A method for decarburizing blast furnace hot metal using blast furnace ashes

A technology for blast furnace molten iron and blast furnace ash, which is applied in the field of processing in the blast furnace molten iron flip-chip process, can solve the problems of aggravating carbon-containing dust, material loss, large heat loss, etc., and achieves low cost, efficient recovery, and high decarburization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

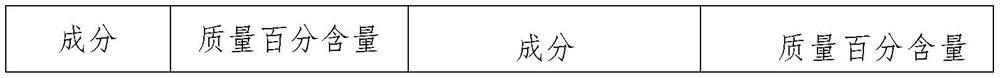

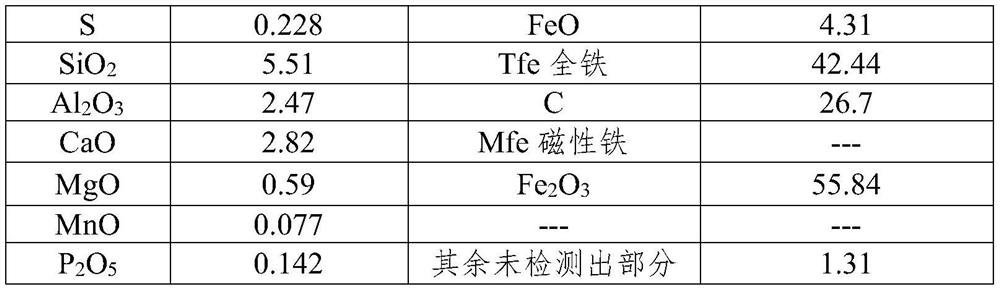

[0056] In this embodiment, blast furnace ash treated with aerobic roasting is used as a decarburizing agent, which is mixed with blast furnace molten iron to realize decarburization. In this embodiment, the composition of the blast furnace ash sample before roasting is shown in Table 1:

[0057] Table 1

[0058]

[0059]

[0060] Take 500g of the above-mentioned blast furnace ash and roast it at 1250°C for 6 hours in the air environment, and measure the composition of the blast furnace ash after roasting, see Table 2.

[0061] Table 2

[0062] Element Mass percentage Element Mass percentage S 0.310 FeO 1.493 SiO 2

7.481 Tfe full iron 57.619 Al 2 o 3

3.353 C 0.000 CaO 3.829 Mfe magnetic iron --- MgO 0.801 Fe 2 o 3

80.65 MnO 0.105 --- --- P 2 o 5

0.193 The remaining undetected parts 1.78

[0063] Take the roasted blast furnace ash in Table 2, mix it with bentonite and an a...

Embodiment 2

[0071] In this example, the roasted blast furnace ash (see Table 2 for the composition) was added to bentonite (bentonite accounts for the total amount of the block decarburizer), an appropriate amount of water was mixed evenly to make a slurry, and pelletized by a disc pelletizer. After drying, the diameter The spherical decarburizing agent is 2 cm in size and dried at 110-120° C. for 3-5 hours to obtain the spherical decarburizing agent. Among them, bentonite accounts for 5% of the mass of the block decarburizer. The preparation process of the decarburizer refers to Example 1.

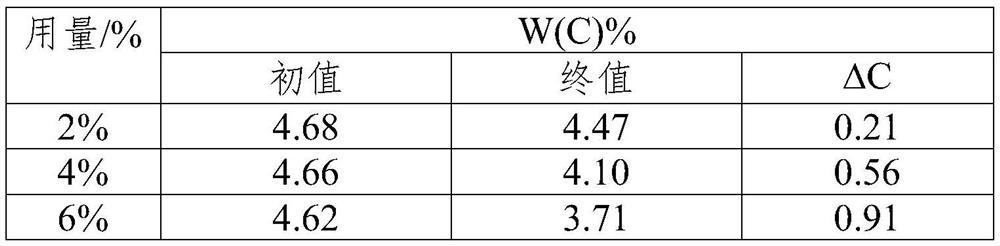

[0072] The amount of the above-mentioned massive decarburizer is 2% of the mass of molten iron (which does not contain bentonite), and the reaction temperatures of the molten iron for the decarburization reaction are kept at 1330°C, 1390°C, and 1450°C respectively, and each group of temperature experiments is paralleled for 3 times, and the calculation Average of 3 times. The experimental results a...

Embodiment 3

[0077] In this embodiment, the roasted blast furnace ash and iron ore powder are mixed in a mass ratio of 70:3 to make a decarburizer. The composition of iron concentrate powder is shown in Table 5.

[0078] table 5

[0079]

[0080] The composition of the mixture is shown in Table 6 after the fully roasted blast furnace ash and iron concentrate powder are mixed according to the mass ratio of 70:30.

[0081] Table 6

[0082] Element Mass percentage Element Mass percentage S 0.217 FeO 1.201 SiO 2

6.334 Tfe full iron 59.902 al 2 o 3

2.797 C 0.000 CaO 2.680 Mfe magnetic iron --- MgO 0.561 Fe 2 o 3

84.24 MnO 0.280 --- --- P 2 o 5

0.135 The remaining undetected parts 1.55

[0083] Mix the components in Table 6 with bentonite and an appropriate amount of water to uniformly make a slurry, pelletize through a disc pelletizer, and obtain a spherical decarburizer with a diameter of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com