Floating boring head for processing inner surface of bent tube billets

A technology of inner surface and tube blank, applied in the field of floating boring head, can solve the problems of good surface quality, large transformation investment, low processing efficiency, etc., and achieve the effect of wide processing range, small transformation investment and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

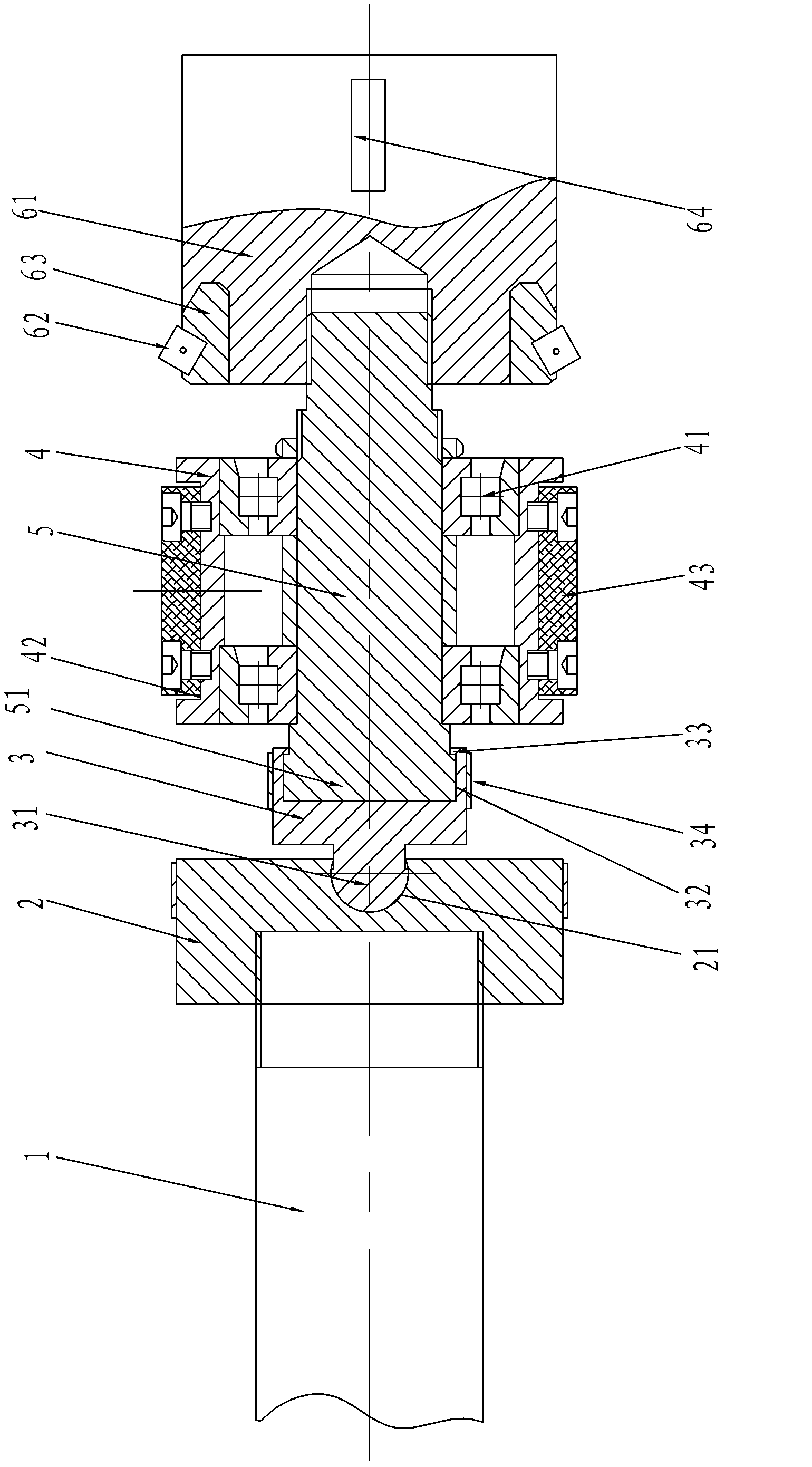

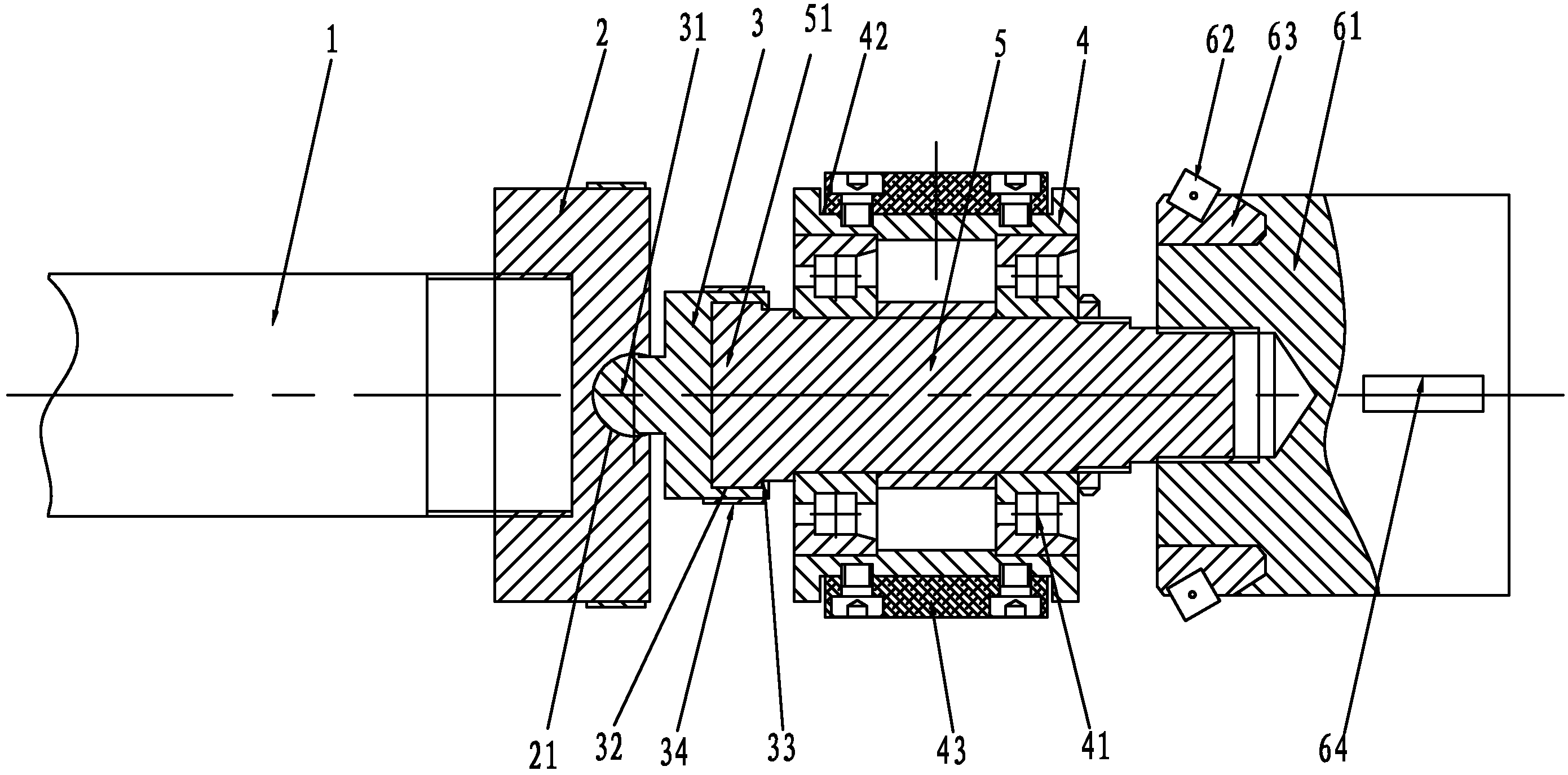

[0021] Such as figure 1 As shown, the floating boring head for processing the inner surface of the curved tube blank in the present invention includes a boring bar 1, a boring bar connecting head 2, a universal connecting block 3, a guide die 4, a supporting shaft 5, a boring tool mechanism, and the boring bar connecting head 2. One end is threaded with the boring bar 1, the other end of the boring bar connector 2 is provided with a spherical groove 21, and one end of the universal connection block 3 is provided with a spherical protrusion 31, and the arcs of the spherical protrusion 31 and the spherical groove 21 are both larger than 180° , and the arc of the spherical protrusion 31 is smaller than the arc of the spherical groove 21, the spherical protrusion 31 is embedded in the spherical groove 21, the spherical protrusion 31 can rotate freely in the spherical groove 21, and one end of the support shaft 5 is provided with a bump 51 , the protrusion 51 is embedded in the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com