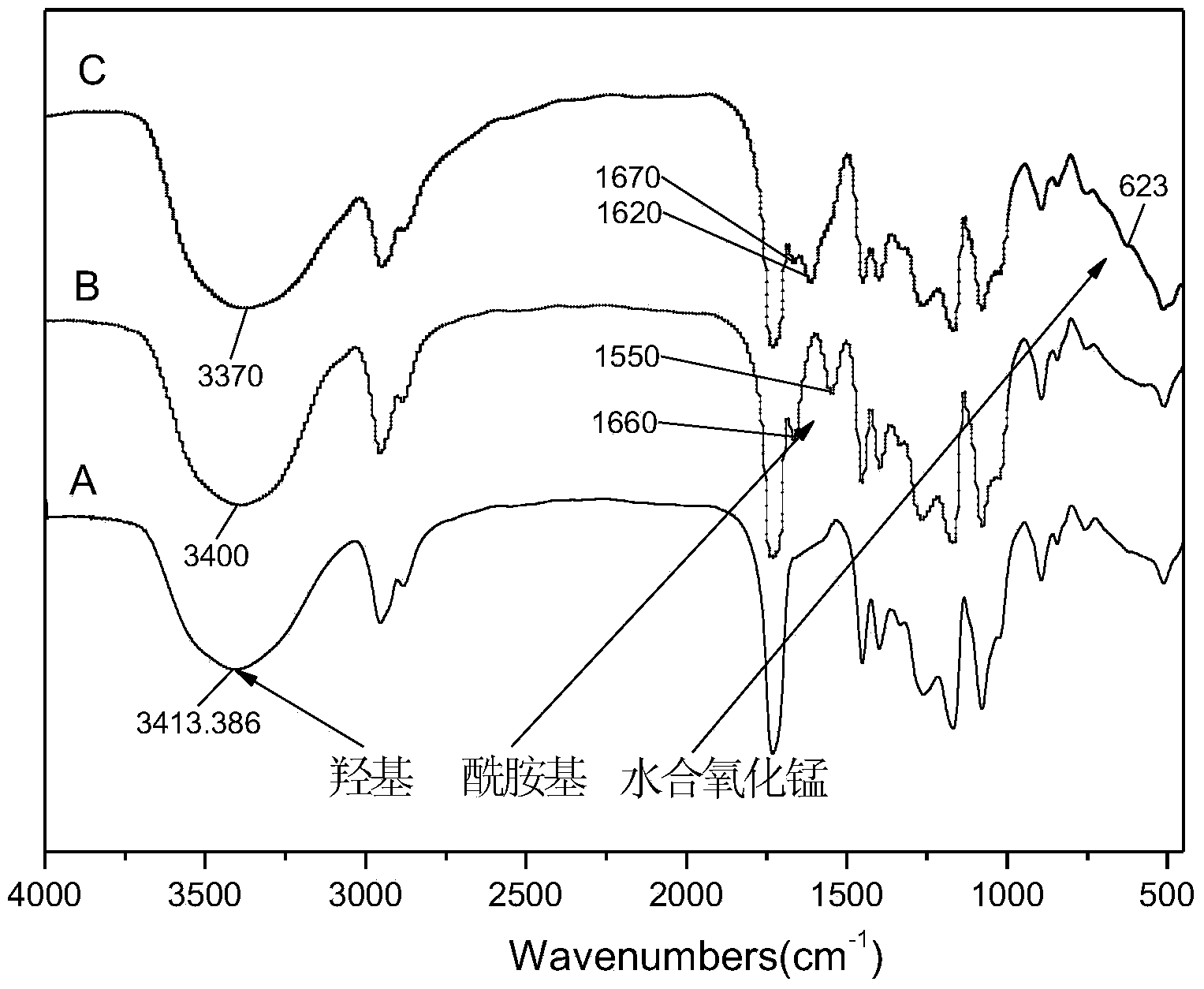

Preparation method and application of composite hydrogel provided with amide group and hydroxyl group and loaded with nano manganese oxide hydrate

A technology of composite hydrogel and hydrated manganese oxide, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of complex synthesis route, low purity of polymer hydrogel, etc. Good absorption, good mechanical strength, large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Weigh a certain mass of N-methylolacrylamide monomer and dissolve it in deionized water as component A, then add a certain amount of 2-hydroxyethyl acrylate to the above solution as component B, distilled water as component Divide into C, mix according to (A+B):C is 1:1 (V / V), where A:B is 1:9 (mol / mol); ultrasonic 30min to mix the solution evenly, fill the mixed solution with N 2 to ensure anaerobic conditions.

[0037] 2. Radiation polymerization process: by directly adding refrigerant, at -78°C, using 60 Co-γ high-energy rays, the radiation dose is controlled to 1×10 5 Gy.

[0038] 3. In-situ loading of nano-hydrated manganese oxide: Weigh 0.5g of xerogel into a 100ml Erlenmeyer flask, add 50ml of 0.204mol / l MnSO 4 .H 2 O solution, placed in a constant temperature shaker for 24h, filtered out the hydrogel, dried at room temperature, and then placed in 50ml of 0.138mol / l KMnO 4 The solution was shaken for 24h. The formation of HMO was indicated when the color...

Embodiment 2

[0041] (A+B): C is 1:2 (V / V), monomer solution ratio: A: B is 3:7 (mol / mol);

[0042] Radiation polymerization process: at a temperature of -78°C, using 60 Co-γ high-energy rays, the radiation dose is controlled to 1×10 5 Gy;

[0043] MnSO used 4 .H 2 The concentration of O solution is 0.068mol / l, the KMnO used 4 The concentration of the solution is 0.046mol / l;

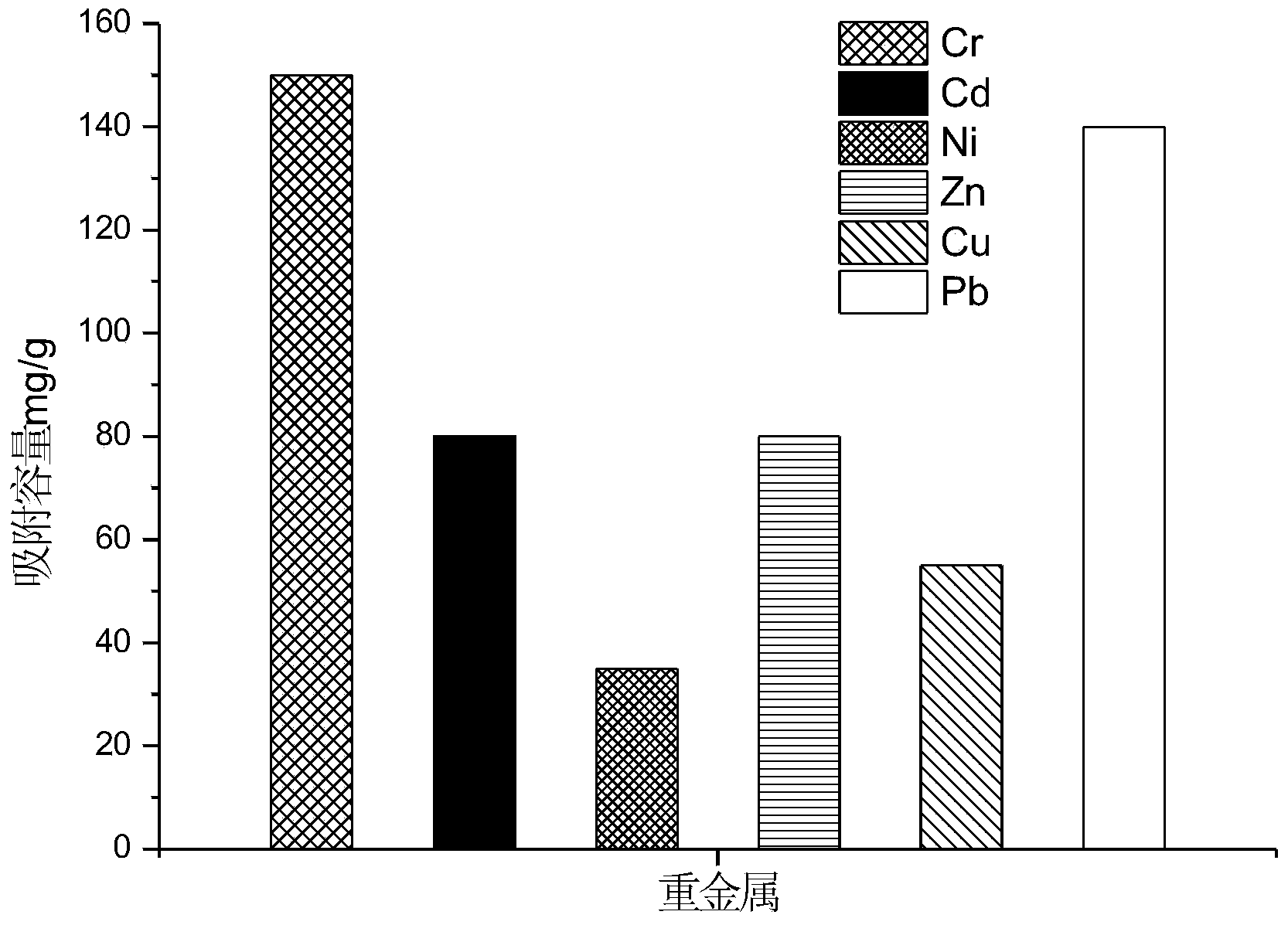

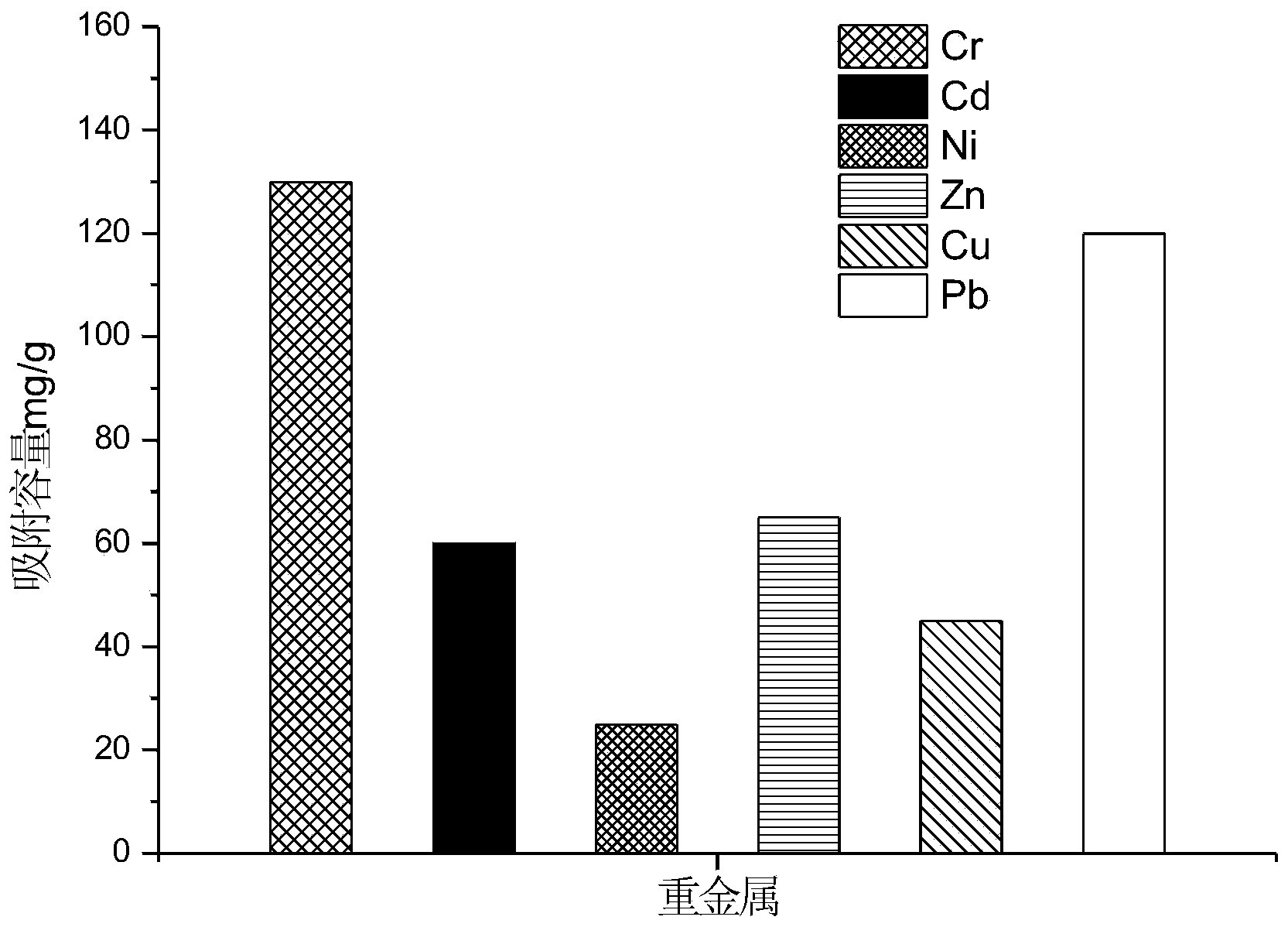

[0044] Composite hydrogel for six metal ions Cr 3+ 、Cd 2+ 、Ni 2+ , Zn 2+ 、Cu 2+ , Pb 2+ The adsorption capacities are 140mg / g, 70mg / g, 30mg / g, 70mg / g, 50mg / g, 130mg / g respectively. Due to the loading of nanometer hydrated manganese oxide, the mechanical strength of the hydrogel is greatly enhanced, the service life is long, and the adsorption effect is also enhanced.

Embodiment 3

[0046] (A+B): C is 1:1 (V / V), monomer solution ratio: A: B is 1:1 (mol / mol);

[0047] Radiation polymerization process: at a temperature of -63°C, using 137 Cs-γ high-energy rays, the control radiation dose is 1×10 4 Gy;

[0048] MnSO used 4 .H 2 The concentration of O solution is 0.204mol / l, the KMnO used 4 The concentration of the solution is 0.138mol / l;

[0049] Composite hydrogel for six metal ions Cr 3+ 、Cd 2+ 、Ni 2+ , Zn 2+ 、Cu 2+ , Pb 2+ The adsorption capacities are 120mg / g, 55mg / g, 20mg / g, 60mg / g, 40mg / g, 110mg / g respectively. Due to the loading of nanometer hydrated manganese oxide, the mechanical strength of the hydrogel is greatly enhanced, the service life is long, and the adsorption effect is also enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com