High-gloss and high-freshness bus finishing paint and preparation method thereof

A bus, fullness technology, applied in the field of car topcoat, can solve the problems of inability to guarantee the fineness of mixed raw materials, poor chemical resistance, poor car aesthetics, etc., and achieve excellent outdoor aging resistance and excellent appearance effect. , the effect of excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A bus finish paint with high fullness and high distinctness of image, which includes component A and component B; said component A includes resin A, 5-10% resin A, 5-10% by mass percentage Resin C, 4-8% wetting and dispersing agent A, 1-2% wetting and dispersing agent B, 25-40% pigment, 10-30% solvent, 0.5-1% leveling agent, 0.1 - 0.3% defoamer, 0.5-1.5% light stabilizer, 0.5-1.5% ultraviolet absorber; the B component includes a curing agent.

[0041] Wherein the total mass of component B is 40-50% of the total mass of component A, preferably 50%. Among the said pigments, 20-30% are light-colored pigments, and 5-10% are dark-colored pigments. The solvent includes 5-15% butyl acetate and 5-15% propylene glycol methyl ether acetate.

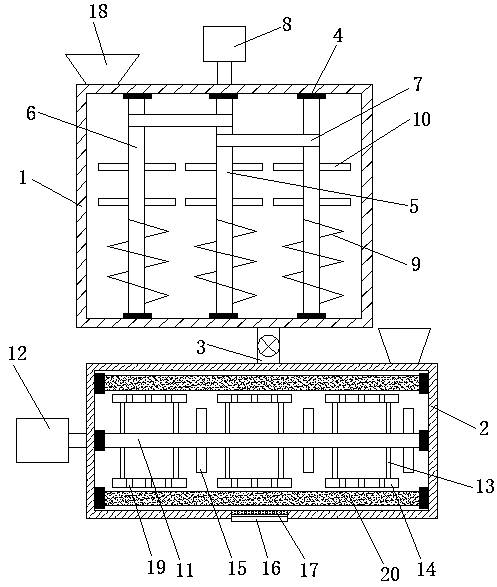

[0042] Such as Figure 4Shown, the present invention also provides a kind of preparation method of the bus finish paint of high fullness, high distinctness of image, comprises the steps:

[0043] S1. Material selection: select component ...

Embodiment 2

[0060] A bus finish paint with high fullness and high distinctness of image, which includes component A and component B; said component A includes resin A, 5-10% resin A, 5-10% by mass percentage Resin C, 4-8% wetting and dispersing agent A, 1-2% wetting and dispersing agent B, 25-40% pigment, 10-30% solvent, 0.5-1% leveling agent, 0.1 - 0.3% defoamer, 0.5-1.5% light stabilizer, 0.5-1.5% ultraviolet absorber; the B component includes a curing agent.

[0061] Wherein the total mass of component B is 40-50% of the total mass of component A, preferably 50%. Among the said pigments, 20-30% are light-colored pigments, and 5-10% are dark-colored pigments. The solvent includes 5-15% butyl acetate and 5-15% propylene glycol methyl ether acetate.

[0062] In order to effectively increase the high fullness and vividness of the bus finish paint, further, the product of the content m1 of the light-colored pigment and the content m2 of the dark-colored pigment: m1·m2 is greater than or e...

Embodiment 3

[0081] A bus finish paint with high fullness and high distinctness of image, which includes component A and component B; said component A includes resin A, 5-10% resin A, 5-10% by mass percentage Resin C, 4-8% wetting and dispersing agent A, 1-2% wetting and dispersing agent B, 25-40% pigment, 10-30% solvent, 0.5-1% leveling agent, 0.1 - 0.3% defoamer, 0.5-1.5% light stabilizer, 0.5-1.5% ultraviolet absorber; the B component includes a curing agent.

[0082] Wherein the total mass of component B is 40-50% of the total mass of component A, preferably 50%. Among the said pigments, 20-30% are light-colored pigments, and 5-10% are dark-colored pigments. The solvent includes 5-15% butyl acetate and 5-15% propylene glycol methyl ether acetate.

[0083] Such as Figure 4 Shown, the present invention also provides a kind of preparation method of the bus finish paint of high fullness, high distinctness of image, comprises the steps:

[0084] S1. Material selection: select component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com