Preparation method of water-based nitrocellulose emulsion and nitrocellulose film

A nitrocellulose, emulsion technology, applied in the direction of coating, can solve the problems of poor adhesion, excessive residual surfactant, poor stability of dispersion system, etc., to achieve excellent water resistance and weather resistance, strong anti-ultraviolet ability, storage good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

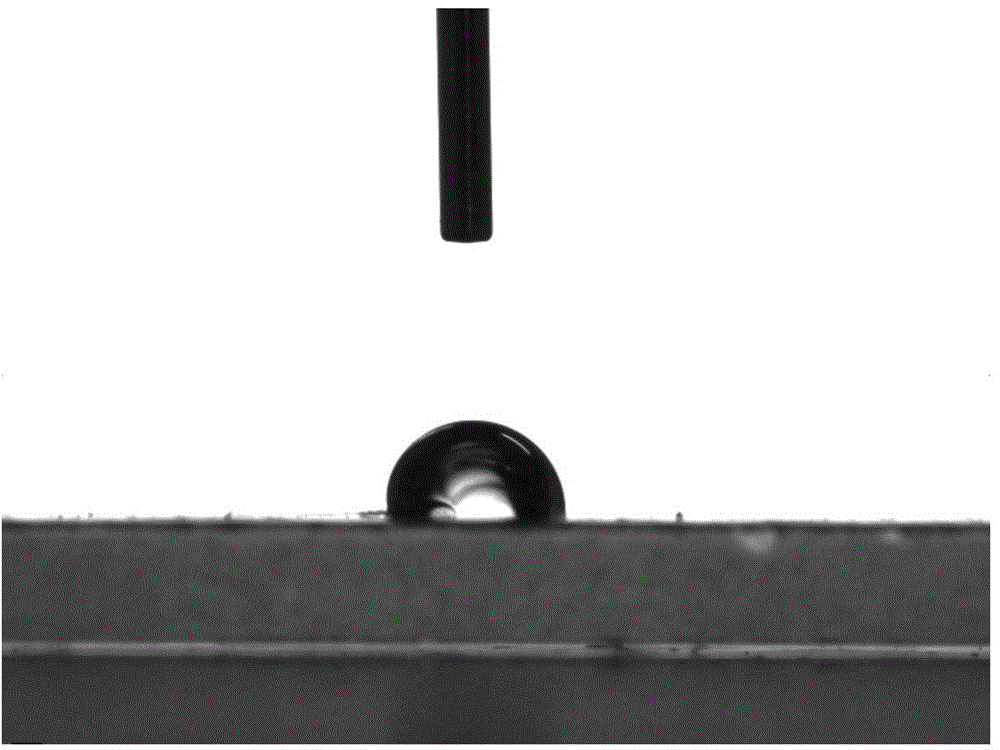

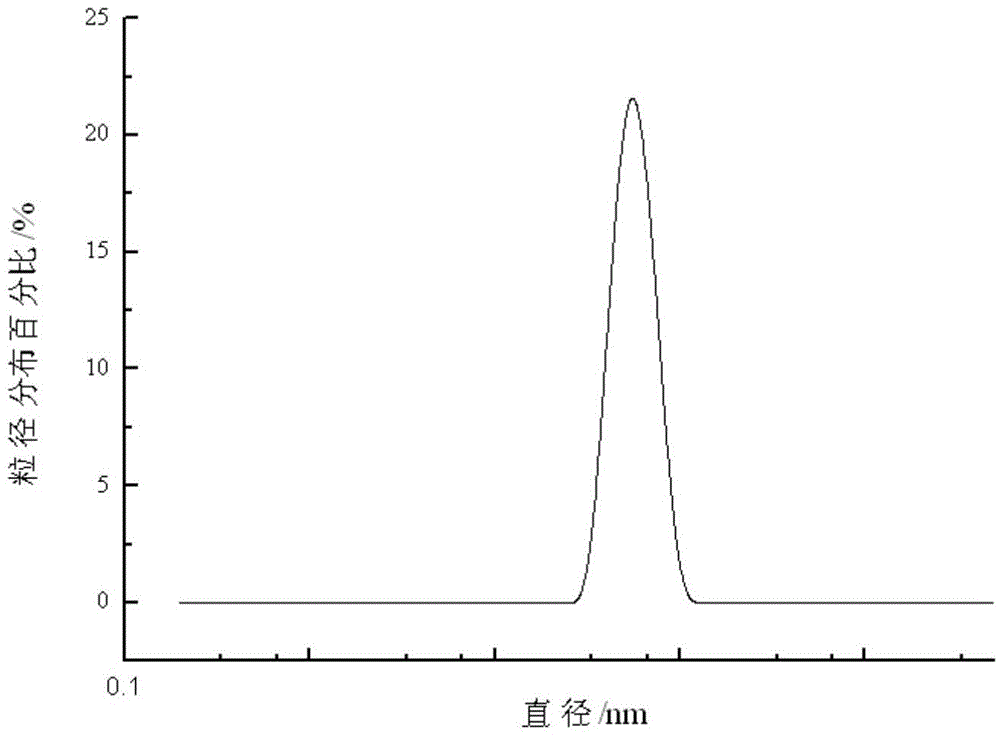

[0019] In the preparation method of the water-based nitrocellulose emulsion of the present invention, 1.0-5.0 g of hydroxyethyl acrylate, 2.0-8.0 g of acrylic acid, 10-20 g of butanone are added to a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, and 0.5 g of hydroxyethyl acrylate is added. -2.5g of recrystallized azobisisobutyronitrile was used as an initiator to react at 50-90℃ for 2-3h; after the reaction, under nitrogen protection, add 4A molecular sieve dehydration-treated dibutyltin dilaurate 0.1- 1.0g, isophorone diisocyanate (IPDI) 0.5-4.5g, and react at a constant temperature of 25-65°C for 1-2h; then raise the temperature to 70-95°C, add nitrocellulose containing 2.0-5.0g of nitrocellulose. The butanone solution was incubated for 2-3h; then the temperature was lowered to 30-60°C, the pH value of the reaction system obtained by adding sodium hydroxide was 8-9, and then 60mL of deionized water was added at a stirring speed of 800rpm, an...

Embodiment 1

[0022] Synthesis of nitrocellulose emulsion: add 1.0 g of hydroxyethyl acrylate, 8.0 g of acrylic acid, and 10 g of methyl ethyl ketone into a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, and add 1.2 g of recrystallized azobisisobutyronitrile As an initiator, the reaction was carried out at 60 °C for 2.5 h; under nitrogen protection, under nitrogen protection after the reaction, 0.6 g of dibutyltin dilaurate and 0.8 g of isophorone diisocyanate (IPDI) dehydrated by 4A molecular sieve were added to it. g, and reacted at a constant temperature of 30 °C for 1 h; then the temperature was raised to 85 °C, a nitrocellulose solution of butanone containing 5.0 g of nitrocellulose was added, and the reaction was incubated for 2 h; then the temperature was lowered to 30 °C, and sodium hydroxide was added to neutralize to pH= Add 60 mL of deionized water at a stirring speed of 8 to 9,800 rpm, keep heat for 30 minutes, and discharge to obtain an aqueous ...

Embodiment 2

[0025] Synthesis of nitrocellulose emulsion: add 4.0 g of hydroxyethyl acrylate, 2.0 g of acrylic acid, and 15 g of methyl ethyl ketone into a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, and add 1.4 g of recrystallized azobisisobutyronitrile As an initiator, the reaction was carried out at 70 °C for 2.5 h; under nitrogen protection, under nitrogen protection after the reaction, 0.7 g of dibutyltin dilaurate dehydrated by 4A molecular sieve, and 1.5 g of isophorone diisocyanate (IPDI) were added to it. g, and reacted at a constant temperature of 65 °C for 1 h; then heated to 90 °C, added nitrocellulose-butanone solution containing 2.0 g of nitrocellulose, and incubated for 2 h; then cooled to 40 °C, added sodium hydroxide to neutralize to pH= Add 60 mL of deionized water at a stirring speed of 8 to 9,800 rpm, keep heat for 30 minutes, and discharge to obtain an aqueous nitrocellulose emulsion.

[0026] Preparation of nitrocellulose film: pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com