Method for processing non-oriented electrical steel material

A technology of grain-oriented electrical steel and treatment method, which can be applied in the direction of pretreatment surface, metal material coating process, device for coating liquid on the surface, etc. , to achieve the effect of improving coating adhesion, excellent coating performance and excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

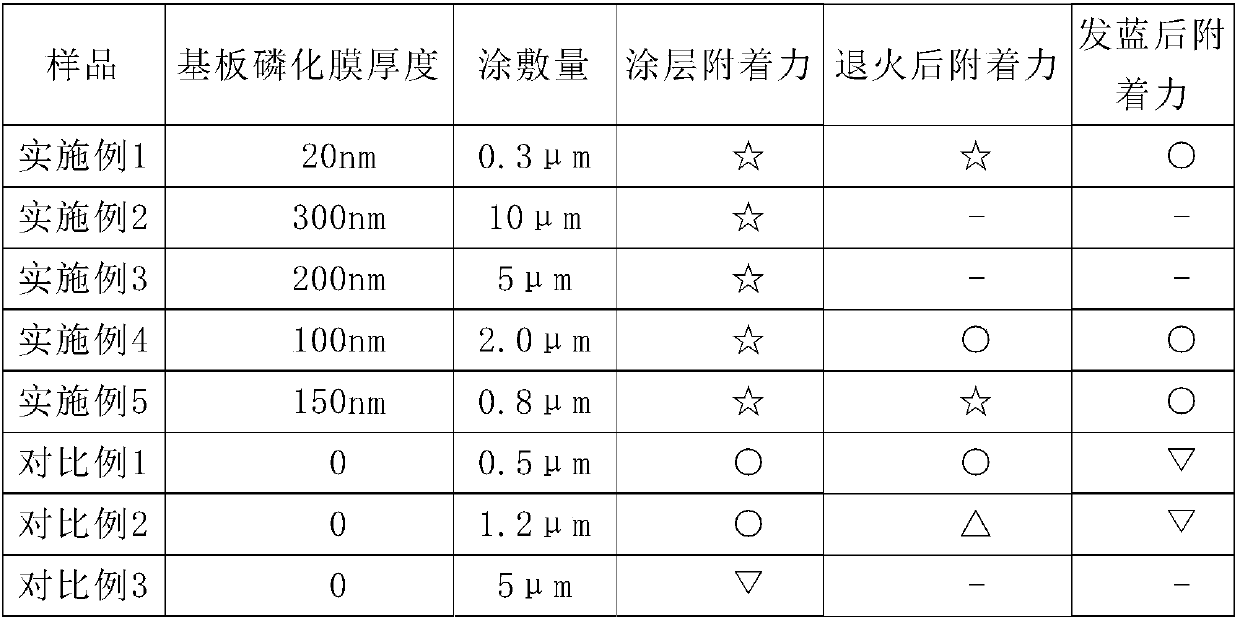

Examples

Embodiment 1

[0031] After cold rolling and annealing, the surface of the non-oriented electrical steel strip is clean and clean, and enters the strip surface treatment process. The strip is immersed in a surface treatment liquid tank containing 5wt% phosphoric acid and 1.0wt% silane coupling agent for 3s. Squeeze the polyurethane material with a squeeze roll, press the squeeze roll with a force of 10kg, and dry it with hot air at 35°C for 3 seconds to obtain a steel strip with a phosphating film on the surface with a thickness of 20nm.

[0032] The electrical steel plate enters the coating chamber, and the specific gravity of the coating liquid is 1.02g / m 2 , Viscosity 12 seconds, using a two-roller coating machine, the target film thickness of one-sided dry film is 0.3μm, and then baked in a baking oven at 350°C for 30s, the product coating adhesion and other properties are good.

Embodiment 2

[0034] After cold rolling and annealing, the surface of the non-oriented electrical steel strip is clean and clean, and enters the strip surface treatment process. The strip is immersed in a surface treatment liquid tank containing 50wt% phosphoric acid and 20wt% silane coupling agent for 35s. Two pairs of Squeeze with a squeeze roller made of polyurethane, with a pressure of 0.5kg, and dry with hot air at 90°C for 25s to obtain a steel strip with a phosphating film on the surface with a thickness of 300nm.

[0035] The electrical steel plate enters the coating chamber, and the specific gravity of the coating liquid is 1.8g / m 2 , Viscosity 150 seconds, using a three-roller coating machine, the target film thickness of one-sided dry film is 10μm, and then baked in a baking oven at 500°C for 70s, the product coating adhesion and other properties are good.

Embodiment 3

[0037] After cold rolling, the surface of the non-oriented electrical steel strip after annealing is clean, and enters the strip surface treatment process. The strip is immersed in a surface treatment liquid tank containing 25wt% phosphoric acid and 8wt% silane coupling agent for 10s. Two pairs of Squeeze with a squeeze roller made of polyurethane, with a pressure of 5kg, and dry with hot air at 55°C for 20s to obtain a steel strip with a phosphating film on the surface with a thickness of 200nm.

[0038] The electrical steel plate enters the coating chamber, and the specific gravity of the coating liquid is 1.5g / m 2 , Viscosity 120 seconds, using a three-roller coating machine, the target film thickness of one-sided dry film is 5.0μm, and then baked in a baking oven at 350°C for 40s, the product coating adhesion and other properties are good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com