Online production method of rhamnolipid biosurfactant in cellulose hydrolyzation

A cellulase and biological surface technology, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the technical report on the online production and addition method of biosurfactants, and increase the production cost of rhamnolipids. and other problems to achieve the effect of reducing production cost, simplifying production process and improving hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

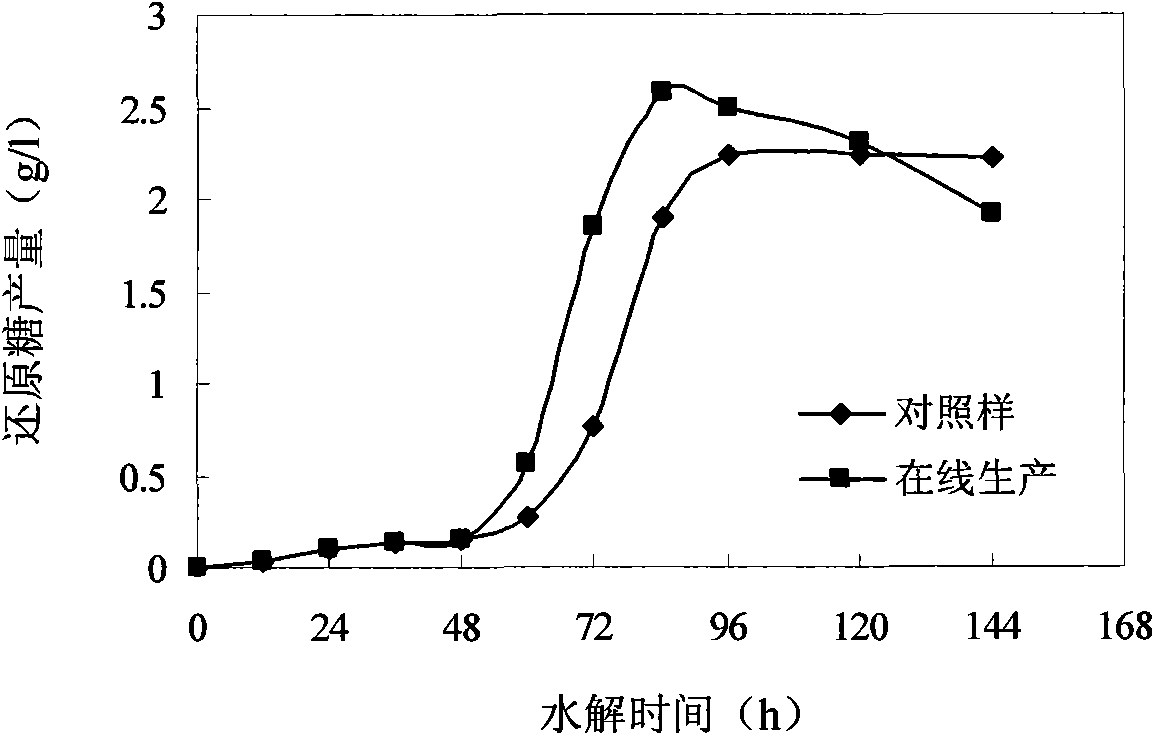

Embodiment 1

[0025] Rinse the harvested straw with tap water 4-5 times to remove impurities and knots, and cut it into small sections of 1-2cm. The cut straw was dried in an oven at 70 °C to constant weight and stored at room temperature for subsequent use. Before enzymatic hydrolysis, the straw that cuts is carried out pretreatment with alkali, and concrete method is: the straw that cuts 10g is placed in the Erlenmeyer flask that the sodium hydroxide of 40ml 2% is housed, keeps solid-liquid mass ratio as 1:4, 85°C water bath for 1h. Wash with distilled water until neutral, and dry in an oven at 70°C until constant weight.

[0026] The pretreated rice straw was hydrolyzed with Trichoderma reesei ZM4-F3 in a shaker at 30° C. and 200 rpm for sugar production.

[0027] Then the Pseudomonas aeruginosa BSZ-07 cultivated to the logarithmic growth phase is inoculated into the rice straw hydrolysis system with 2% inoculum, that is: Pseudomonas aeruginosa BSZ-07 is dissolved in 50mL seed medium t...

Embodiment 2

[0034] Rinse the harvested straw with tap water 4-5 times to remove impurities and knots, and cut it into small sections of 1-2cm. The cut straw was dried in an oven at 70 °C to constant weight and stored at room temperature for subsequent use. Before enzymatic hydrolysis, the straw that cuts is carried out pretreatment with alkali, and concrete method is: the straw that cuts 10g is placed in the Erlenmeyer flask that the sodium hydroxide of 40ml 2% is housed, keeps solid-liquid mass ratio as 1:4, 85°C water bath for 1h. Wash with distilled water until neutral, and dry in an oven at 70°C until constant weight.

[0035] The pretreated rice straw was hydrolyzed with Trichoderma reesei ZM4-F3 in a shaker at 30° C. and 200 rpm for sugar production.

[0036] Then inoculate the Pseudomonas aeruginosa BSZ-07 cultivated to the logarithmic growth phase into the rice straw hydrolysis system with 4% inoculum: dissolve the Pseudomonas aeruginosa BSZ-07 in 50mL seed medium to prepare the...

Embodiment 3

[0043] Rinse the harvested straw with tap water 4-5 times to remove impurities and knots, and cut it into small sections of 1-2cm. The cut straw was dried in an oven at 70 °C to constant weight and stored at room temperature for subsequent use. Before enzymatic hydrolysis, the straw that cuts is carried out pretreatment with alkali, and concrete method is: the straw that cuts 10g is placed in the Erlenmeyer flask that the sodium hydroxide of 40ml 2% is housed, keeps solid-liquid mass ratio as 1:4, 85°C water bath for 1h. Wash with distilled water until neutral, and dry in an oven at 70°C until constant weight.

[0044] The pretreated rice straw was hydrolyzed with Trichoderma reesei ZM4-F3 in a shaker at 30° C. and 200 rpm for sugar production.

[0045] Then the Pseudomonas aeruginosa BSZ-07 cultivated to the logarithmic growth phase was inoculated into the rice straw hydrolysis system with 6% inoculum: Pseudomonas aeruginosa BSZ-07 was dissolved in 50mL seed medium to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com