Paint spraying process for automobile carbon fiber composite material

A composite material and carbon fiber technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve problems such as painting process, and achieve the effect of good coating performance, high gloss and high vividness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

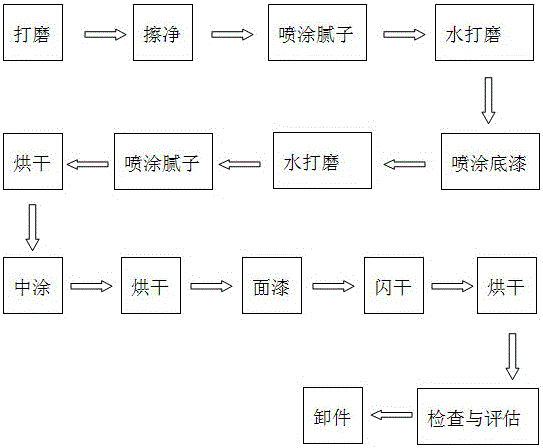

[0028] For carbon fiber composite materials after grinding, the surface roughness Ra is 1.0-1.2, and the surface is allowed to have a little grinding marks and a few pinholes (the pinhole size is generally Φ0.5mm-Φ2mm) for high decorative painting, such as figure 1 The general process flow shown is:

[0029] (1) Grinding: After grinding, the roughness Ra of the substrate is 1.0-1.2;

[0030] (2) Wipe clean: wipe off the sanding dust with a sticky cloth, and check for no dust by visual inspection;

[0031] (3) Spray putty: dry at room temperature for 30 minutes, ambient temperature 18°C~35°C, relative humidity RH40%~70%, thickness 30μm~40μm;

[0032] (4) Water grinding: water grinding treatment is carried out for surface defects of the coating after spraying putty, making it smooth;

[0033] (5) Primer: dry at room temperature for 30 minutes, ambient temperature 18℃~35℃, relative humidity RH40%~70%, thickness 30μm~40μm;

[0034] (6) Water grinding: local water grinding treat...

Embodiment 2

[0047]For carbon fiber composite materials after grinding, the surface roughness Ra is 0.8-1.0, and the surface is allowed to have a little grinding marks and a few pinholes (the pinhole size is generally Φ0.5mm-Φ1mm) for high decorative painting. The general process is:

[0048] (1) Grinding: After grinding, the roughness Ra of the substrate is 0.8-1.0;

[0049] (2) Wipe clean: wipe off the sanding dust with a sticky cloth, and check for no dust by visual inspection;

[0050] (3) Spray putty: dry at room temperature for 30 minutes, ambient temperature 18°C~35°C, relative humidity RH40%~70%, thickness 30μm~40μm;

[0051] (4) Water grinding: water grinding treatment is carried out for surface defects of the coating after spraying putty, making it smooth;

[0052] (5) Primer: dry at room temperature for 30 minutes, ambient temperature 18℃~35℃, relative humidity RH40%~70%, thickness 30μm~40μm;

[0053] (6) Water grinding: local water grinding treatment is carried out for the su...

Embodiment 3

[0064] For carbon fiber composite materials after grinding, the surface roughness Ra is 0.7-0.8, and there are no grinding marks and pinholes on the surface for high decorative painting. The general process is:

[0065] (1) Grinding: After grinding, the roughness Ra of the substrate is 0.7-0.8;

[0066] (2) Wipe clean: wipe off the sanding dust with a sticky cloth, and check for no dust by visual inspection;

[0067] (3) Primer: Dry at room temperature for 30 minutes, ambient temperature 18℃~35℃, relative humidity RH40%~70%, thickness 30μm~40μm;

[0068] (4) Water grinding: local water grinding treatment is carried out for the surface defects of the coating after spraying the primer, which is smooth and smooth;

[0069] (5) Intermediate coating: ambient temperature 18℃~35℃, relative humidity RH40%~70%, thickness 30μm~40μm;

[0070] (6) Drying: The drying temperature is 80°C, and the holding time is 30 min~40 min;

[0071] (7) Topcoat: ambient temperature 18℃~35℃, relative h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com