Printed color coated sheet with high distinctness of image and preparation method thereof

A clear image, color plate technology, used in coatings, pretreated surfaces, anti-corrosion coatings, etc., can solve problems such as foggy surface, poor fresh image, film separation, etc., and achieve complete solvent evaporation and clear image. Good, improve the effect of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

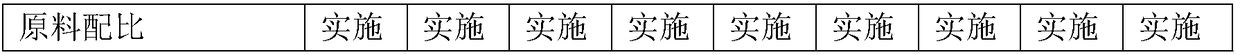

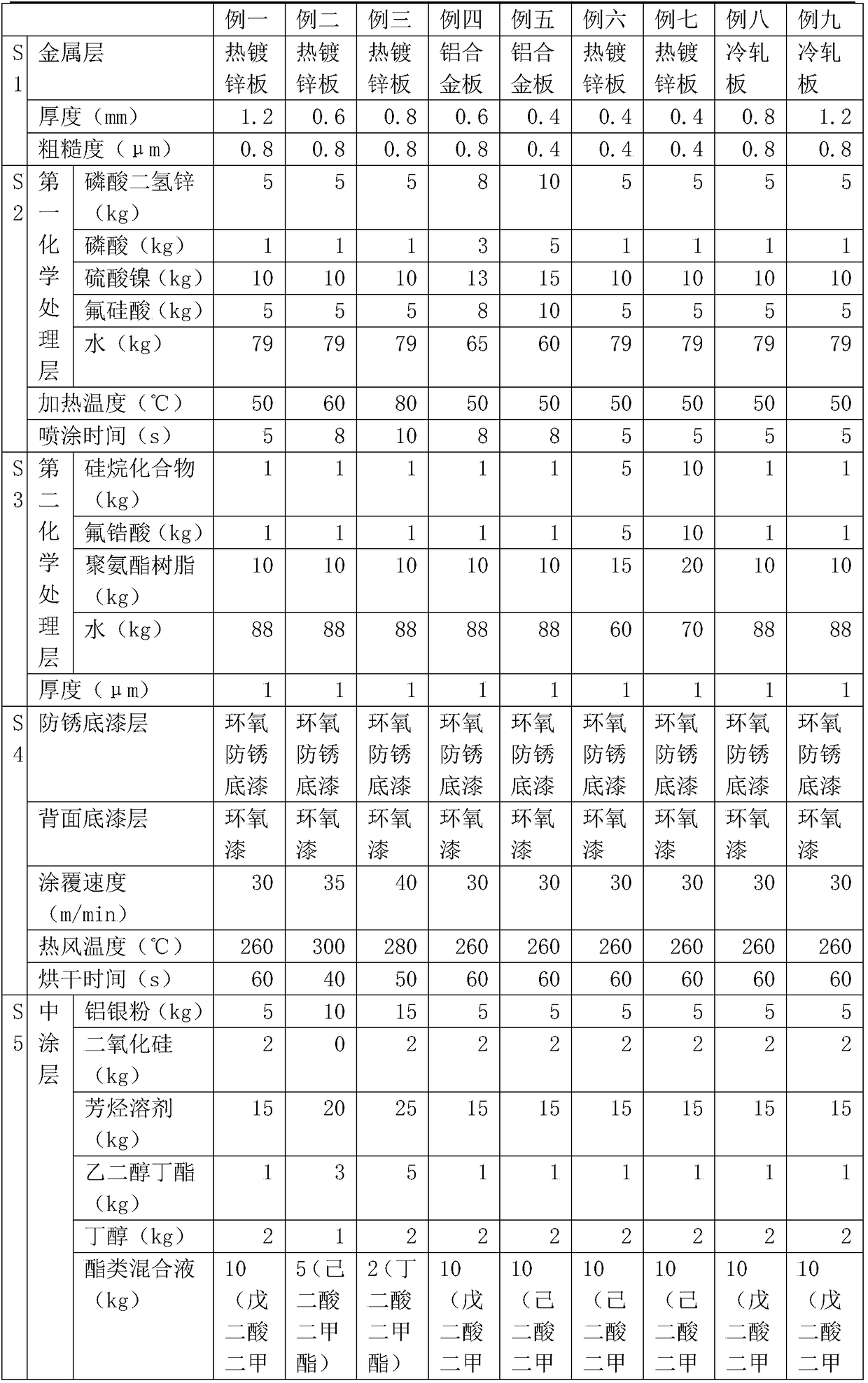

[0039] Embodiment 1: A kind of high-definition printing color plate, including a metal layer, the upper surface of the metal layer is sequentially arranged with a first chemical treatment layer, a second chemical treatment layer, and an antirust primer layer from the surface of the metal layer , middle coating layer, first texture layer, second texture layer, third texture layer, varnish protection layer and protective film layer; the lower surface of the metal layer is arranged with the first chemical treatment layer, the second Two chemical treatment layers, anti-rust back primer layer and back paint layer.

[0040] The above high vividness printing color plate is made according to the following method:

[0041] S1. The metal layer is a hot-dip galvanized sheet with a thickness of 1.2 mm and a surface roughness of 0.8 μm; the metal layer is pre-degreased, washed and air-dried;

[0042] S2. Chemical treatment of the surface of the metal layer: the first chemical treatment la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com