Formaldehyde-free color-fixing agent and preparation method of color-fixing agent

A technology of color-fixing agent and formaldehyde, which is applied in the field of knitted textiles, can solve the problems of restricting the industrialization process of formaldehyde-free color-fixing agent, the unsatisfactory color-fixing effect of color-fixing agent, and the high toxicity of epichlorohydrin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

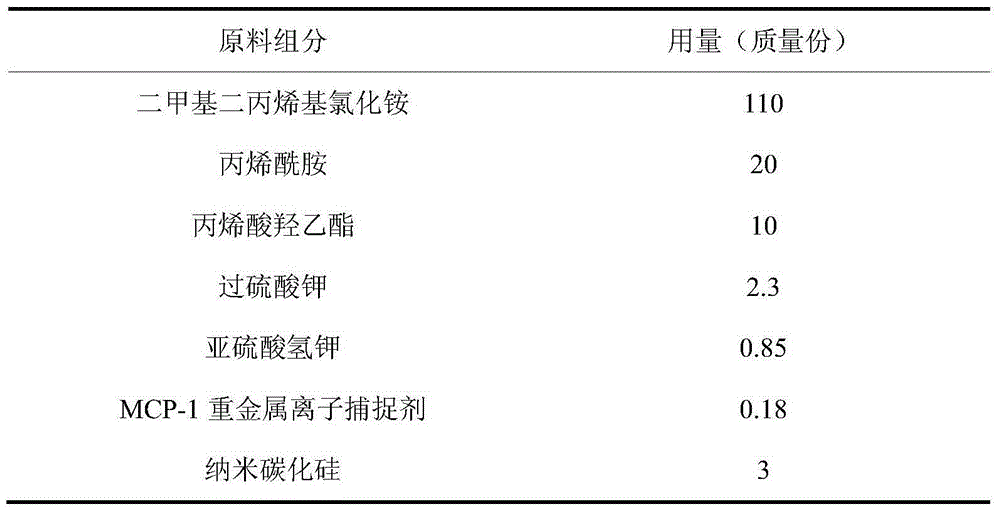

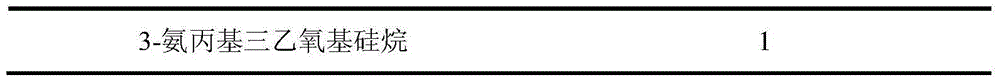

[0036] The ratio of each raw material is as follows:

[0037]

[0038] Table note: MCP-1 heavy metal ion scavenger is MCP produced by Guangzhou Nasen Chemical Co., Ltd. TM One of the models of series products, the following embodiments are all the same.

[0039] The temperature of the polymerization reaction was 70°C; 60 minutes after the start of the polymerization reaction, the remaining monomer solution and initiator solution were added dropwise for 1 hour, and the temperature was lowered to terminate the polymerization reaction after 4 hours after the dropwise addition was completed.

Embodiment 2

[0041] The ratio of each raw material is as follows:

[0042]

[0043]

[0044] The temperature of the polymerization reaction was 80°C; 30 minutes after the start of the polymerization reaction, the remaining monomer solution and initiator solution were added dropwise for 2.5 hours, and the temperature was lowered to terminate the polymerization reaction after 3 hours after the completion of the dropwise addition.

Embodiment 3

[0046] The ratio of each raw material is as follows:

[0047]

[0048] The temperature of the polymerization reaction was 75°C; 45 minutes after the start of the polymerization reaction, the remaining monomer solution and initiator solution were added dropwise for 105 minutes, and 210 minutes after the completion of the dropwise addition, the temperature was lowered to terminate the polymerization reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com