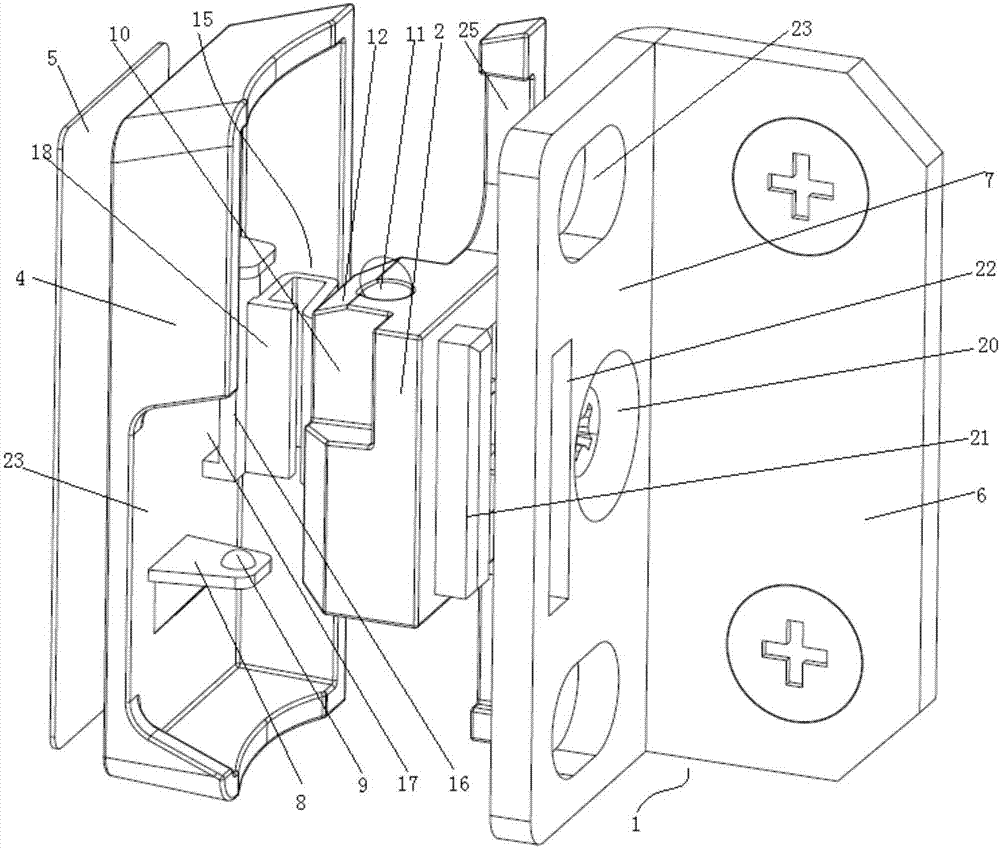

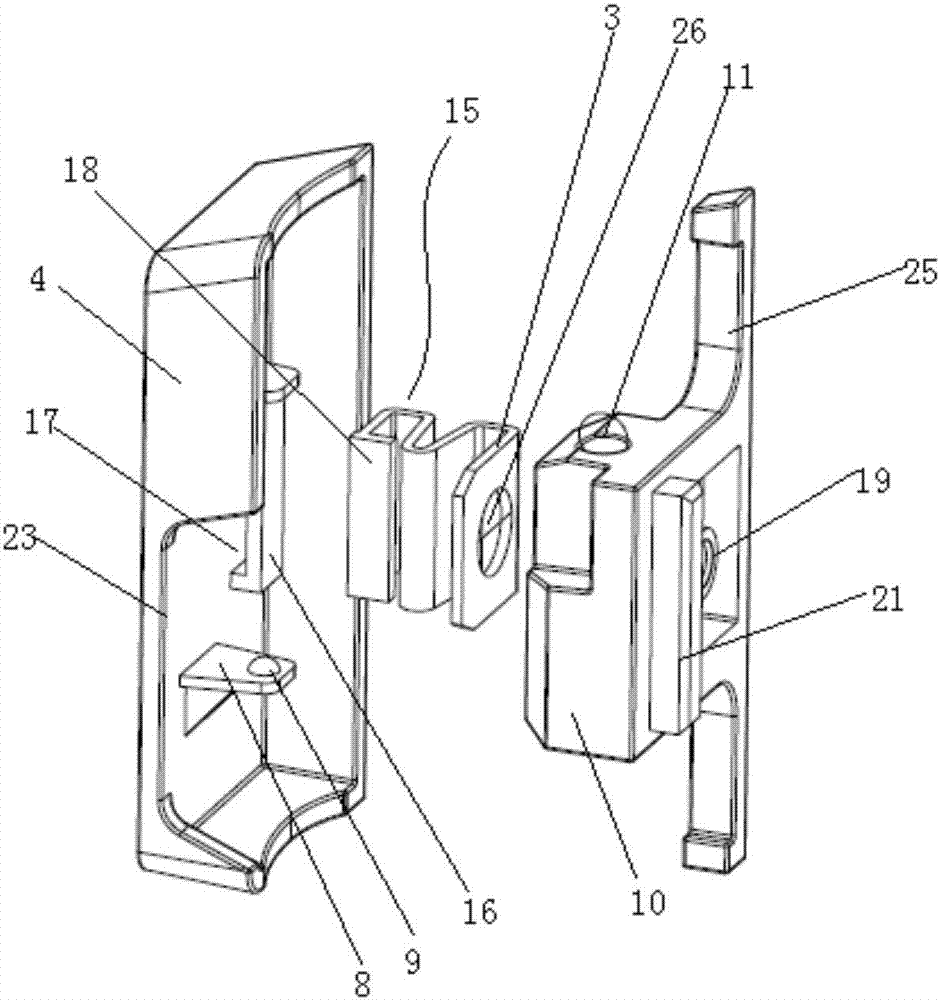

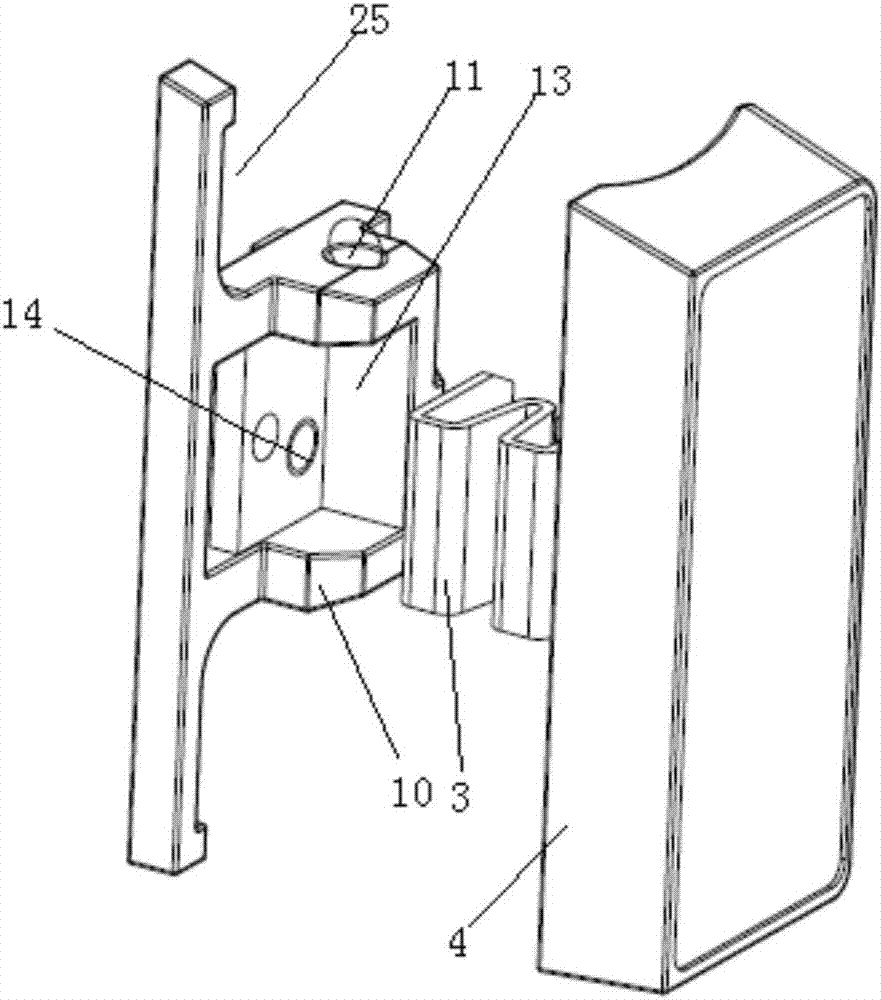

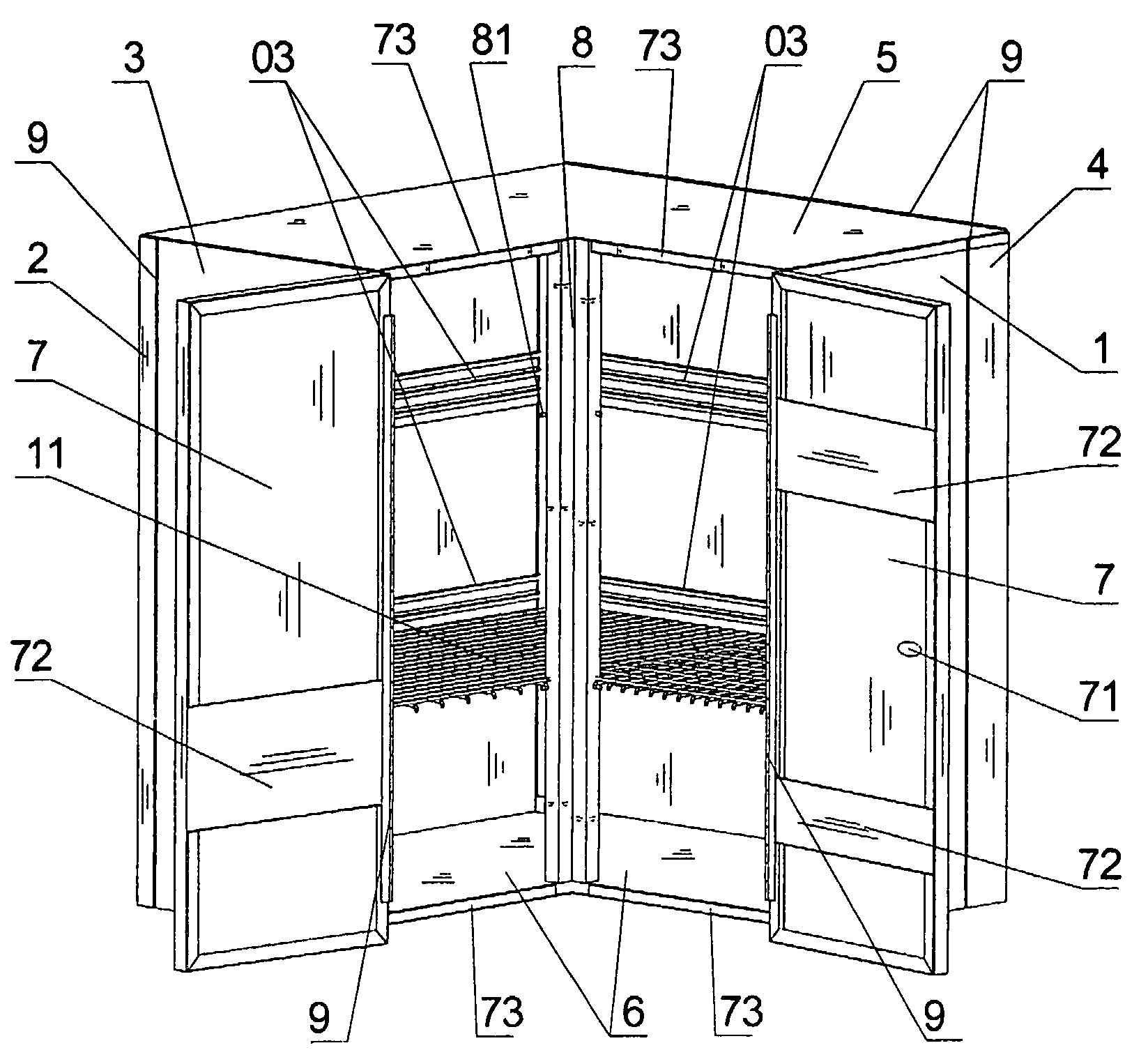

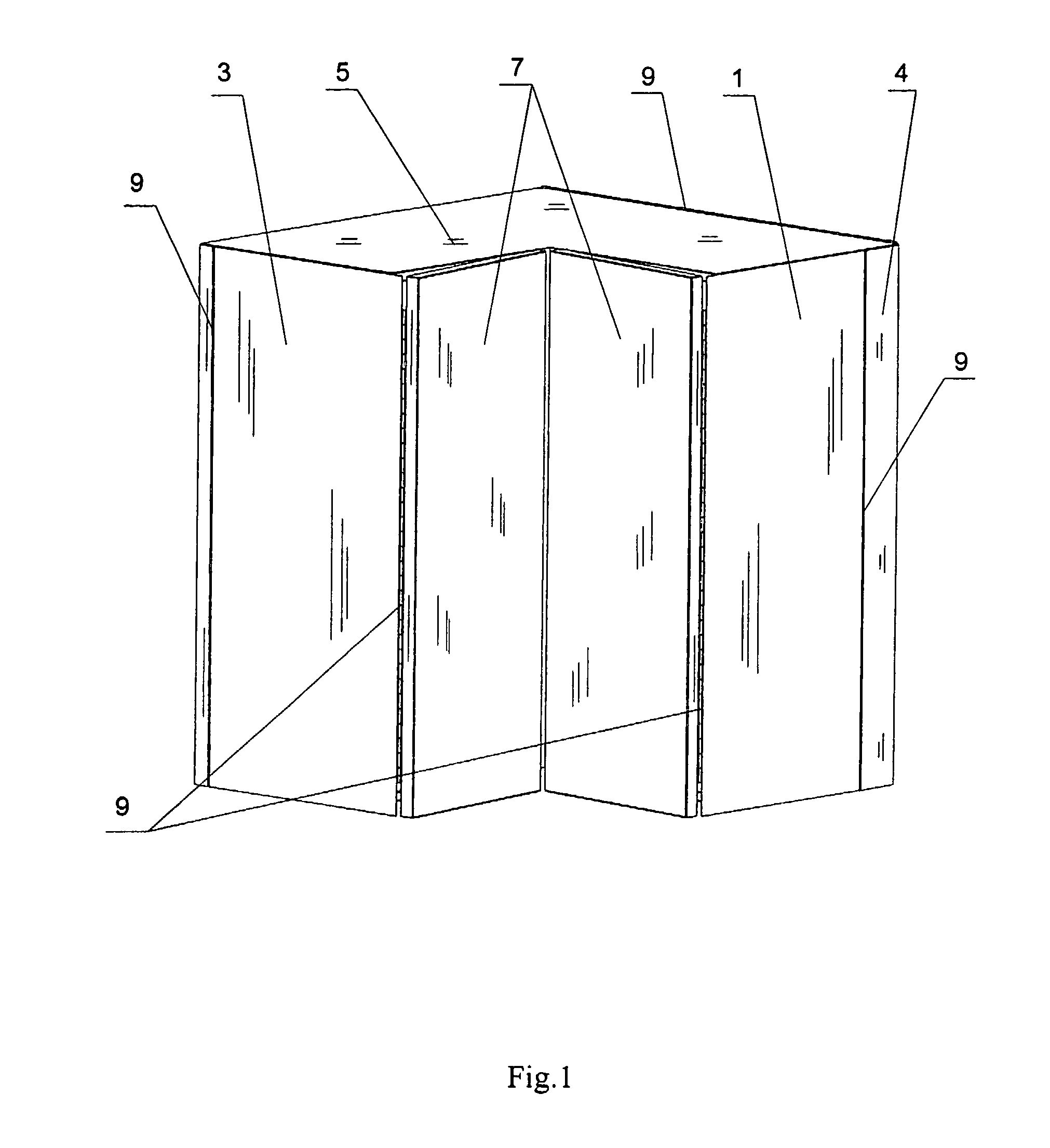

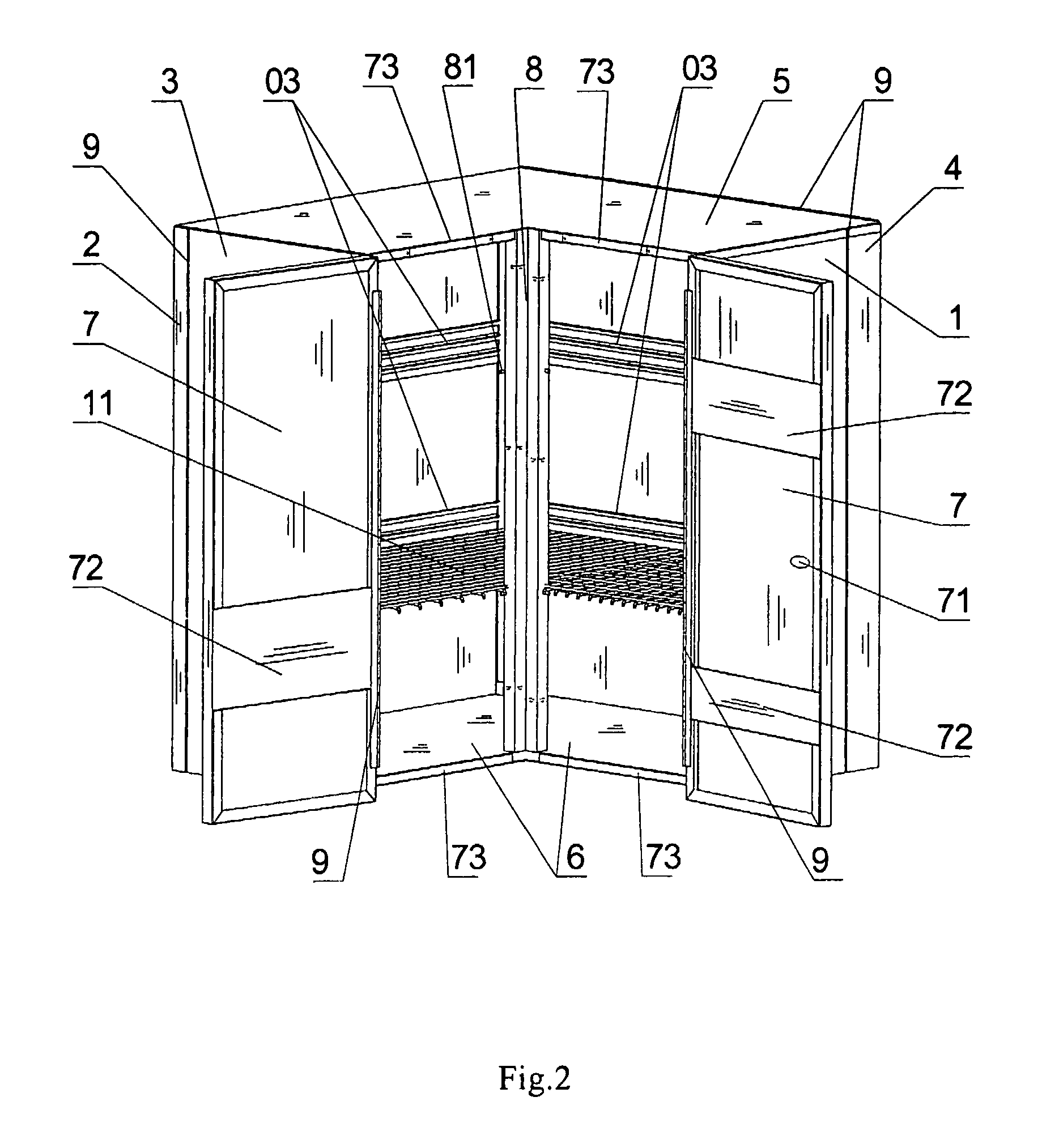

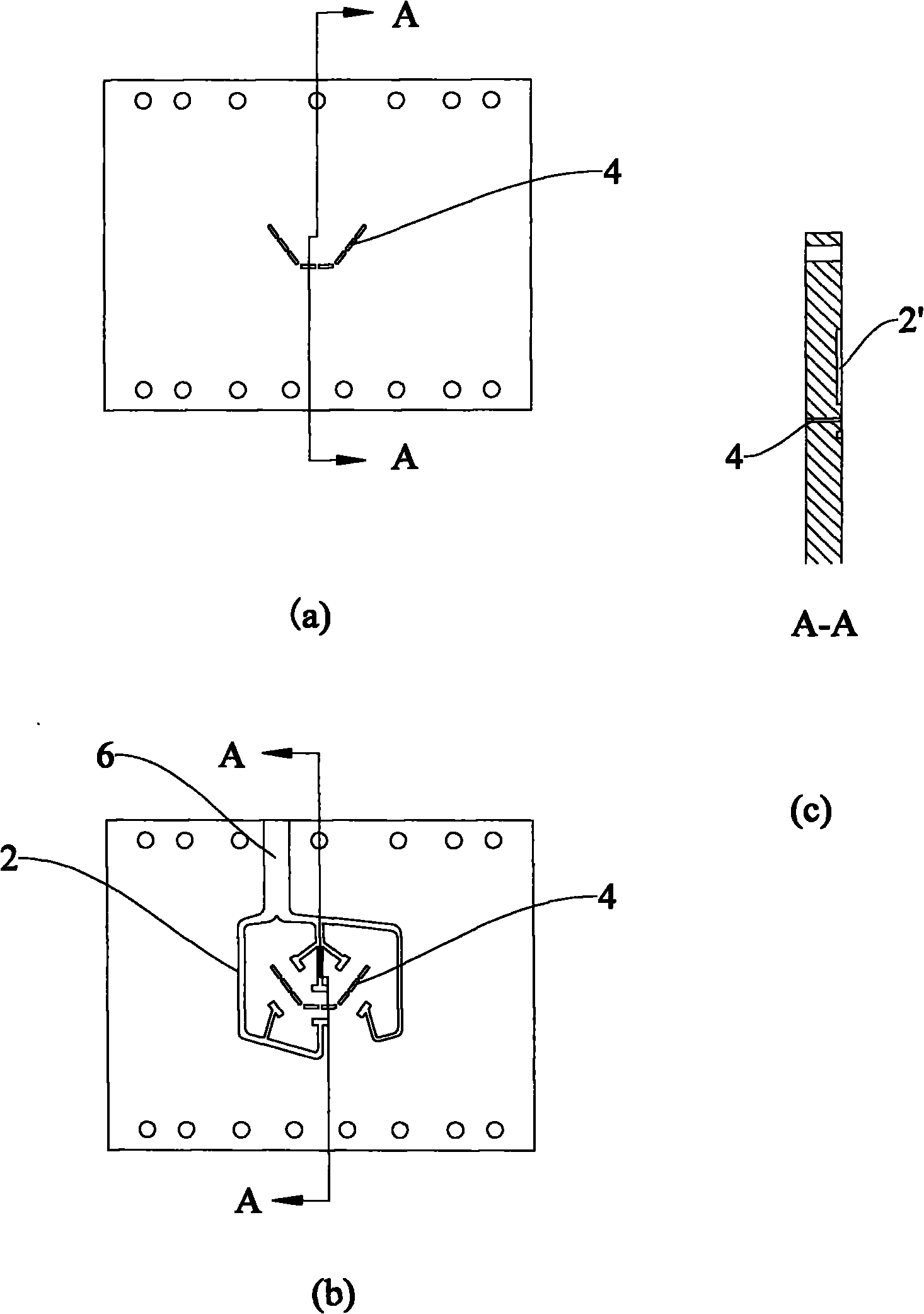

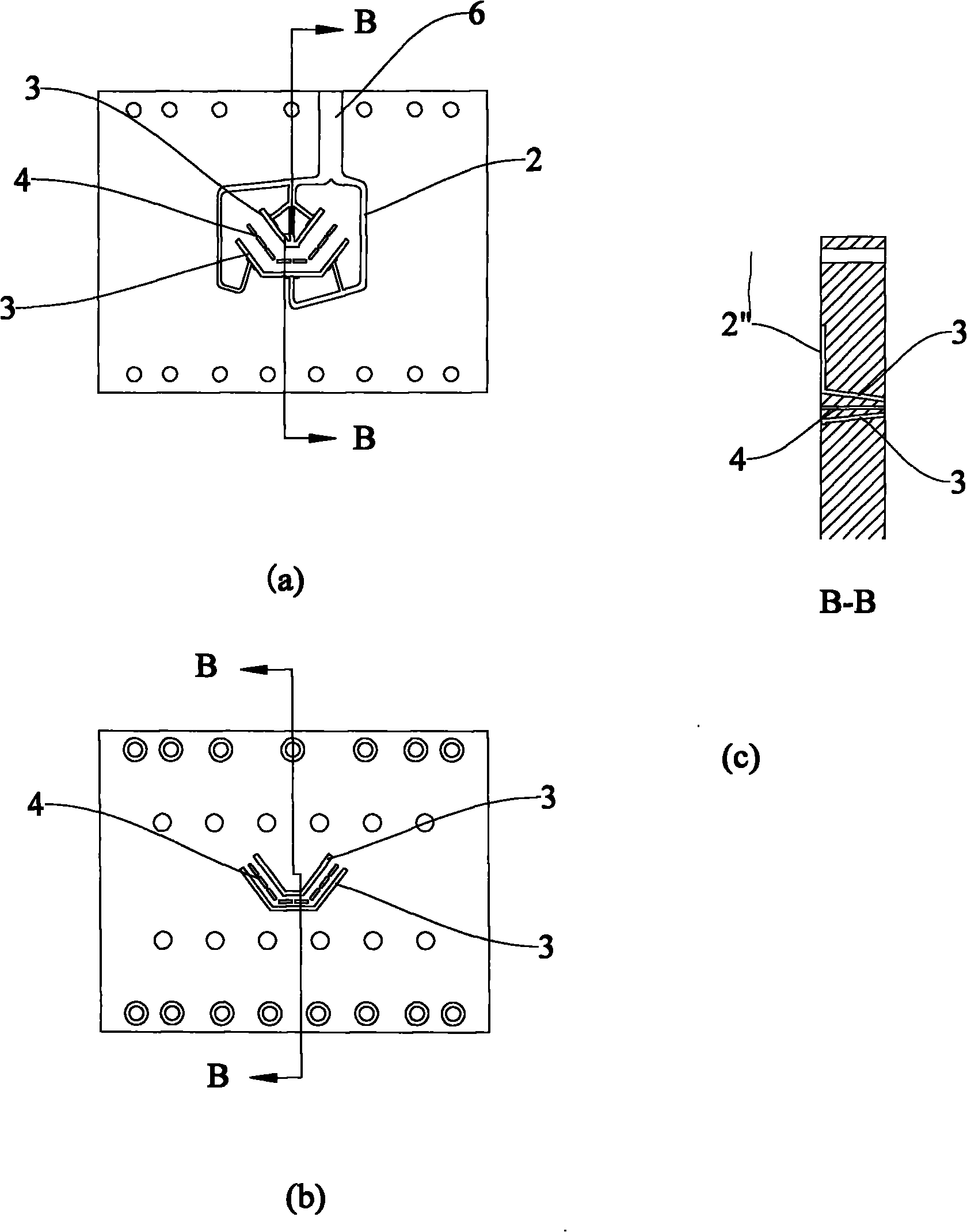

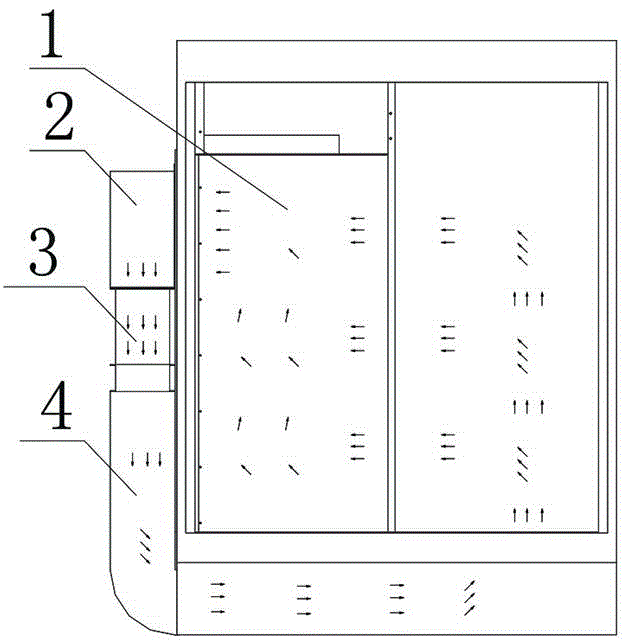

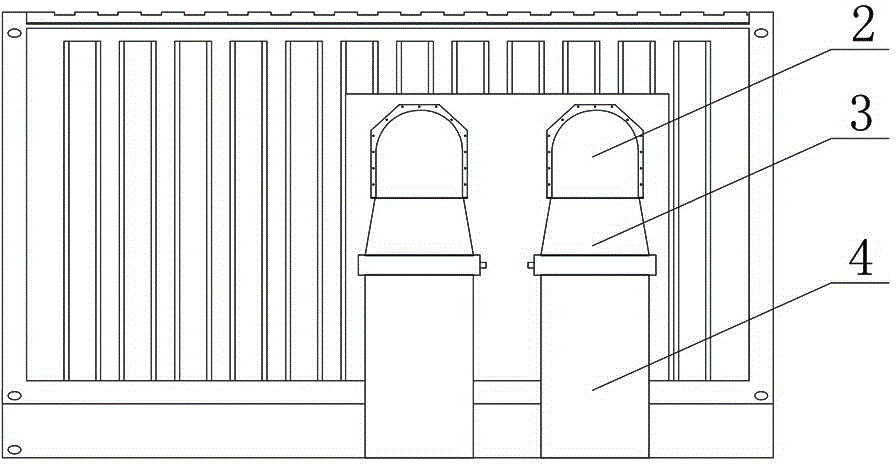

Tool cabinet

InactiveUS20080012455A1Simple structureEasy to assembleFolding cabinetsDismountable cabinetsEngineeringBackplane

A tool cabinet including an upper cover, a bottom board, a case body and a shelf accessory. The case body includes rotatably interconnected case boards, which are foldable with each other. The upper cover and the bottom board are loosely rabbetted into the case body. Without disconnecting each case board, each case board can be folded only by pulling out the pin in the upper cover, turning over the upper cover, then taking out the shelf and the upright column, releasing the block rabbeting, and folding the case boards. It is done after the shelf and the upright column are placed into a predetermined space of the right board and the back board during the folding process. It is very simple and convenient. Hence, it is convenient to carry the tool cabinet after it is folded. In another embodiment, a tool cabinet is also constructed with hinged panels and doors that after assembly can be easily folded into a compact unit for storage or shipping.

Owner:JINHUA ZHENFEI TOOLS

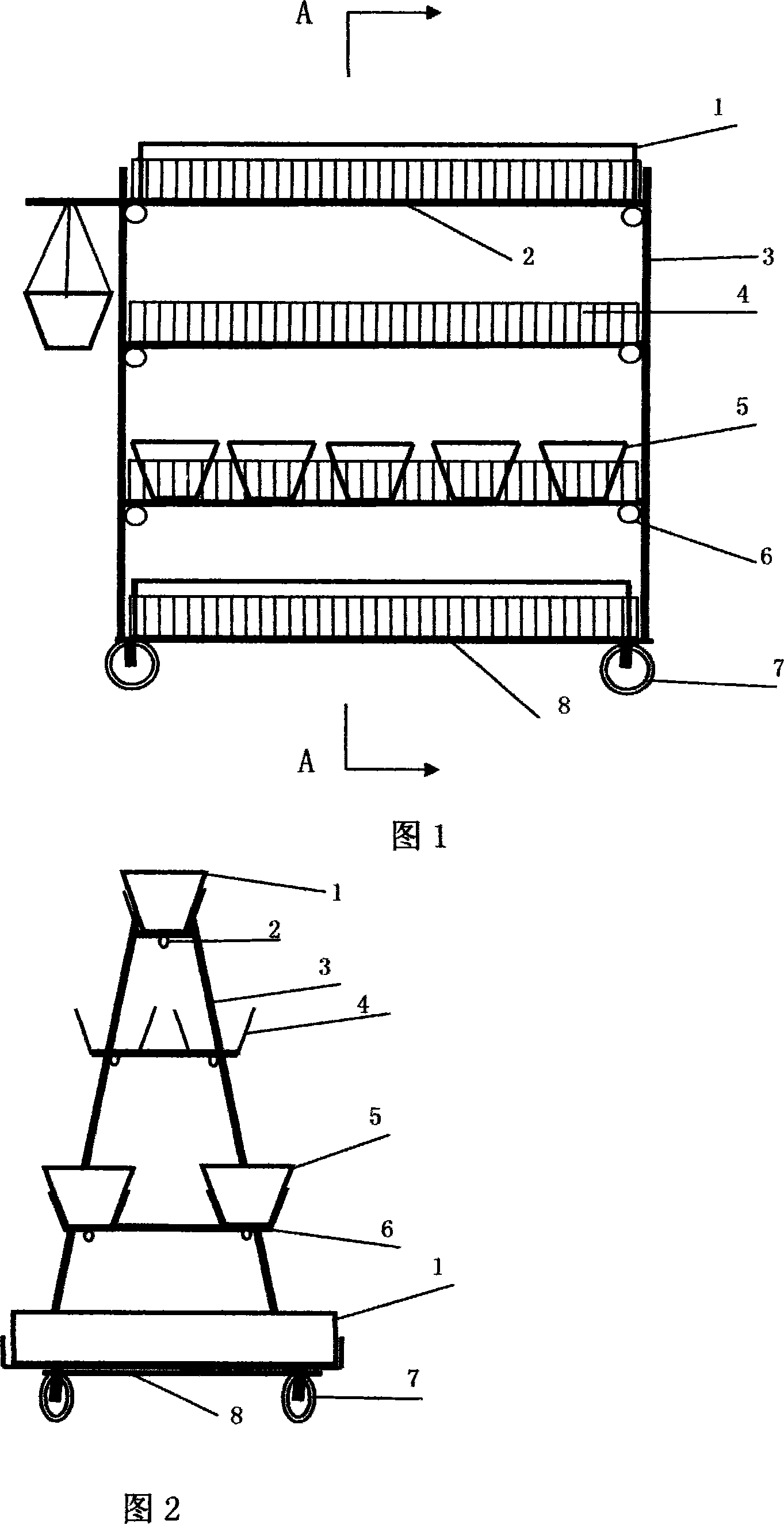

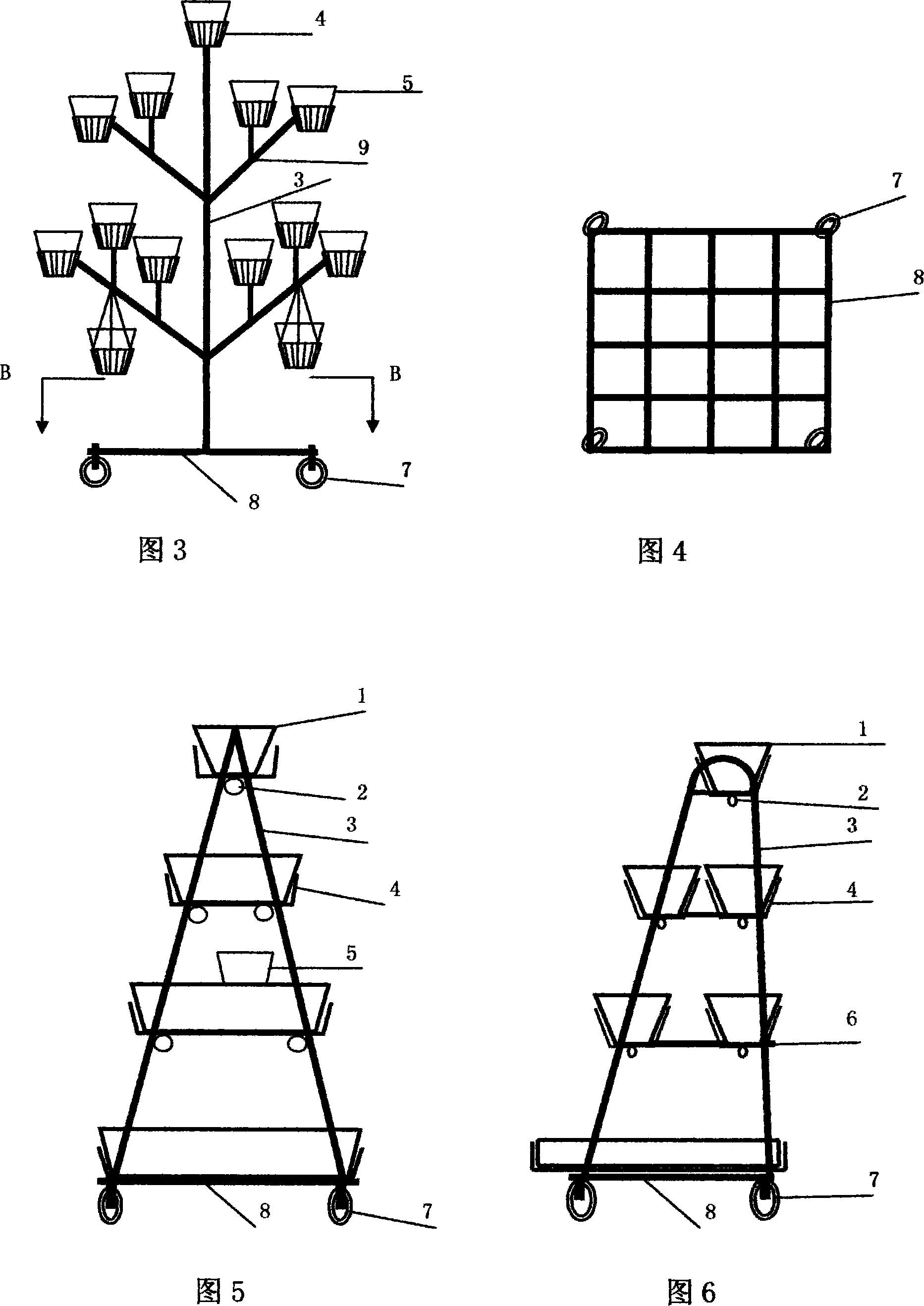

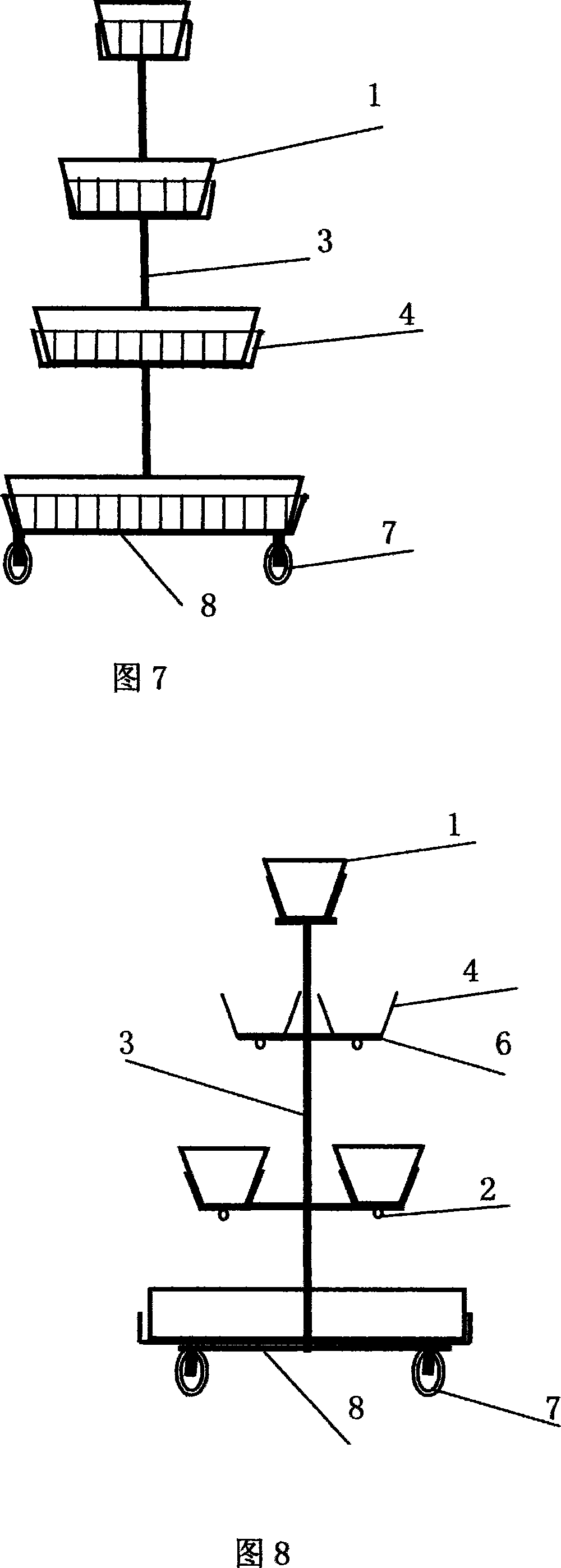

Moveable 3-D flower-culturing rack and manufacturing method and use

The present invention relates to a mobile flower-growing frame, its manufacture method and application. Said mobile flower-growing frame is made up by supporting frame body, and is characterized by that on the supporting frame body several layers of supporting nets are fixedly set, in every supporting net interior a flower-growing groove is set, in the flower-growing groove interior a culture soil is added for planting flowers and plants, also the flower-growing pot can be placed in the flower-growing groove interior or on the supporting net for growing flowers and plants.

Owner:张朝峰

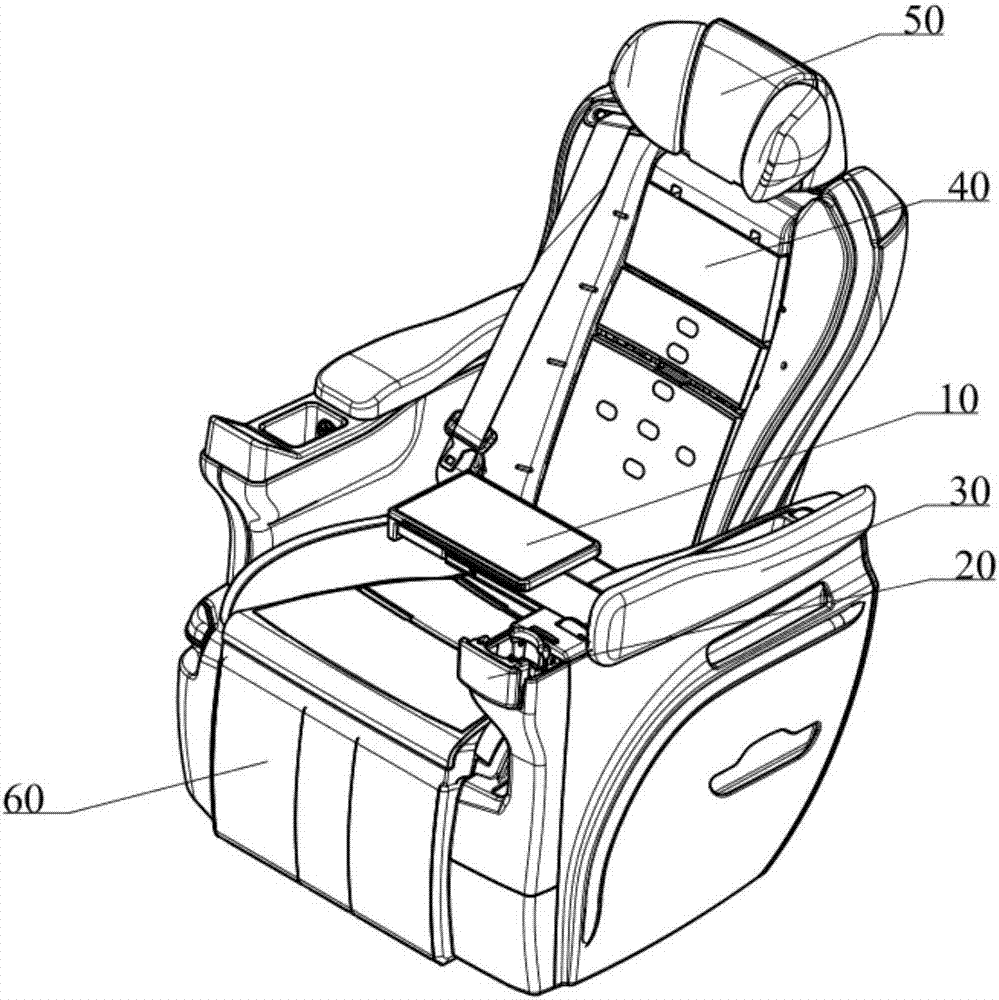

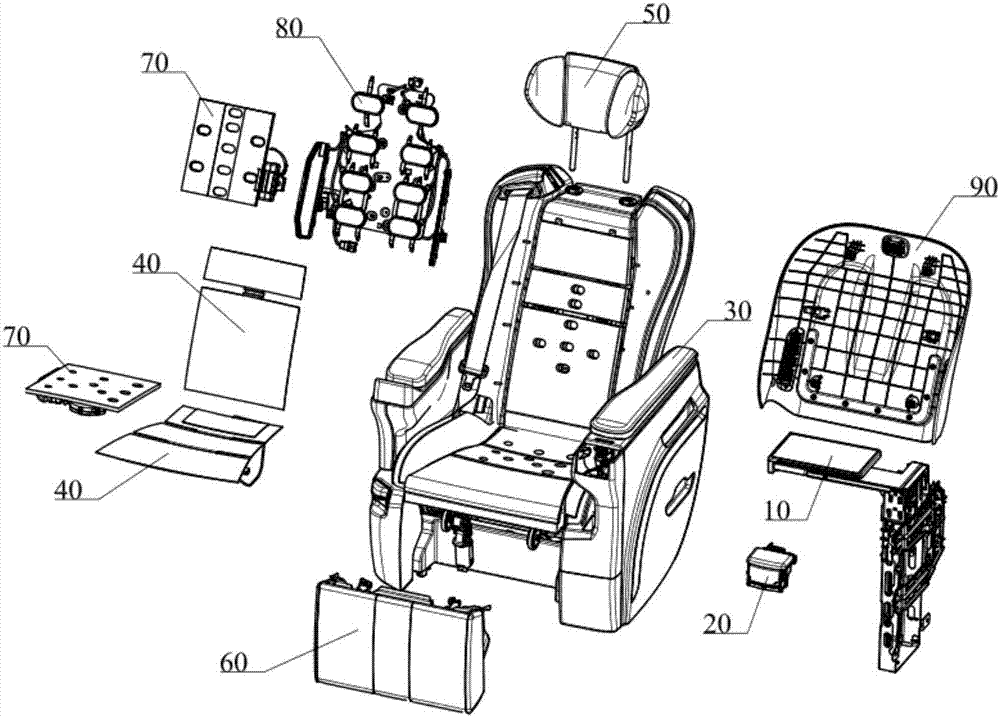

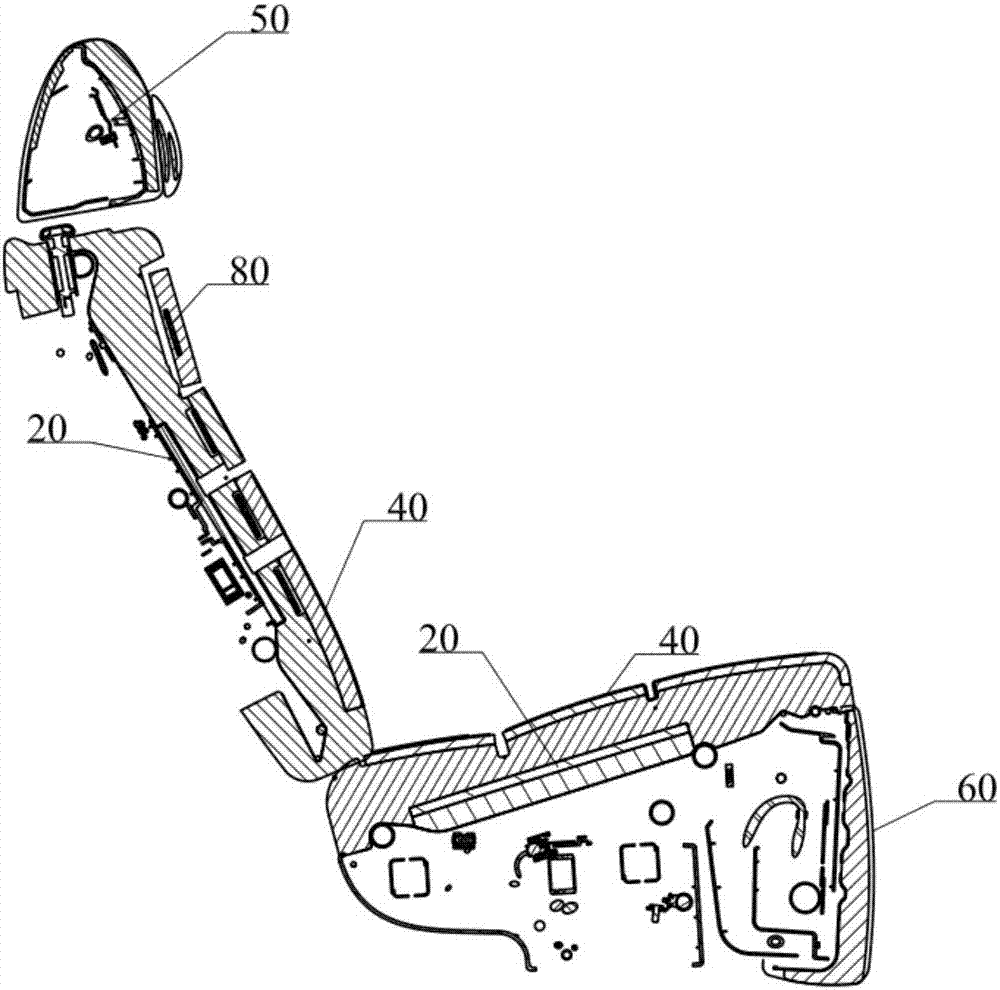

Automobile seat

The invention discloses an automobile seat and belongs to the technical field of automobiles. A seat skeleton of the automobile seat comprises armrest parts, a backrest part and a cushion part. The armrest parts each comprise an armrest face plate and an armrest cover assembly which are slidably or rotatably connected. Cup holder structures or table plate structures are arranged on the armrest face plates. The table plate structures can slide out of the armrest parts and rotate relative to the armrest parts and can also slide into the armrest parts and locked with the armrest parts. The cup holder structures are arranged on the armrest face plates in a foldable mode, and a space for containing a water cup is formed when the cup holder structure is unfolded. The rotatable table plate structures, the foldable cup holder structures, the armrest face plates and the armrest cover assemblies are arranged on the armrest parts, wherein the armrest face plates and the armrest cover assemblies are connected rotatably or slidably, so that the automobile seat has an office function, attractiveness and comfort are easily improved, the space can be reasonably utilized, and the automobile seat is high in integration level, small in occupied space and attractive, and dust is not liable to be accumulated on the automobile seat.

Owner:天津陆耐酷车科技有限公司

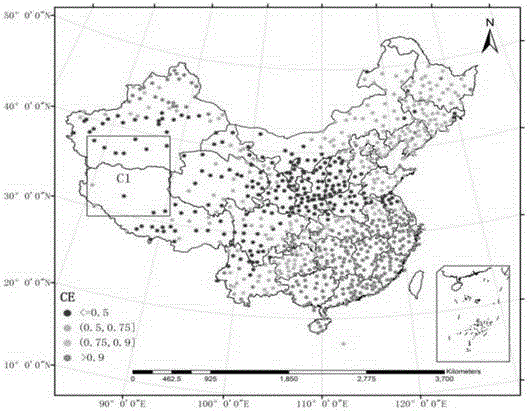

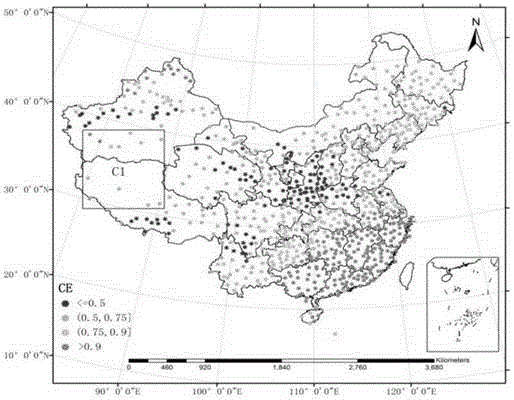

Sparse region rainfall estimation fusion method based on dual-smoothing method

InactiveCN105975791ASmooth visualization resultsReasonable spaceInformaticsSpecial data processing applicationsData setRainfall estimation

The invention discloses a sparse region rainfall estimation fusion method based on a dual-smoothing method. On the basis of data assimilation thought, rainfall point data observed by rain gauges and TMPA grid rainfall data are integrated together to form a set of discrete points, finally, and the two integrated data sets are turned into an improved novel data set; meanwhile, smoothing is adopted for correcting discontinuity formed before TMPA fusion. According to the dual-smoothing method, rainfall values and spatial distribution are more reasonable and effective, average deviation and root-mean-square errors of a region where rain gauges are distributed sparsely change slightly along with time, heavy rainfall can be more accurately estimated, and meanwhile the rainfall visual result is smoother. The method is particularly applicable to regions where automatic meteorological stations are spatially distributed sparsely in a western region.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

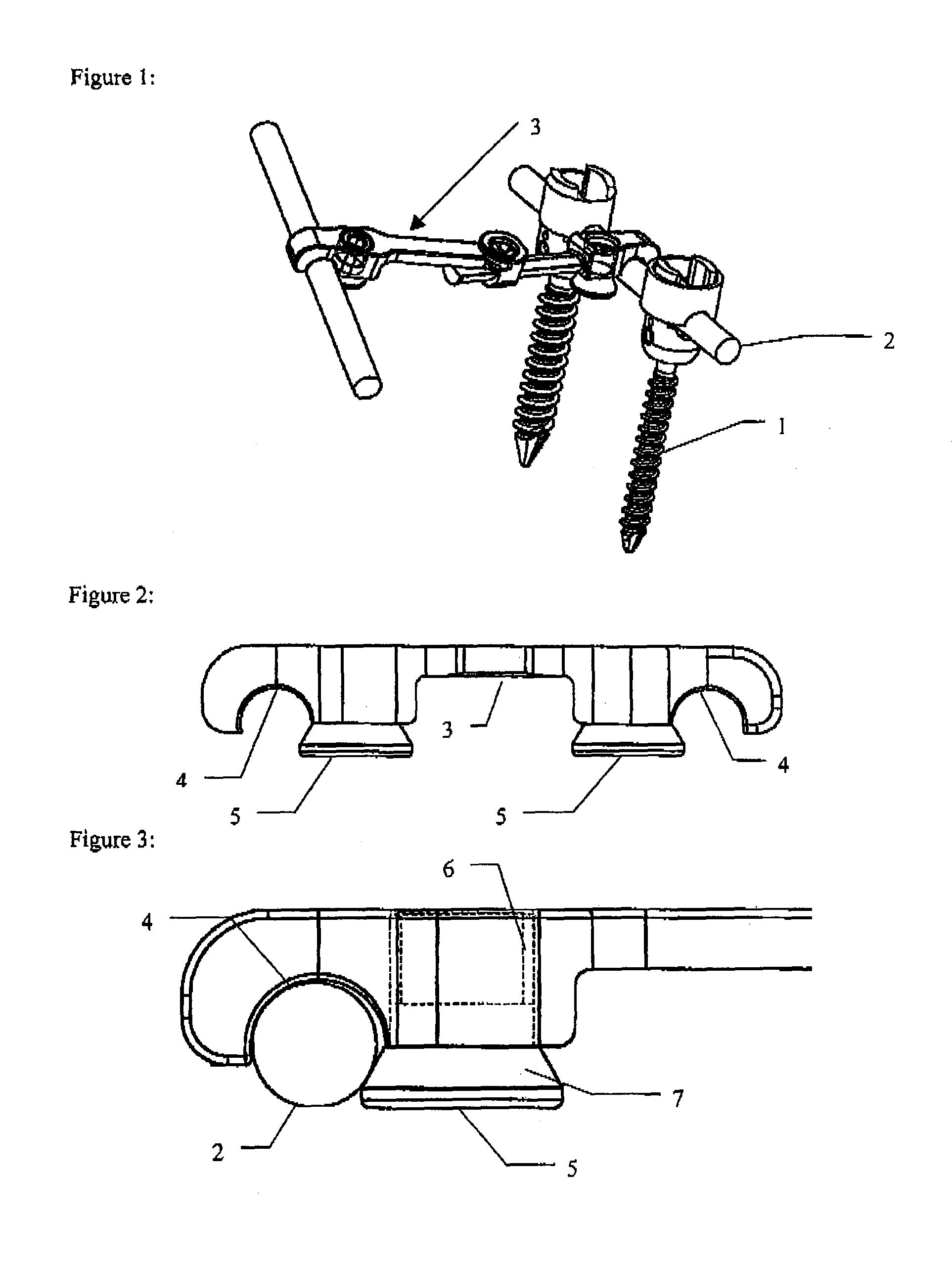

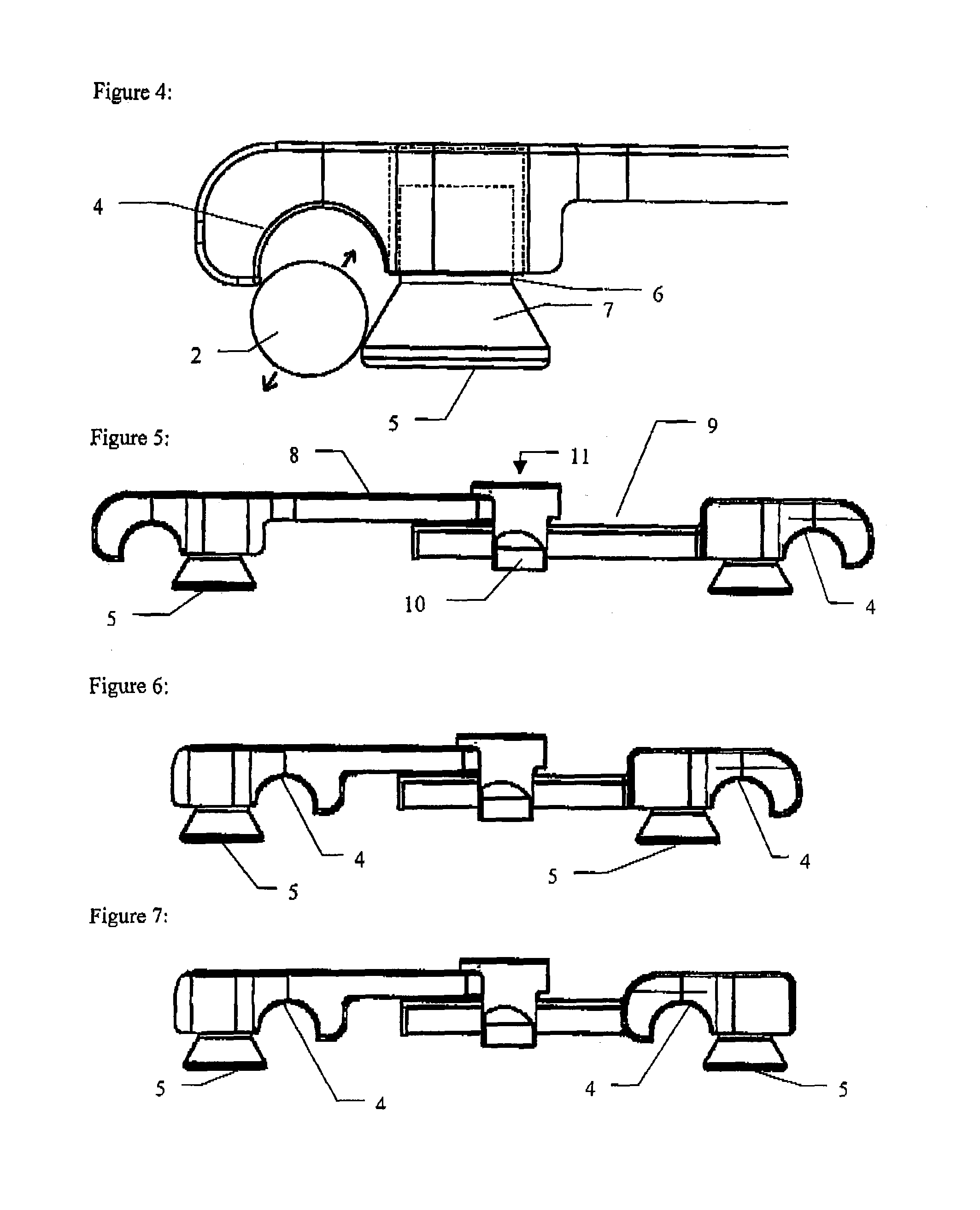

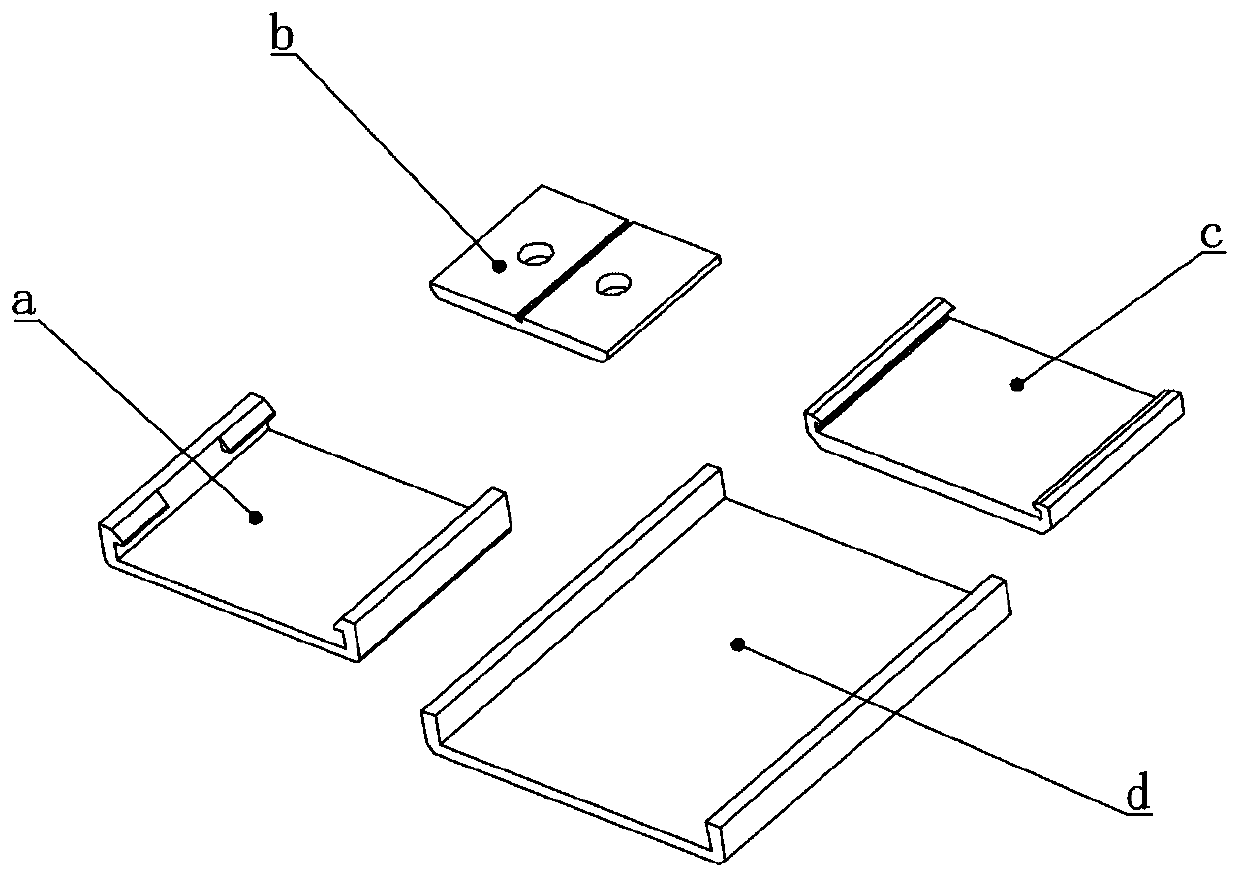

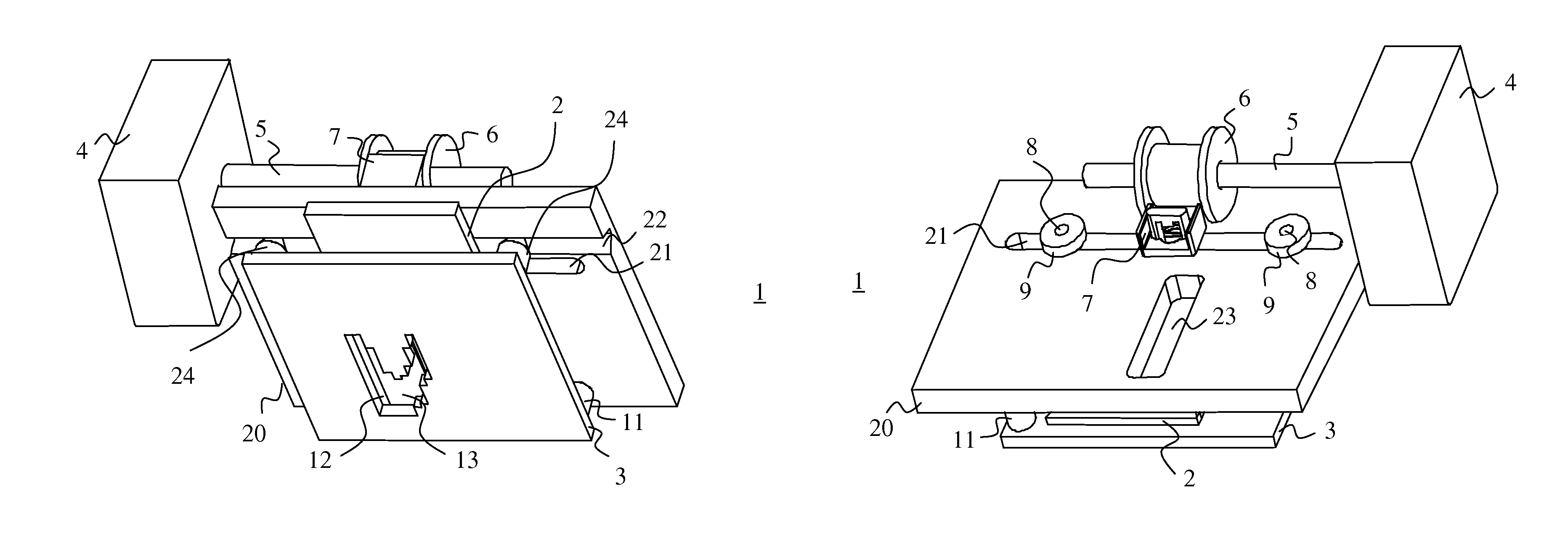

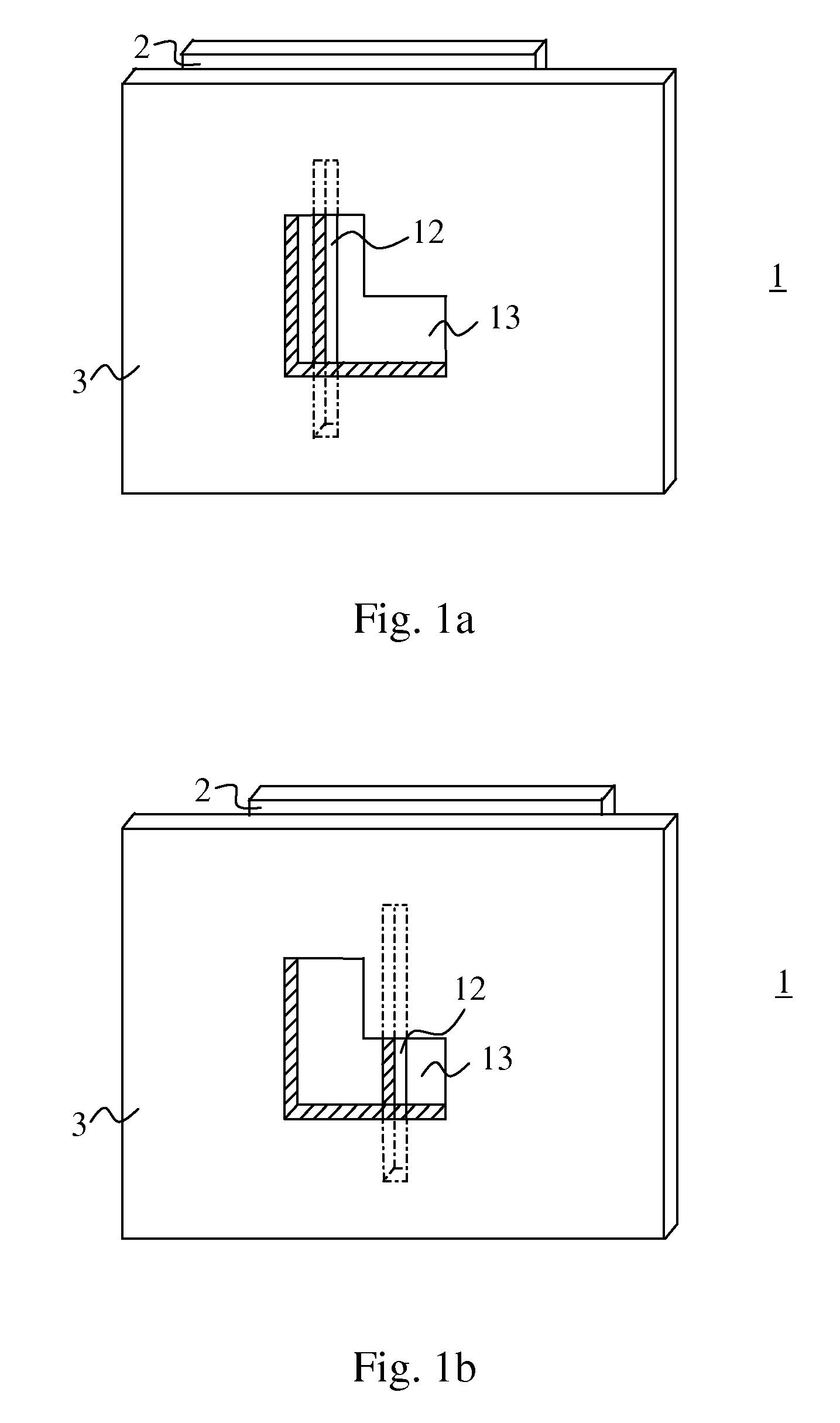

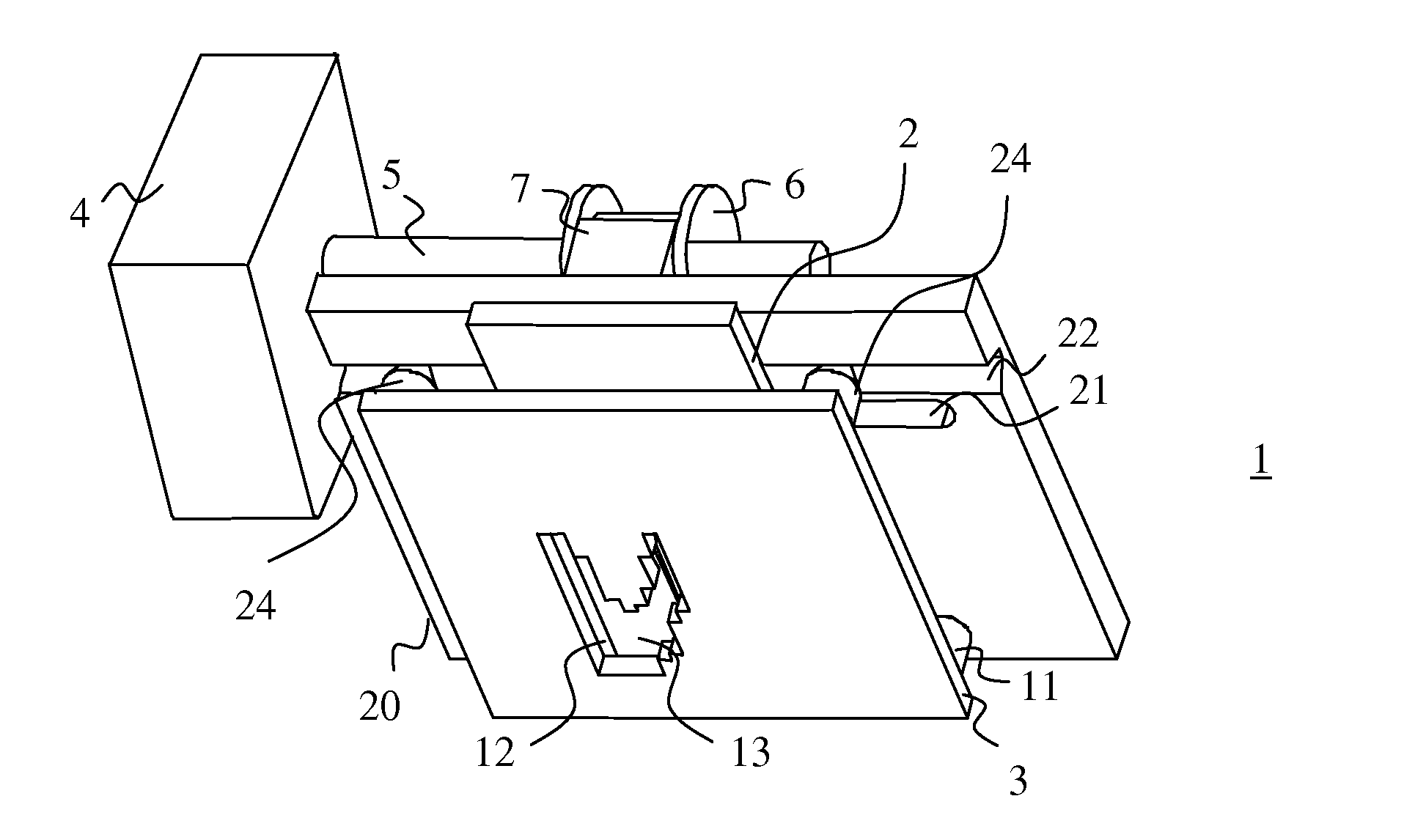

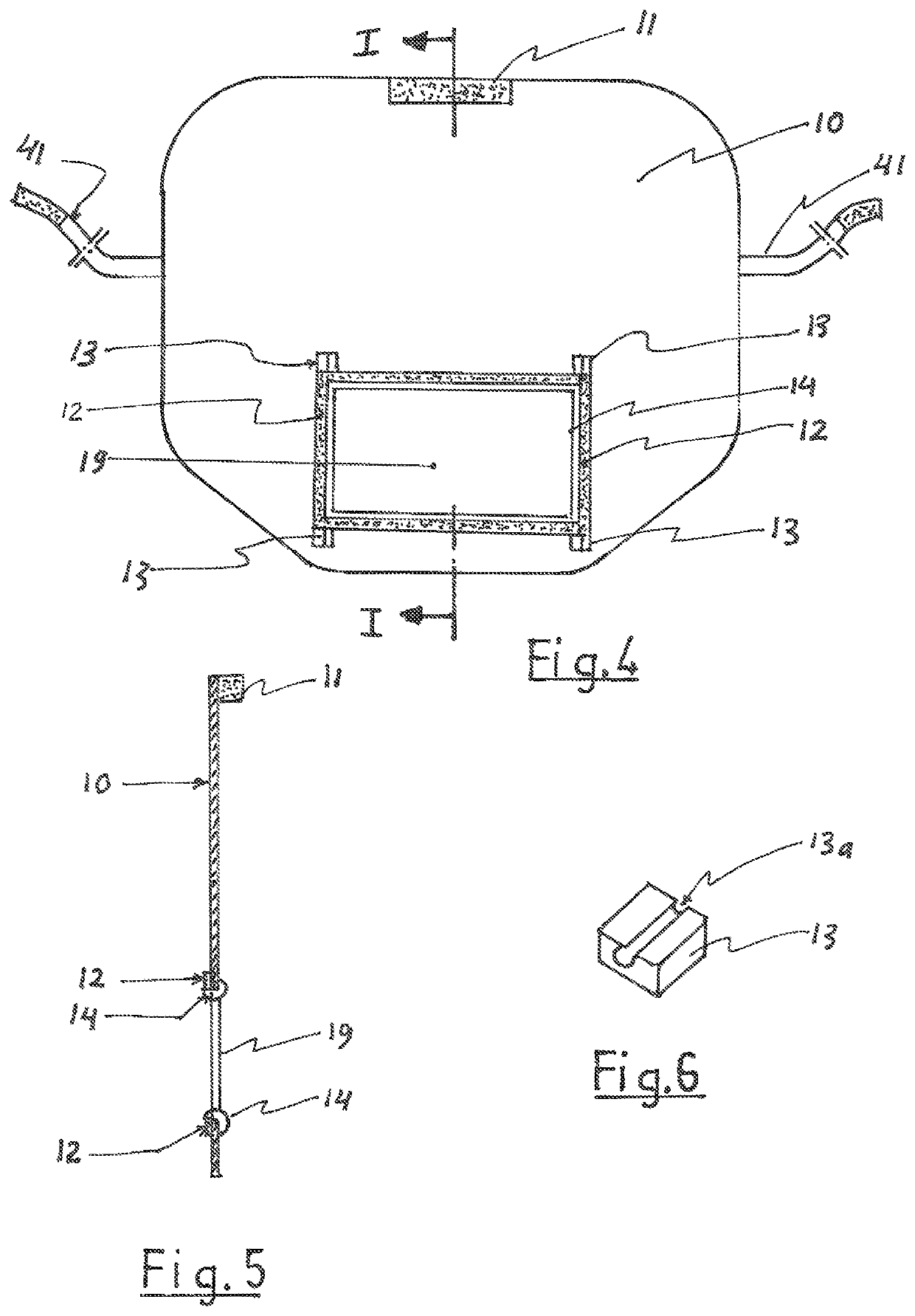

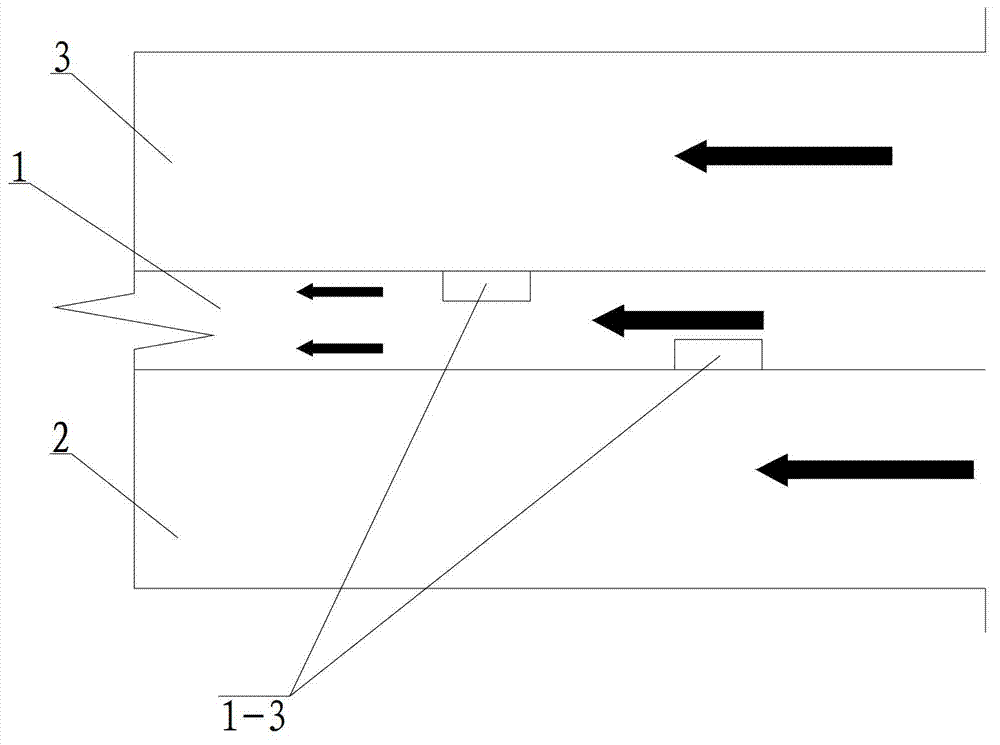

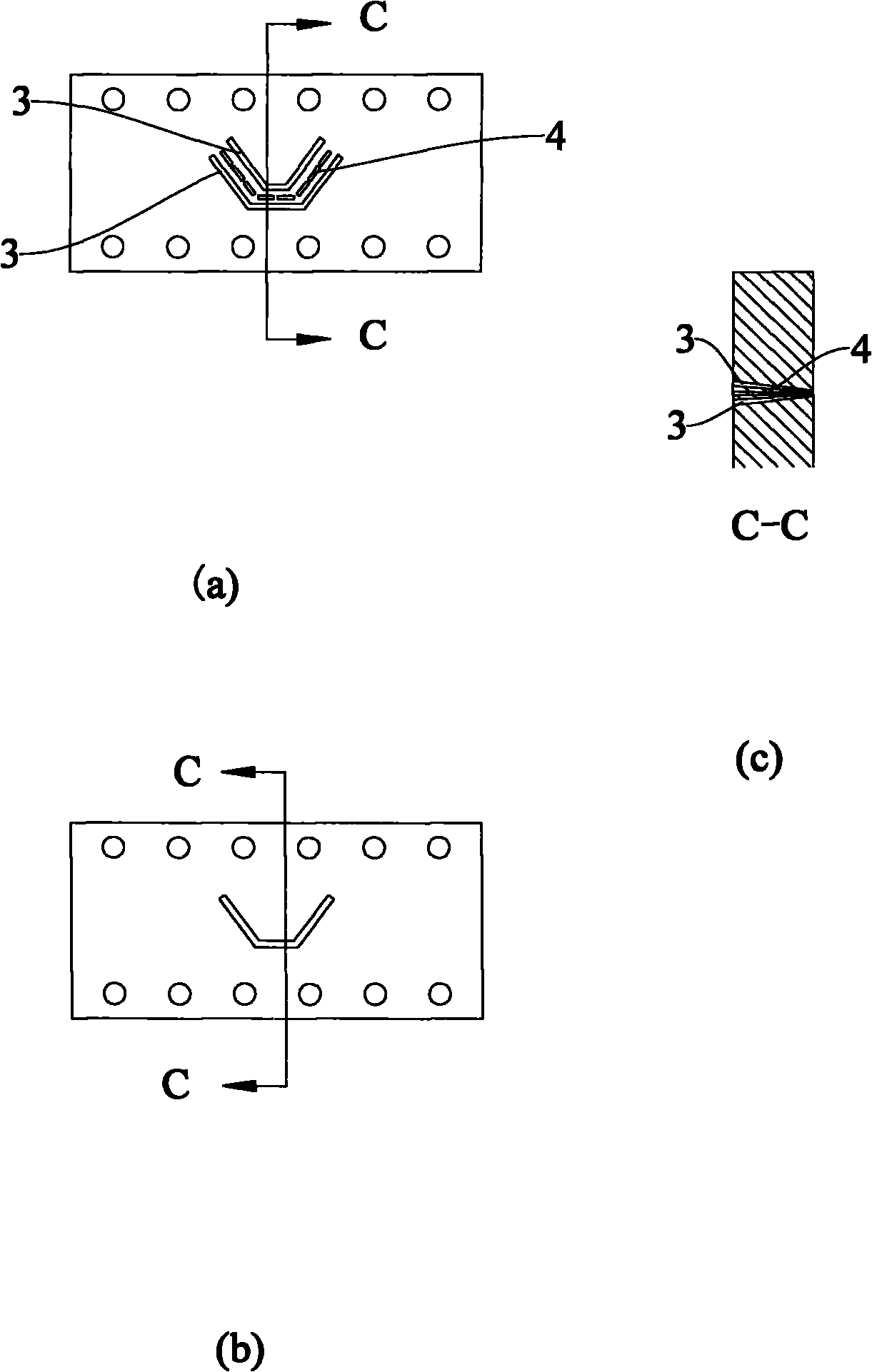

Limiting an X-ray beam in connection with dental imaging

ActiveUS8130901B2Low costReasonable spaceHandling using diaphragms/collimetersTomographyEngineeringActuator

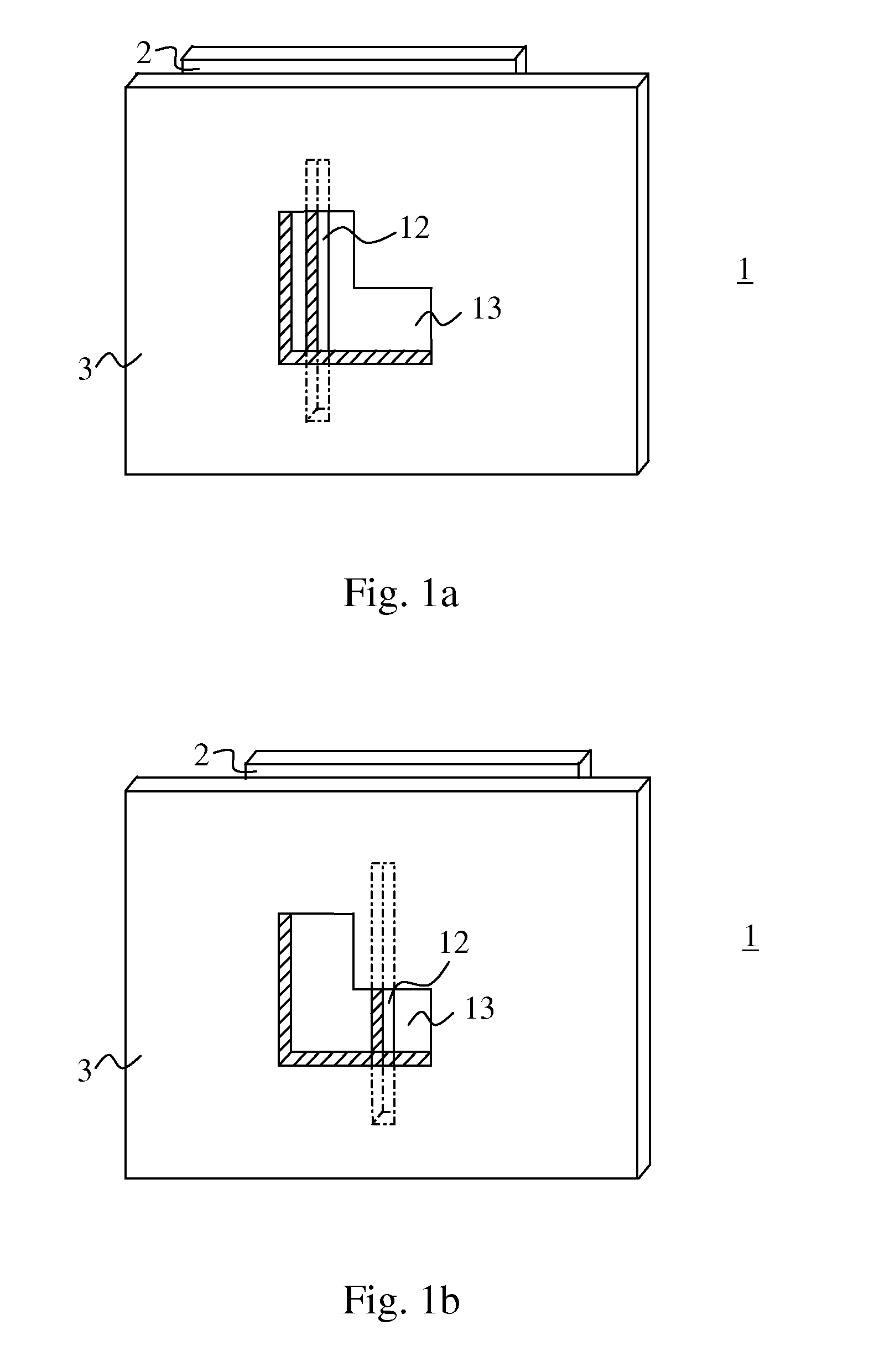

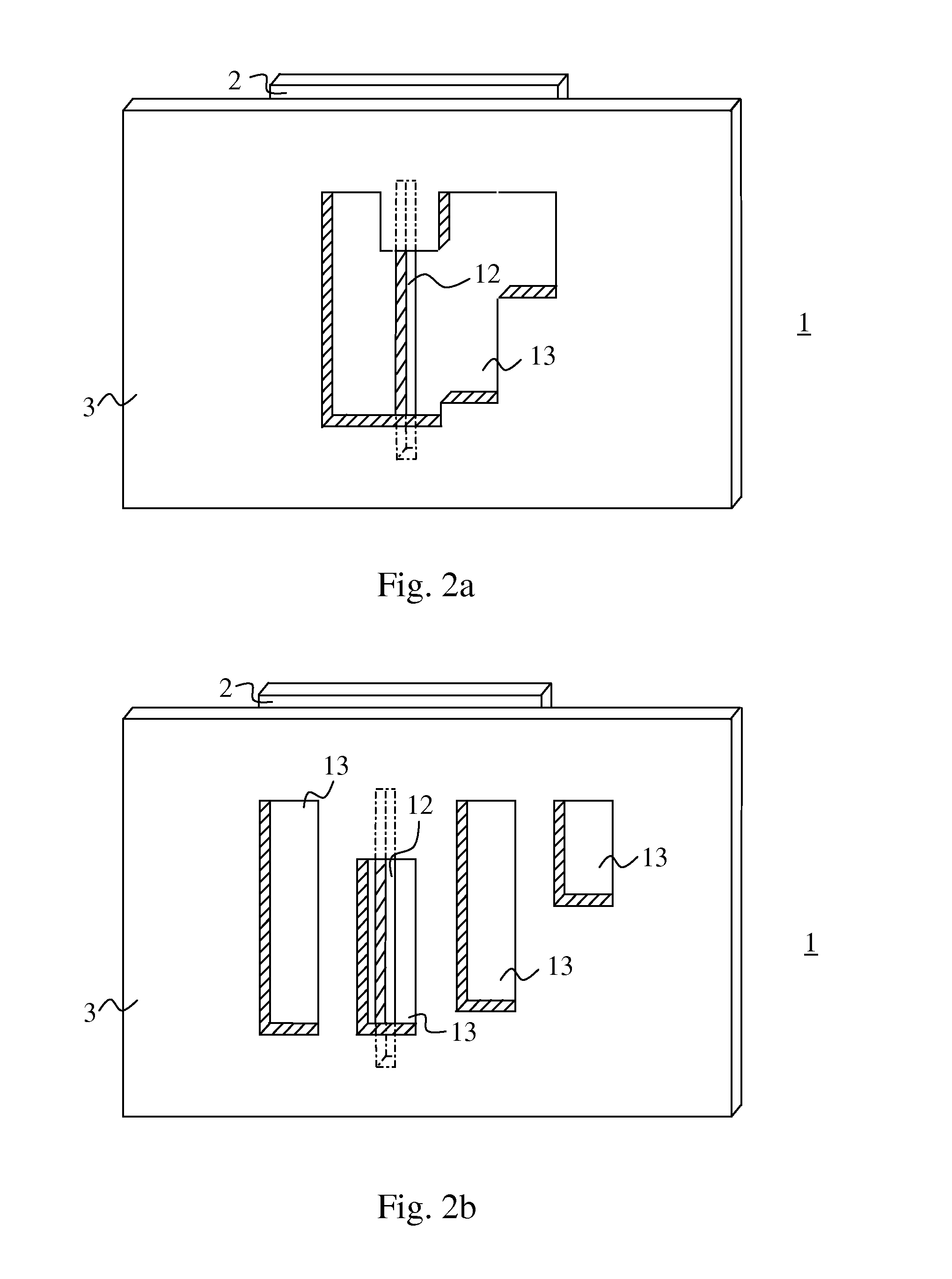

The present invention relates to limiting an x-ray beam used in connection with dental extra oral imaging by a plate mechanism (1) arranged to be operated by a drive mechanism including an actuator (3) arranged to move at least one plate element (2, 3) comprised in the mechanism (1). The plate mechanism (1) includes at least a first and a second plate element (2, 3) which include at least a first slot (12) and a second slot (13), respectively, and said drive mechanism is arranged to directly or indirectly move said first plate element (2) independently of location of said second plate element (3) and said second plate element (3) is arranged to be moved as dependent on the movements of said first plate element (2) only.

Owner:PLANMECA

Tool cabinet

InactiveUS20070007867A1Simple structureConvenient to assembleFurniture partsFolding cabinetsBackplaneMechanical engineering

Owner:ZHEJIANG LIMAI METAL PRODS

Limiting An X-Ray Beam In Connection With Dental Imaging

ActiveUS20100119036A1Low costReasonable spaceHandling using diaphragms/collimetersTomographyX ray beamEngineering

The present invention relates to limiting an x-ray beam used in connection with dental extra oral imaging by a plate mechanism (1) arranged to be operated by a drive mechanism including an actuator (3) arranged to move at least one plate element (2, 3) comprised in the mechanism (1). The plate mechanism (1) includes at least a first and a second plate element (2, 3) which include at least a first slot (12) and a second slot (13), respectively, and said drive mechanism is arranged to directly or indirectly move said first plate element (2) independently of location of said second plate element (3) and said second plate element (3) is arranged to be moved as dependent on the movements of said first plate element (2) only.

Owner:PLANMECA

Double-crank three-dimensional rotating garage structure

The invention discloses a double-crank three-dimensional rotating garage structure, which belongs to the field of traffic facilities. A double-crank parallelogram mechanism is adopted: according to a principle that if a rack of the mechanism is horizontal, the lengths of the two cranks are equal, and the length of a connecting rod is equal to the length of the rack, no matter where the cranks rotate, the trajectory of the connecting rod is also horizontal, the parallelogram mechanism is formed through three-dimensional deformation. Because the mechanism rotates but a platform thereof is always horizontal, the problem of platform stability is solved, and the space can be reasonably arranged, therefore, as vehicles are increasing today, the rotating garage structure as another kind of three-dimensional rotating garage has reasons for being. The platform also can be applied to various fields such as various logistics delivery and factory flow lines and workbenches and the like.

Owner:CHONGQING JIAOTONG UNIVERSITY

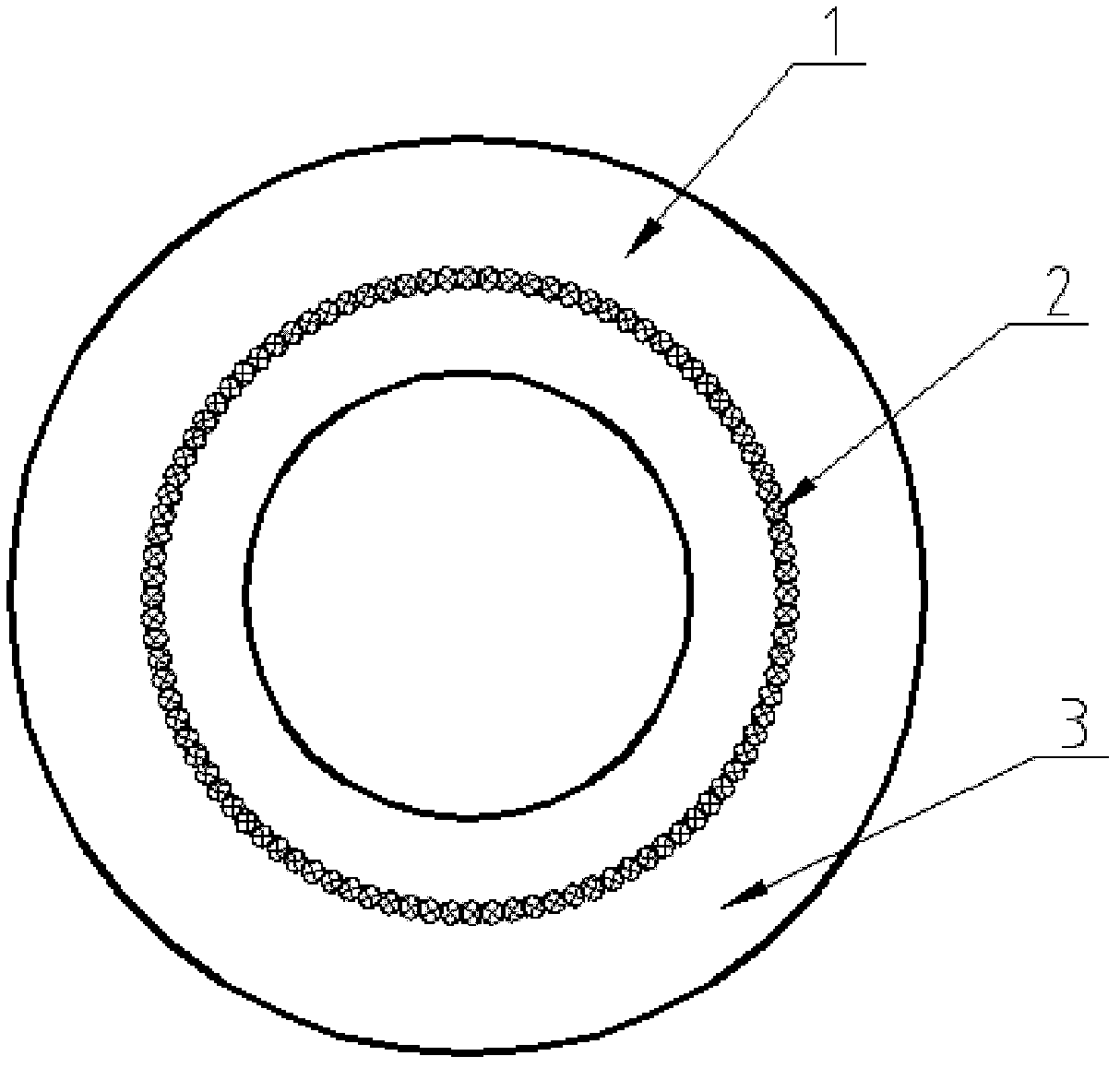

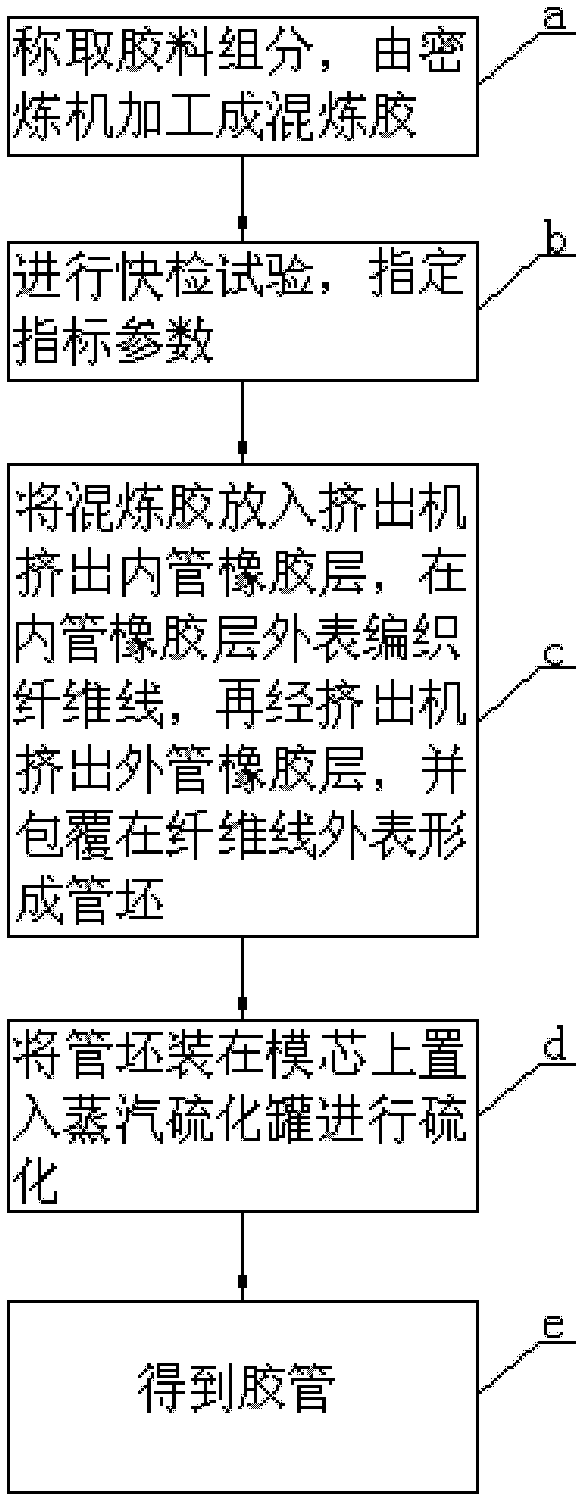

High-pressure power steering gear rubber tube and manufacturing process thereof

ActiveCN102628531AGood oil resistanceExcellent heat and aging resistanceFlexible pipesTubular articlesFiberVulcanization

The invention relates to the technical filed of automotive part manufacture, in particular to a high-pressure power steering gear rubber tube and a manufacturing process of the high-pressure power steering gear rubber tube. The high-pressure power steering gear rubber tube is formed by sequentially compositing an inner pipe rubber layer, a fiber wire enhancement layer and an outer pipe rubber layer from inside to outside. The main sizing material is chlorosulfonated polyethylene rubber (CSM). Each layer of rubber enables a banburying machine to be manufactured into rubber compounds to be compounded and extruded, two copies of fiber wires are weaved on the outer surface of the inner pipe rubber layer, then a pipe blank is formed by extruding the outer pipe rubber layer and wrapping on the surface of the fiber wire, the pipe blank is sleeved on a pipe die core to be arranged in a steam vulcanization tank for vulcanization, and the rubber pipe is obtained after depoling and level pressure of the pipe blank. The high-pressure power steering gear rubber tube has the advantages of being heat-resisting, oil-resisting, voltage-resisting, age-resisting, good in pulse performance, low in manufacture cost and high in percent of pass, and greatly meeting development requirements of modern automotives.

Owner:ZHEJIANG JUNHE RUBBER TECH

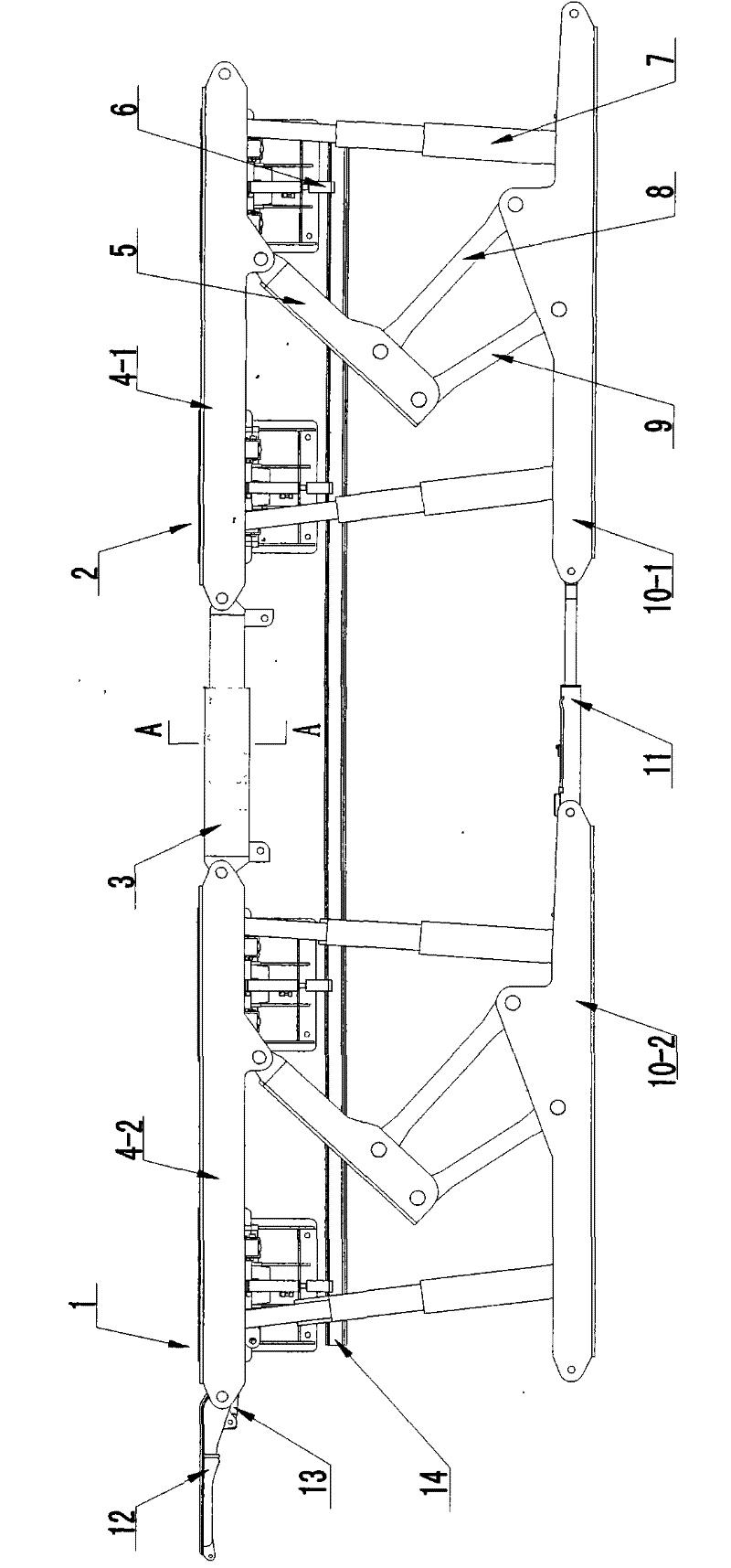

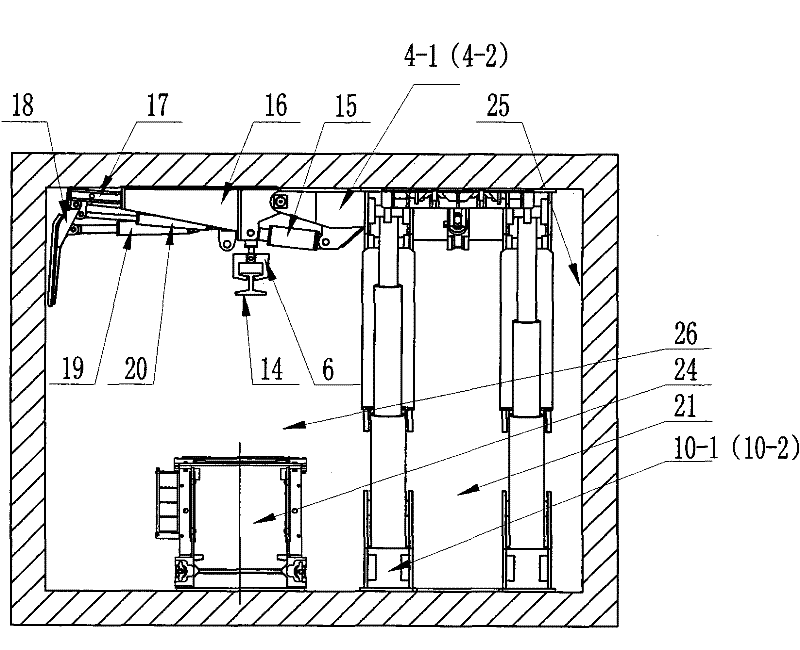

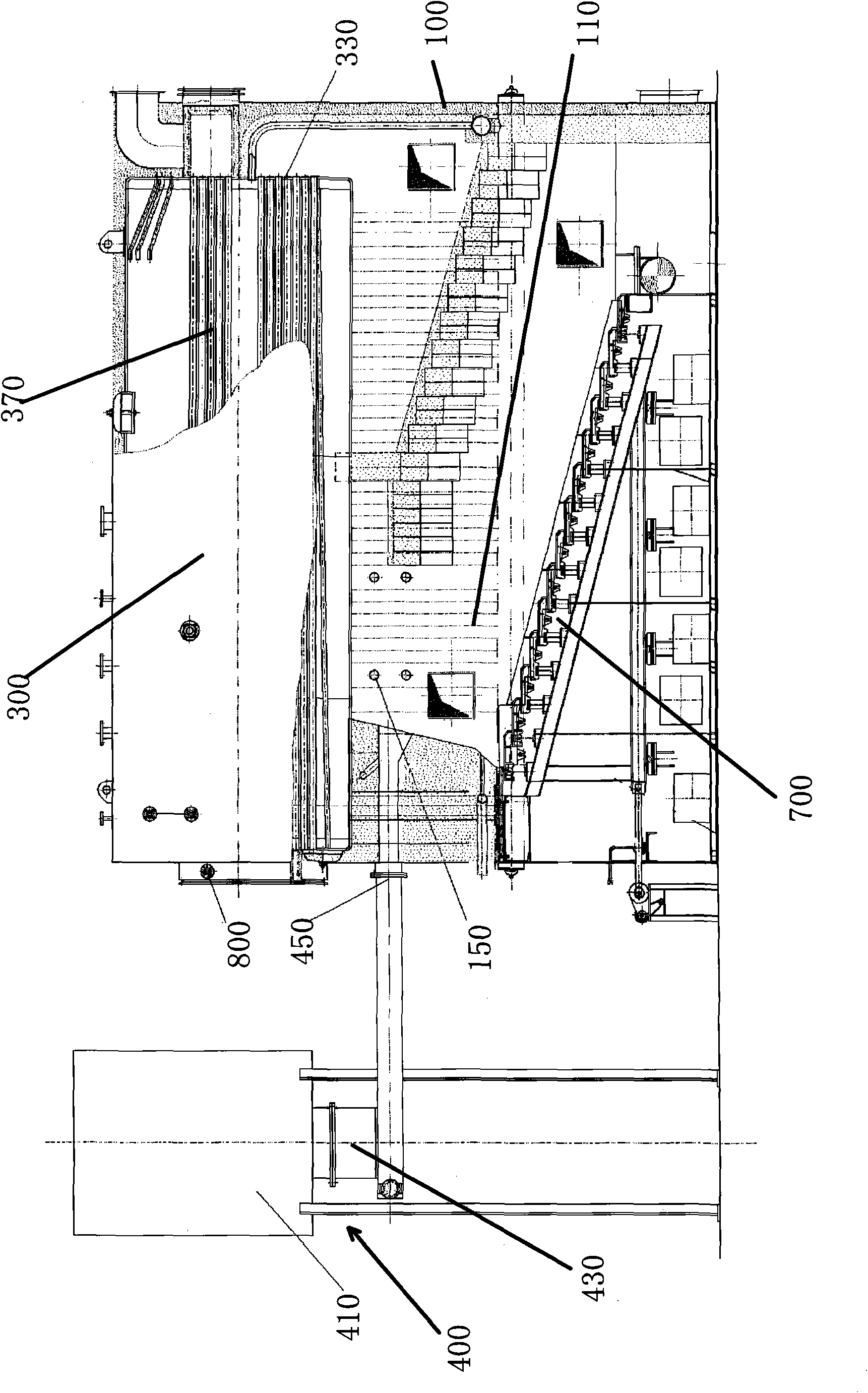

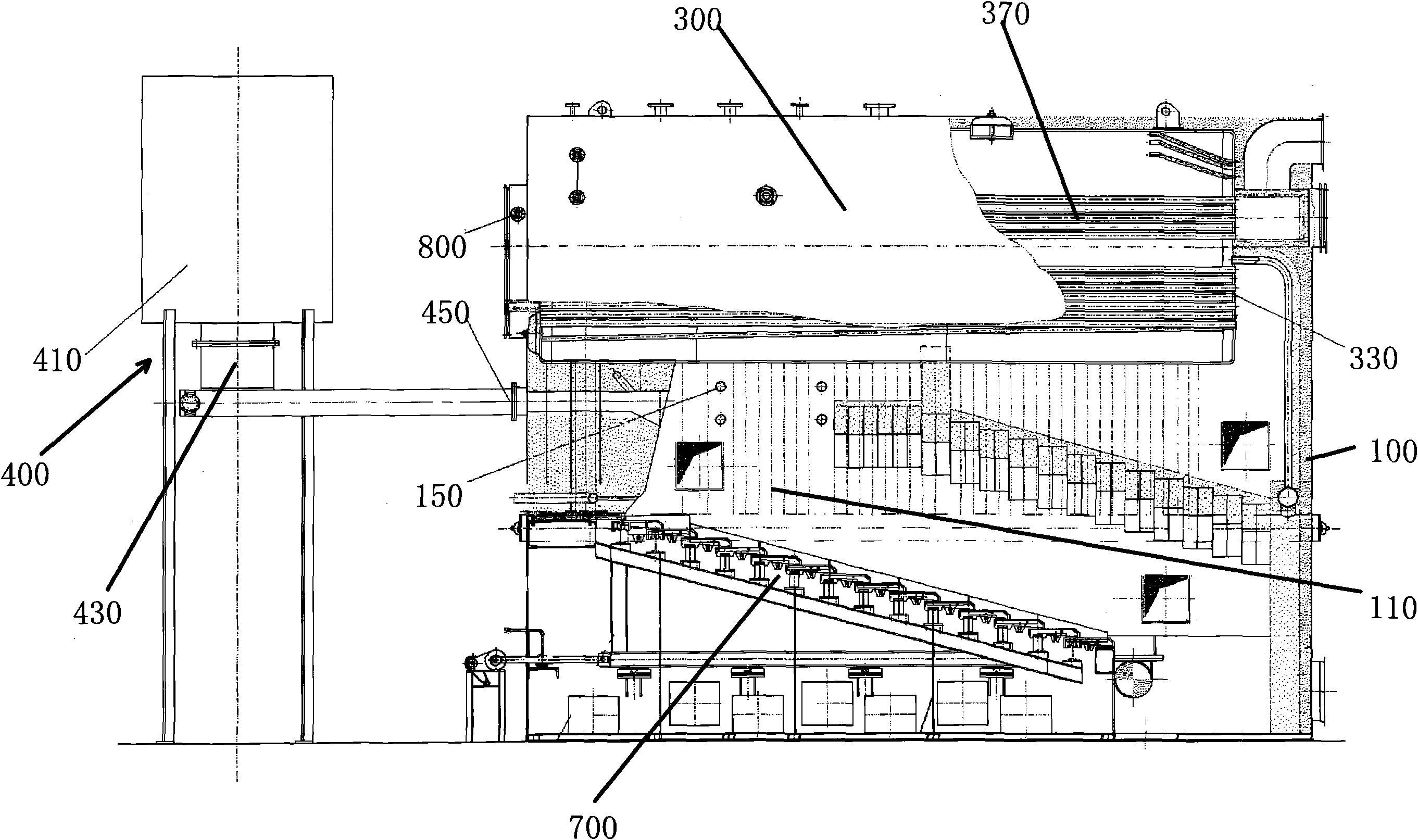

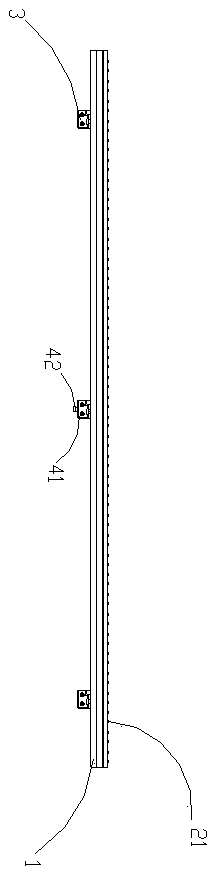

Advance support bracket set special for conveyor gateway on fully-mechanized coal mining working surface

InactiveCN102207003AReduce labor intensityImprove support strengthMine roof supportsPush pullJackscrew

The invention relates to the field of advance support equipment, in particular to an advance support bracket set special for a conveyor gateway on a fully-mechanized coal mining working surface. The bracket set is at least composed of two hydraulic bracket units. Lower parts between the hydraulic bracket units are connected through a push-pull jack. Upper parts between the hydraulic bracket units are connected through a drawer sliding beam mechanism. Bottoms of hydraulic upright posts of the hydraulic bracket units are hinged with a base. Tops of the hydraulic upright posts are hinged with a top beam. The bottom of the top beam is hinged with a shield beam. The lower part of the shield beam is hinged with the base through a front connecting rod and a rear connecting rod. A lateral protective beam unit is also hinged with the side surface of the top beam. An edge protection plate is hinged with the front end of the lateral protective beam unit. According to the invention, the problems that the advance support bracket set special for the conveyor gateway on the fully-mechanized coal mining working surface is difficult to arrange, is even interfered with equipment in the conveyor gateway, and the like because of the factors of concentrated equipment in the conveyor gateway, narrow space, high reciprocating movement quantity of the head of a scraper machine and an elevating conveyor along a coal flow direction of the working surface and so on can be solved effectively. The mechanized support is realized.

Owner:SANY HEAVY EQUIP

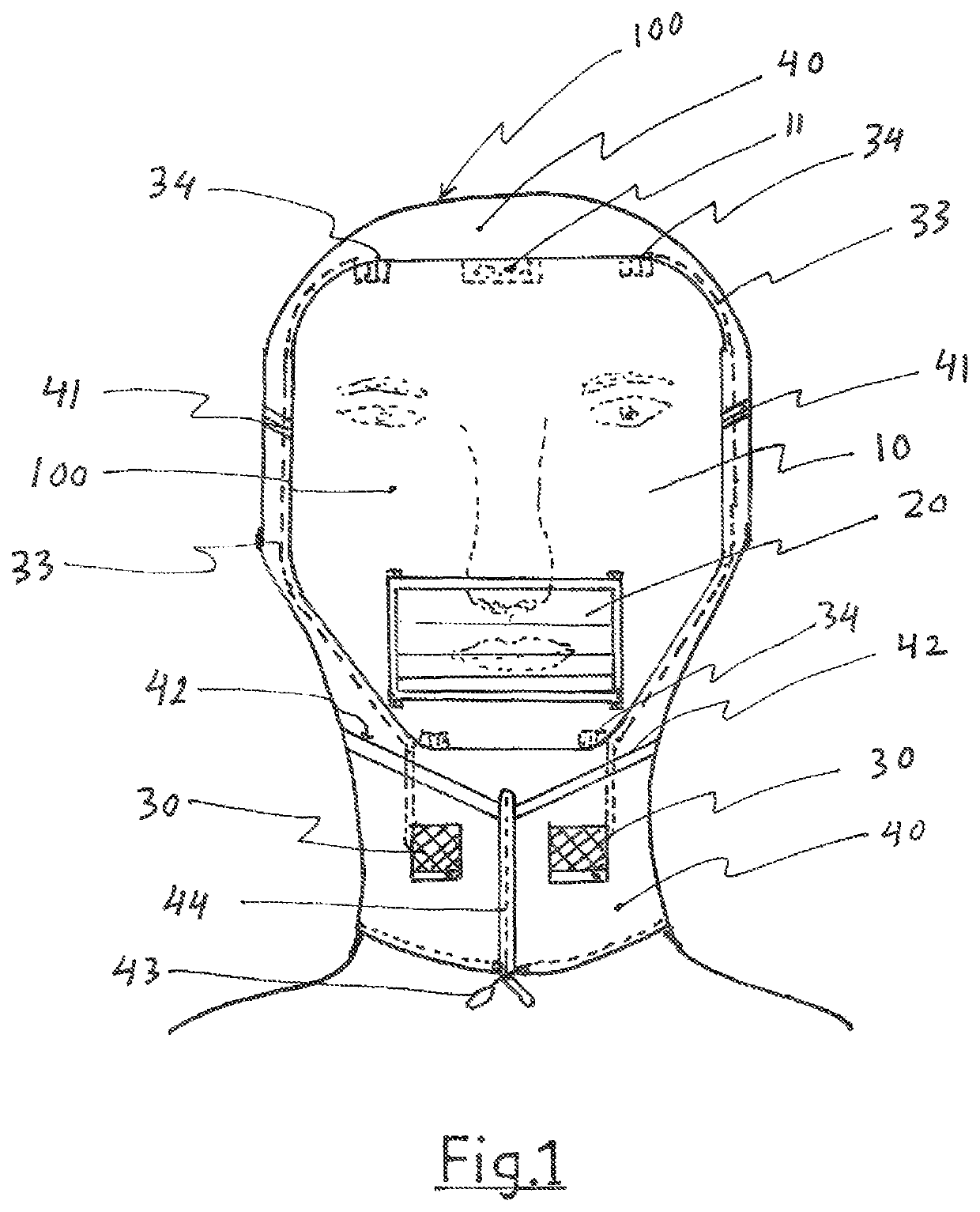

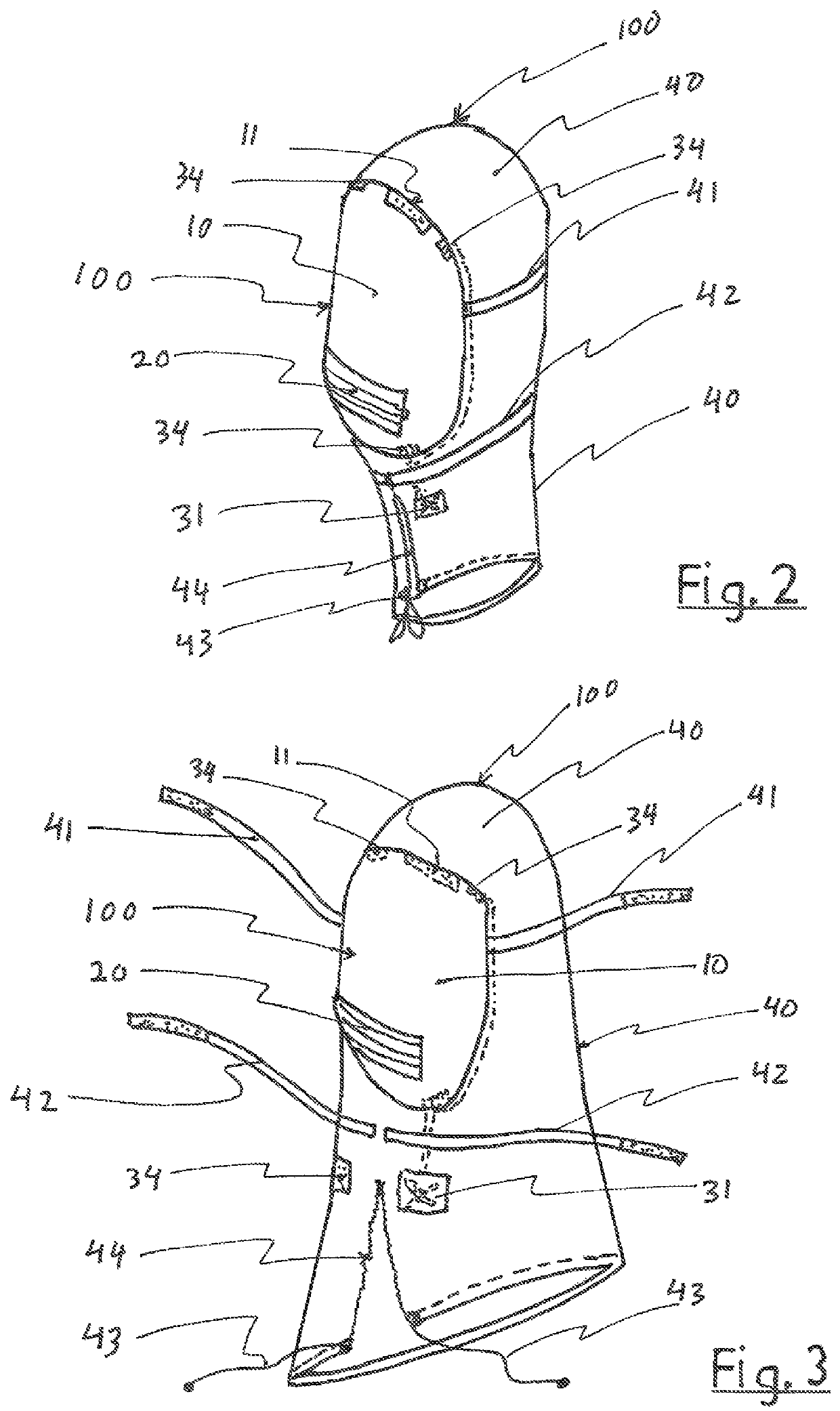

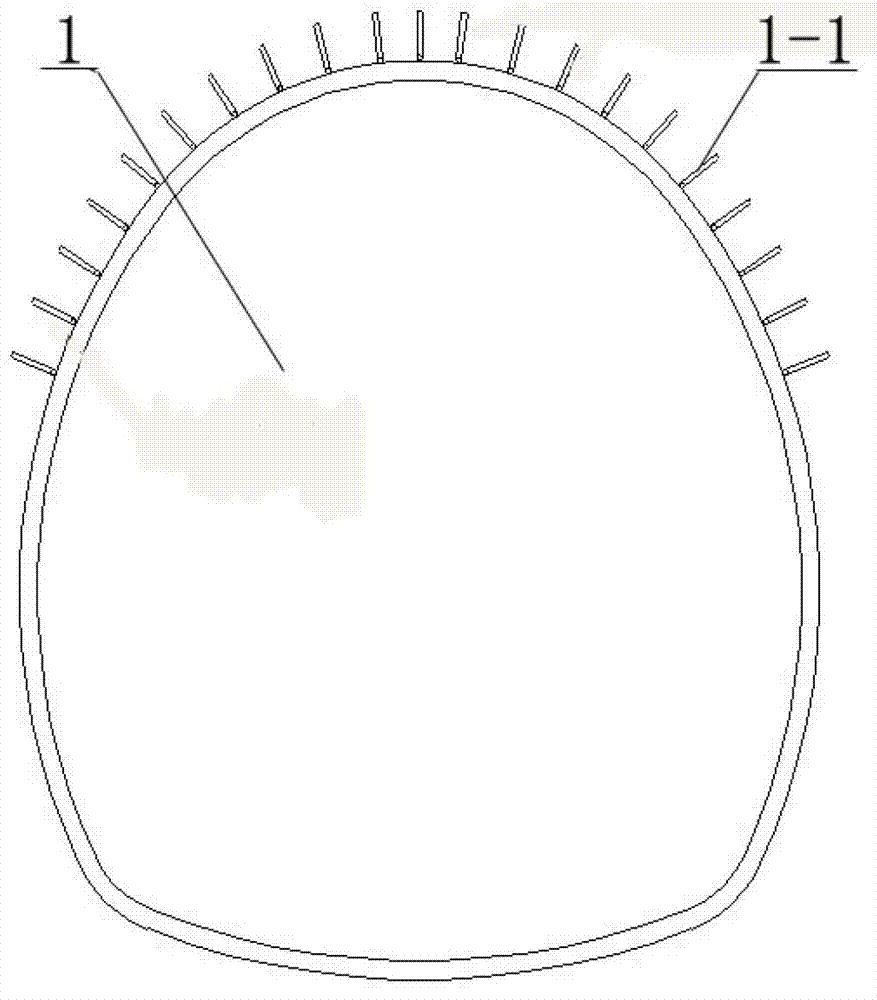

Full face and head mask

ActiveUS11202925B1Effective protectionImprove ventilationChemical protectionHeat protectionMedicineEyewear

A multi-purpose protection mask for protecting the human face and head against viruses, bacteria, dust or environmental harsh impacts is presented. It has four elements. A face shield transparent sheet covers comfortably the user's face providing adequate space for freely breathing and wearing glasses. A removable and replaceable filter mask element which is a multi-layer filter piece of a proper material affixed over an opening window in the face shield. A ventilator for draining and filtering the exhalation air and humidity before dumping into the atmosphere and it consists of exhaust fans, suction tubes, suction vents, and exit filters. The ventilator prevents condensation of fogging on the face shield and glasses. Another element is a head cover mask made of a fabric material affixed to the face shield element. Fastener strips means are provided for keeping the face shield comfortable and stable on the wearer's face.

Owner:AWAD WADIE M

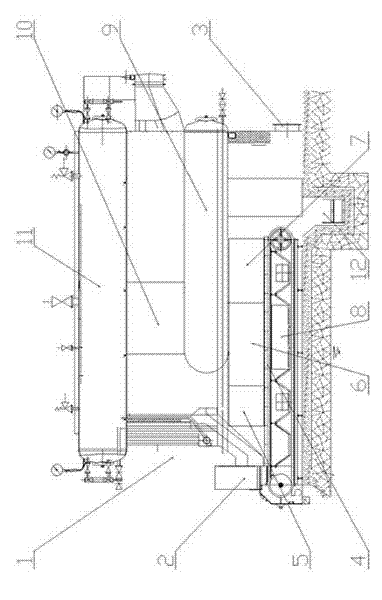

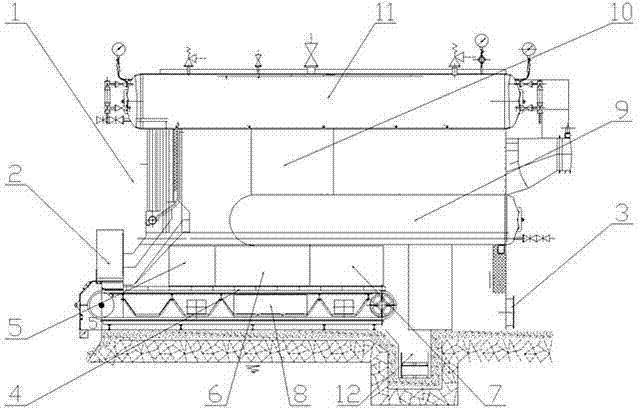

Steam boiler capable of burning biomass

InactiveCN101881433AHigh heat resistanceBig spaceTravelling grateAir/fuel supply for combustionCombustionHearth

The invention discloses a steam boiler capable of burning biomass, comprising a boiler body, a loading system and a vapour-water pipe system, wherein the boiler body is provided with a hearth in which the biomass fuel burns so as to release heat and a heat exchange device positioned above the hearth; the loading system is connected with the boiler body so as to convey the biomass fuel to the hearth for burning; the vapour-water pipe system is connected with the heat exchange device so as to exchange heat generated by the burning of the biomass; the hearth is internally provided with a reciprocal grate which downward slopes relatively to the level in an angle of inclination of 5-25 degrees from the end of the hearth close to the loading system to the far end far away from the loading system so as to enable the biomass fuel falling on the fire grate to be pushed and extruded and to roll relatively to the fire grate. In the invention, the fire grate moves relatively to fuel, the fuel is constantly extruded in the process of being pushed so as to damage coke and ash shells; and the fuel rolls slowly, thereby enabling the material layer to be loosened and facilitating full combustion.

Owner:GUANGZHOU DEVOTION THERMAL TECH

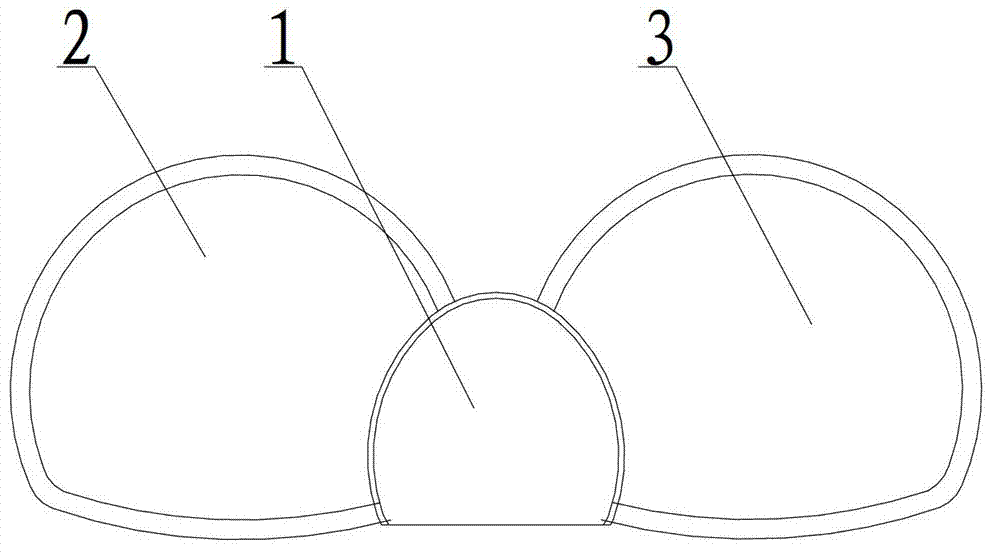

Method for quickening construction of multiple-arch tunnel

ActiveCN103244127ASave the construction period of entering the holeShorten the construction periodTunnelsDischarge efficiencyBuilding construction

The invention relates to a method for quickening construction of a multiple-arch tunnel. The method includes: firstly, pre-supporting a middle pilot tunnel; and secondly, excavating the middle pilot tunnel, constructing a left main tunnel, a right main tunnel, and a cover arch and a long pipe roof of the middle pilot tunnel, setting a widened segment allowing a loader to turn around in the middle of the middle pilot tunnel, and after the middle pilot tunnel is through, constructing a middle partition wall from an entrance of the middle pilot tunnel to an exit of the middle pilot tunnel. The method has the advantages that construction entering is assisted by advanced small pilot pipes so that entering construction period of the middle pilot tunnel is reduced; the section of the middle pilot tunnel is locally enlarged, the loader is used with a dumper for construction, and accordingly residue discharging efficiency is improved greatly; the construction method of the middle partition wall is modified, so that the main tunnels can be constructed in advance; and the middle partition wall and the main tunnels are constructed in parallel, time and space are more reasonable, and accordingly personnel idleness and machine idleness are avoided and construction speed is increased.

Owner:CHINA COMM NORTH ROAD & BRIDGE +1

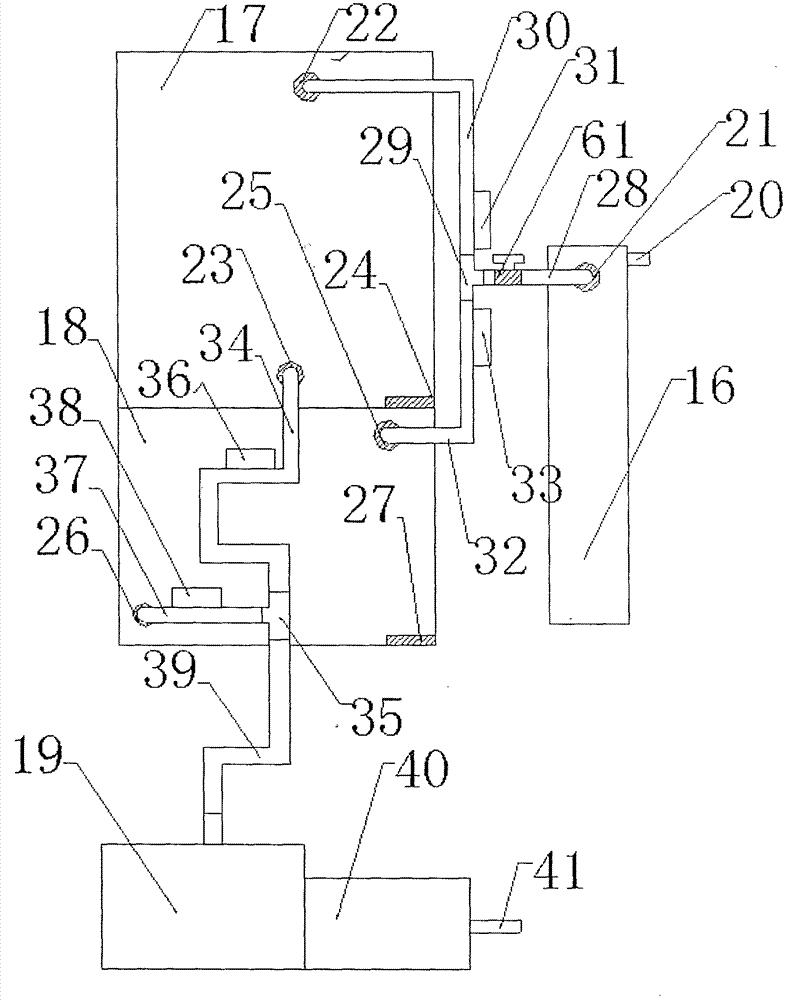

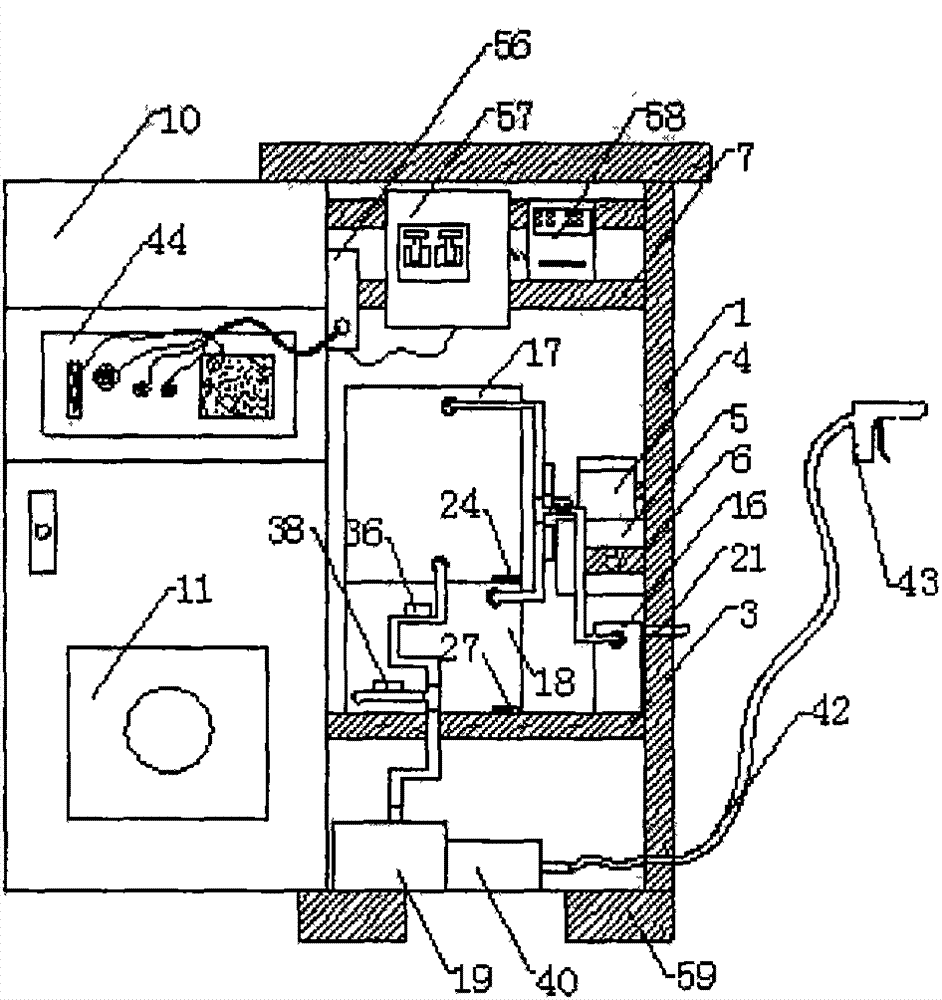

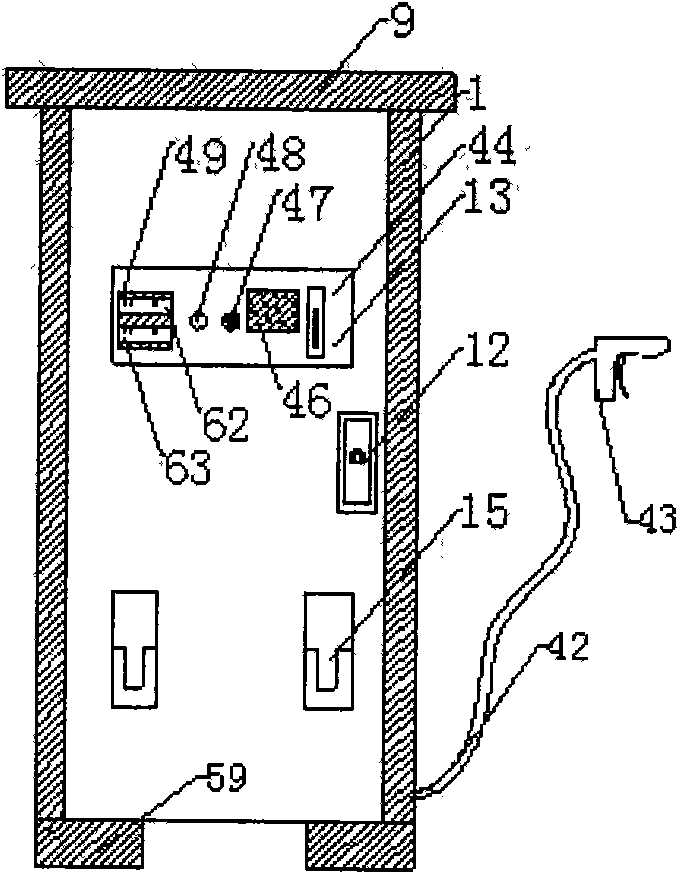

Self-service car washer

ActiveCN104299326AProtection securityEnsure safetyApparatus for meter-controlled dispensingControl valvesSelf-service

The invention relates to a self-service car washer. The self-service car washer comprises a machine body device used for supporting, an intelligent water control device used for conducting car washing, and a control device used for switching of car washing functions, wherein the machine body device comprises a case body, a supporting frame and a bearing cross beam are arranged inside the case body, a one-way openable door is further arranged on the case body, a panel window is arranged on the one-way openable door, the intelligent water control device comprises a filter, a water tank and a washing fluid tank, the filter, the water tank and the washing fluid tank are connected through guide pipes, a pressure sensor A and a pressure sensor B are arranged on the bottom of the water tank and on the bottom of the washing fluid tank and are connected through a control valve A and a control valve B, the control device comprises a panel body, a water outlet control key, a bubble outlet control key, a magnetic card sensing area and a coin slot are arranged on the panel body, and then diversified consumption of customers is facilitated. The self-service car washer has the advantages of being simple in structure, convenient to use and complete in function.

Owner:訾伟旗

Folding hanger and electronic equipment

ActiveCN106900160AFunction increaseFirmly connectedSupport structure mountingTelecommunicationsElastic component

The invention provides a folding hanger and electronic equipment. The folding hanger comprises a bending board, a connection component, an elastic component and a panel body, wherein the bending board comprises a mounting board and a connection board which are fixedly connected, the connection component is fixedly arranged on the connection board, the elastic component is connected between the connection component and the panel body, and the connection component and the panel body are clamped. The folding hanger is advantaged in that ports on a panel and pluggable modules can be made to realize high-density distribution, resource waste can be avoided, and product competitiveness is improved.

Owner:NEW H3C TECH CO LTD

Tool cabinet

InactiveUS7559614B2Simple structureEasy to assembleFurniture partsFolding cabinetsMechanical engineering

Owner:ZHEJIANG LIMAI METAL PRODS

Plastic guardrail plate mould and plastic guardrail plate molding process adopting mould

InactiveCN101804689AEnsure safetyReduce maintenance costsDomestic articlesPlastic bagMaterials science

The invention relates to a plastic guardrail plate mould which comprises n layers of plastic rib passages, n+1 layers of molten plastic passages and molten plastic filling passages, wherein the n layers of plastic rib passages for arranging plastic ribs are molded inside the mould, the n+1 layers of molten plastic passages are used for molding molten plastics of a plate body, and the molten plastic filling passages for filling the molten plastics are communicated with the inlets of the molten plastic passages; the plastic rib passages and the molten plastic passages are alternately arranged, and each layer of plastic rib passage is clamped between the molten plastic passages; and the plastic rib passages and the molten plastic passages are converged at the molding outlet of a plastic guardrail plate at the outlet end of the mould, wherein the n is a natural number larger than or equal to 1. The invention solves the technical problem that the physical characteristic of the plastic ribs is difficult to ensure in the process of manufacturing the plastic guardrail plate containing the plastic ribs.

Owner:井志田

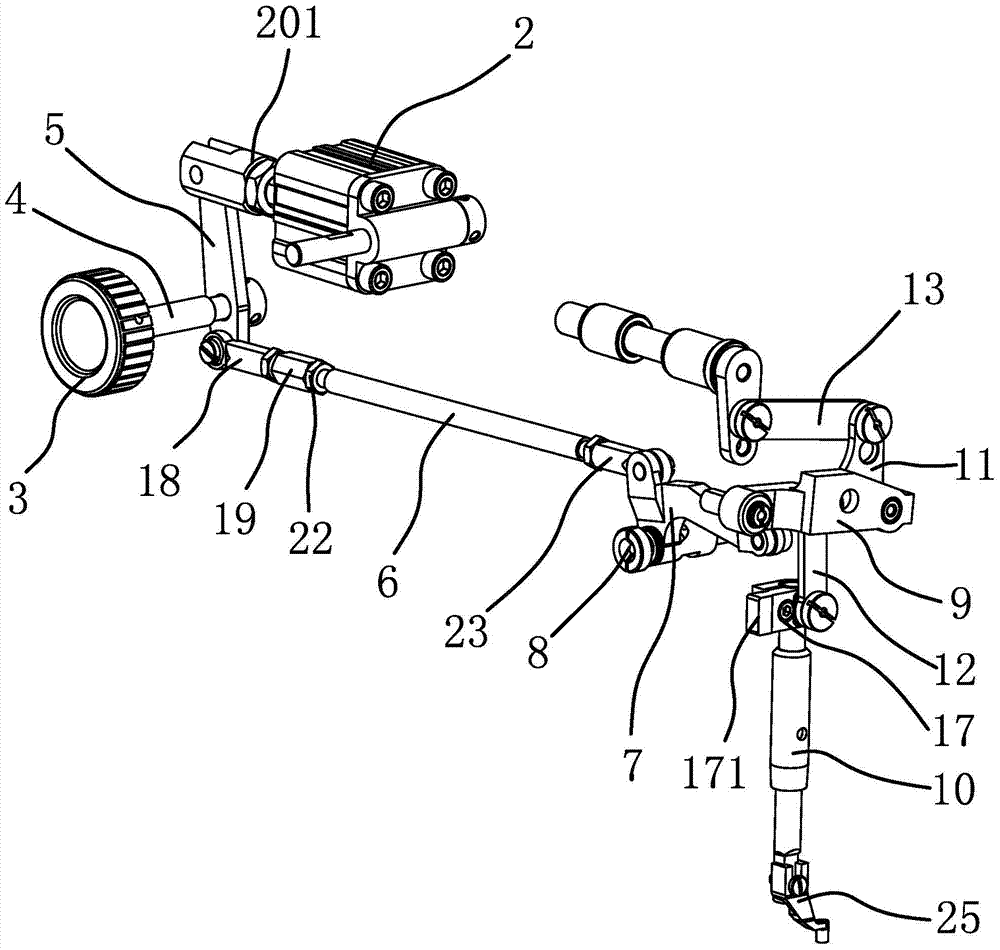

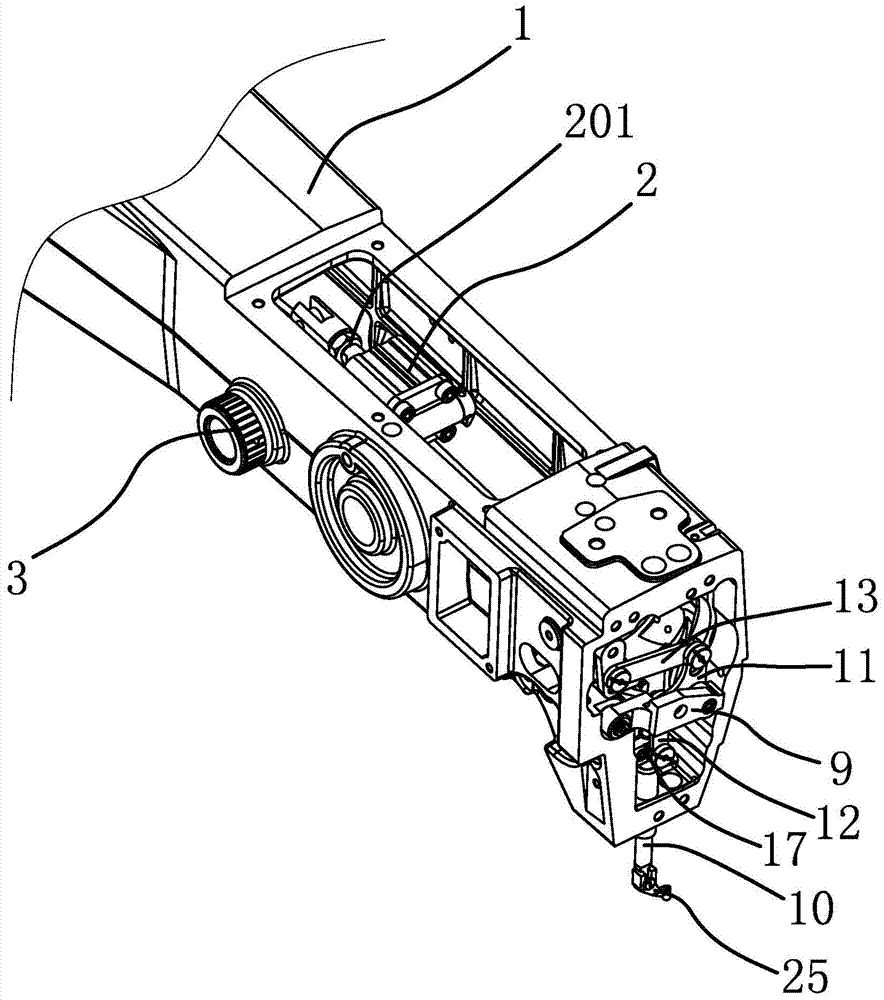

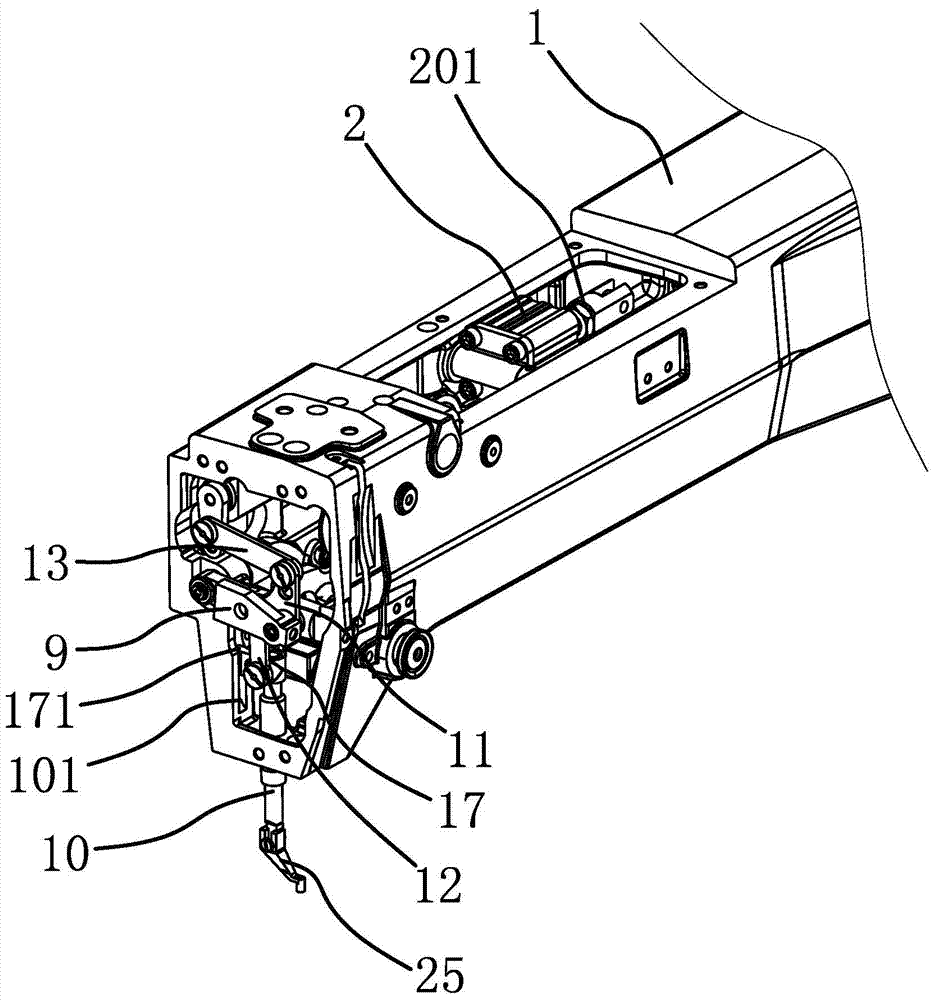

Presser foot height adjusting mechanism for sewing machine

The invention provides a presser foot height adjusting mechanism for a sewing machine and belongs to the technical field of sewing machine manufacturing. The adjusting mechanism solves the problem that the height of a presser foot of an existing sewing machine is hard to adjust. The sewing machine comprises a machine head and a cylinder, wherein the cylinder is fixed in the machine head, the outer end of a piston rod of the cylinder is hinged to the top of a lifting lever, and the bottom of the lifting lever is connected with a presser foot through a lifting connecting rod, an intermittent lifting rod, a connecting plate and a pressing rod. The adjusting mechanism comprises a stitch length scaleplate and an adjusting shaft, wherein the stitch length scaleplate is located on the outer wall of the machine head and is connected with the lower middle portion of the lifting lever through the adjusting shaft, the lifting lever rotates around the adjusting shaft, and the presser foot can be driven to move up and down by rotating the stitch length scaleplate. The mechanism has the advantage that the height of the presser foot is convenient to adjust.

Owner:浙江长兴绿色电池科技有限公司

Unpowered roller conveying platform

The invention discloses an unpowered roller conveying platform which can be detachably connected with a rack. The unpowered roller conveying platform comprises a bracket and a plurality of roller mechanisms arranged on the bracket, and the roller mechanisms are arranged on the bracket in an array type. According to the unpowered roller conveying platform, the platform composed of the bracket and the roller mechanisms is used for replacing a traditional conveying platform, rolling of rollers in the roller mechanisms drives products to be processed to move forwards to achieve the conveying process, power is needless in the conveying process, power consumption is lowered, and cost is saved.

Owner:SUZHOU IND ROBOT TECH

Unsaturated polyester resin with excellent insulating property, and preparation method thereof

The present invention discloses an unsaturated polyester resin with excellent insulating property, wherein the raw materials comprise maleic anhydride, m-phthalic anhydride, tetrachlorophthalic anhydride, a D-33 monomer, pyrogallol, hydroquinone, cobalt naphthenate, styrene, phosphate melamine, methyl ethyl ketone peroxide, a silane coupling agent KH-550, nanometer titanium dioxide, nanometer alumina, micro-nano-fiber, raw ramie, palm fiber, a modified filler, ethylene glycol, diethylene glycol and propylene glycol. The present invention further provides a preparation method of the unsaturated polyester resin with excellent insulating property. The prepared unsaturated polyester resin of the present invention has excellent insulating property.

Owner:滁州常源新材料有限公司

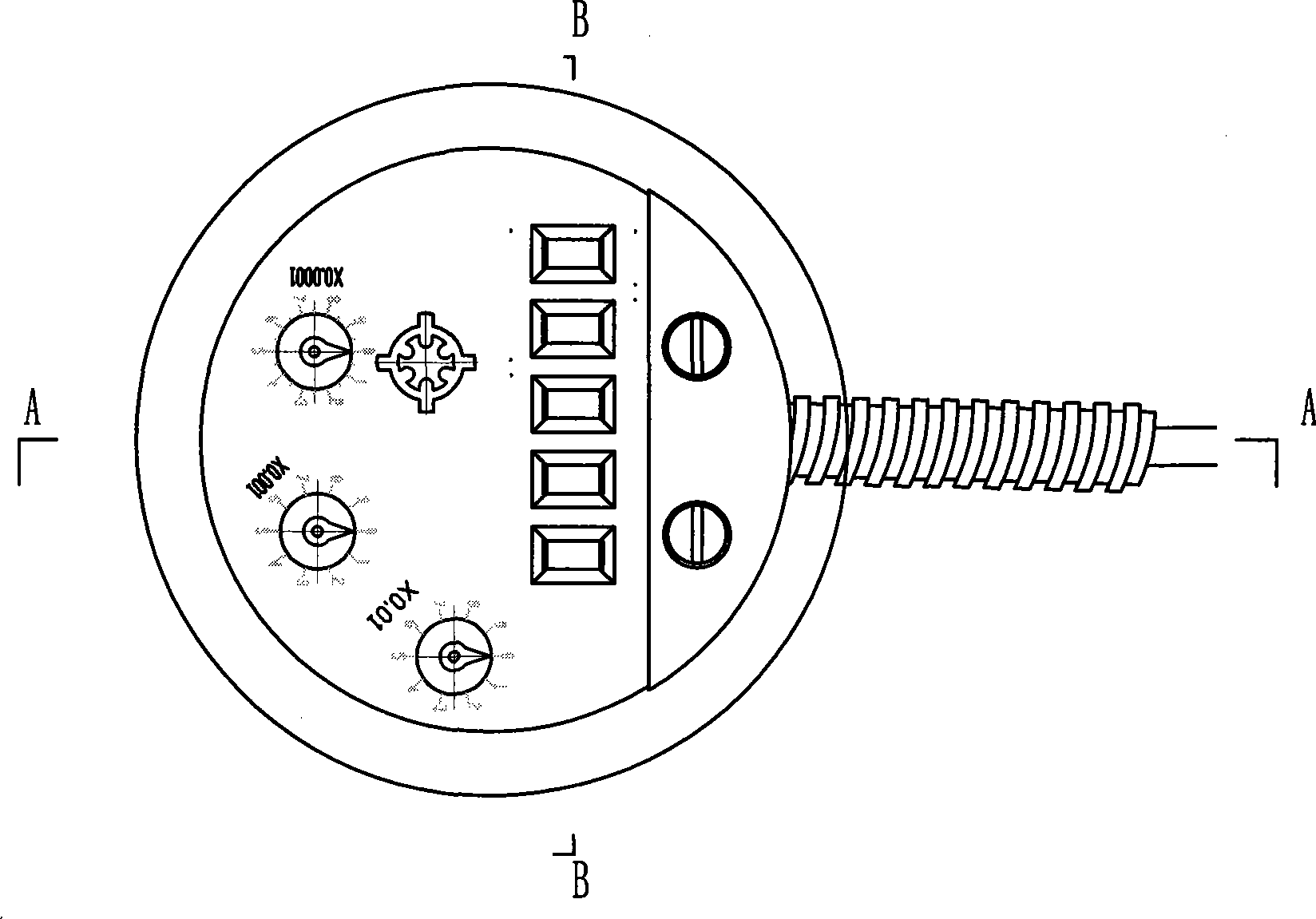

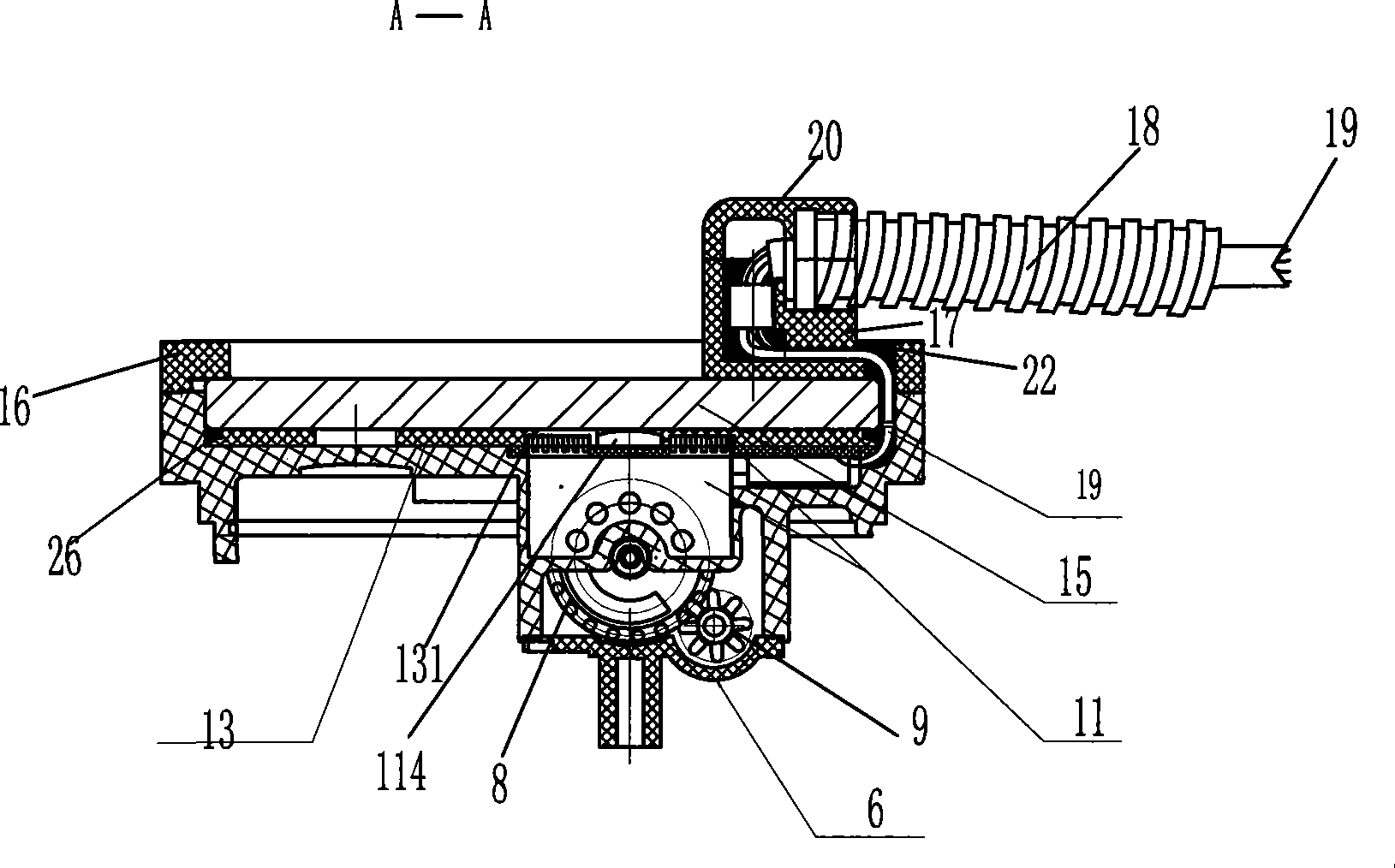

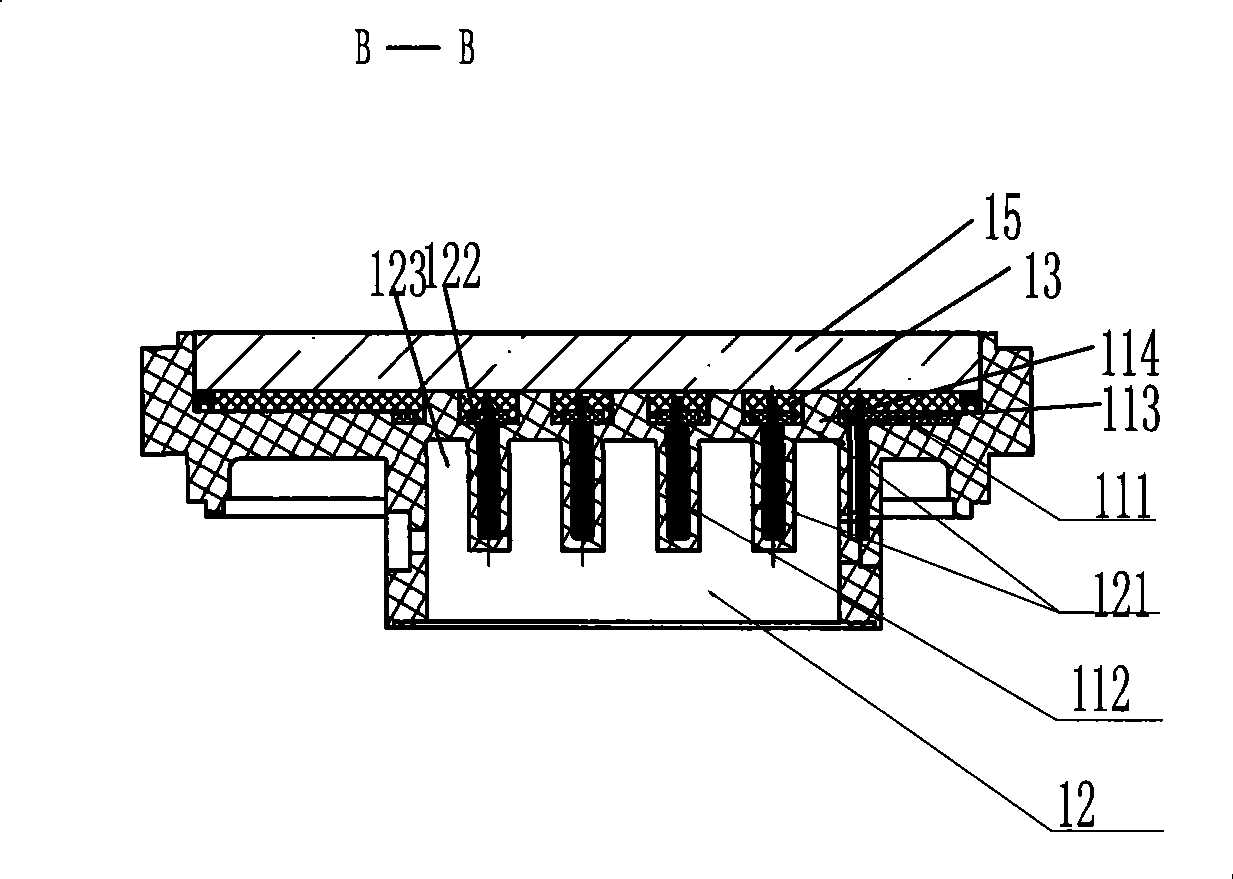

Liquid seal electronic direct-reading water meter

InactiveCN101368832AEffective protectionAvoid Insufficient SealingVolume indication and recording devicesVolume/mass flow by mechanical effectsImpellerEngineering

A liquid sealed electronic direct reading water meter comprises a dial, a photovoltaic module, a counting mechanism of a liquid sealed character wheel box, and an impeller measuring mechanism with upper and lower splints; the photovoltaic module is arranged above the liquid sealed character wheel box and separated from the character wheel by a partition board with interval grooves on both sides; a photovoltaic panel of the photovoltaic module at the upper part and the character wheel at the lower part are respectively positioned at both sides of the partition board and are corresponding to each other; and the corresponding positions on the photovoltaic module corresponding to the figures on the character wheel are provided with openings or are transparent. The liquid sealed electronic direct reading water meter has the advantages of effectively protecting the photovoltaic module and overcoming the disadvantage that the original structure needs to use special glue layer to seal the photovoltaic module, under the premise of ensuring a clear reading; besides, the production of the water meter is simpler, so that the production efficiency can be improved and the production cost is reduced; at the same time, the lead wire of the photovoltaic module can be directly and easily educed out, and has lower sealing requirements. Only a simple sealing at the lead wire position can easily and rapidly solve the sealing problem of the entire photovoltaic module space.

Owner:NINGBO KEYTURE TECH CO LTD

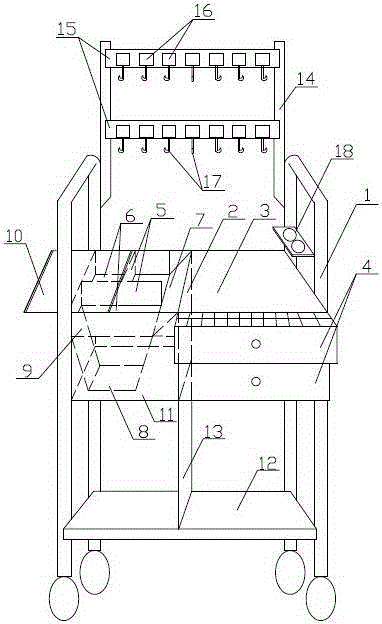

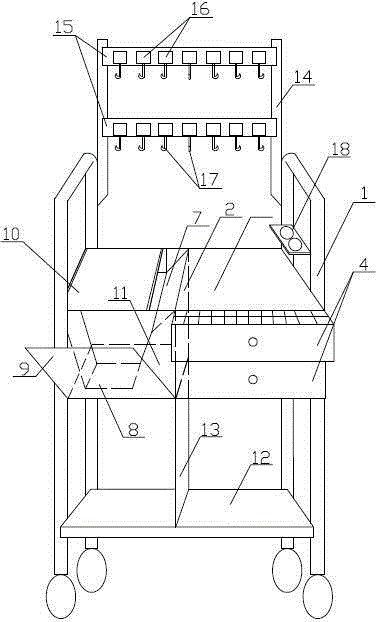

Medical treatment vehicle with function division effect

The invention relates to a medical treatment vehicle with the function division effect and belongs to the technical field of medical equipment. Function division is conducted on the treatment vehicle. An operation and storage region is separated from a rubbish storage region, the structure is reasonable, tabletops of the two regions have a height difference, a slope is adopted for buffering, division of the operation and storage region and the rubbish storage region is obvious, and cross contamination is avoided; the two regions are both arranged at the upper portion of the treatment vehicle, and therefore occupational diseases caused when medical staff continuously lower the heads and stoop can be avoided; rubbish can be stored through the structure of the rubbish storage region, storage motion is conducted in the rubbish storage region, the operation and storage region is not polluted, and use is reliable and safe.

Owner:THE WEST CHINA SECOND UNIV HOSPITAL OF SICHUAN

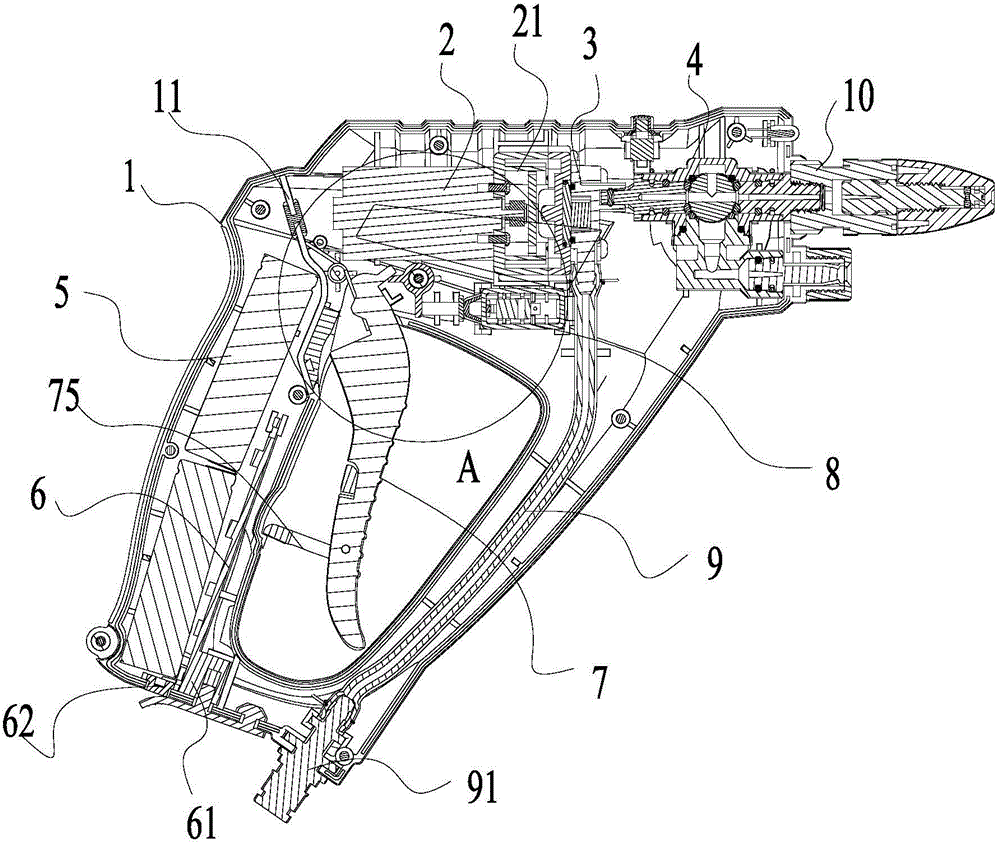

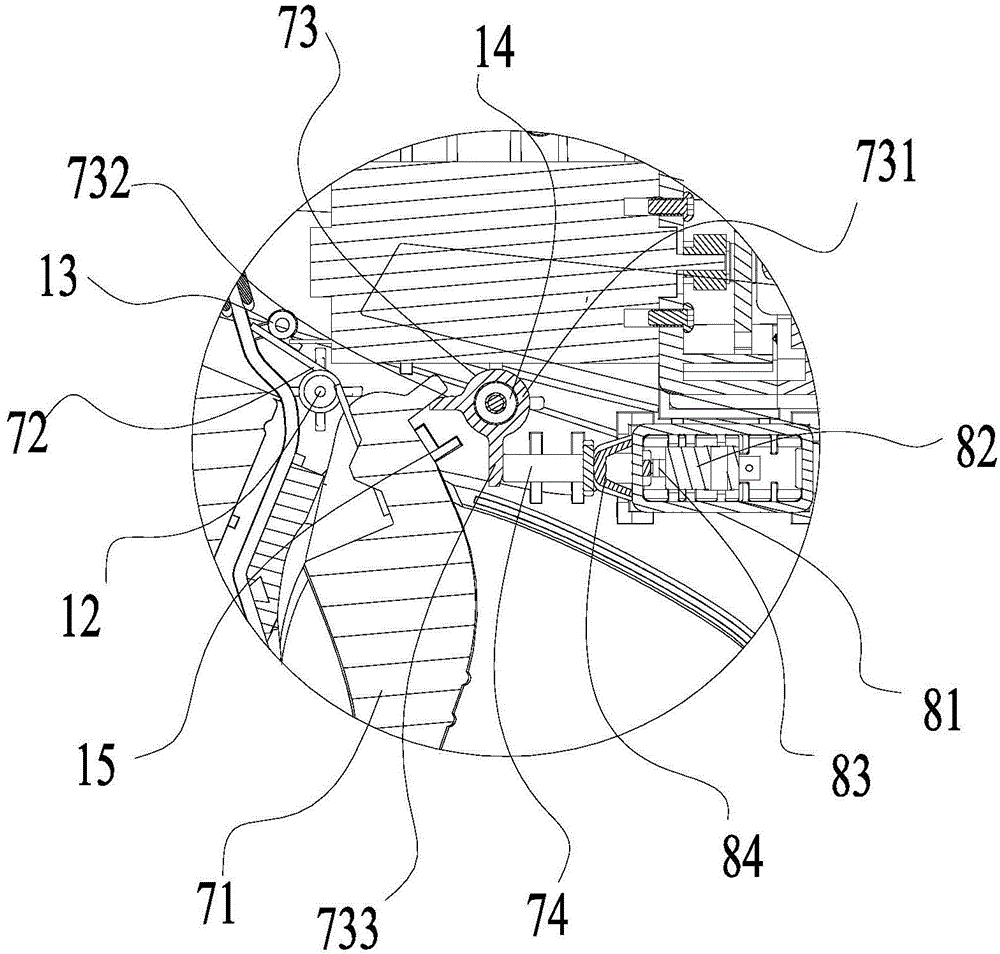

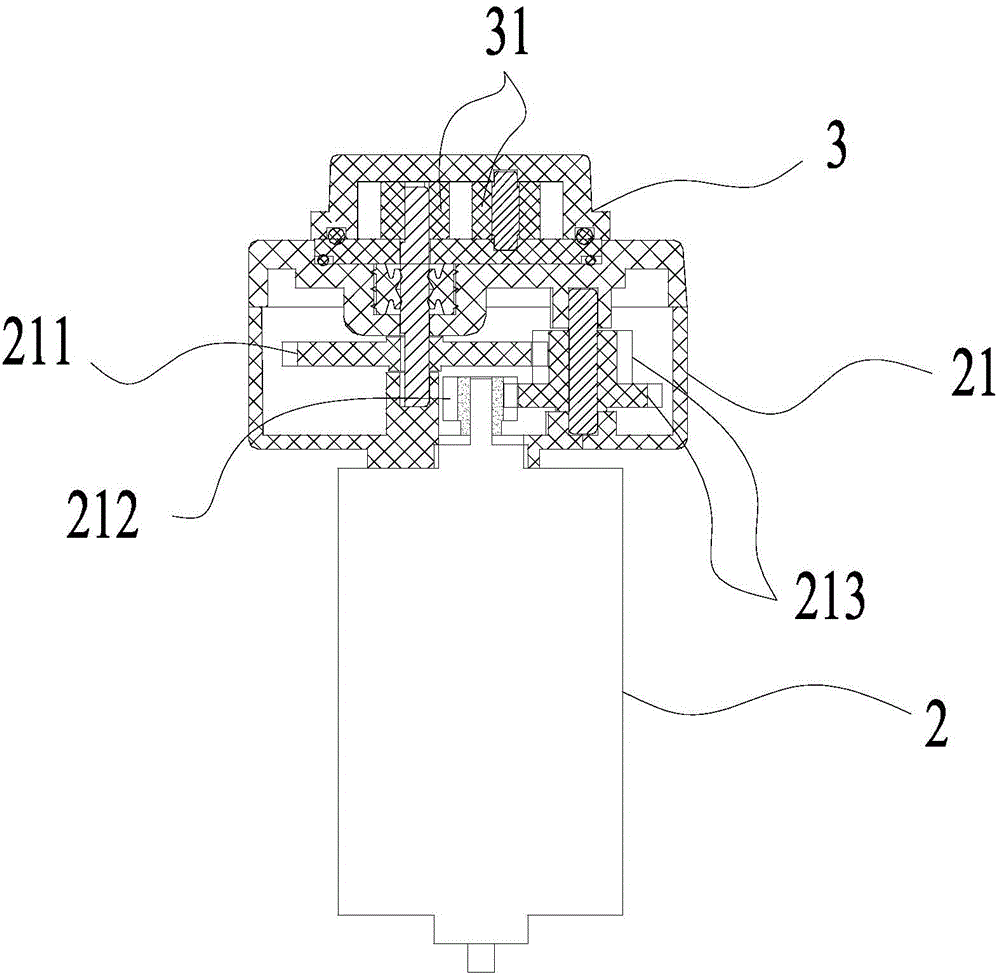

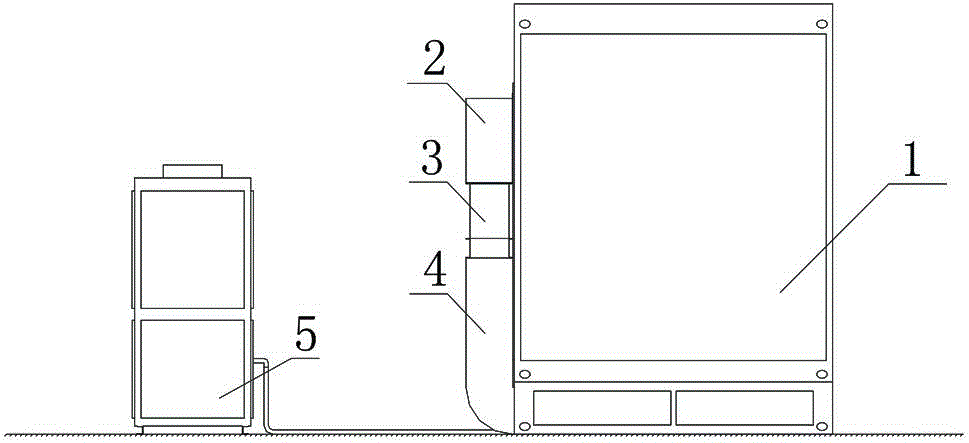

Spraying gun for sprayer

ActiveCN104858081ACompact structureReliable functionLiquid spraying apparatusSprayerElectric machinery

The invention discloses a spraying gun for a sprayer. The spraying gun comprises a gun body with a trigger device. A detachable rapid-replacing spraying nozzle is arranged at the front part of the gun body, and the gun body is internally provided with a motor (2), a water pump (3), a control valve (4) and a power supply device. A water inlet of the water pump (3) is connected with a water inlet pipe (9), and a water outlet of the water pump (3) is connected to the rapid-replacing spraying nozzle through the control valve (4). The trigger device comprises a wrench (71) pivoted to the gun body, a transmission mechanism and a reset mechanism (72), the gun body is provided with a limiting part (15), the wrench (71) is arranged between the reset mechanism (72) and the limiting part (15), the wrench (71) is used for controlling a microswitch (82) for the work of the motor to be in a normally-open state under the un-triggered condition, and in the using process, the microswitch (82) is triggered through the transmission mechanism after the wrench (71) is triggered. The spraying gun for the sprayer is reasonable in structure, compact in layout and reliable in function.

Owner:SUZHOU CROSSTEC CO LTD

Circulating heat radiation method of high-voltage frequency converter

InactiveCN104917355AImprove applicabilityHigh protection levelCooling/ventilation/heating modificationsPower conversion systemsFrequency conversionEngineering

The invention discloses a circulating heat radiation method of a high-voltage frequency converter. All devices of the high-frequency converter are mounted in a box-shaped frequency conversion chamber, heat generated during work of the high-frequency converter is led out in the air exhausting form, air is cooled outside the frequency conversion chamber and then sent into the frequency conversion chamber to carry out cooling, and thus, circulating heat radiation is formed. The circulating heat radiation method is good in heat radiation effect, high in environmental adaptability and low in operation cost.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

De-oiling furnace for waste oil catalyst

The invention discloses a de-oiling furnace for waste oil catalyst, comprising a furnace body; the furnace body is provided with a material inlet and a material outlet; a furnace grate for sending material is disposed in the furnace body; wherein the material inlet and the material outlet are both provided with a cooling device; and a pre-heating chamber, a burning chamber and a cooling chamber are orderly arranged between the material inlet and the material outlet; a firebrick layer is set in the burning chamber; and the furnace wall of the burning chamber is provided with a ventilation door connected with a ventilation room; and the end part of the furnace grate is further provided with a slag remover; a water heating pot cylinder is disposed in the furnace above the burning chamber; the water heating pot cylinder is provided with a drainage pipeline. The invention is featured in simple structure and smart design; the oil, sulfur and carbon compound are removed from the waste oil catalyst by the way of burning; and the heat produced by waste heat is used for heating the media, so as to supply industrial production or other occasions which need high-temperature media.

Owner:DALIAN DONGTAI RESOURCE RENEWABLE

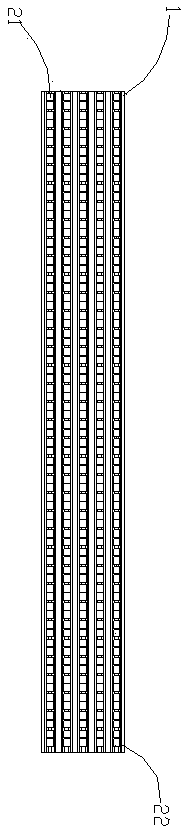

Warp knitting fabrics having ground organization expressing various design patterns

Warp knitted fabric is weaved by combination of pattern organization and ground organization by a Raschel machine. The ground organization comprises a unit weave of a constant form exposed by forming a plurality of mesh structure, wherein one unit pattern of a constant form is continuously and compositely formed to form a loop and displayed along the vertical direction. Two or more unit designs of same form or different forms are compositely arranged in the transverse direction, in the aspect of the whole vision, compared with the conventional Raschel machine, the fabrics can more obviously form various design patterns and realize high-grade of the fabrics and more show ground organization expressing various design patterns.

Owner:WON GAB

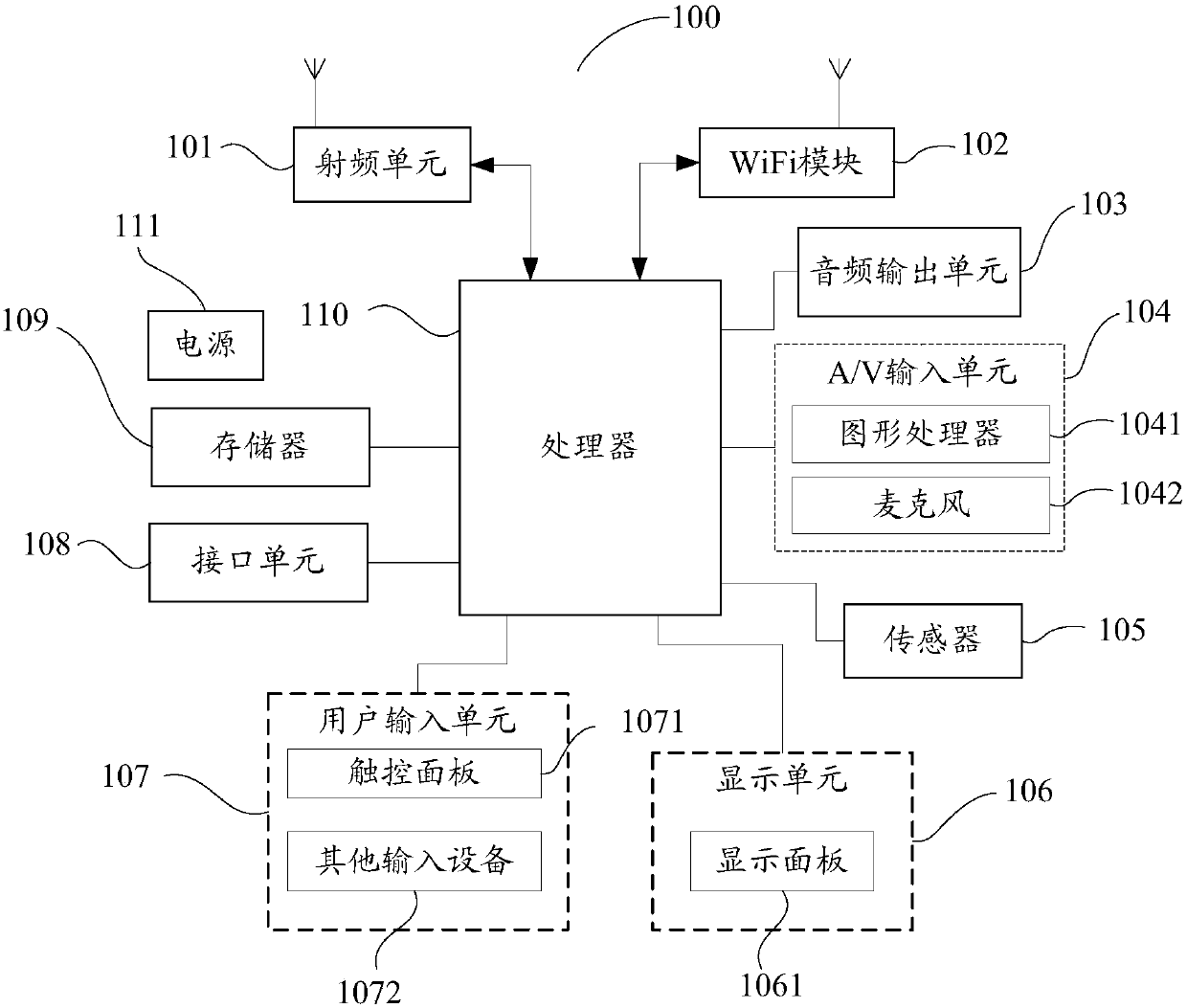

Mobile terminal shell structure and mobile terminal

InactiveCN107770343AReasonable use of spaceReasonable spaceDigital data processing detailsTelephone set constructionsComputer terminalEngineering

The invention discloses a mobile terminal shell structure and a mobile terminal. The mobile terminal shell structure comprises a screen used for displaying terminal information and interacting with auser; a shell forming an outer frame of the terminal, and comprising a front side, a back side, a left side surface, a right side surface, a top side surface and a bottom side surface, and the front side of the shell is covered by the screen; two rows of holes are formed in the bottom side surface of the shell, one row of holes are sound emission holes, a power indication light is arranged in at least one hole of the other row of holes, and the power indication light is used for indicating an electric quantity level of the terminal. According to the structure provided by the invention, the power indication light is arranged by using the design of the idle hole in the bottom side surface of the mobile terminal, and thus the purpose of reasonably using the space is achieved.

Owner:NUBIA TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com