Method for preparing photosensitive ceramic precursor for manufacturing ceramic products by additive manufacturing technology

A technology of additive manufacturing and photosensitive ceramics, which is applied in the field of photosensitive ceramic precursor preparation, can solve the problems of difficult strength and reliability of ceramic products, enlarge the internal defects of ceramics, time-consuming and labor-intensive problems, and achieve high-efficiency photo-curing performance, compact structure, The effect of smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]A method for preparing a photosensitive ceramic precursor for manufacturing ceramic products by additive manufacturing technology, the synthesis route is as follows:

[0039]

[0040] In the formula, n is a positive integer;

[0041] The specific synthesis method is as follows:

[0042] Step 1, as shown in the formula (I), the Schlenk bottle with a capacity of 250mL is pretreated to ensure that the gas in the bottle is Ar gas, and it is anhydrous and oxygen-free, and then under the protection of Ar gas, 38.98mL of chloromethyl formazan Dichlorosilane and 40.40mL dichloromethylvinylsilane were added to the Schllenk bottle, and mixed evenly under 500rpm magnetic stirring; then 10mL deionized water was added dropwise to the above-mentioned Schllenk bottle at a rate of 1 drop / 10s In, add HCl gas absorption bottle on the Schllenk bottle after the dropwise addition to absorb the HCl gas produced in the reaction process; react at room temperature until no bubbles are produc...

Embodiment 2

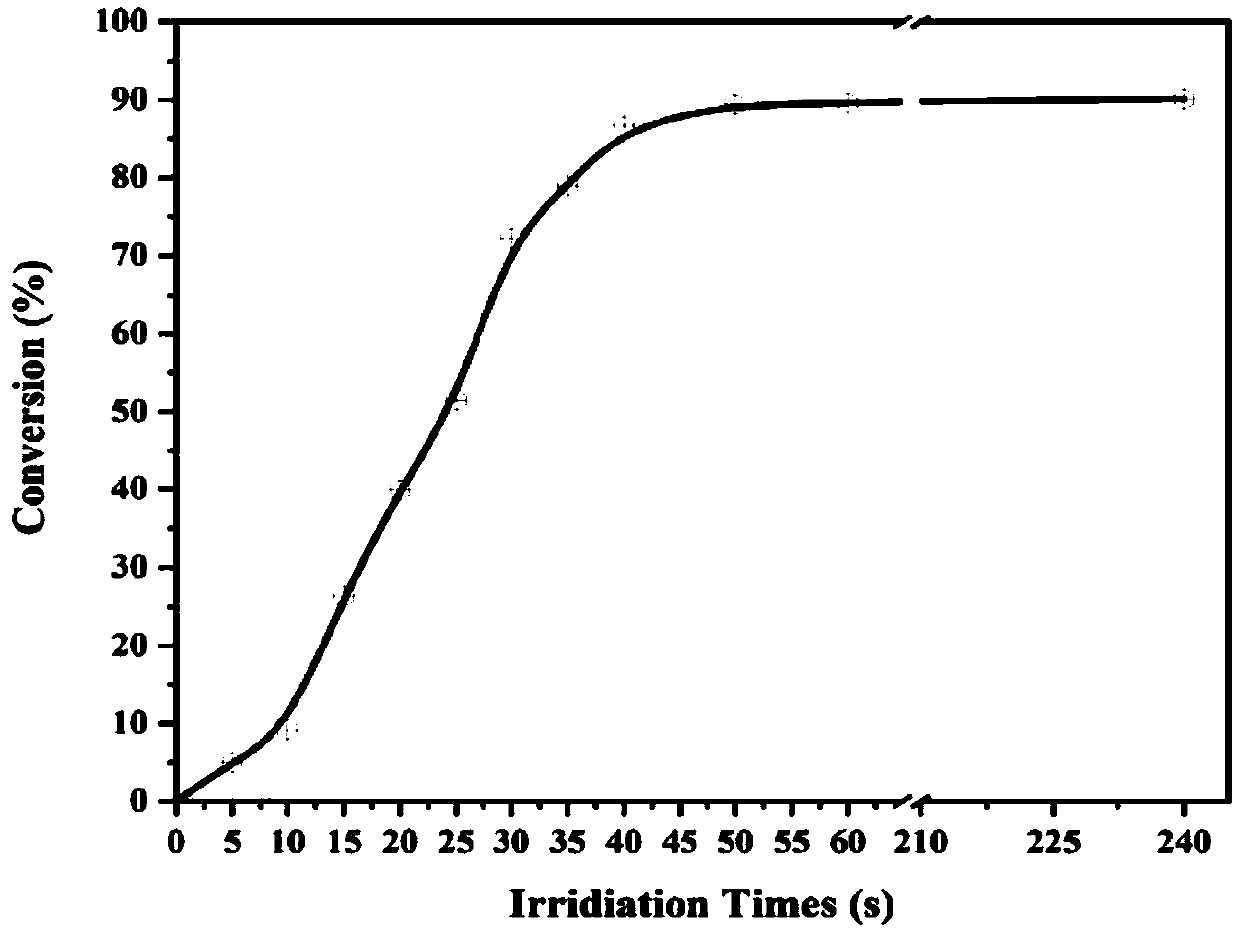

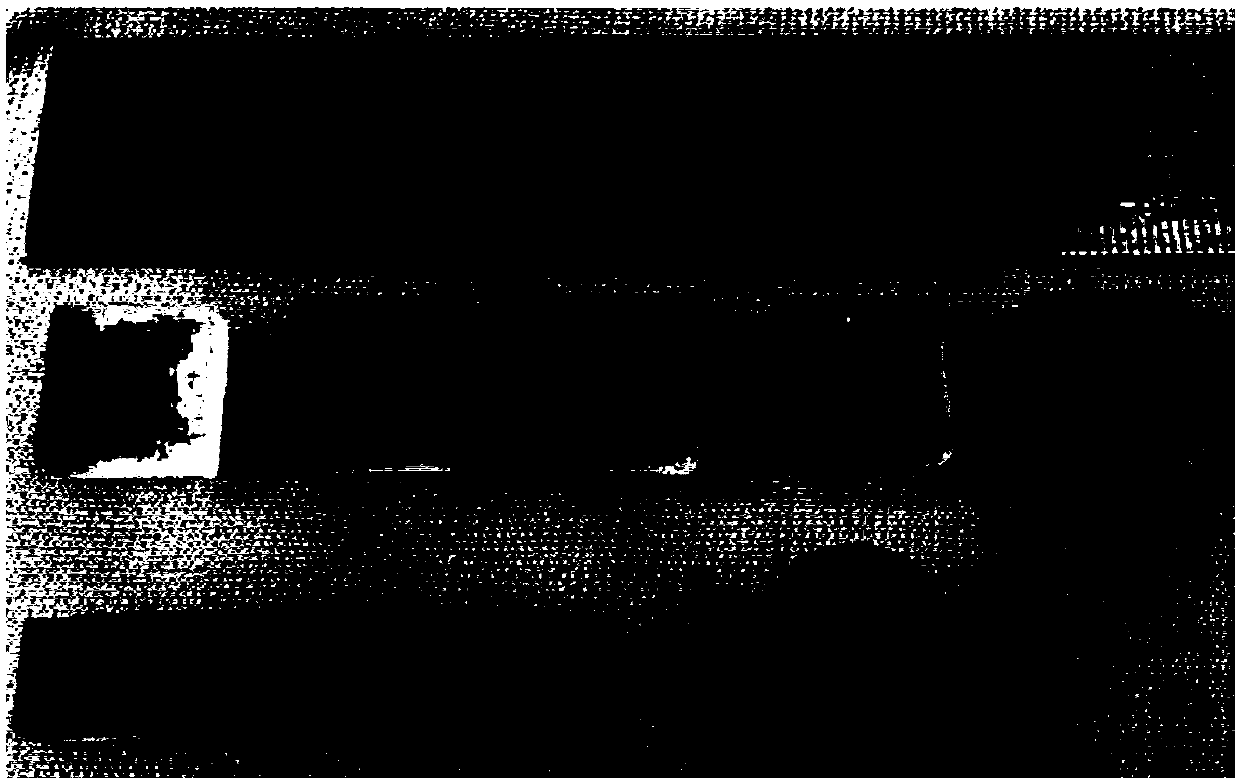

[0052] The photosensitive ceramic precursor added with a photoinitiator is used as a raw material, and a Form2 3D printer is used for 3D printing operation, and a simple three-dimensional structure is printed. The printing result is as follows: figure 2 shown.

[0053] from figure 2 It can be seen that the surface of the printed three-dimensional structure is smooth and flat, the edges are sharp and tidy, the interior is uniform, there are no pores and cracks, and it has a certain strength. This result proves that the photosensitive ceramic precursor prepared by the present invention can be combined with immediate photocuring molding technology to prepare ceramic products by means of additive manufacturing, which has broad application prospects.

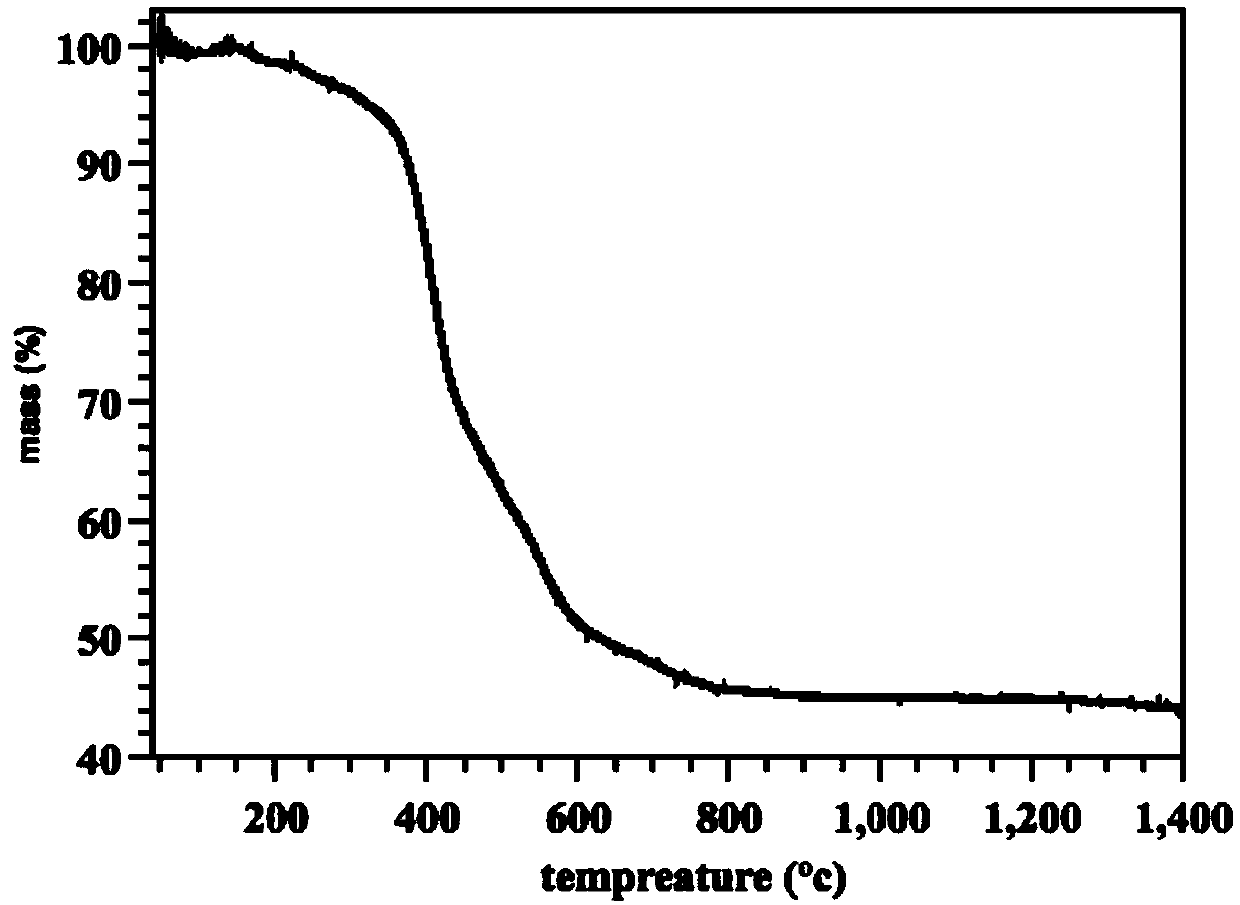

[0054] The above 3D printed samples were subjected to thermogravimetric analysis and thermal linear shrinkage calculation. The specific experimental process is as follows:

[0055] 1. Thermogravimetric analysis

[0056] Take 3-6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com