Water-based acrylic resin with high distinctness of image and preparation method thereof

A water-based acrylic and distinct-image technology, applied in coatings and other directions, can solve the problems of water-based acrylic coatings with insufficient gloss, insufficient water-resistance effect, and unsatisfactory sharpness, etc., and achieves excellent hydrophobicity and UV resistance. ability, improve inversion effect, improve gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

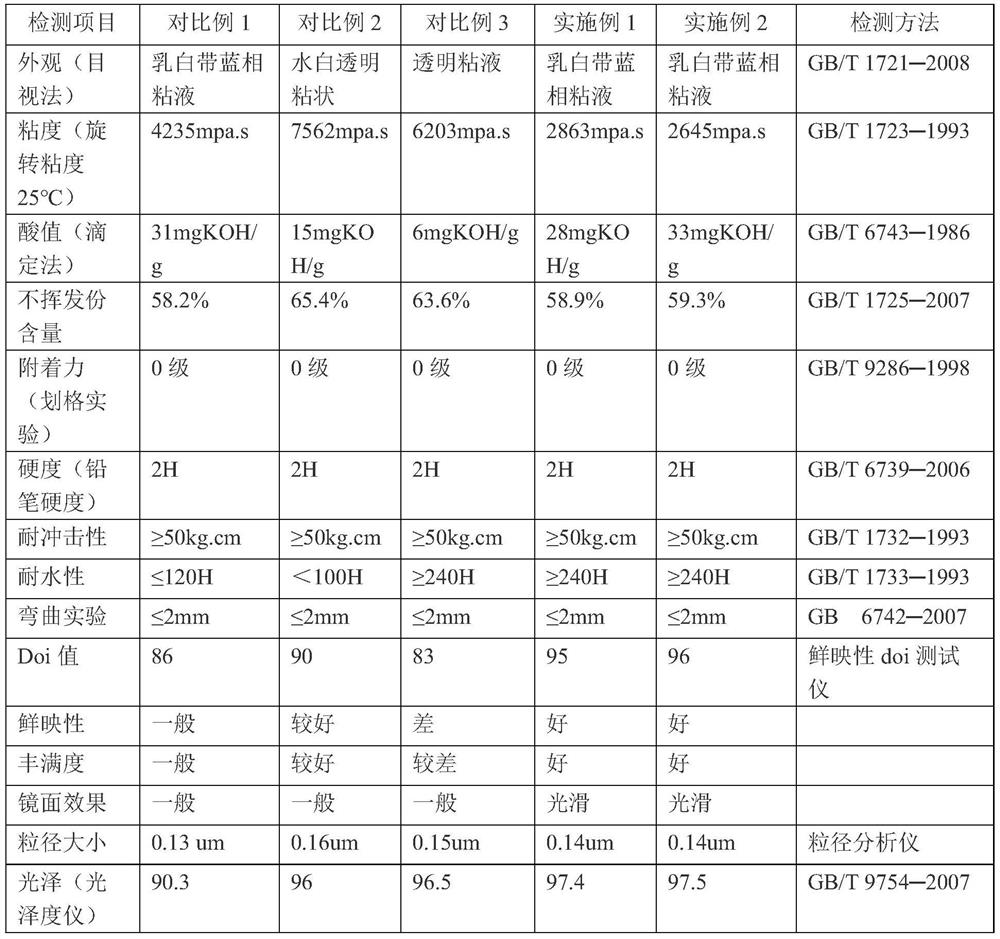

Examples

Embodiment 1

[0040] A high freshness water-based acrylic resin of the present invention, mainly made of raw materials of the following number of parts by weight:

[0041] Acrylic monomer (4 parts acrylate, 35 parts methyl methacrylate, 16 parts hydroxyacrylate, 23 parts butyl acrylate, 11 parts isooctyl acrylate): 89 parts,

[0042] Styrene monomer (styrene): 12 parts,

[0043] Initiator (azodiisobutyronitrile): 4.7 parts,

[0044]Chain transfer agent (dodecyl mercaptan): 1.2 parts,

[0045] Amine neutralizer (N, N─ dimethylethanolamine): 2.8 parts,

[0046] Mixed solvent (2.5 parts, tert-vinyl carbonate 1 part): 3.5 parts,

[0047] Solvent (propylene glycol butyl ether 25 parts, propylene glycol methyl ether acetate 25 parts): 50 parts.

[0048] The preparation method of the high freshness of the present embodiment of the aqueous acrylic resin, comprising the following steps:

[0049] (1) Take 80% of the solvent into the reactor, stir and pass nitrogen, heat the reflux, control the temperatur...

Embodiment 2

[0055] A high freshness water-based acrylic resin of the present invention, mainly made of raw materials of the following number of parts by weight:

[0056] Acrylic monomer (20 parts methyl ether acetate, 4.5 parts acrylic acid, 40 parts methyl methacrylate, 13 parts hydroxyacrylate, 22 parts butyl acrylate, 12 parts isooctyl acrylate): 111.5 parts,

[0057] Styrene monomer (styrene): 10 parts,

[0058] Initiator (azodiisobutyronitrile): 4.7 parts,

[0059] Chain transfer agent (dodecyl mercaptan): 1.5 parts,

[0060] Amine neutralizer (N, N─ dimethylethanolamine): 3.0 parts,

[0061] Mixture (5 parts of tert-carbonated glycidyl esters, 2 parts of tert-vinyl carbonate): 7 parts,

[0062] Solvent (31 parts of propylene glycol butyl ether, 25 parts of methyl ether acetate of propylene glycol): 56 parts.

[0063] The preparation method of the high freshness of the present embodiment of the water-based acrylic resin is the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com