Circulating heat radiation method of high-voltage frequency converter

A high-voltage frequency converter, circulation heat dissipation technology, applied in the direction of output power conversion device, cooling/ventilation/heating transformation, electrical components, etc., can solve the space limitation of high-voltage frequency converter, increase investment and maintenance costs, and cannot build frequency conversion problems such as equipment room, to improve the applicable ability and application scope, avoid infrastructure construction and investment, and prolong the effect of equipment use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

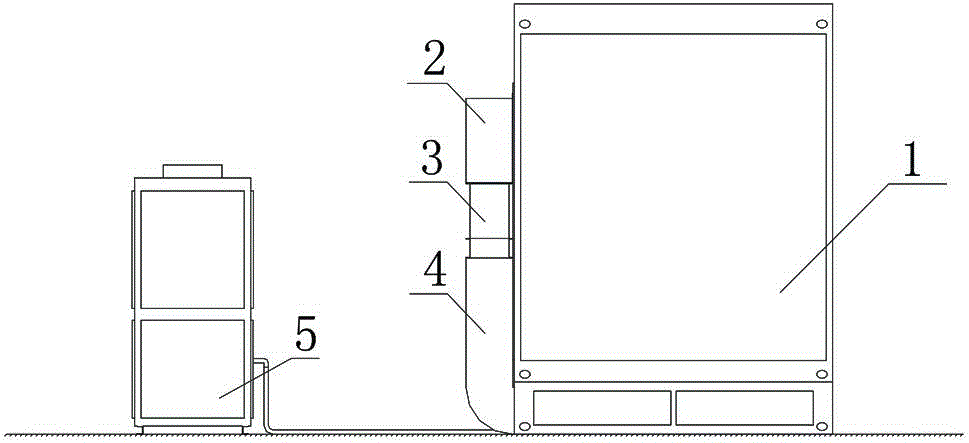

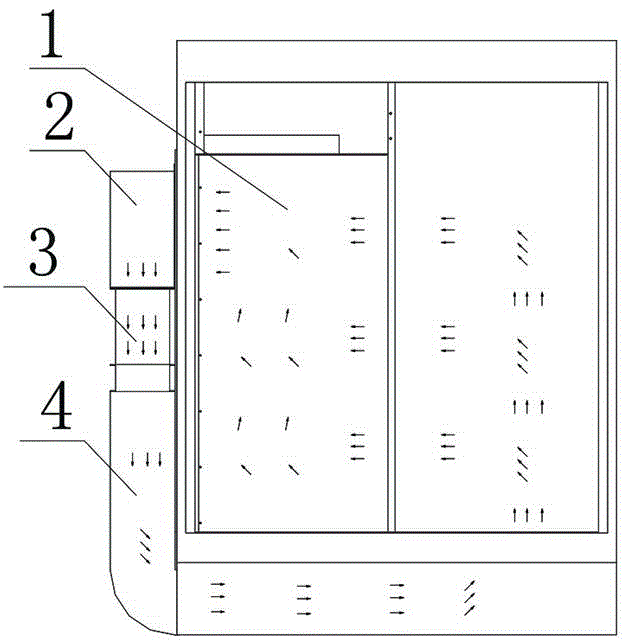

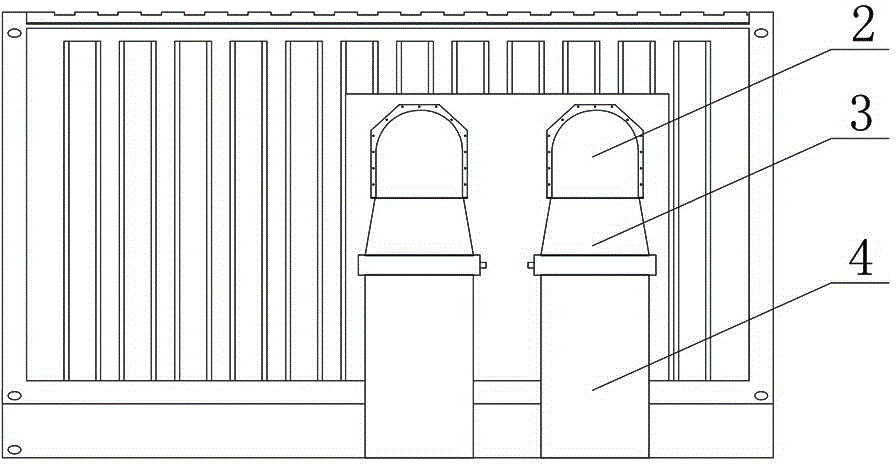

[0027] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0028] The invention provides a method for circulating heat dissipation of a high-voltage frequency converter. All the components of the high-voltage frequency converter are installed in a box-shaped frequency conversion room, and the device working area and the operation area are separated in the frequency conversion room, and the high-voltage frequency converter is installed in the device working area. , install the control cabinet and bypass cabinet in the operation area; set the air inlet at the bottom of the device working area, and use multiple air inlet meshes for air supply; set the air outlet on the upper part of the frequency conversion room; the high-voltage frequency converter works, The heat generated is exported in the form of draft from the air outlet, and after being cooled outside the inverter room, it is re-sent into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com