Molybdenum concentrate decarburization agent and process for reducing carbon content of molybdenum concentrate

A technology for molybdenum concentrate and carbon content, applied in the field of molybdenum concentrate decarburizer, can solve problems such as environmental pollution and resource waste, and achieve the effects of low production energy consumption, resource saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

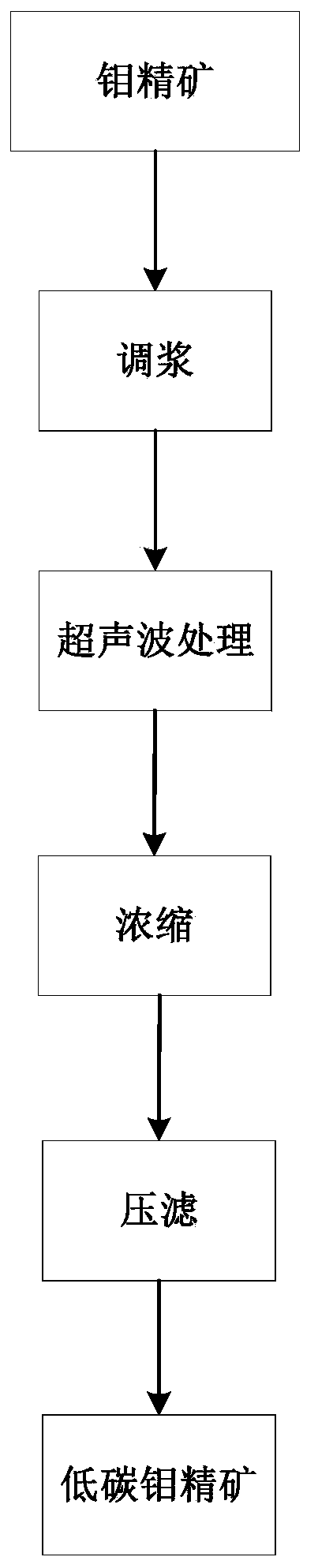

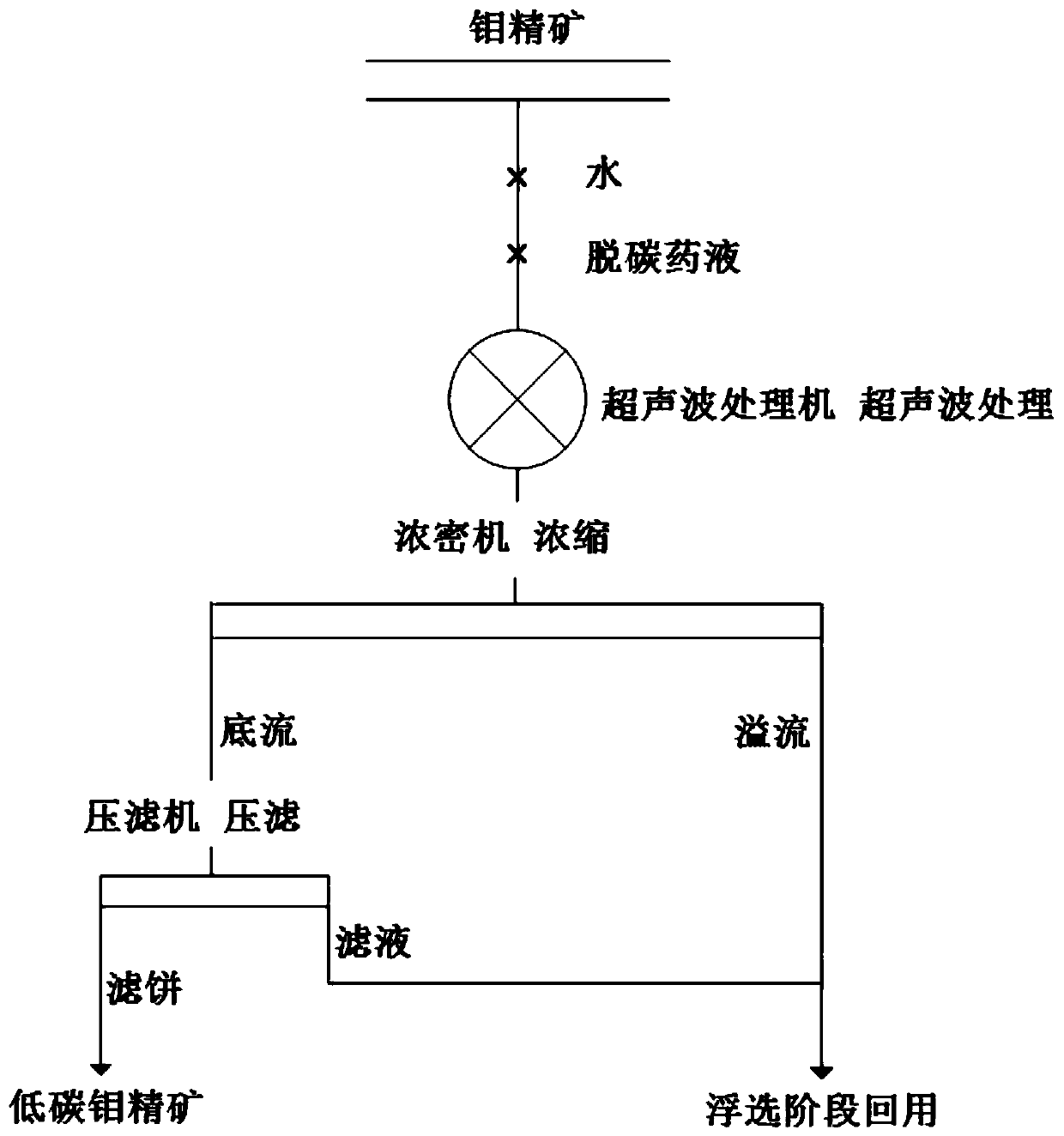

Method used

Image

Examples

Embodiment 1

[0028] A molybdenum concentrate decarburizer, the raw material components are as follows: 20kg of sodium dodecylbenzenesulfonate, 5kg of sodium hexametaphosphate, 1kg of diethanolamine, 2kg of propylene glycol block polyether.

Embodiment 2

[0030] A molybdenum concentrate decarburizer, the raw material components are as follows: 22kg of sodium dodecylbenzenesulfonate, 3kg of sodium tripolyphosphate, 1kg of diethanolamine, 2kg of propylene glycol block polyether.

Embodiment 3

[0032] A molybdenum concentrate decarburizer, the raw material components are as follows: 25kg of sodium dodecylbenzenesulfonate, 2kg of trisodium phosphate, 2kg of diethanolamine, 1kg of dopamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com