Anti-dazzling and anti-reflection abrasion-resistant mobile phone cover plate with sterilization function and preparation method thereof

A mobile phone cover and anti-glare technology, which is applied in branch office equipment, telephone structure, ion implantation plating, etc., can solve the problems of lack of anti-glare, human injury, infection of bacteria, etc., so as to relieve visual fatigue, improve wear resistance, Anti-scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

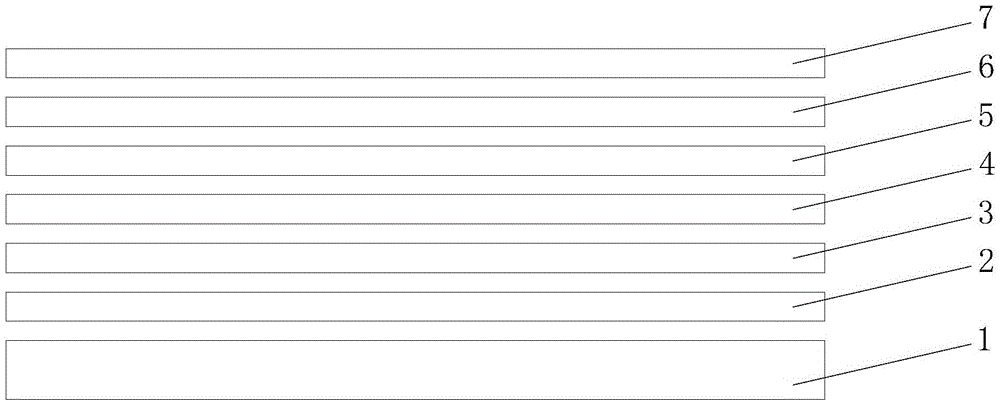

[0055] Example 1, when the substrate 1 of the mobile phone cover is formed by resin, the preparation method of the sterilizing, anti-glare and anti-reflection wear-resistant mobile phone cover specifically includes the following steps:

[0056] 1) Cleaning the outer surface of the substrate 1;

[0057] 2) coating the outer surface of the substrate 1;

[0058] A. Coating the first film layer 2:

[0059] Adjust the vacuum degree in the vacuum coating chamber to less than or equal to 5.0×10 -3 Pa, and control the temperature in the vacuum coating chamber to 50-70°C, use an electron gun to bombard the film material of the first film layer 2, and the film material of the first film layer 2 evaporates and deposits on the outer surface of the substrate 1 in the form of nano-scale molecules , while controlling the evaporation rate of the first film layer 2 to be 2.5 ? / S, the thickness of the first film layer 2 after the final formation is 10-100nm; wherein, the film material of the ...

Embodiment 2

[0072] Embodiment 2, when the substrate 1 of the mobile phone cover plate is formed from glass, the preparation method specifically includes the following steps:

[0073] 1) Cleaning the outer surface of the substrate 1;

[0074] 2) coating the outer surface of the substrate 1;

[0075] A. Coating the first film layer 2:

[0076] Adjust the vacuum degree in the vacuum coating chamber to less than or equal to 5.0×10 -3 Pa, and control the temperature in the vacuum coating chamber to 200-300°C, use an electron gun to bombard the film material of the first film layer 2, and the film material of the first film layer 2 evaporates and deposits on the outer surface of the substrate 1 in the form of nano-scale molecules , while controlling the vapor deposition rate of the first film layer 2 to be 2.5 ? / S, the final thickness of the first film layer 2 after formation is 10-100nm; wherein, the film material of the first film layer 2 is trititanium pentoxide , forming a trititanium pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com