Creep epoxy asphalt and preparation method thereof

A technology of epoxy asphalt and epoxy resin, applied in the direction of asphalt coating, epoxy resin coating, coating, etc., can solve the problems of construction workers and atmospheric environment, pollution, limited extension performance, etc., and achieve excellent coating performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

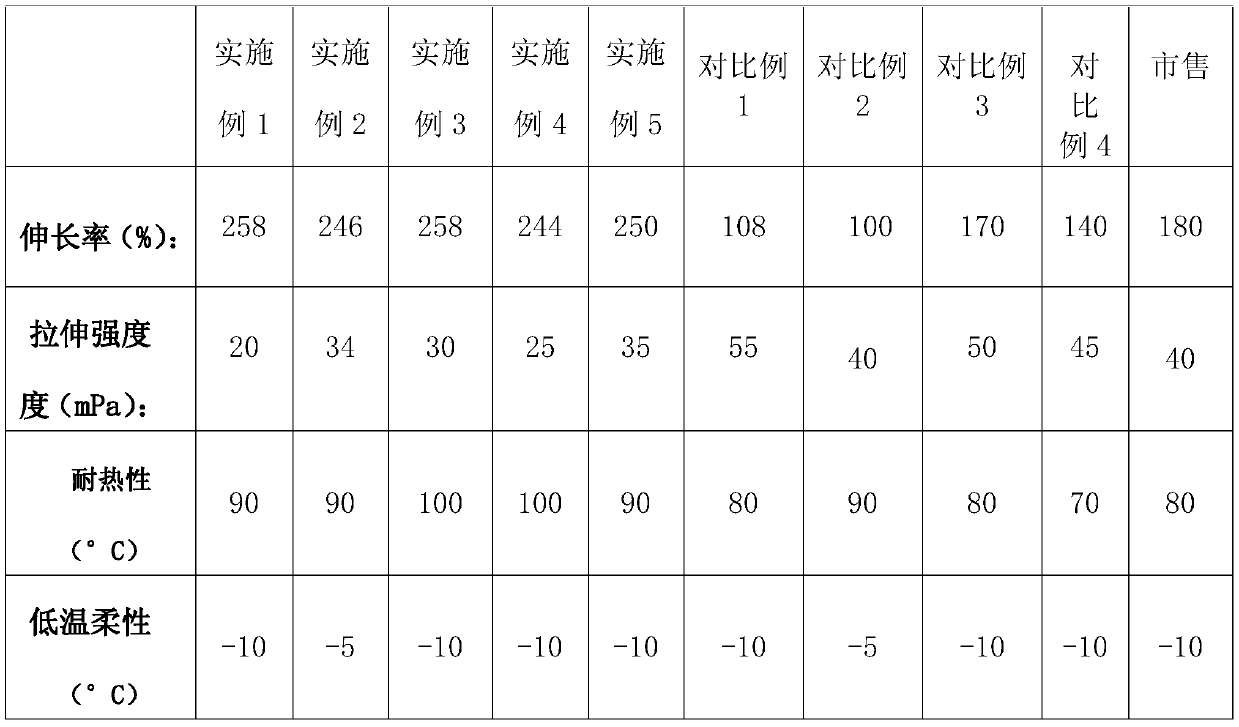

Examples

Embodiment 1

[0015] Epoxy pitch resin: 80 parts, epoxy resin: 20 parts, curing agent: 35 parts, described epoxy resin is bisphenol A epoxy resin, and described curing agent is the mixture of aliphatic amine, alicyclic amine.

[0016] A method for preparing a creep type epoxy asphalt, the steps include (1) mixing and stirring an epoxy asphalt resin, an epoxy resin and a curing agent in a container; wherein the epoxy asphalt resin and the epoxy resin The preparation method is as follows: heat the reaction kettle to 150°C, add epoxy resin and epoxy resin in turn, disperse and stir at high speed until the mixture is uniform, and the rotation speed is 200r / min.

Embodiment 2

[0018] Epoxy asphalt resin: 50 parts, epoxy resin: 40 parts, filler: 10 parts, curing agent: 26 parts, described epoxy resin is the epoxy resin that is single molecular structure, and described curing agent is aromatic amine and polyamide Amide curing agent.

[0019] A kind of method for preparing a kind of creep type epoxy asphalt, the steps include (1) epoxy asphalt resin, epoxy resin, filler and curing agent are mixed and stirred in a container and get final product; wherein epoxy asphalt resin, epoxy asphalt resin, epoxy asphalt resin The preparation method of epoxy resin and filler is as follows: heat up the reaction kettle to 150°C, add epoxy resin, epoxy resin and filler in turn, disperse and stir at high speed until uniformly mixed, and the speed is 400r / min.

Embodiment 3

[0021] Epoxy pitch resin: 40 parts, epoxy resin: 20 parts, filler: 30 parts, curing agent: 40 parts, described epoxy resin is bisphenol F epoxy resin, and described curing agent is aminoethylpiperazine AE .

[0022] The method for preparing creep type epoxy asphalt, the steps include (1) epoxy asphalt resin, epoxy resin and curing agent are mixed in a container and stirred evenly; wherein the preparation method of epoxy asphalt resin and epoxy resin is : Heat up the reaction kettle to 100°C, add epoxy resin and epoxy resin in turn, disperse and stir at a high speed until the mixture is uniform, and the rotation speed is 200r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com