Method for preparing degradable organic-inorganic nanometer hybrid material containing POSS (Polyhedral Oligomeric Silsesquioxanes)

A technology of inorganic nano and hybrid materials, which is applied in the field of preparation of degradable organic-inorganic nano hybrid materials, can solve the problems of affecting the performance of composite materials and poor dispersion of POSS particles, and achieves improved degradation performance, improved aggregation, and improved operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

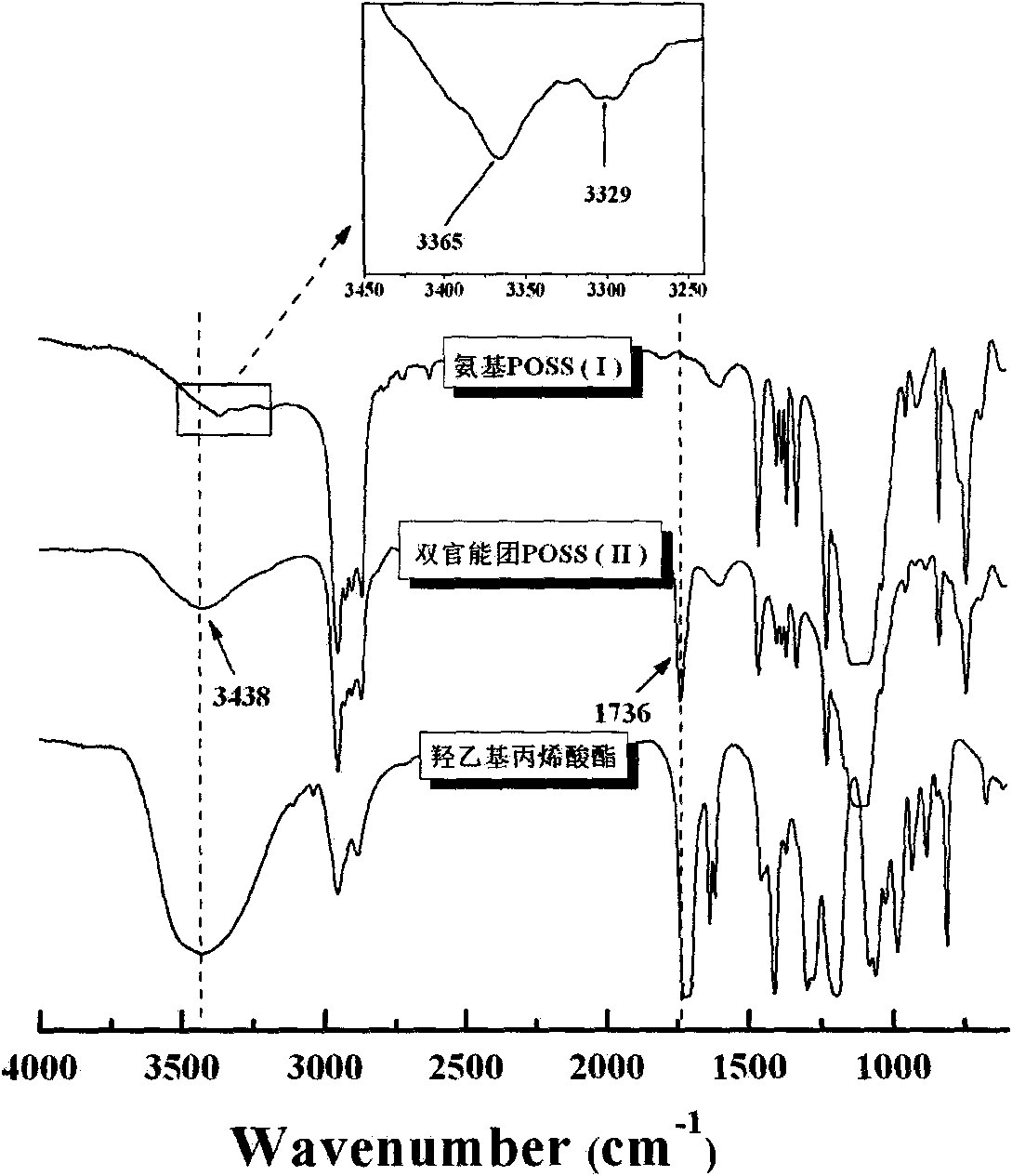

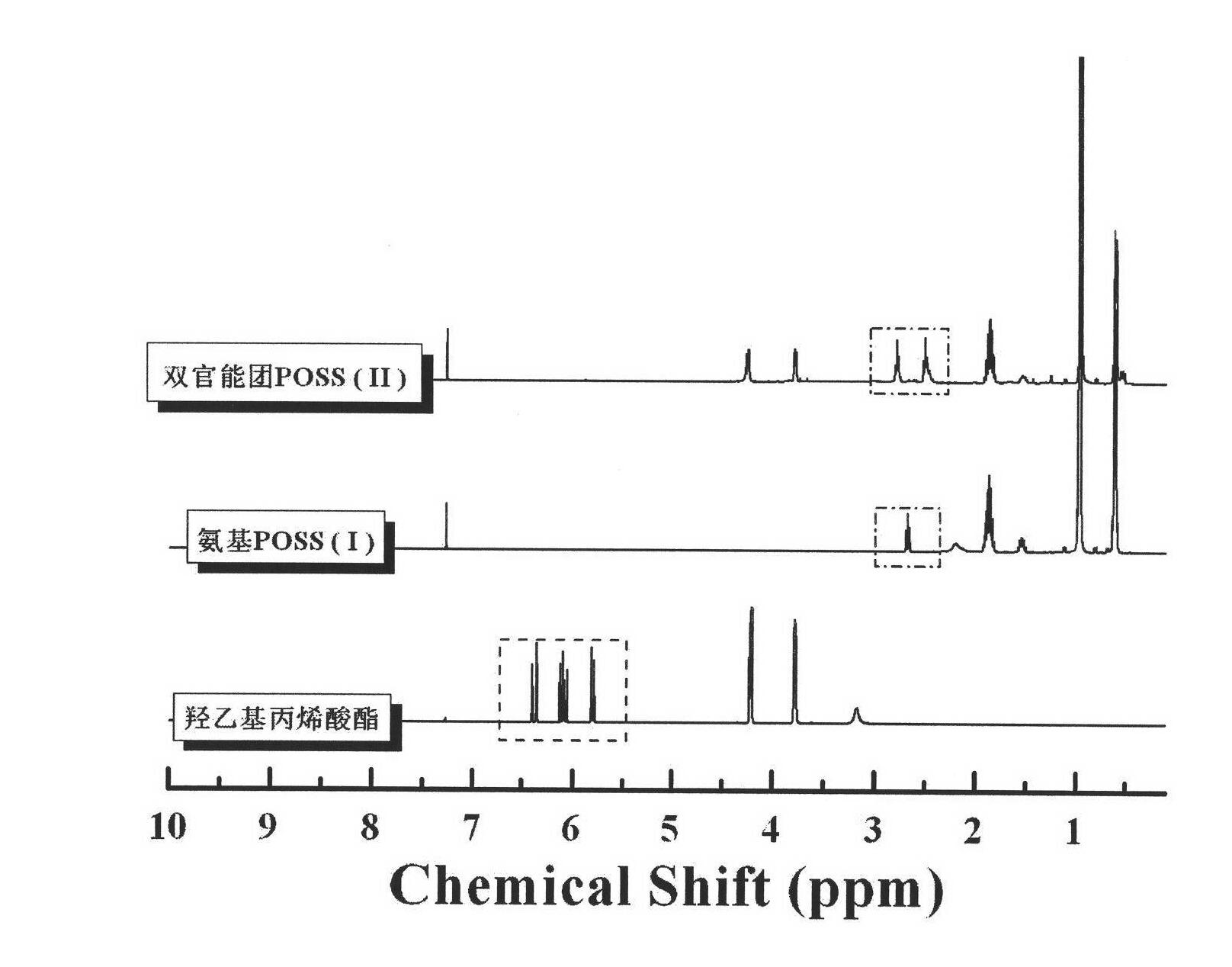

[0031] (1) Preparation of bifunctional POSS derivatives (II)

[0032]Add 8.74g of amino POSS (I) and 1.16g of hydroxyethyl acrylate into a three-necked flask filled with 100ml of dichloromethane, and stir vigorously for 72h at 20°C under normal pressure. After the reaction, the solution was distilled and purified to obtain the target product, the bifunctional POSS derivative (II), with a yield of 95%.

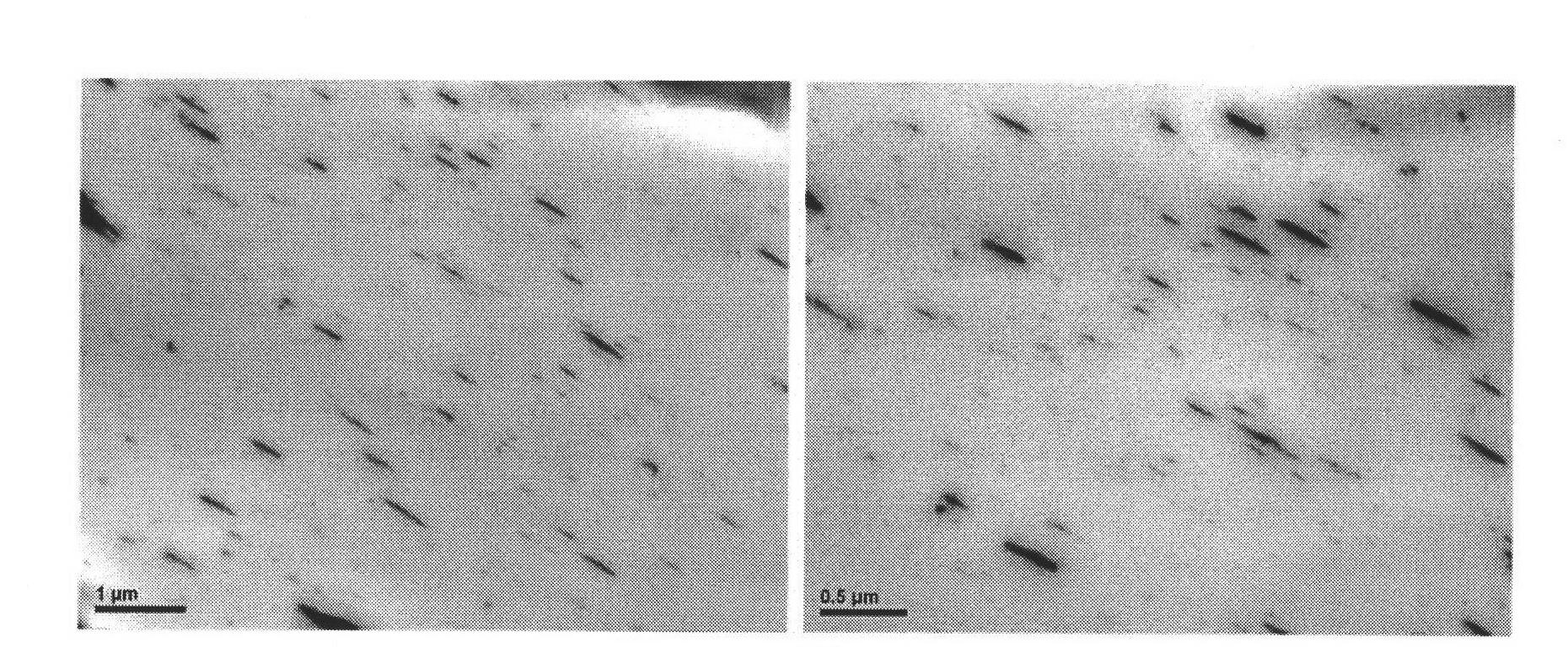

[0033] (2) Preparation of degradable organic-inorganic nano-hybrid copolyester containing POSS

[0034] 83.1g terephthalic acid, 90.1g 1,4-butanediol and 0.5wt% tetrabutyl titanate (Ti[OBu] 4 ) into a 250ml flask, at 200°C, under normal pressure (i.e. standard atmospheric pressure), magnetically stirred and reacted for 1 hour, then raised the temperature to 210°C, stirred at normal pressure for 0.5 hours, and stirred at 220°C for 0.5 hours at normal pressure, keeping the temperature constant Reduce the pressure to 20000Pa and continue the reaction for 3h to obtain a homogeneo...

Embodiment 2

[0036] (1) Preparation of bifunctional POSS derivatives (II)

[0037] Add 13.11 g of amino POSS (I) and 1.16 g of hydroxyethyl acrylate into a three-neck flask containing 150 ml of tetrahydrofuran, and stir vigorously for 48 h at 10° C. under normal pressure. After the reaction, the solution was distilled and purified to obtain the target product with a yield of 97%.

[0038] (2) Preparation of degradable organic-inorganic nano-hybrid copolyester containing POSS

[0039] 33.2g of phthalic acid, 76.1g of 1,3-propanediol (1:5) and 1.0wt% Ti[OBu] accounting for the total amount of the above two 4 Add it into a 250ml flask, stir it under normal pressure at 200°C for 1 hour, then raise the temperature to 215°C, stir it under normal pressure for 0.5 hour, then stir it under normal pressure at 230°C for 0.5 hour, keep the temperature constant and lower the pressure to 10000Pa, continue After reacting for 1.5h, a homogeneous, transparent and clear esterification product was obtained...

Embodiment 3

[0041] (1) Preparation of bifunctional POSS derivatives (II)

[0042] Add 10.48g of amino POSS (I) and 1.16g of hydroxyethyl acrylate into a three-necked flask filled with 200ml of acetone, and stir vigorously for 96h at 25°C under normal pressure. After the reaction, the solution was distilled and purified to obtain the target product with a yield of 97%.

[0043] (2) Preparation of degradable organic-inorganic nano-hybrid copolyester containing POSS

[0044] 75.5g terephthalic acid, 144.12g 1,4-cyclohexanedimethanol and 3.0wt% Ti[OBu] accounting for the total amount of the above two 4 Add it into a 250ml flask, stir it under normal pressure at 200°C for 1 hour, then raise the temperature to 210°C, stir it under normal pressure for 0.5 hour, then stir it under normal pressure at 220°C for 0.5 hour, keep the temperature constant and lower the pressure to 10000Pa, continue After 4 hours of reaction, a homogeneous, transparent and clear esterification product was obtained. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com