Method for improving tobacco shred preparing quality stability

A quality stability, silk-making technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of large investment and equipment transformation, different storage environment temperature and humidity, high energy consumption of industrial warehouses, etc., to achieve process change Small size, improved material moisture stability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

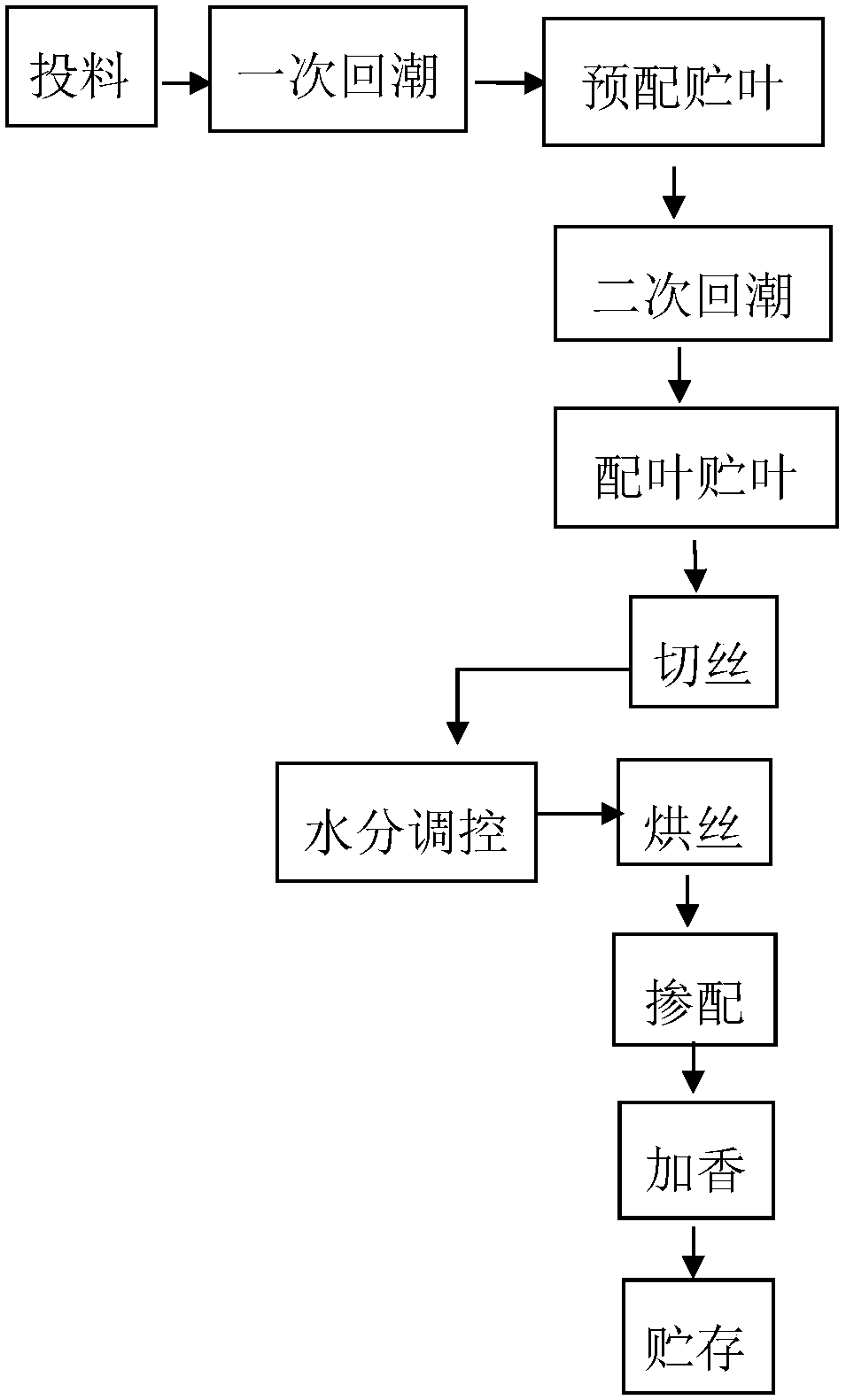

[0044] (1) After the tobacco leaves are fed, after the vacuum regains moisture and quantitatively feeds to the super-return feeding link, after the pre-mixed leaves are stored, the leaves are moistened and fed, and the leaf storage cabinets are fully absorbed by the tobacco leaves. HT, shredding machine, complete the pre-drying process.

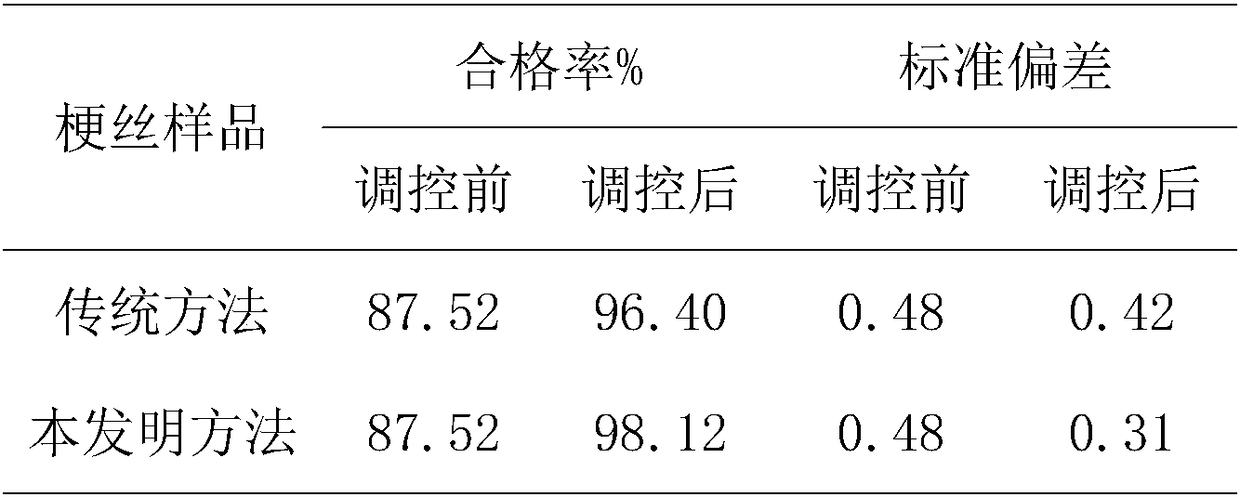

[0045] (2) After the shredding process, use moisture control to complete the moisture control of the material before drying, and add moisture control equipment on the production line between the shredding machine and the heating and humidifying equipment to realize the humidification or drying of the cut tobacco at the entrance of the shreds Moderately increase or decrease the moisture content of the material to improve the physical processing resistance of cut tobacco, which is beneficial to the subsequent drying process. At the same time, it also improves the stability of HT processing strength and provides a guarantee for the stability of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com