Unpowered roller conveying platform

A conveying platform and roller technology, applied in transportation, packaging, roller table, etc., can solve the problems of high power consumption, unenvironmental protection, waste, etc., and achieve the effect of reducing power consumption, saving costs and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

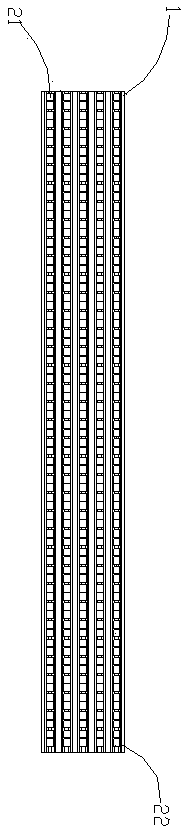

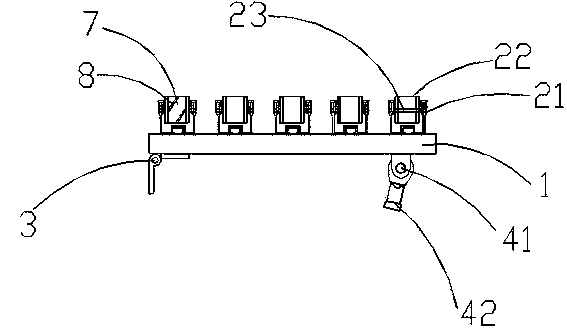

[0025] Such as figure 1 As shown, the unpowered roller conveying platform in this embodiment includes a bracket 1, and a plurality of roller mechanisms arranged on the bracket 1, and the plurality of roller mechanisms are arranged in an array on the bracket. In the embodiment, two roller mechanisms are combined to form a roller mechanism, and 5 rows and 36 columns are formed. There are gaps between rows and columns, forming a matrix in this embodiment. Of course, the arranged multiple roller mechanisms can also be arranged in an array of other styles, such as a curved pattern, so as to meet other needs, such as space setting needs.

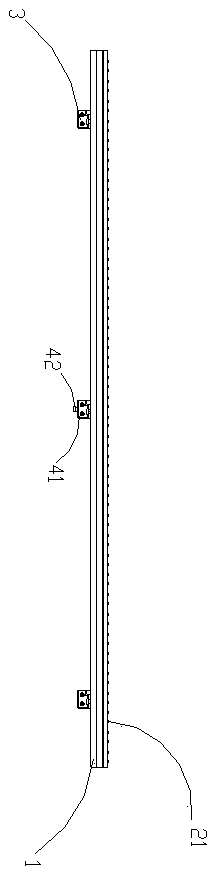

[0026] Such as figure 1 , figure 2 As shown, the above-mentioned bracket 1 includes a roller bracket 22, the above-mentioned roller mechanism includes a roller shaft 23 and a roller 21, the roller bracket 22 is horizontally erected on the bracket 1, and the roller 21 is connected to the roller bracket 22 through the roller shaft 23, The roller...

Embodiment 2

[0030] Others are the same as those described in Embodiment 1, except that the roller bracket 22, as a part of a single roller mechanism, forms a roller mechanism together with the roller shaft 23 and the roller 21, and is then installed on the bracket 1 one by one. In this way, the material for manufacturing the roller bracket 22 can be saved.

Embodiment 3

[0032] Others are the same as those described in Embodiment 1 or 2, except that the rubber skin 7 is not added to the roller 21, but several grooves are directly provided on the roller 21, which can also achieve the purpose of increasing the friction.

[0033] The working principle of the present invention is introduced below:

[0034] A number of roller mechanisms including rollers 21 are set on the bracket 1 of the platform, which are arranged on the bracket 1 in an array. Through the rotation of the rollers 21, the traditional belt transmission is replaced by a non-powered form, and the transmission process does not require power. , reduces power consumption and saves cost; the addition of optional rubber skin 7 and groove 8 increases the friction between the roller 21 and the product to be processed, making the roller 21 corrosion-resistant and wear-resistant, and extending the life of the roller 21 Long service life; Cylinder 5 enables the height of the platform to be adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com