Oxygen blowing apparatus for smelting steel, technology and application

A technology of equipment and process, which is applied in the direction of lighting and heating equipment, improvement of process efficiency, furnace components, etc., can solve the problems of short jet injection distance, weak impact force, dispersion, etc., to improve utilization efficiency, reduce gas concentration, Strong penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

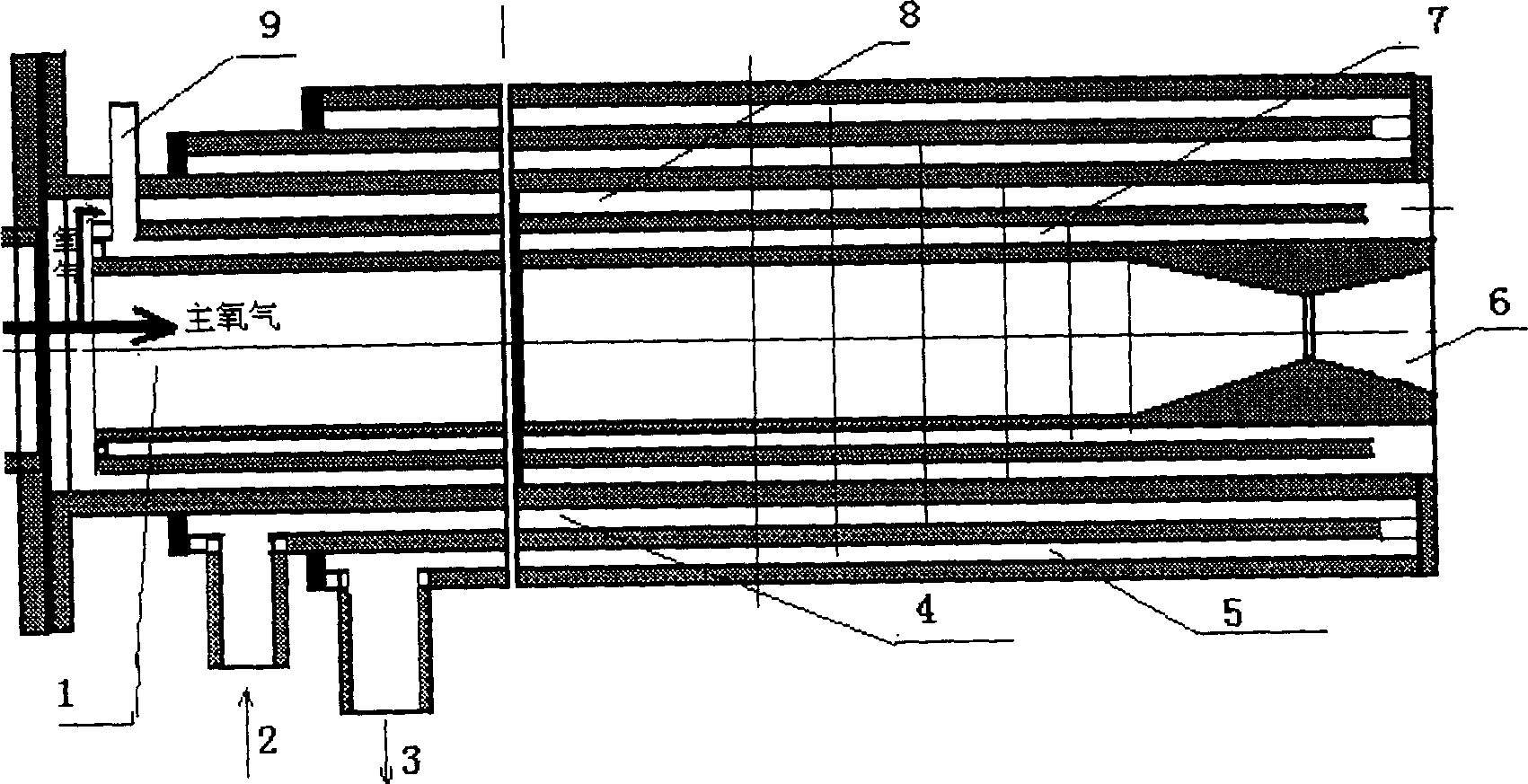

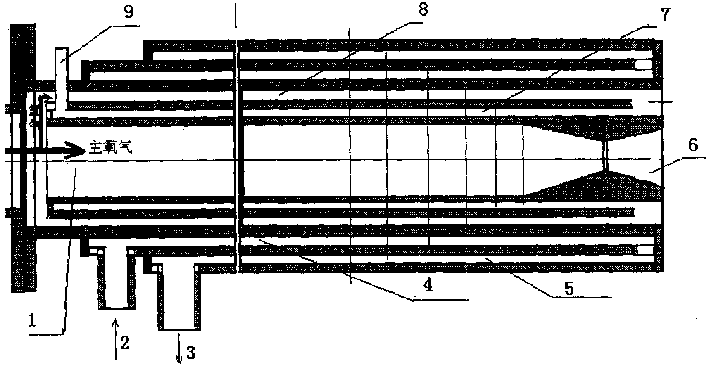

[0008] The equipment of the present invention is composed of four parts: a main oxygen injection system, a secondary oxygen injection system, a fuel injection system and a water cooling system. The main oxygen injection system is located in the center of the cluster jet oxygen lance; the main oxygen protection system is located in the outer layer of the main oxygen injection system, with gas (oil) and secondary oxygen injection; the water cooling system is located in the outermost layer of the spray gun, in the One end of the oxygen lance is provided with water inlet and outlet.

[0009] The present invention designs a cluster jet oxygen lance, the outlet diameter of the oxygen lance is 25.98mm, the throat diameter is 20mm, the length of the oxygen lance is 1000mm, the oxygen lance is inserted into the center of the electric arc furnace, the outer diameter of the main oxygen pipe is 45mm, and the auxiliary The outer diameter of the oxygen pipe is 70mm, the outer diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com