Nano silver loaded graphene silver kettle and preparation method thereof

A graphene and nano-silver technology, applied in botanical equipment and methods, utensils for boiling water, chemicals for biological control, etc. Excellent physical and chemical properties, improving service life and saving business costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

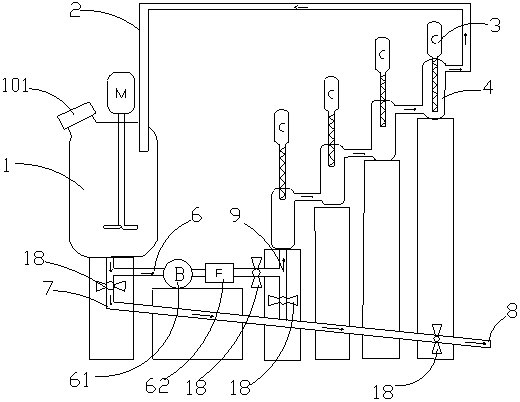

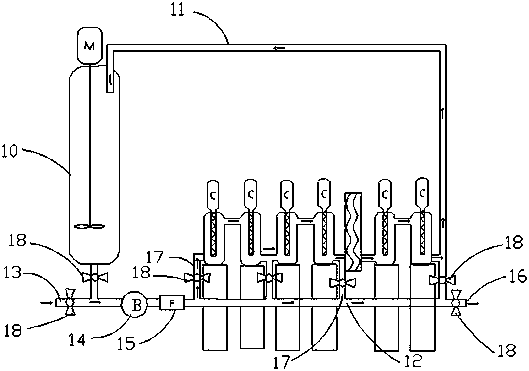

Image

Examples

Embodiment 1

[0040] The present embodiment provides a method for preparing a graphene antibacterial composite material loaded with nano-silver, comprising the following steps:

[0041] S1. Preparation of graphene oxide aqueous solution: graphene oxide was prepared by the improved Hummers method, and then subjected to secondary ultrasonic dispersion to obtain a 0.04g / L single-layer graphene oxide aqueous solution, and then silver nitrate was added to obtain a silver nitrate / graphene oxide mixed solution , wherein the concentration of silver nitrate is 0.08g / L;

[0042] S2. add glucose and soluble starch to step silver nitrate / graphene oxide mixed solution, glucose concentration is 0.072g / L, and soluble starch concentration is 0.08g / L, then is placed in hydrothermal reaction kettle, adopts hydrothermal method reaction, The reaction temperature is 100°C, the reaction time is 6 hours, and the water vapor pressure is 0.3-4Mpa. After the reaction, it is naturally cooled to room temperature, and ...

Embodiment 2

[0056] The present embodiment provides a method for preparing a graphene antibacterial composite material loaded with nano-silver, comprising the following steps:

[0057] S1. Preparation of graphene oxide aqueous solution: graphene oxide was prepared by the improved Hummers method, and then subjected to secondary ultrasonic dispersion to obtain a 0.09g / L single-layer graphene oxide aqueous solution, and then silver nitrate was added to obtain a silver nitrate / graphene oxide mixed solution , wherein the concentration of silver nitrate is 0.18g / L;

[0058] S2. add glucose and soluble starch to step silver nitrate / graphene oxide mixed solution, glucose concentration is 0.432g / L, and soluble starch concentration is 0.16g / L, then is placed in hydrothermal reaction kettle, adopts hydrothermal method reaction, The reaction temperature is 140°C, the reaction time is 4 hours, and the water vapor pressure is 0.3-4Mpa. After the reaction, it is naturally cooled to room temperature, and ...

Embodiment 3

[0064] This example is basically the same as Example 1, except that the hydrothermal reaction temperature in step S2 is 200°C and the reaction time is 4h, and the hydrothermal reaction temperature in step S3 is 140°C and the reaction time is 6h.

[0065] The loading capacity of nano-silver particles in the graphene / nano-silver composite material prepared in this embodiment is 42.00%. When the concentration is 0.09 μg / ml, the antibacterial rate to Escherichia coli reaches 99.7%. The loading of nano-silver particles in this embodiment The main reason is that in step S2, the graphene oxide will show a thermogravimetric behavior, and the oxygen-containing functional groups will be decomposed in large quantities, resulting in a reduction in the amount of reduced silver ions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com