Low-temperature water-based vehicle body coating as well as preparation method and use method thereof

A low-temperature, water-based technology, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as high energy consumption, large environmental pressure, and business operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A low-temperature water-based body paint, comprising a low-temperature water-based one-component primer, a low-temperature water-based one-component base paint and a low-temperature oily two-component varnish;

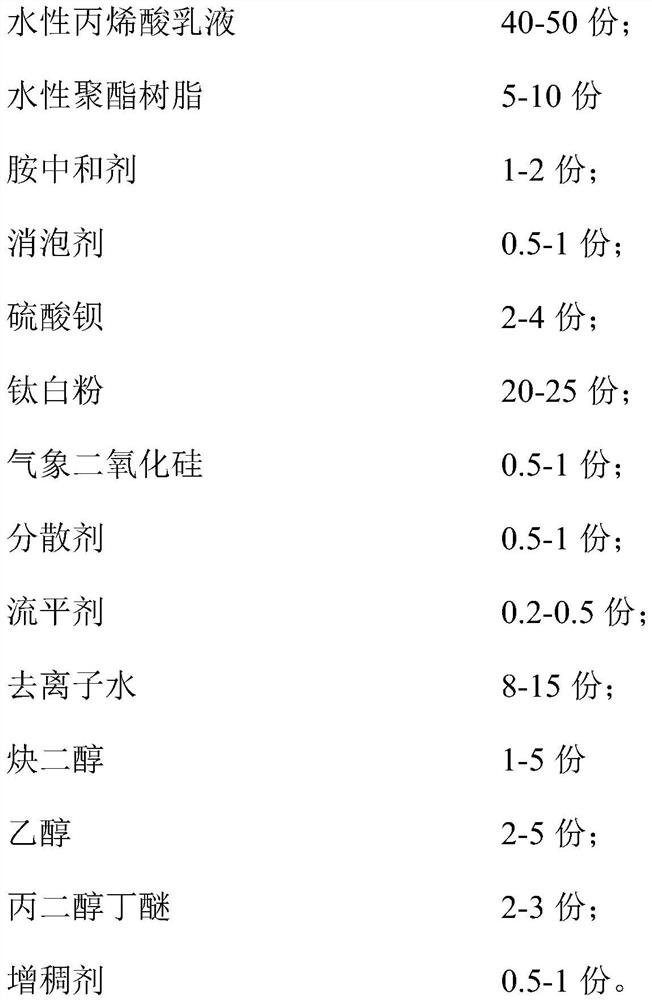

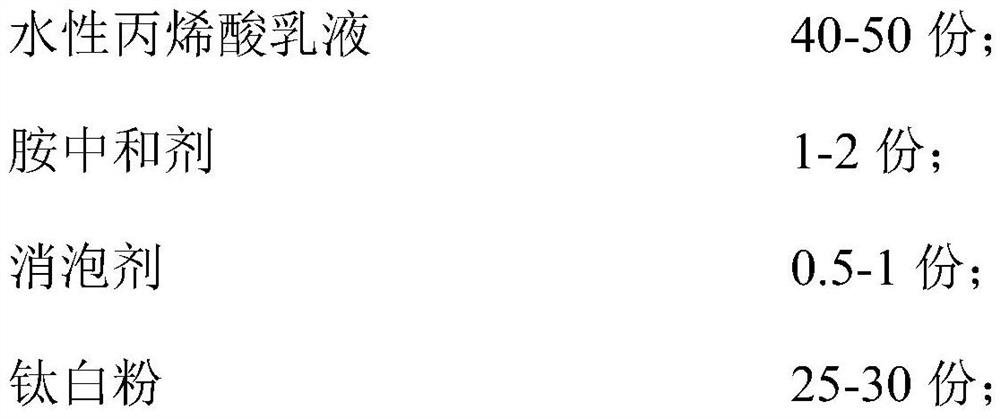

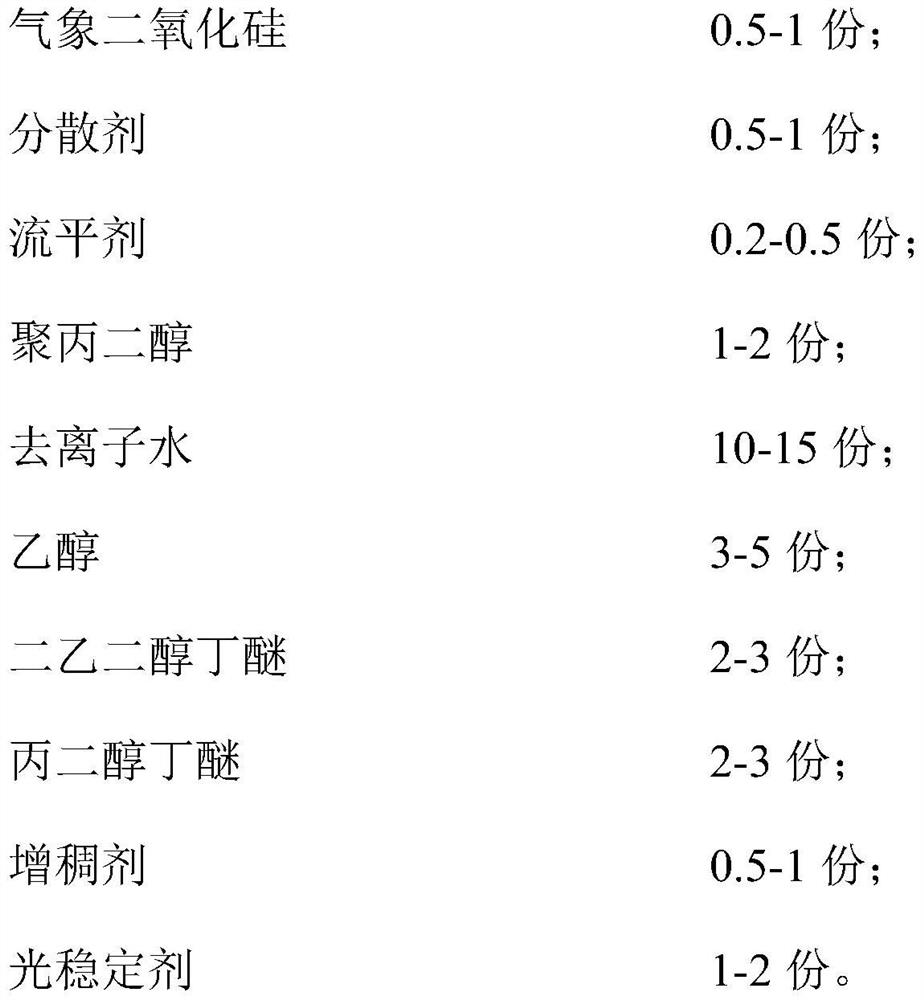

[0045] The low-temperature water-based one-component mid-coat paint includes the following raw materials, as shown in Table 1:

[0046] Paint formulation in table 1 embodiment 1

[0047] serial number Material name model supplier Example 1 1 Water-Based Acrylic Emulsion R4000 DSM 40 2 Waterborne Polyester Resin R986 DSM 10 3 Defoamer 011 Pick 1 4 Dispersant 180 Pick 0.8 5 Amine neutralizer AM-95 Dow 2 6 Alkyne diol FS204 Tu Yile 2 7 fumed silica R974 Evonik 0.8 8 leveling agent 3560 Pick 0.2 9 Titanium dioxide 2195 dawn 25 10 Deionized water Domestic 11.2 11 Propylene glycol butyl ether PNB Dow 2 12 Precipitated Barium Sulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com