Tool cabinet

a tool cabinet and tool body technology, applied in the field of tool cabinets, can solve the problems of wasting time, wasting space, and wasting tools, and achieve the effects of saving much room free of use, simple structure, and simple and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

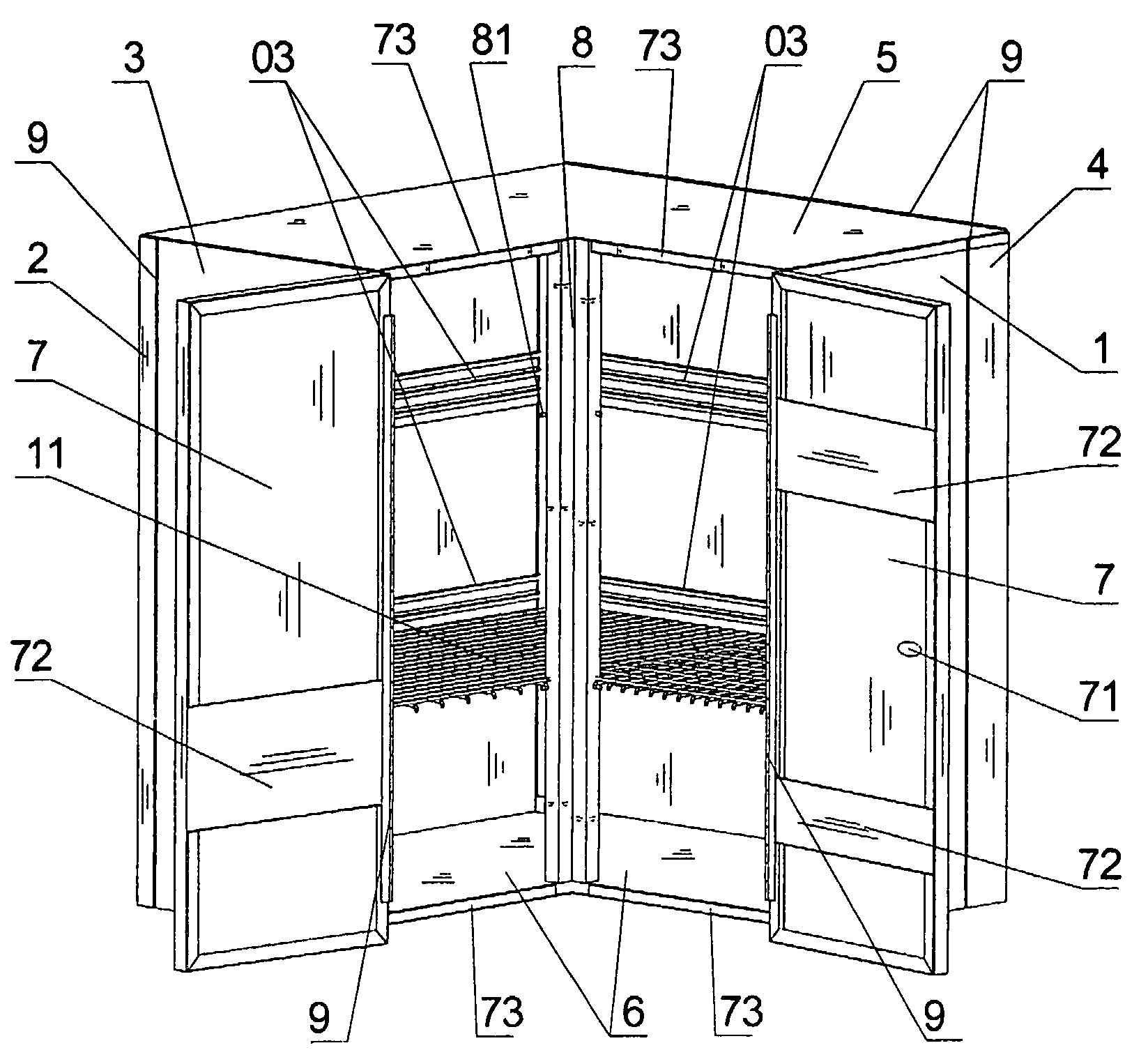

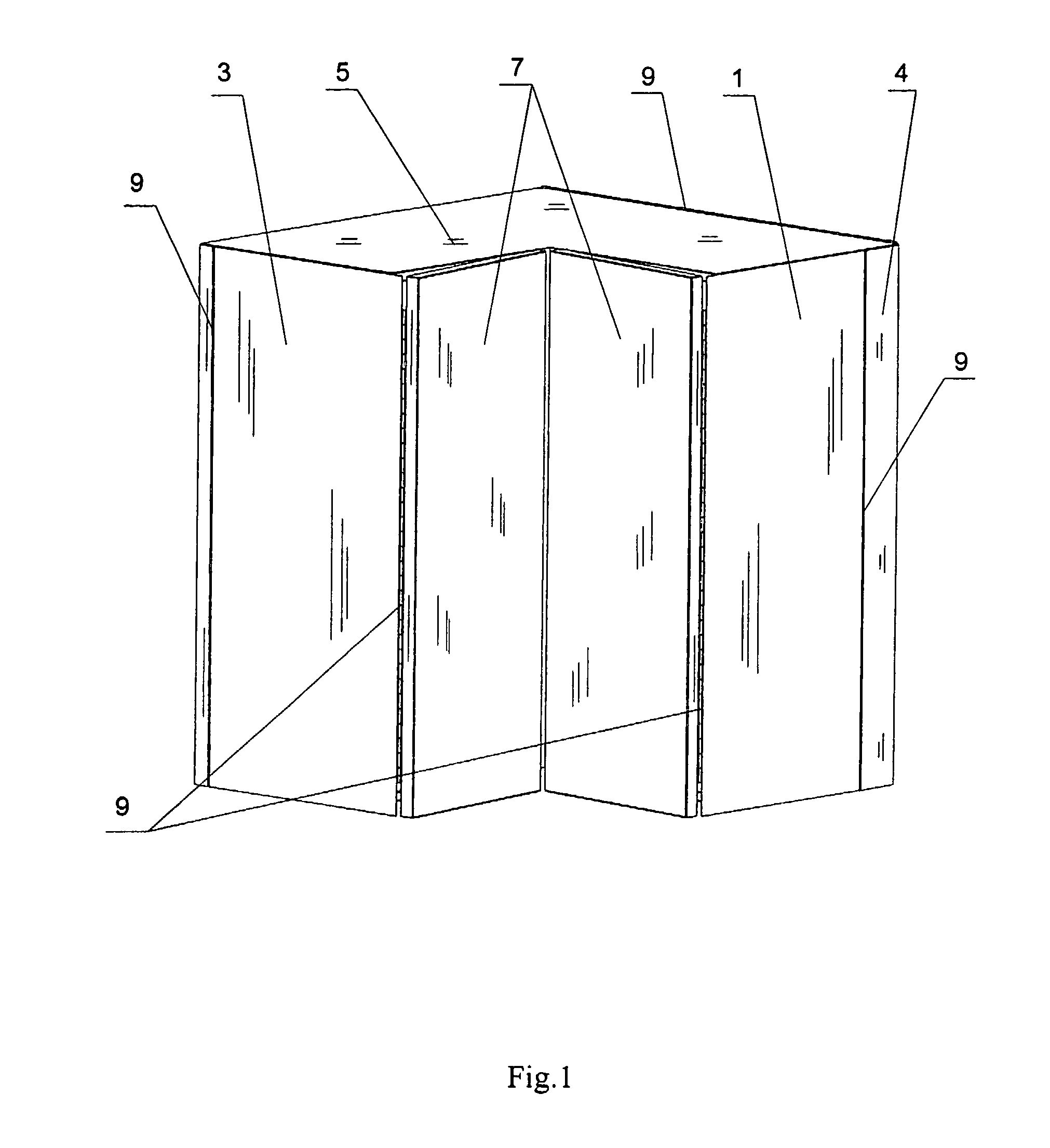

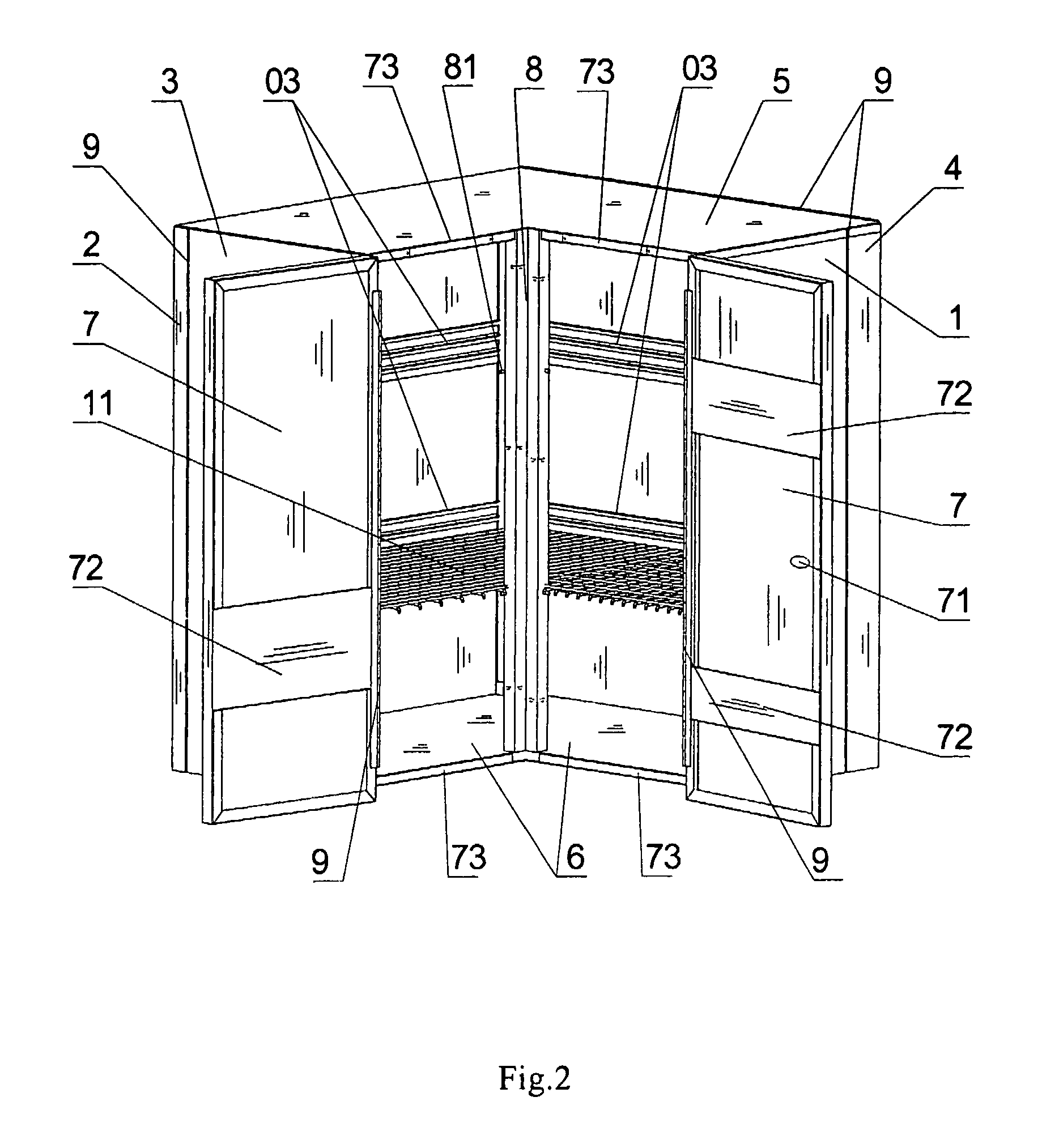

[0036]As shown in FIG. 1 and FIG. 2, the tool cabinet according to the embodiment of the invention comprises the front board 1, the back board 2, the left board 3, the right board 4, the upper cover 5, the bottom board 6, the door boards 7, the shelf 11 and the L-type upright column 8. The structure of the front board 1 is the same as that of the left board 3 and the back board 2 and the right board 4. The door lock 71 is set on the door board 7 with several tool slots 72 set at its inner side. One side of the right board 4 loosely and rotatably connects with the front board 1 and with the back board 2 on the other side. The other side of the back board 2 loosely and rotatably connects with the left board 3. The above-mentioned loose connection is inwardly rotatable connection by the hinges 9. As shown in FIG. 7 and FIG. 8, single hems 31 are set on one side of the front board 1 and the left board 3. Slot-type hems 41 are set on the back board 2 and the right board 4. It is convenie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| compatibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com