Advance support bracket set special for conveyor gateway on fully-mechanized coal mining working surface

A technology of fully mechanized mining face and transportation trough, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of difficult arrangement of advanced support supports, poor safety of hydraulic props, high cost, etc., and achieves easy maintenance Part replacement work, high safety, and strong support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific accompanying drawings:

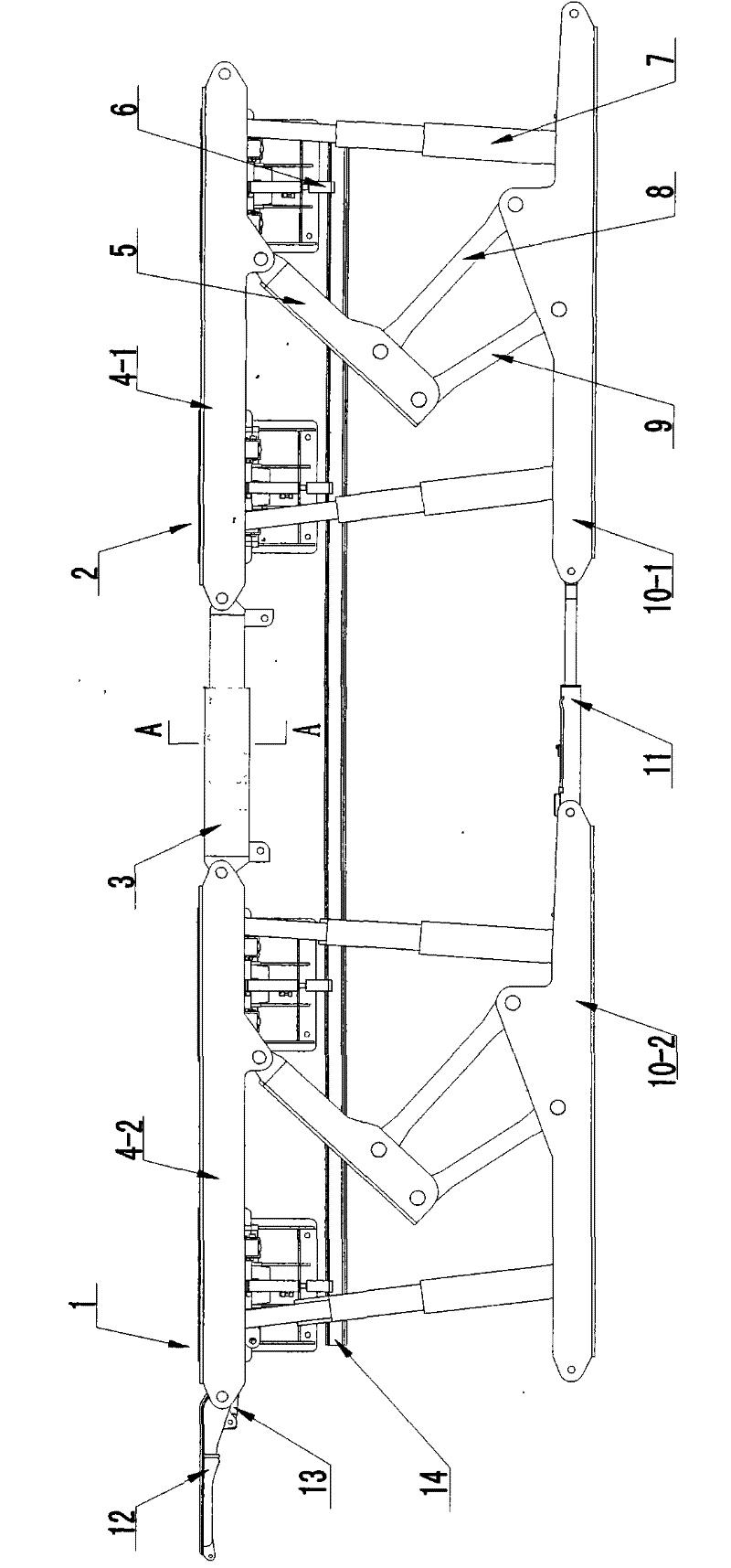

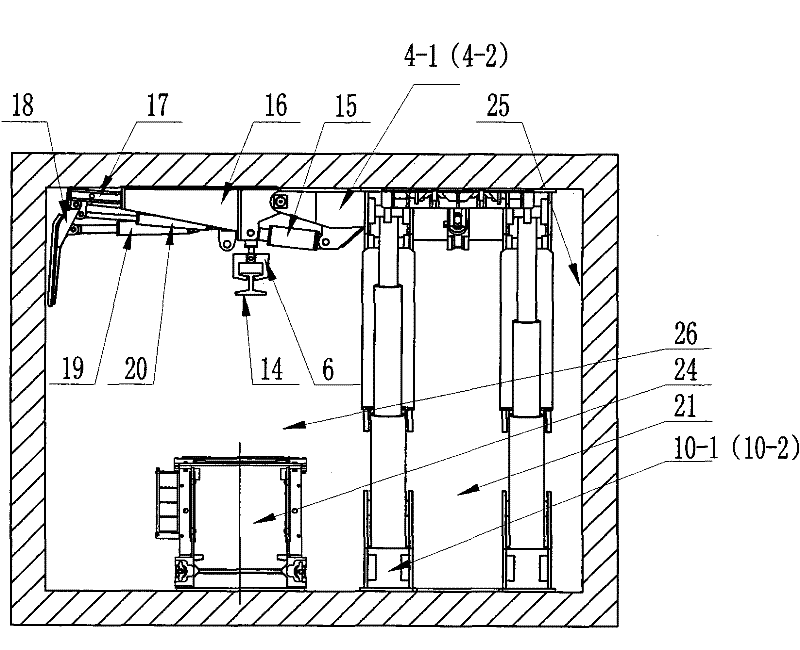

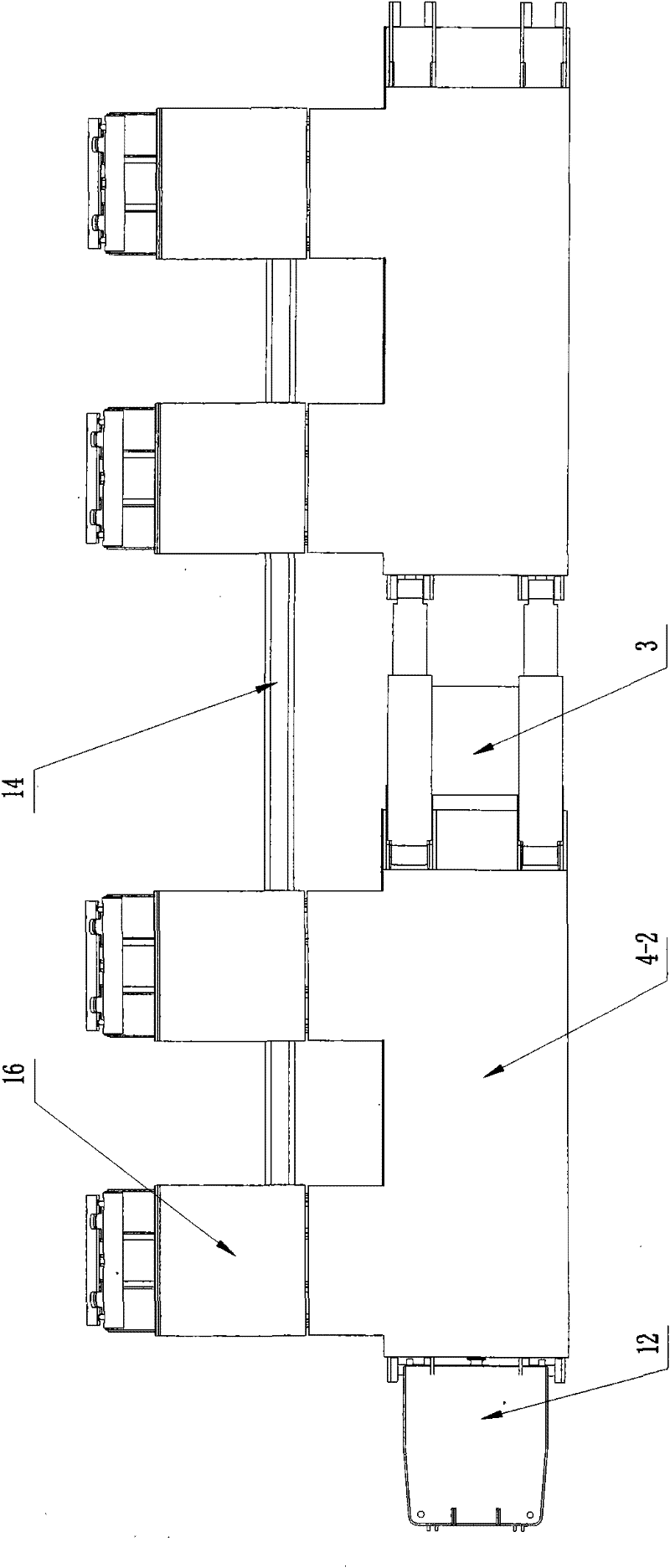

[0026] Such as Figure 1-4 As shown, the advanced support bracket group specially used for transporting along the trough of the fully mechanized mining face of the present invention is arranged near the coal side 25 of the transport top trough 26 of the fully mechanized mining face, which mainly includes the front hydraulic support unit 1 and the rear hydraulic support unit 2, and the front hydraulic support unit 2. The upper top beam II 4-2 of the hydraulic support unit 1 and the upper top beam I 4-1 of the rear hydraulic support unit 2 are connected through the drawer sliding beam 3, and the lower base II 10-2 of the front hydraulic support unit 1 and the rear hydraulic support unit The lower base I 10-1 of the support unit 2 is connected by a push-pull jack 11.

[0027] The rear hydraulic support unit 2 includes a top beam I 4-1, a shield beam 5, a hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com