Belt filter press for sludge dehydration

A sludge dewatering and filter technology, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of inability to dewater sludge in depth, and achieve the effects of compact structure, low energy consumption, and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

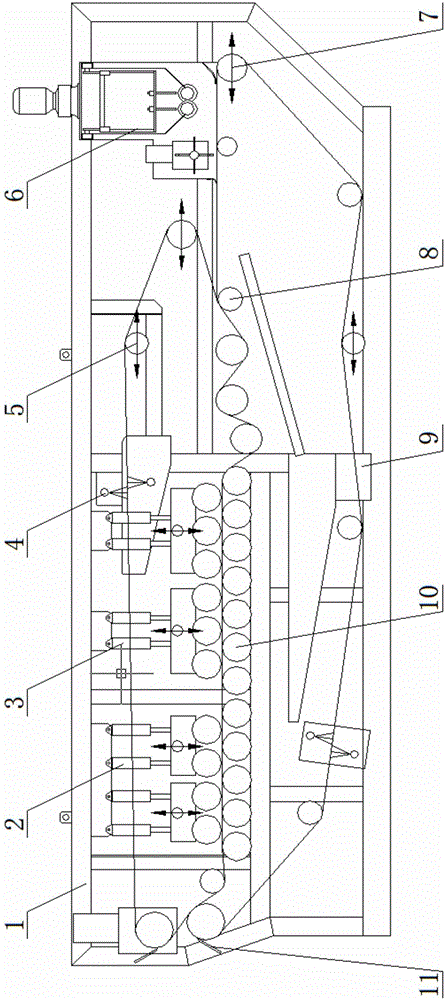

[0029] The belt press filter for sludge dewatering in this embodiment adopts a new structure of shearing uniform distribution mechanism and a multi-group, high-pressure, counter-pressure roller arrangement, and has adjustable pressing pressure, and is equipped with double-sided It is a new type of belt press dehydrator with structural design such as flushing, belt feedback deviation correction, synchronous tensioning of filter belt, shaft-mounted drive, and high-strength frame. For details, please refer to the schematic diagram of the whole equipment structure. figure 1 , figure 2 shown.

[0030] Part 1: Rack

[0031] The carrier of the complete set of equipment provides high-strength support guarantee for the equipment, and all other components are installed on the rack.

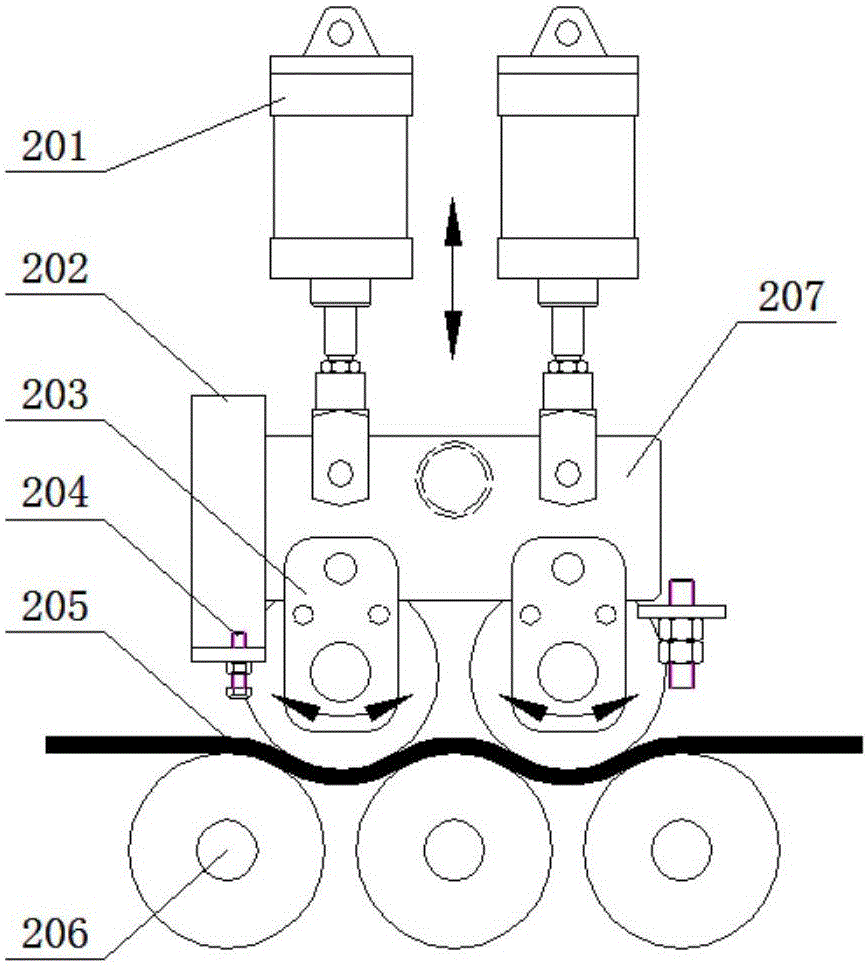

[0032] Component 2: High pressure press area (core component)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com