Chemical transfer membrane coating process for automobile carbon fiber composite

A chemical transfer, composite material technology, applied in the direction of replication/marking method, printing, etc., can solve the problems of inability to produce high decorative, high-performance coatings, and the coating process is too simple, saving energy and coating performance. Good and satisfying coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

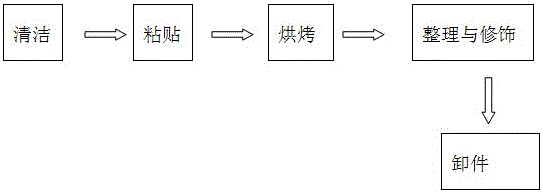

[0024] The thickness of the functional layer of the coated chemical transfer film is 100 μm-250 μm and the thickness of the functional varnish layer is 50 μm-100 μm. For its process, see figure 2 , take the following steps:

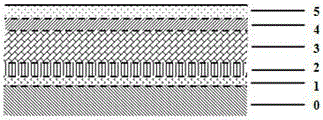

[0025] (1) Cleaning: Visually inspect the surface of the carbon fiber composite workpiece ( figure 1 , 0 layers), no dust;

[0026] (2) Sticking: Remove the lining layer of the chemical transfer film to expose the adhesive layer, and attach the transfer film to the surface of the carbon fiber composite workpiece.

[0027] (3) Baking: Stretch and pull the chemical transfer film according to the surface shape of the carbon fiber composite material workpiece, and heat the chemical transfer film with a hand-held infrared heating lamp. The purpose is to make the functional layer and functional varnish layer according to the shape of the carbon fiber composite material workpiece. Appropriate deformation. Use a tool to remove the air bubbles between the tra...

Embodiment 2

[0034] The thickness of the functional layer of the coated chemical transfer film is less than 100 μm and the thickness of the functional varnish layer is less than 50 μm. For its process, see figure 2 , take the following steps:

[0035] (1) Cleaning: Visually inspect the surface of the carbon fiber composite workpiece without dust;

[0036] (2) Sticking: Remove the lining layer of the chemical transfer film to expose the adhesive layer, and attach the transfer film to the surface of the carbon fiber composite workpiece.

[0037] (3) Baking: Stretch and pull the chemical transfer film according to the surface shape of the carbon fiber composite workpiece, and heat the chemical transfer film with an infrared heating lamp. In this process, the functional layer and the functional varnish layer deform greatly, are easy to wrinkle, and are easy to be damaged due to stretching after heating and baking.

[0038] (4) Modification: remove the paper lining or polyvinyl chloride lin...

Embodiment 3

[0044]The thickness of the functional layer of the coated chemical transfer film is greater than 250 μm and the thickness of the functional varnish layer is greater than 100 μm. For its process, see figure 2 , take the following steps:

[0045] (1) Cleaning: Visually inspect the surface of the carbon fiber composite workpiece without dust;

[0046] (2) Sticking: Remove the lining layer of the chemical transfer film to expose the adhesive layer, and attach the transfer film to the surface of the carbon fiber composite workpiece.

[0047] (3) Baking: Stretch and pull the chemical transfer film according to the surface shape of the carbon fiber composite workpiece, and heat the chemical transfer film with an infrared heating lamp. This process is prone to problems such as coating cracking due to heating of the thicker functional layer and functional varnish layer.

[0048] (4) Modification: remove the paper lining or polyvinyl chloride lining on the outer surface of the chemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com