Resin composition and semiconductor device

A resin composition and resin technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problem of high viscosity of raw materials, high viscosity of resin composition, and failure to satisfy solder resistance at the same time Solve problems such as cracking and coating operability, and achieve the effect of excellent coating operability and excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Maleic anhydride-modified polybutadiene (manufactured by Satomer, Ricobond 1731, number average molecular weight 5400) obtained by the reaction of polybutadiene and maleic anhydride as the (co)polymer (A) of the conjugated diene compound , acid anhydride equivalent 583, hereinafter referred to as low stress agent 1), as thermosetting resin (B), propoxylated bisphenol A diacrylate (manufactured by Shin Nakamura Chemical Co., Ltd., NK ester A-BPP-3, hereinafter referred to as Monomer 1), 1,6-hexanediol dimethacrylate (manufactured by Kyoeisha Chemical Co., Ltd., LIGHT ESTER1, 6HX, hereinafter referred to as monomer 2), isobornyl methacrylate (Kyoeisha Chemical Co., Ltd. Co., Ltd., LIGHT ESTER IBX, hereinafter referred to as monomer 3), as a (meth)acrylic (co)polymer (C), a (co)polymer (A) that can be combined with a conjugated diene compound. Glycidyl-based acrylic copolymers reacted with acid anhydride groups (manufactured by Toagosei Co., Ltd., ARUFON UG-4010, weight av...

Embodiment 2~8

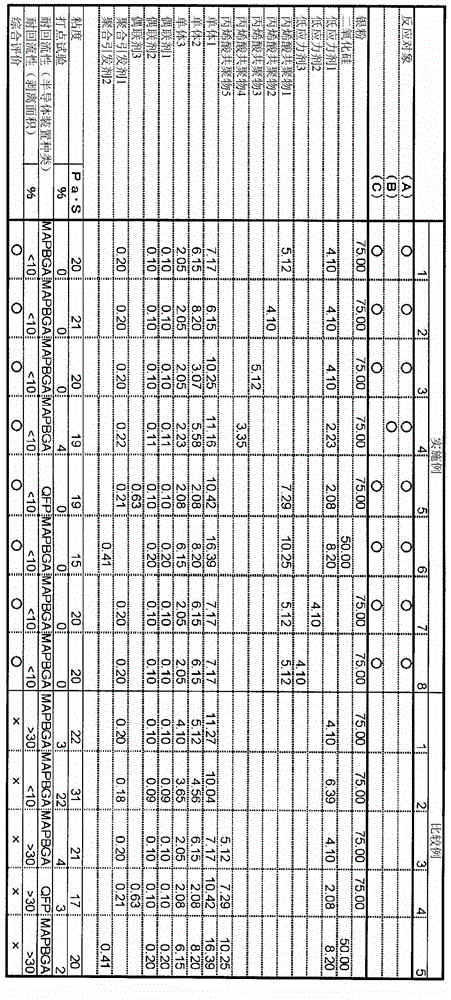

[0066] After blending at the ratio shown in Table 1, and obtaining a resin composition in the same manner as in Example 1, evaluation was performed.

[0067] In addition, in Example 2, as the (meth)acrylic acid (co)polymer (C), a glycidyl group capable of reacting with the maleic anhydride group of the (co)polymer (A) of the conjugated diene compound was used. Acrylic copolymer (manufactured by Toagosei Co., Ltd., ARUFON UG-4035, weight average molecular weight 11000, epoxy equivalent 556, hereinafter referred to as acrylic copolymer 2); in Example 3, as (meth)acrylic acid (co) As the polymer (C), an acrylic copolymer having a hydroxyl group capable of reacting with the maleic anhydride group of the (co)polymer (A) of a conjugated diene compound (manufactured by Toagosei Co., Ltd., ARUFON UH-2000, weight average molecular weight 11000, hydroxyl equivalent weight 2806, hereinafter referred to as acrylic acid copolymer 3); in embodiment 4, as (meth)acrylic acid (co)polymer (C), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com