A rotary moving bed biological filter device

A biological filtration, moving bed technology, applied in sustainable biological treatment, biological water/sewage treatment, water pollutants, etc., can solve the problems of high maintenance cost, large area, complex structure, etc., to promote metabolism, distribution Uniform, good mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

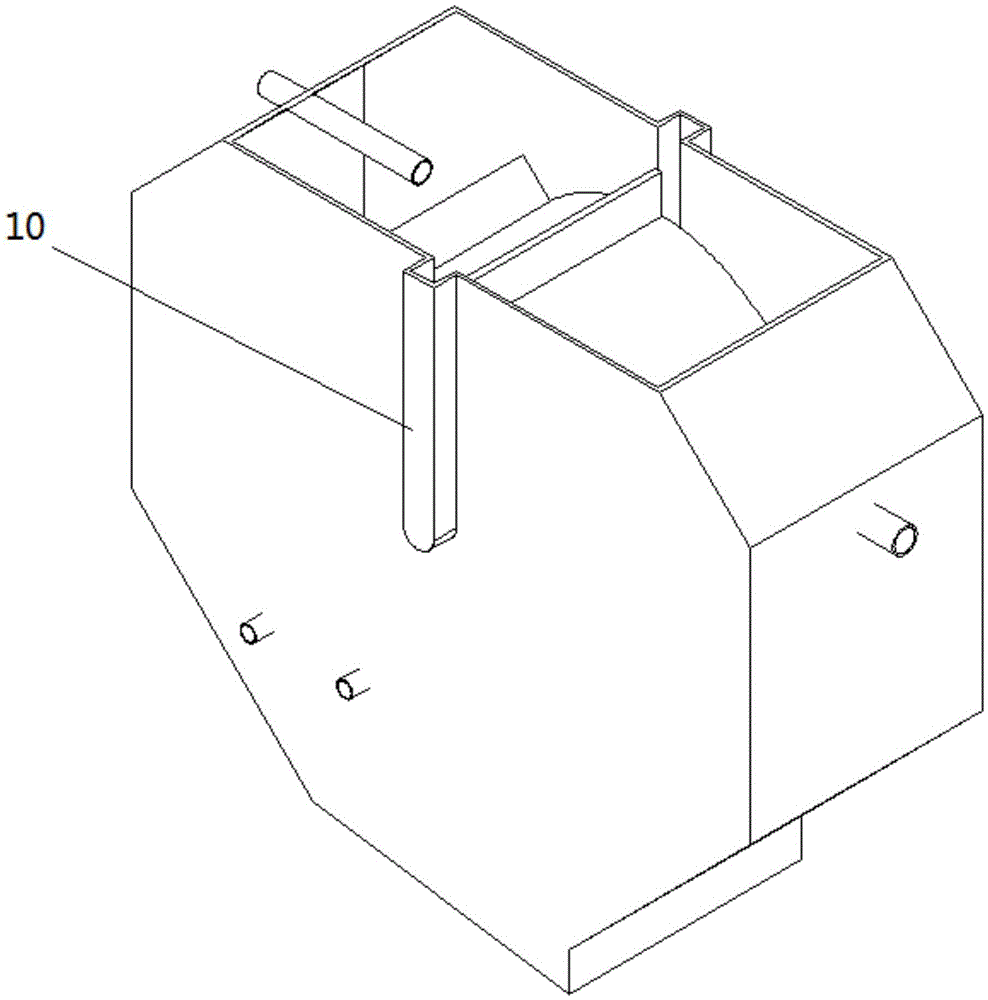

[0030] This embodiment is a biological filtration device that uses water flow and air flow to drive the drum to rotate, more specifically, it refers to a moving bed that can perform biological filtration and is used for the treatment of aquaculture wastewater. The device is mainly used in the water treatment of the industrial circulating aquaculture system, and can also be used in other sewage treatment fields.

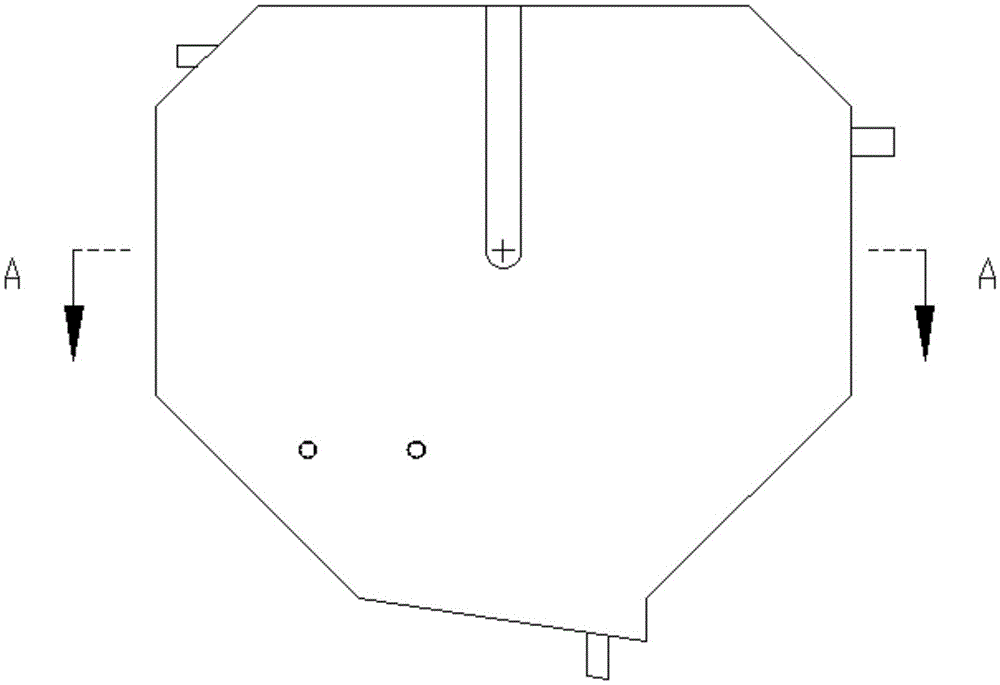

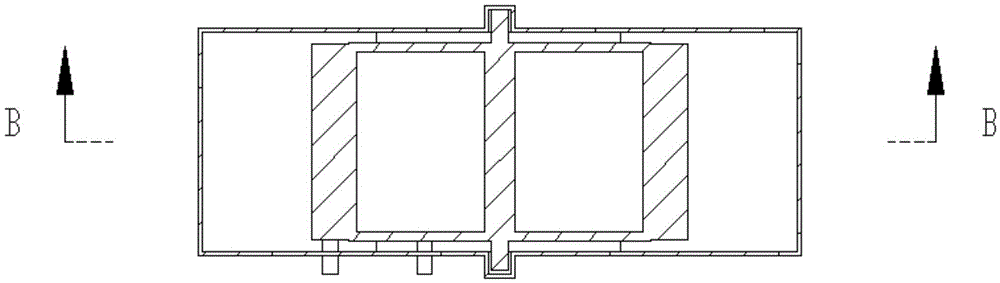

[0031] see Figure 1-5 , a rotary moving bed biological filtration device, comprising a moving bed box, a drum 3 is horizontally arranged inside the moving bed box, and the drum 3 is supported by a baffle 2 and can rotate around its central shaft; The outer wall of the drum 2 is made of a porous plate material, and the drum 2 is provided with a biological filter material, the outer diameter of the biological filter material is larger than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com