Polyurethane primer and finishing coat combined coating

A technology of polyurethane primer and polyurethane resin, applied in the field of coatings, can solve problems such as easy corrosion, achieve high adhesion, excellent coating performance, and solve the effect of poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

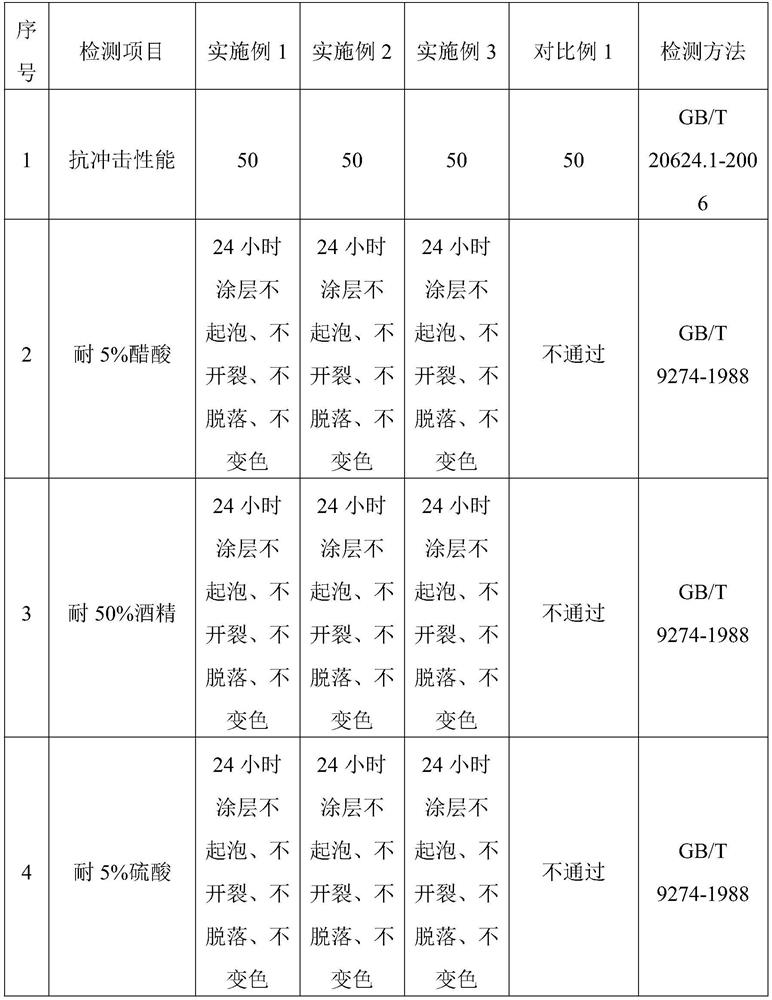

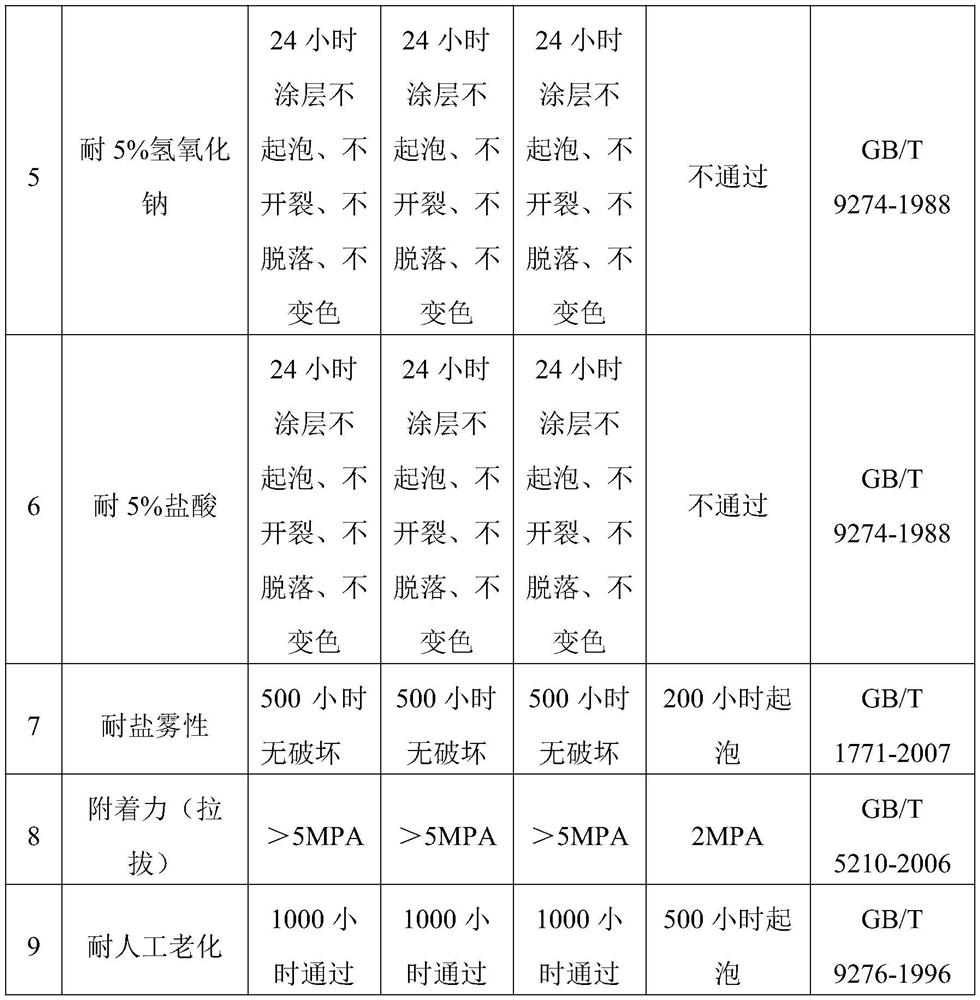

Examples

Embodiment 1

[0048] Preparation of moisture-curing polyurethane primer and topcoat:

[0049] Preparation of Moisture Curing Polyurethane Primer:

[0050] Preparation of thickener slurry: Add 85kg of xylene solvent into the dispersing and stirring tank, add 5kg of BYK163 dispersant at 400rpm, stir 10kg of thickener for 10min, disperse at 1000rpm for 35min at high speed and mix well for later use.

[0051]Preparation of moisture-curing polyurethane primer: Add 9.35kg of Covestro E21 moisture-curing polyurethane resin, 3.7kg of xylene solvent, and 4.5kg of thickener slurry into the dispersion stirring tank, and add 81.73kg of zinc powder and 4kg of quartz powder at a speed of 400rpm , disperse at 1500rpm at high speed for 25 minutes, reduce the speed to 400rpm, add 0.5kg water absorbent ADDITIVE TI, 1kg Momentive MP200 silane, and stir evenly.

[0052] Preparation of top coat

[0053] Preparation of component A of the topcoat: add 50kg of Covestro NH1420 aspartate resin and 2kg of xylene so...

Embodiment 2

[0059] Preparation of moisture-curing polyurethane primer and topcoat:

[0060] Preparation of thickener slurry: Add 85kg of butyl acetate solvent into the dispersion stirring tank, add 5kg of ANTITERRA 203 dispersant and 10kg of BENTONE27 thickener at 600rpm and stir for 5min, then disperse at 1000rpm at high speed for 35min and mix evenly for later use.

[0061] Preparation of moisture-curing polyurethane primer: Add 30kg of Covestro E21 moisture-curing polyurethane resin, 18kg of butyl acetate solvent, and 20kg of thickener slurry into the dispersion stirring tank, add 32kg of zinc powder and 4kg of barium sulfate at 500rpm, and add 32kg of zinc powder at 1200rpm Disperse at high speed for 30 minutes, reduce the speed to 500rpm, add 0.5kg of water-absorbing agent ADDITIVE OF, 1kg of Momentive A187 silane, and stir evenly.

[0062] Preparation of top coat

[0063] Preparation of component A of the topcoat: Add 38kg of Feiyang F520 aspartate resin and 4kg of butyl acetate so...

Embodiment 3

[0069] Preparation of moisture-curing polyurethane primer and topcoat:

[0070] Preparation of thickener slurry: Add 85kg of trimethylbenzene solvent into the dispersing stirring tank, add 5kg of BYK110 dispersant at 600rpm, and 10kg of Hemings SD-2 thickener, stir for 10min, disperse at 1500rpm for 25min and mix evenly for later use.

[0071] Preparation of moisture-curing polyurethane primer: Add 10kg of Covestro E21 moisture-curing polyurethane resin, 14kg of trimethylbenzene solvent, and 16kg of thickener slurry into the dispersion stirring tank, add 60kg of zinc powder and 2kg of barium sulfate at 600rpm, and then add 60kg of zinc powder and 2kg of barium sulfate at a high speed of 1500rpm. Disperse for 35 minutes, reduce the rotation speed to 600rpm, add 0.5kg water absorbent ADDITIVE TI, 1kg Momentive A187 silane, and stir evenly.

[0072] Preparation of top coat

[0073] Preparation of component A of topcoat: Add 18kg Feiyang 420 aspartate resin, 42kg Nupace 1753 hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com