Coating method of anti-radiation eyeglasses

A technology of radiation mirrors and lenses, applied in the field of lenses, can solve the problems of reducing versatility, eye fatigue, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

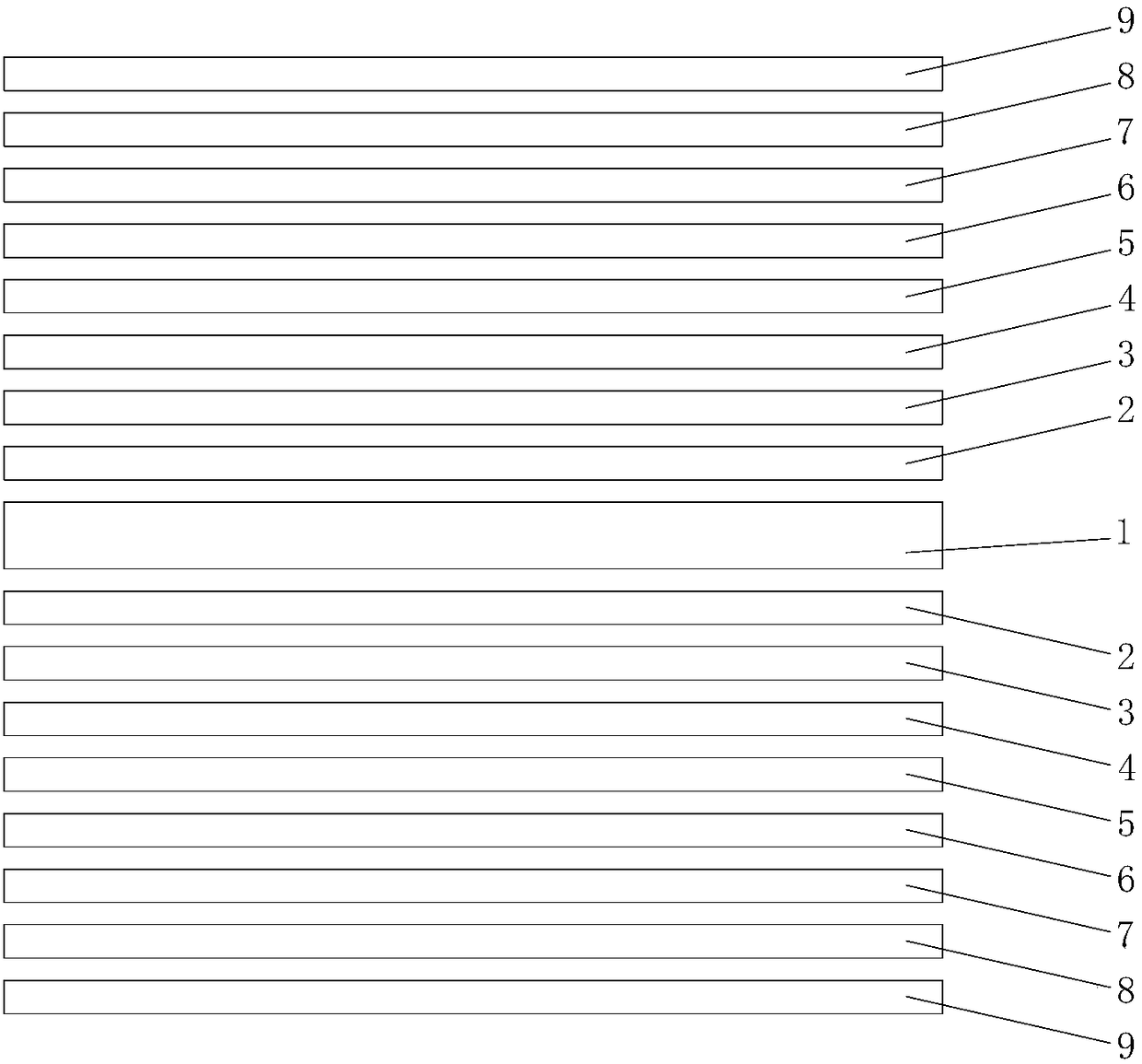

[0059] Such as figure 1 As shown in the coating method of the radiation-proof lens of the present invention, the lens includes a substrate 1 molded by resin or glass, and the inner and outer surfaces of the substrate 1 are sequentially provided with a first film symmetrically from the inside to the outside. Layer 2, second film layer 3, third film layer 4, fourth film layer 5, fifth film layer 6, sixth film layer 7, seventh film layer 8, eighth film layer 9 and ninth film layer 10 ; The first film layer 2, the fourth film layer 5 and the seventh film layer 8 are silicon dioxide layers with a thickness of 60-90nm; the second film layer 3, the fifth film layer 6 and the eighth film layer The film layers 9 are all titanium pentoxide layers with a thickness of 20-80nm; the third film layer 4 is a metal layer with a thickness of 25-40nm; the sixth film layer 7 and the ninth film layer 10 are both The ITO layer has a thickness of 30-80nm; when the substrate is molded by resin, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com