Processing method for decarbonization of blast furnace molten iron based on converter LT dust-removing ash

A treatment method and blast furnace molten iron technology, which is applied in the field of blast furnace molten iron decarburization treatment based on converter LT dedusting ash, can solve problems such as potential safety hazards, large heat loss, and molten iron splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

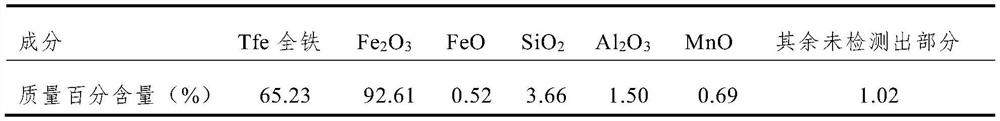

Embodiment 1

[0042] In this embodiment, converter LT dedusting ash is used as a decarburizing agent, which is mixed with blast furnace molten iron to realize decarburization. In this embodiment, the composition of converter LT dedusting ash sample is:

[0043] Element Mass percentage Element Mass percentage S 0.069 Tfe full iron 59.49 SiO 2

1.63 C 1.53 Al 2 o 3

0.36 Mfe magnetic iron -- CaO 8.12 Fe 2 o 3

52.23 MgO 4.19 ZnO trace MnO 0.426 Na 2 o

trace P 2 o 5

0.199 K 2 o

trace FeO 29.48 The remaining undetected parts 1.77

[0044] The particle size of the converter LT dedusting ash is 10-50 microns. A certain amount of the above-mentioned converter LT dedusting ash is fully mixed with bentonite and water to make a slurry and pressed into a block, and dried at 110-120°C for 3-5 Hour, obtain the decarburizing agent of cylindrical block, and diameter is 1cm, height 1.5cm. ...

Embodiment 2

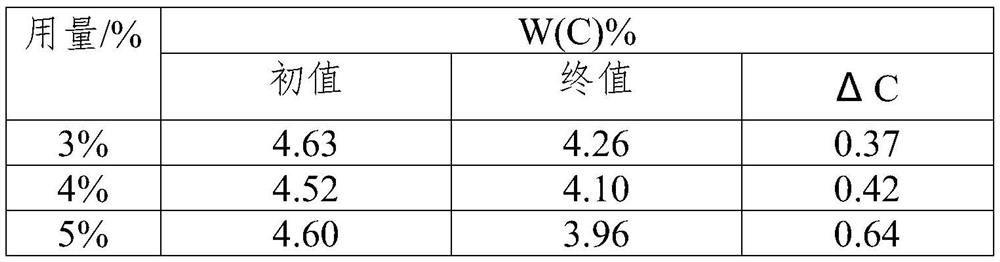

[0051] In this embodiment, converter LT dedusting ash is used as a decarburizing agent, which is mixed with blast furnace molten iron to achieve decarburization, and the composition, specifications, and briquetting steps of converter LT dedusting ash are the same as those in Example 1. During the measurement, each sample was tested three times and the average value was taken.

[0052] In this example, the influence of converter LT dedusting ash as a decarburizing agent on the decarburization effect of molten iron is studied at different temperatures. Specifically, the temperature of the molten iron for maintaining the decarburization reaction was 1420°C, 1450°C, and 1480°C, respectively, and in each temperature experiment, the amount of dedusting ash of the converter LT was 4% of the mass of the molten iron. The experimental results are recorded in Table 2.

[0053] Table 2

[0054]

[0055] It can be seen from the above table that when the amount of dedusting ash in conv...

Embodiment 3

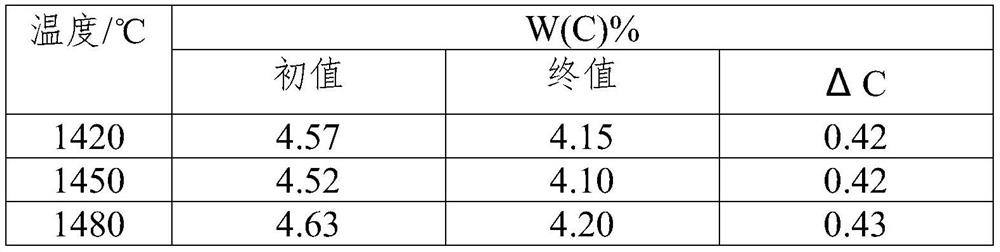

[0057] In this example, converter LT dedusting ash and iron concentrate powder (Brazilian iron ore concentrate powder) are mixed according to the mass ratio of 80:20 as a decarburizer, and the composition, specifications, and briquetting steps of converter LT dedusting ash are the same as in Example 1 same. The composition of iron concentrate powder is as follows:

[0058]

[0059] In this example, the influence of different amounts of decarburizers on the decarburization effect of molten iron is studied, specifically adding 3% and 4% (converter LT dedusting ash + iron concentrate powder mass and the mass percentage of molten iron) to molten iron. Block decarburizer (made from converter LT dedusting + iron concentrate powder, 5% bentonite briquette), keep the temperature of molten iron at 1450°C. The experimental results are recorded in Table 3.

[0060] table 3

[0061]

[0062] It can be seen from the above table that the ideal carbon reduction effect can also be ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com