High-pressure power steering gear rubber tube and manufacturing process thereof

A power steering gear and manufacturing process technology, applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of high cost, low product qualification rate, insufficient pulse performance, etc., achieve low cost, ensure appearance quality, space shape and towards reasonable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

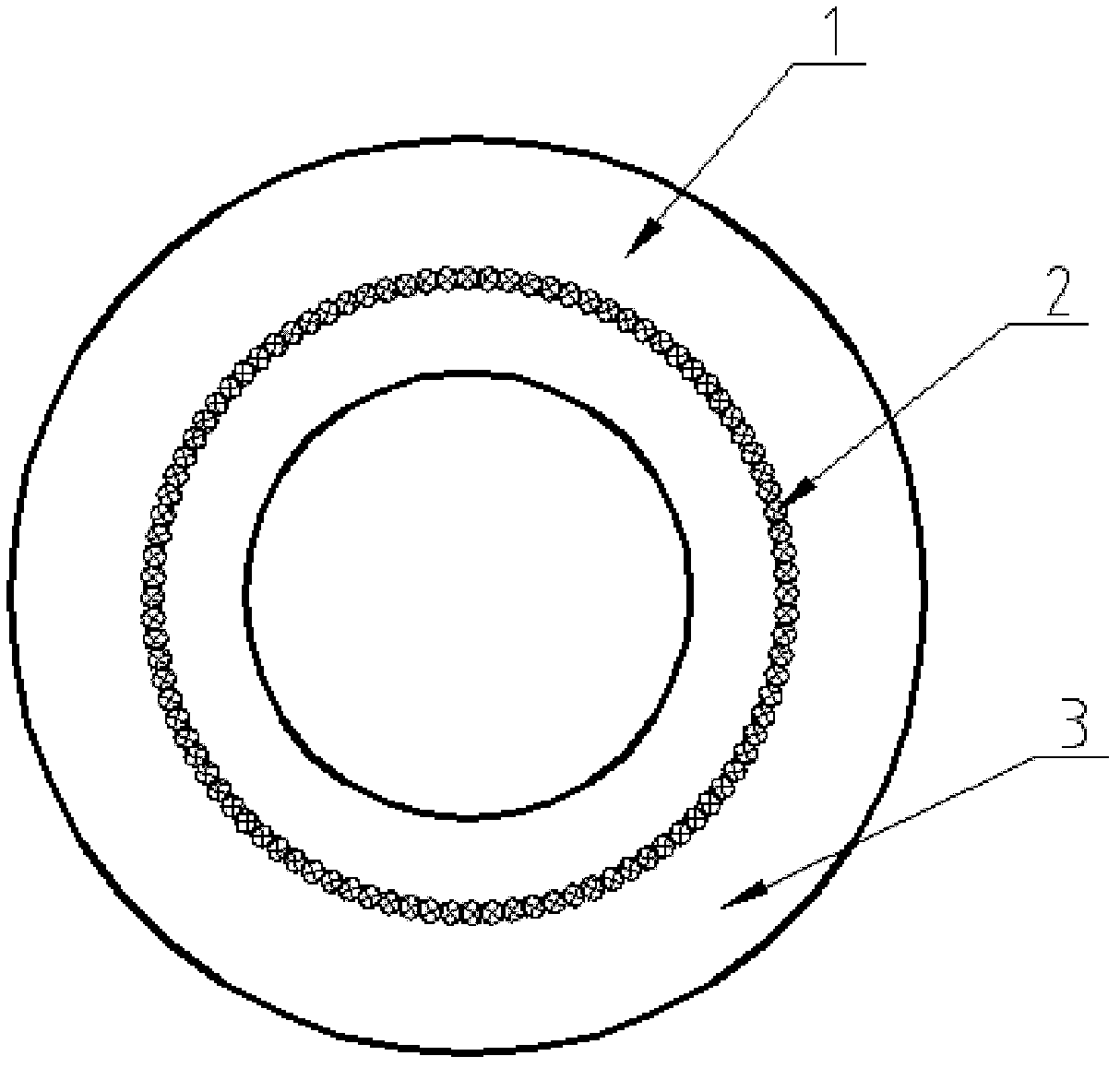

[0037] A kind of high pressure power steering gear rubber hose of the present invention such as figure 1 As shown, the rubber hose of the high-pressure power steering gear is composed of the inner tube rubber layer 1, the fiber thread reinforcement layer 2 and the outer tube rubber layer 3 sequentially from the inside to the outside; in this embodiment, the inner tube rubber layer 1 or the The rubber component weight ratio of the outer tube rubber layer 3 is:

[0038] Chlorosulfonated polyethylene rubber CSM: 100; Magnesium oxide: 15;

[0039] Anti-scorch agent: 0.7; Carbon black 660: 50;

[0040] Paraffin oil: 5; Accelerator DM: 1.5;

[0041] Accelerator TMTD: 0.5.

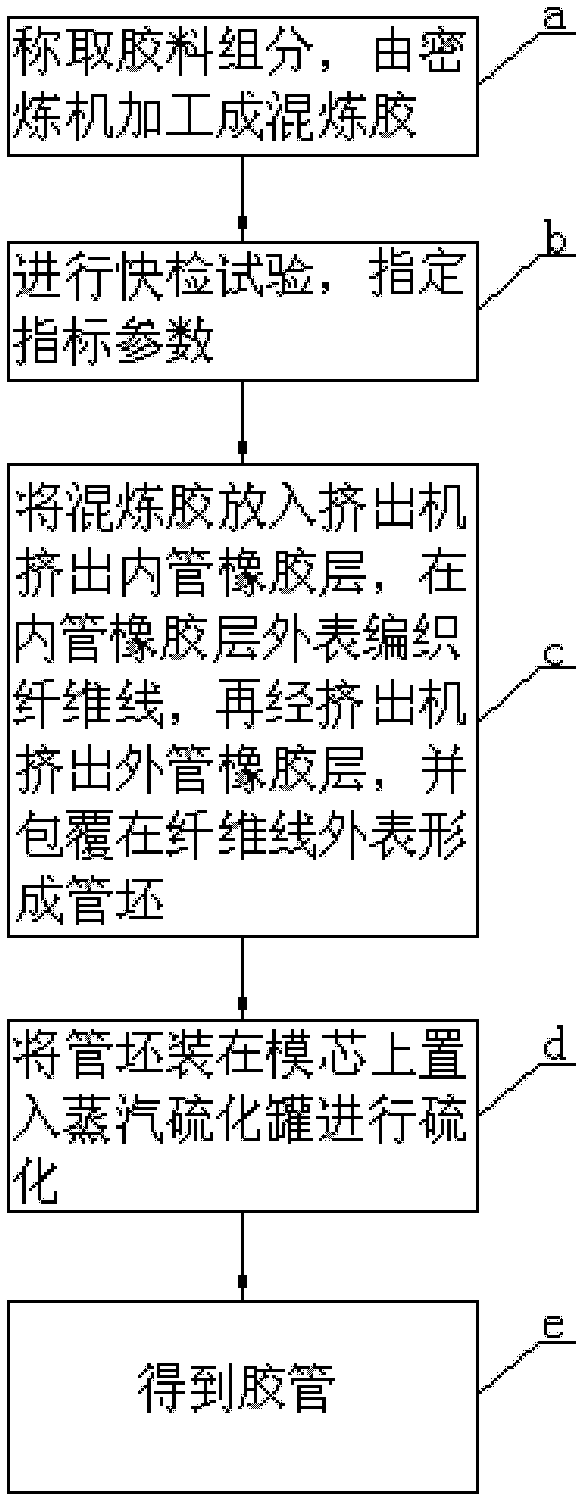

[0042] The manufacturing process of a kind of high-pressure power steering rubber hose of the present invention is as follows: figure 2 shown, including the following steps:

[0043] a. Weigh the rubber components of the rubber layer of the inner tube or the rubber layer of the outer tube according to the a...

Embodiment 2

[0051] The second embodiment is basically the same as the first embodiment, except that in this embodiment, the weight ratio of the rubber components of the inner tube rubber layer 1 or the outer tube rubber layer 3 is:

[0052] Chlorosulfonated polyethylene rubber CSM: 100; magnesium oxide: 13;

[0053] Anti-scorch agent: 0.5; Carbon black 660: 45;

[0054]Paraffin oil: 3; Accelerator DM: 1;

[0055] Accelerator TMTD: 0.3.

[0056] In the manufacturing process steps of the high pressure power steering hose:

[0057] a. Weigh the rubber components of the rubber layer of the inner tube or the rubber layer of the outer tube according to the above weight ratio, and process them by an internal mixer. In order to prevent the rubber from overheating and scorching, the rubber components are reversely mixed. Mixing, and using a rotor speed of 15RPM, the inlet temperature of the cooling water is controlled below 20°C, and the glue output temperature after mixing is 120°C, so that th...

Embodiment 3

[0061] The third embodiment is basically the same as the first embodiment, except that in this embodiment, the weight ratio of the rubber components of the inner tube rubber layer 1 or the outer tube rubber layer 3 is:

[0062] Chlorosulfonated polyethylene rubber CSM: 100; Magnesium oxide: 18;

[0063] Anti-scorch agent: 1.2; Carbon black 660: 55;

[0064] Paraffin oil: 8; Accelerator DM: 2.5;

[0065] Accelerator TMTD: 0.8.

[0066] In the manufacturing process steps of the high pressure power steering hose:

[0067] a. Weigh the rubber components of the rubber layer of the inner tube or the rubber layer of the outer tube according to the above weight ratio, and process them by an internal mixer. In order to prevent the rubber from overheating and scorching, the rubber components are reversely mixed. Mixing, and using a rotor speed of 20RPM, the inlet temperature of the cooling water is controlled below 20°C, and the glue outlet temperature after mixing is 130°C. Thus fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com