Automatic perspiration-removing varnish

A perspiration and automatic technology, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problem that colored stainless steel substrates cannot automatically eliminate sweat stains, and achieve excellent gloss and color retention, high adhesion, and high freshness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

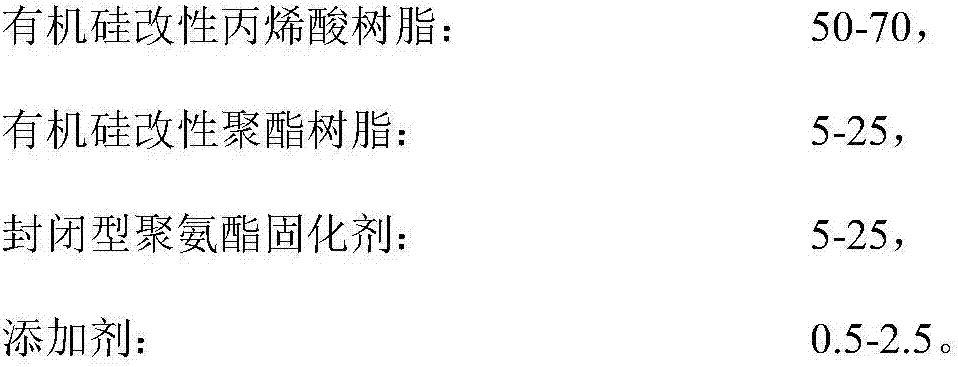

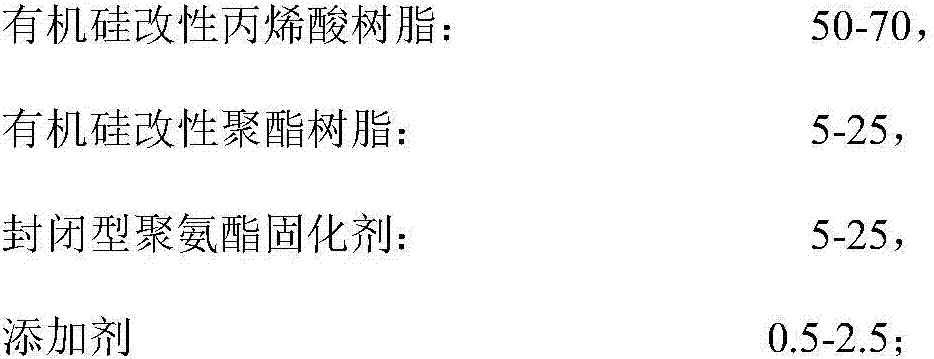

Method used

Image

Examples

Embodiment

[0029]

[0030]

[0031] 5. There are no relevant national or industry standards in testing the product of the present invention, which is highly professional. The product of the present invention is tested according to the enterprise standard Q / CYQ1008-2015 of Chongqing Three Gorges Paint Co., Ltd. and the samples collected in the market.

[0032]

[0033] To sum up: the automatic perspiration stain varnish of the present invention achieves the expected purpose through the synergistic effect of each component, and each index achieves the expected purpose, and finally manifests as fast and automatic perspiration stain elimination, which exceeds the performance of collecting samples in the market. Carry out the anti-fingerprint test on the paint film prepared by the product of the present invention, press the paint film with clean fingers and palms at any time, and then remove it, it can be seen that the sweat stains disappear quickly within 5 seconds. The same effect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com