Environment-friendly HAA low-temperature-curing high-Tg high-toughness high-leveling ultra-weatherability powder coating

A kind of powder coating, environment-friendly technology, applied in the direction of powder coating, polyester coating, coating, etc., can solve the problems of poor storage stability, poor mechanical properties, practical application difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

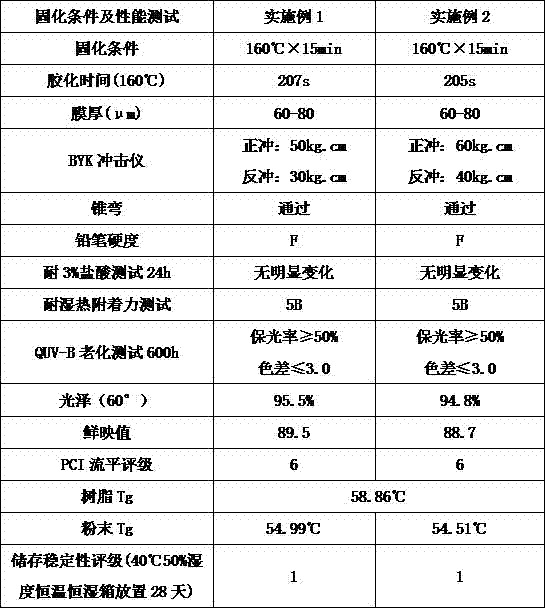

Examples

Embodiment 1

[0027] An environmentally friendly HAA low-temperature curing high Tg high toughness high leveling super weather-resistant powder coating formula is as follows:

[0028] Carboxylated polyester resin 65%

[0029] HAA curing agent 4.8%

[0030] Imported leveling agent 1.2%

[0031] Degasser 0.8%

[0032] Antioxidant 0.3%

[0033] Brightener 0.8%

[0034] Dispersing aid 0.5%

[0035] Degassed wax 0.6%

[0036] Toughener 0%

[0037] Weather-resistant pigments 26%

Embodiment 2

[0039] An environmentally friendly HAA low-temperature curing high Tg high toughness high leveling super weather-resistant powder coating formula is as follows:

[0040] Carboxylated polyester resin 63%

[0041] HAA curing agent 4.8%

[0042] Imported leveling agent 1.1%

[0043] Degasser 0.7%

[0044] Antioxidant 0.3%

[0045] Brightener 1.0%

[0046] Dispersing aid 0.5%

[0047] Degassed wax 0.6%

[0048] Toughener 3%

[0049] Weather-resistant pigment 25%

[0050] The powder coating preparation steps are as follows:

[0051] (1) According to the formula of above-mentioned embodiment 1-2, weigh with electronic balance, carry out sufficient premixing then, make it fully mix;

[0052] (2) Melt and extrude the uniformly mixed material, the extrusion parameters are set as: 105°C in the first zone, 105°C in the second zone, the screw speed is 45HZ, cool and pulverize after extrusion to obtain flakes;

[0053] (3) Carry out vertical grinding to sheet material with coffee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com