Polyether carboxylic acid water reducer and preparation method thereof

A water-reducing agent, polyether-type technology, applied in the field of concrete admixture and its preparation, can solve the problems of difficult control of reaction process, unsatisfactory water reduction rate and slump retention value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1: Add 320Kg allyl alcohol ether CH 2 =CHCH 2 O(CH 2 CH 2 O) n H (where n=10-60), 420Kg of maleic anhydride and 50Kg of sodium methacrylate sulfonate were added to 300Kg of water to prepare an aqueous solution, added to the reactor, stirred, and heated to 90°C;

[0020] Step 2: Add 13Kg of acrylamide, 26Kg of 2-hydroxyethyl acrylate and 140Kg of water and 860Kg of 3% aqueous solution of potassium persulfate initiator to the mixture obtained in step 1. During the dropping process Keep the temperature at 90℃, and the dripping time is 3-3.5 hours;

[0021] Step 3: After the dripping is completed, react at a constant temperature at 80-100°C for about 5 hours;

[0022] Step 4: Filter.

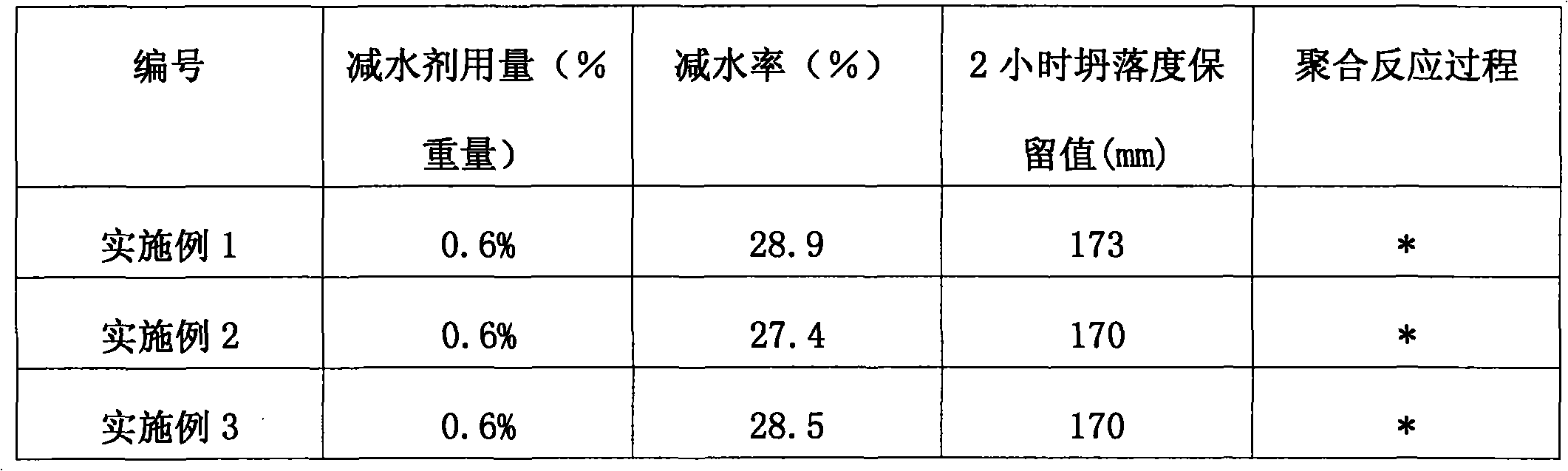

[0023] The yield was 94%. The slump retention value and water reduction rate value of the obtained product are shown in Table 1.

Embodiment 2

[0025] The other steps are the same as in Example 1, except that 320Kg propenol ether is used instead of CH whose n value is 200-300 2 =CHCH 2 O(CH 2 CH 2 O) n H replaces CH where n=10-60 in Example 1 2 =CHCH 2 O(CH 2 CH 2 O) n H. The yield was 90%. The slump retention value and water reduction rate value of the obtained product are shown in Table 1.

Embodiment 3

[0027] The other steps are the same as in Example 1, except that the amount of acrylamide is reduced to 8Kg. The yield was 80%. The slump retention value and water reduction rate value of the obtained product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com