Activation synergist for natural gas decarburization based on MDEA method

A synergist and natural gas technology, which is applied in the field of gas separation and natural gas purification, can solve the problems of severe dissolution of rubber pads, degradation of cycle performance, carbon dioxide corrosion, etc., to solve the problem of system seepage and leakage, small changes in material composition, Low corrosion and swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with embodiment.

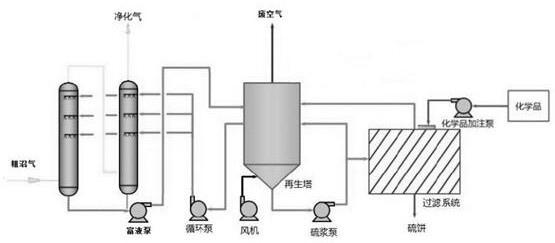

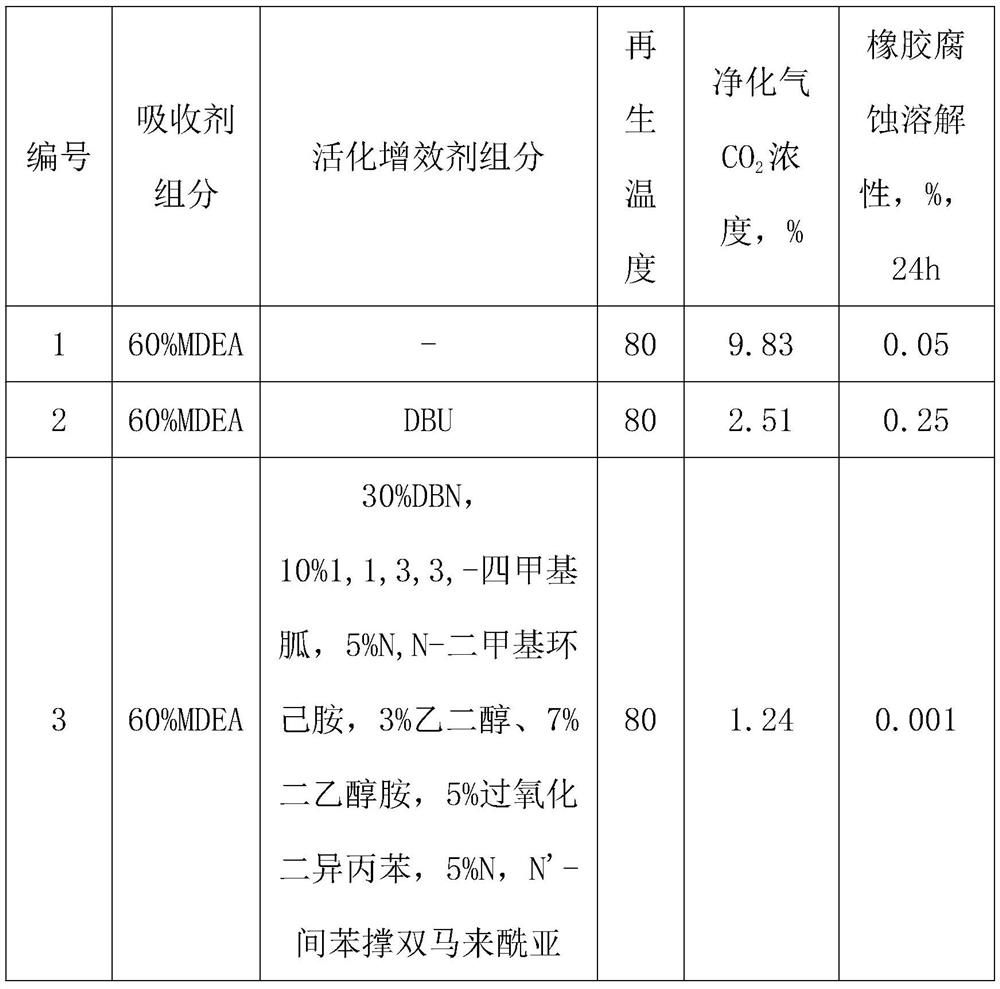

[0026] Configure raw biogas (30% CO 2 , 70% CH 4 )according to figure 1 The technological process enters the bottom of the absorption tower and contacts with the absorbent entering from the top of the tower, the carbon dioxide in the gas is absorbed, and the purified gas is purified gas. Under a certain gas flow rate, a certain solution circulation volume and regeneration temperature, several The operating performance of the activated synergist with different component configurations and different absorbents is shown in the table. For the rubber corrosion solubility, the oil pump gasket is used to evaluate the anti-swelling, and the data is shown in the table:

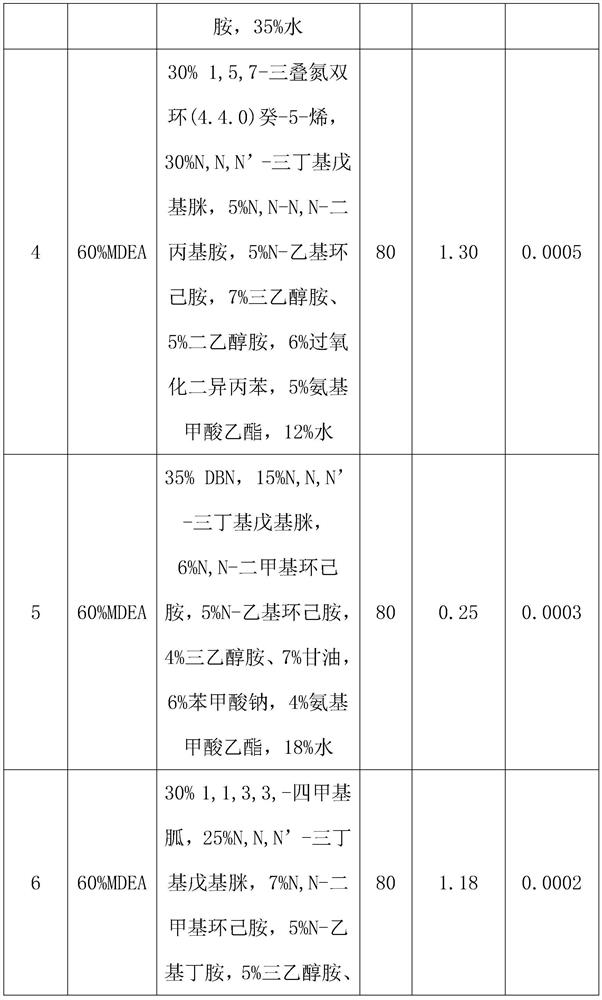

[0027]

[0028]

[0029]

[0030] From the results of the above invention, it can be seen that the decarburization effect of the present invention is better than that of the traditional MDEA, and its corrosion performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com