Efficient exchange membrane device for producing hydrogen by electrolyzing water

A technology for a hydrogen production device and an exchange membrane, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problem that hydrogen cannot be widely used, and achieve the effect of eliminating the water vapor separation device, reducing the mass, and simplifying the equipment system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

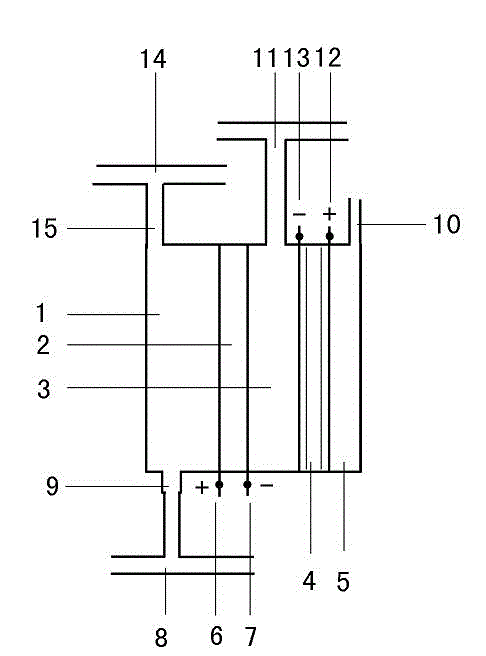

[0026] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0027] see Figure 1 to Figure 3 As shown, the structure of the high-efficiency exchange membrane electrolyzed water hydrogen production device of the present invention is: the porous permeable ion module 2 and the ordinary reinforced membrane module 4 are fixedly arranged in the box respectively, and the box is divided into a water storage chamber 1, a hydrogen generation Chamber 3 and oxygen generation chamber 5; the periphery of both sides of the porous ion-permeable component 2 and the ordinary reinforced membrane component 4 are provided with insulating layers.

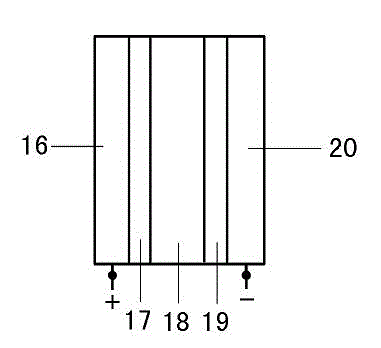

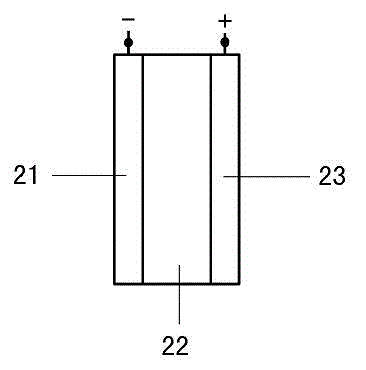

[0028] The porous and permeable ion assembly 2 is composed of the left side support compression metal parts 16, the left side porous catalytic layer 17, the porous permeable ion membrane 18, the right side porous catalytic layer 19 and the right side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com