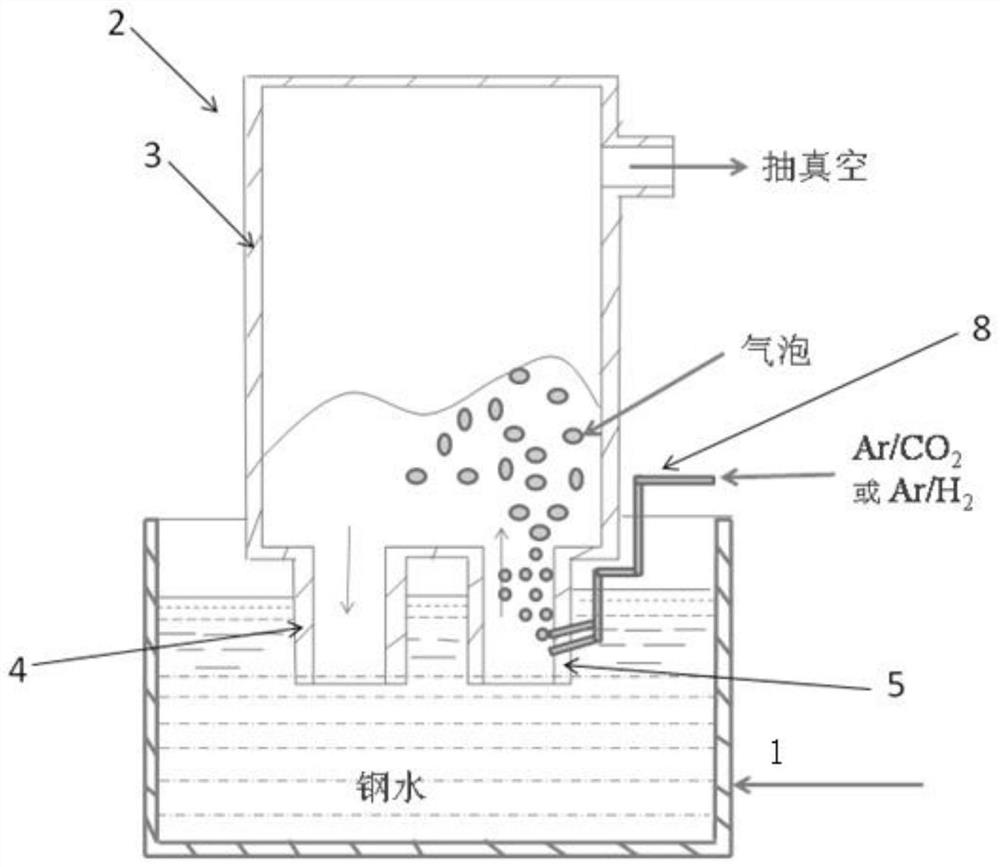

A method for rh deep decarburization of molten steel

A deep decarburization and molten steel technology, applied in the field of metallurgy, can solve the problems of increasing metal Al/Si consumption, unfavorable conditions, and reducing production costs, and achieve the effect of shortening smelting time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

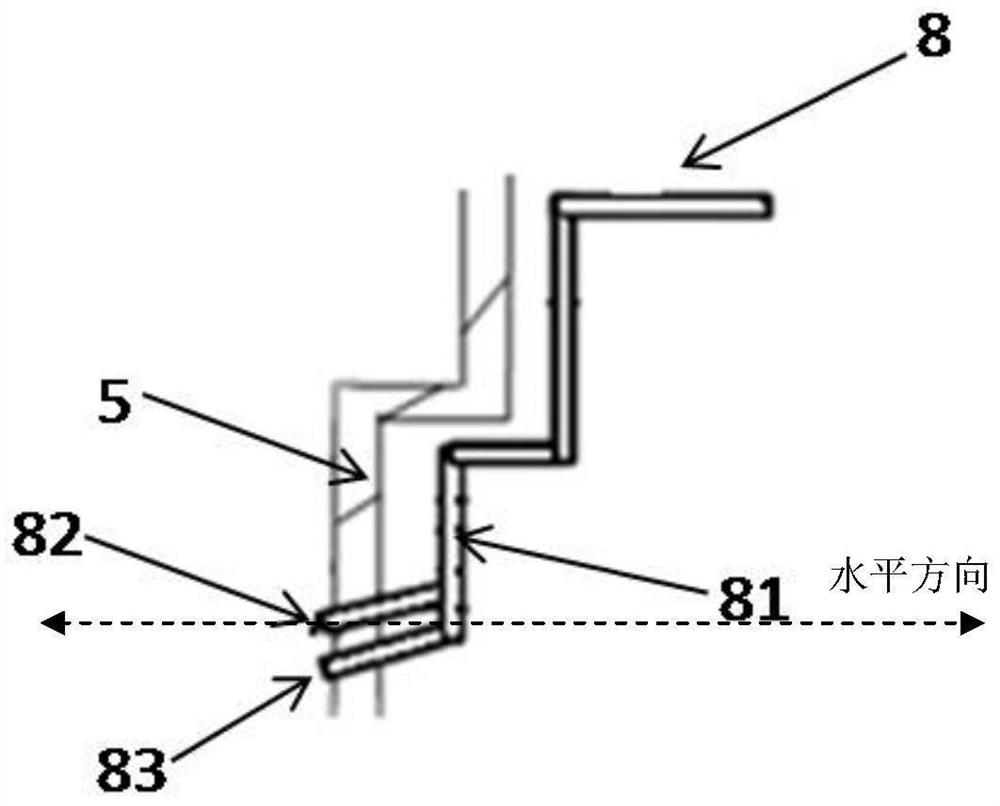

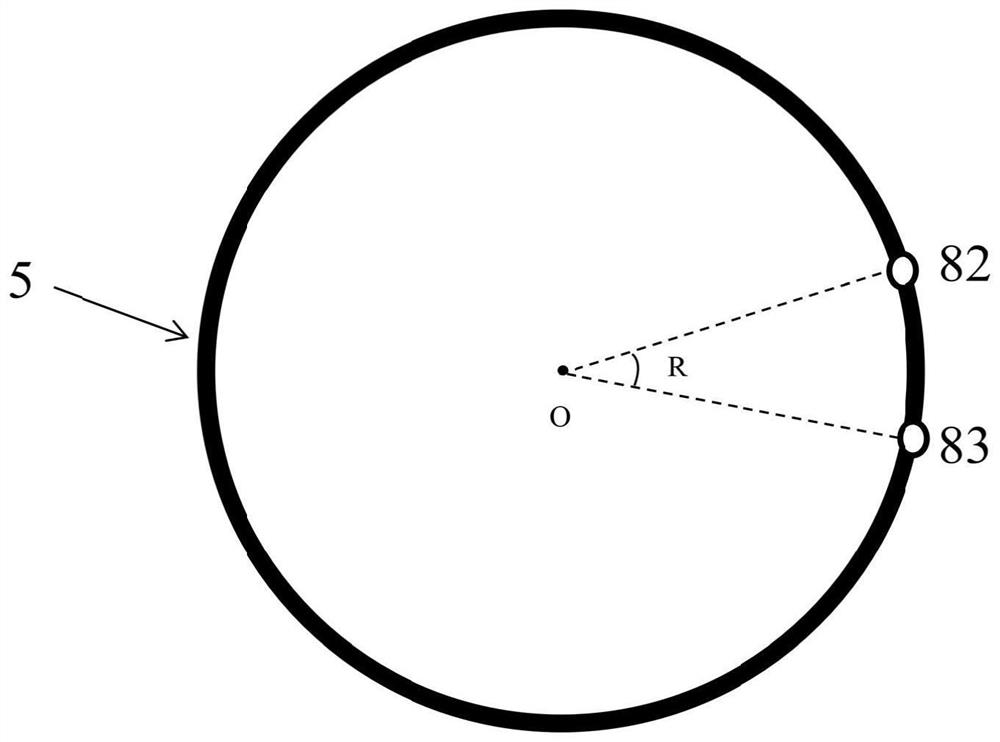

Method used

Image

Examples

Embodiment 1

[0038] The molten steel to be treated meets the following requirements: carbon content 0.035wt%-0.045wt%, oxygen content 0.025wt%-0.040wt%, temperature 1650-1710°C.

[0039] When the ladle is placed in the RH treatment station, insert the dipping tube into the molten steel in the ladle, and start the vacuum pump to pump air. When the pressure in the vacuum degassing tank is less than 17kPa, supply CO through the argon blowing tube 2 -Ar mixed gas is used as cycle gas and reaction medium, CO in the mixed gas 2 Content 65wt%, air supply strength 0.7Nm 3 / h·t, using CO at high temperature 2 Weak oxidation of gas, reaction: C+CO 2 = 2CO. On the one hand, direct decarbonization, CO 2 -Ar mixed gas reduces the partial pressure of CO to promote the reaction. On the other hand, twice as much CO is generated, and the circulation flow rate is increased to accelerate decarbonization. When the pressure in the vacuum degassing tank is less than 300Pa, switch to Ar gas drive, and the...

Embodiment 2

[0041] The molten steel to be treated meets the following requirements: carbon content 0.035wt%-0.045wt%, oxygen content 0.025wt%-0.040wt%, temperature 1650-1710°C.

[0042] When the ladle is placed in the RH treatment station, insert the dipping tube into the molten steel in the ladle, and start the vacuum pump to pump air. When the pressure in the vacuum degassing tank is less than 17kPa, supply CO through the argon blowing tube 2 -Ar mixed gas is used as cycle gas and reaction medium, CO in the mixed gas 2 The content is 50wt%, and the gas supply strength is 1.2Nm 3 / h·t, using CO at high temperature 2 Weak oxidation of gas, reaction: C+CO 2 = 2CO. On the one hand, direct decarbonization, CO 2 -Ar mixed gas reduces the partial pressure of CO to promote the reaction. On the other hand, twice as much CO is generated, and the circulation flow rate is increased to accelerate decarbonization. When the pressure in the vacuum degassing tank is less than 300Pa, switch to Ar ...

Embodiment 3

[0044]The molten steel to be treated meets the following requirements: carbon content 0.035wt%-0.045wt%, oxygen content 0.025wt%-0.040wt%, temperature 1650-1710°C.

[0045] When the ladle is placed in the RH treatment station, insert the dipping tube into the molten steel in the ladle, and start the vacuum pump to pump air. When the pressure in the vacuum degassing tank is less than 17kPa, supply CO through the argon blowing tube 2 -Ar mixed gas is used as cycle gas and reaction medium, CO in the mixed gas 2 The content is 50wt%, and the gas supply strength is 1.2Nm 3 / h·t, using CO at high temperature 2 The gas is weakly oxidizing and reacts: [C]+CO 2 = 2CO. On the one hand, direct decarbonization, CO 2 -Ar mixed gas reduces the partial pressure of CO to promote the reaction. On the other hand, twice as much CO is generated, and the circulation flow rate is increased to accelerate decarbonization. When the pressure in the vacuum degassing tank is less than 300Pa, switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com