Aqueous acrylic polyurethane aluminum powder paint and preparation method thereof

A technology of acrylic polyurethane and silver powder paint, applied in the field of coatings, can solve the problems that two-component water-based acrylic polyurethane silver powder paint has not been widely used, the gloss and vividness of the paint film cannot meet the requirements, and the orientation of water-based silver powder is poor. To achieve the effect of improving the flash effect, high gloss and vividness, and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of waterborne acrylic polyurethane silver powder paint of the present invention, described waterborne acrylic polyurethane silver powder paint is made up of A component and B component,

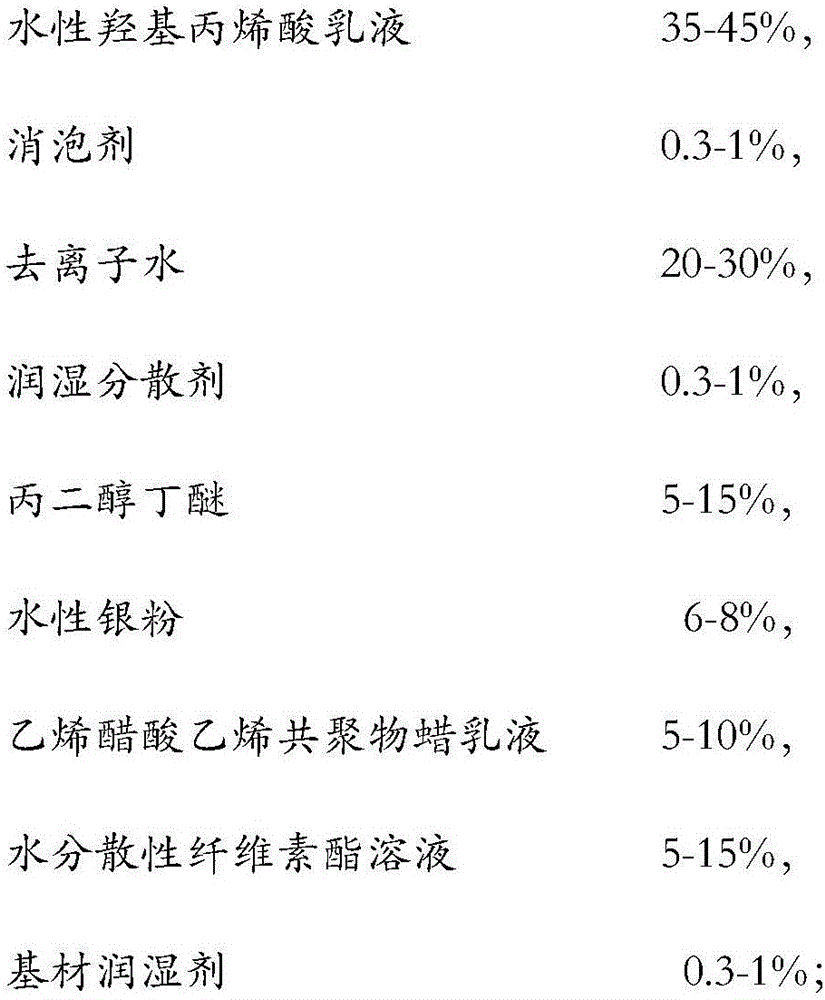

[0031] The A component consists of the following components by weight percentage:

[0032]

[0033]

[0034] The B component is an isocyanate curing agent;

[0035] The weight ratio of the A component and the B component is 7:1.

[0036] The water-based hydroxyl acrylic emulsion is VSM 6299w of allnex resins.

[0037] The curing agent is Covestro's N3900.

[0038] The water-dispersible cellulose ester solution is an aqueous solution of water-dispersible cellulose ester with a mass fraction of 20%, and the water-dispersible cellulose ester is Eastman Solus 3050.

[0039] The ethylene-vinyl acetate copolymer wax emulsion is Bik AQUATIX 8421 from Germany.

[0040] The preparation method of waterborne acrylic polyurethane silver powder paint of the present invention, compr...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1:

[0049] A kind of waterborne acrylic polyurethane silver powder paint of the present invention, described waterborne acrylic polyurethane silver powder paint is made up of A component and B component,

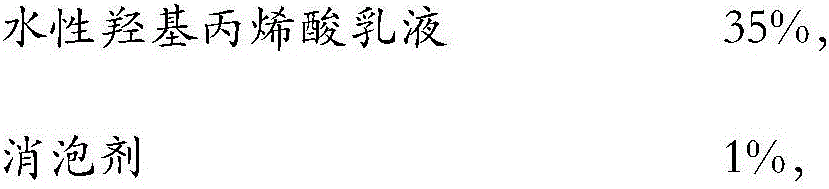

[0050] The A component consists of the following components by weight percentage:

[0051]

[0052] The B component is an isocyanate curing agent;

[0053] The weight ratio of the A component and the B component is 9:1.

[0054] The aqueous hydroxyacrylic emulsion is Setaqua 6516 of Nupace.

[0055] The preparation method of waterborne acrylic polyurethane silver powder paint of the present invention, comprises the steps:

[0056] Preparation method of component A:

[0057] (1) Add propylene glycol butyl ether into the paint mixing tank, add wetting and dispersing agent under stirring at 260r / min, then slowly add water-based silver powder, stir for 20min and then let stand for 2h to prepare water-based aluminu...

Embodiment 3

[0063] The difference between embodiment 3 and embodiment 1:

[0064] A kind of waterborne acrylic polyurethane silver powder paint of the present invention, described waterborne acrylic polyurethane silver powder paint is made up of A component and B component,

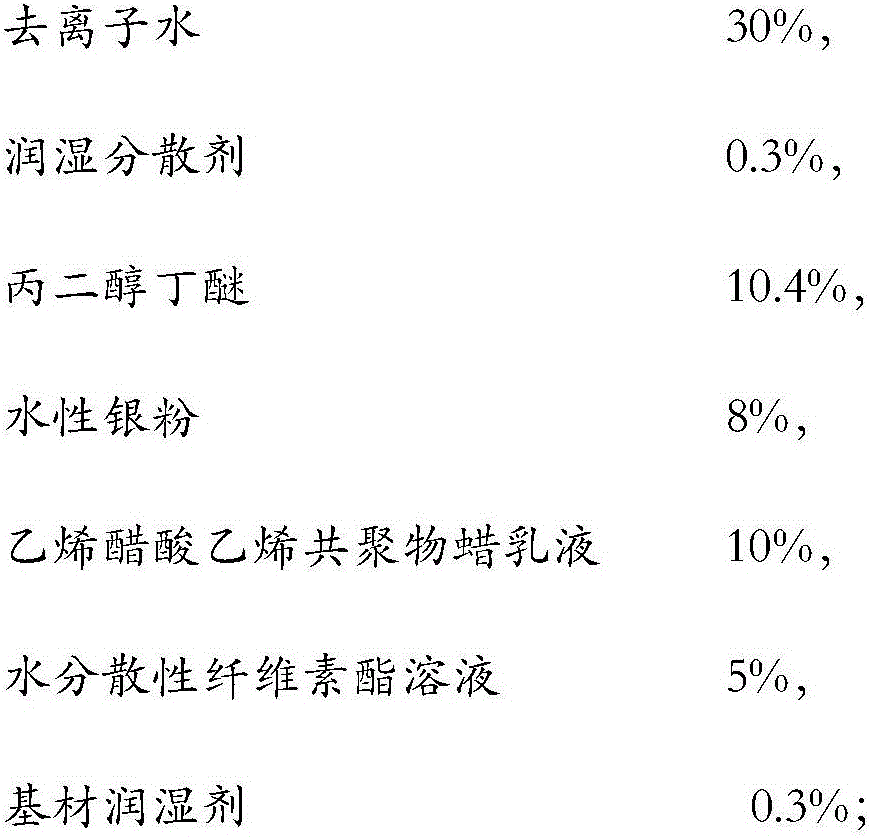

[0065] The A component consists of the following components by weight percentage:

[0066]

[0067]

[0068] The B component is an isocyanate curing agent;

[0069] The weight ratio of the A component and the B component is 8:1.

[0070] The water-based hydroxyl acrylic emulsion is a combination of two kinds of VSM 6299w of Allnex resin and Setaqua 6516 of New Pace.

[0071] The preparation method of waterborne acrylic polyurethane silver powder paint of the present invention, comprises the steps:

[0072] Preparation method of component A:

[0073] (1) Add propylene glycol butyl ether into the paint mixing tank, add wetting and dispersing agent under stirring at 300r / min, then slowly add water-based silver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com