Biologically-bactericidal acrylic resin and novel marine antifouling paint composition prepared from resin

An acrylic resin, bactericidal technology, used in antifouling/underwater coatings, rosin coatings, and biocide-containing paints, etc., can solve problems such as slow accumulation and marine biological hazards, improve adhesion, and simplify the process. Reliable, antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

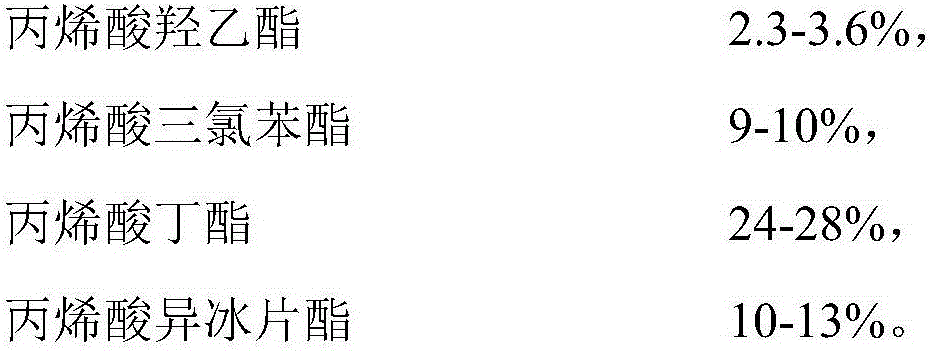

[0024] The synthesis of embodiment 1 biocidal type acrylic resin (PAA)

[0025] The formula of biocidal type acrylic resin is shown in Table 1, in the four-necked flask that stirrer, reflux condenser, constant pressure dropping funnel are equipped with, add 0.2g azobisisobutyronitrile (AIBN), 2.0g dodecanethiol , 200g butyl acetate, mix and heat up to 100°C, then weigh 12g hydroxyethyl acrylate, 37g trichlorophenyl acrylate, 100g butyl acrylate, 51g isobornyl acrylate, 1.7g azobisisobutyronitrile and 1.7g of azobisisovaleronitrile mixed solution was added dropwise at a constant speed for 3 hours with a constant pressure dropping funnel, then 0.1g of azobisisovaleronitrile was added, and the constant temperature reaction was continued for 0.5 hours, then the temperature was raised to 110°C. After continuing to react for 2.5 hours, it was cooled to room temperature to complete the reaction. The reaction scheme is shown in the following formula:

[0026]

[0027] Detected by...

Embodiment 2-3

[0031] The synthesis of embodiment 2-3 biocidal type acrylic resin (PAA)

[0032] The formula of biocidal type acrylic resin is shown in Table 1, and the specific method is the same as in Example 1, wherein the raw material azobisisovaleronitrile is put into two times, and the first addition of azobisisovaleronitrile is 90%- 95%, add the remainder of azobisisovaleronitrile for the second time.

Embodiment 4

[0034] A novel marine antifouling paint composition, the composition of which is shown in Table 2. A new type of marine antifouling paint is prepared by mixing the raw materials. According to different formula systems, it can be divided into short-term, medium-term and long-term antifouling antifouling coatings.

[0035] Table 2 (unit: kg)

[0036]

[0037] Note: The short-term anti-pollution period is 1 year, the medium-term is 2 years, and the long-term is 3-5 years.

[0038] After testing, the novel antifouling paint quality index detection result of the present invention is as shown in table 3:

[0039] table 3

[0040] Test items

results of testing

Testing method

Adhesion / level

≤2

GB / T1720-79

Impact resistance / (kg·cm)

≥45

GB / T1732-93

Flexibility / mm

≤2

GB / T1731-79

Oil resistance (normal temperature, 30d)

No change in coating

GB / T1734-93

[0041] After 2 cycles (2 years) tests of real...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com